CONTENTS

1 Introduction............................................................................................................................................................ 2

1.1 Features of the instrument......................................................................................................................... 2

1.2 Technical specifications..............................................................................................................................3

1.3 Standards and regulations applied...........................................................................................................3

1.4 Operating conditions...................................................................................................................................3

1.5 Application examples.................................................................................................................................. 3

1.6 Scope of delivery.........................................................................................................................................4

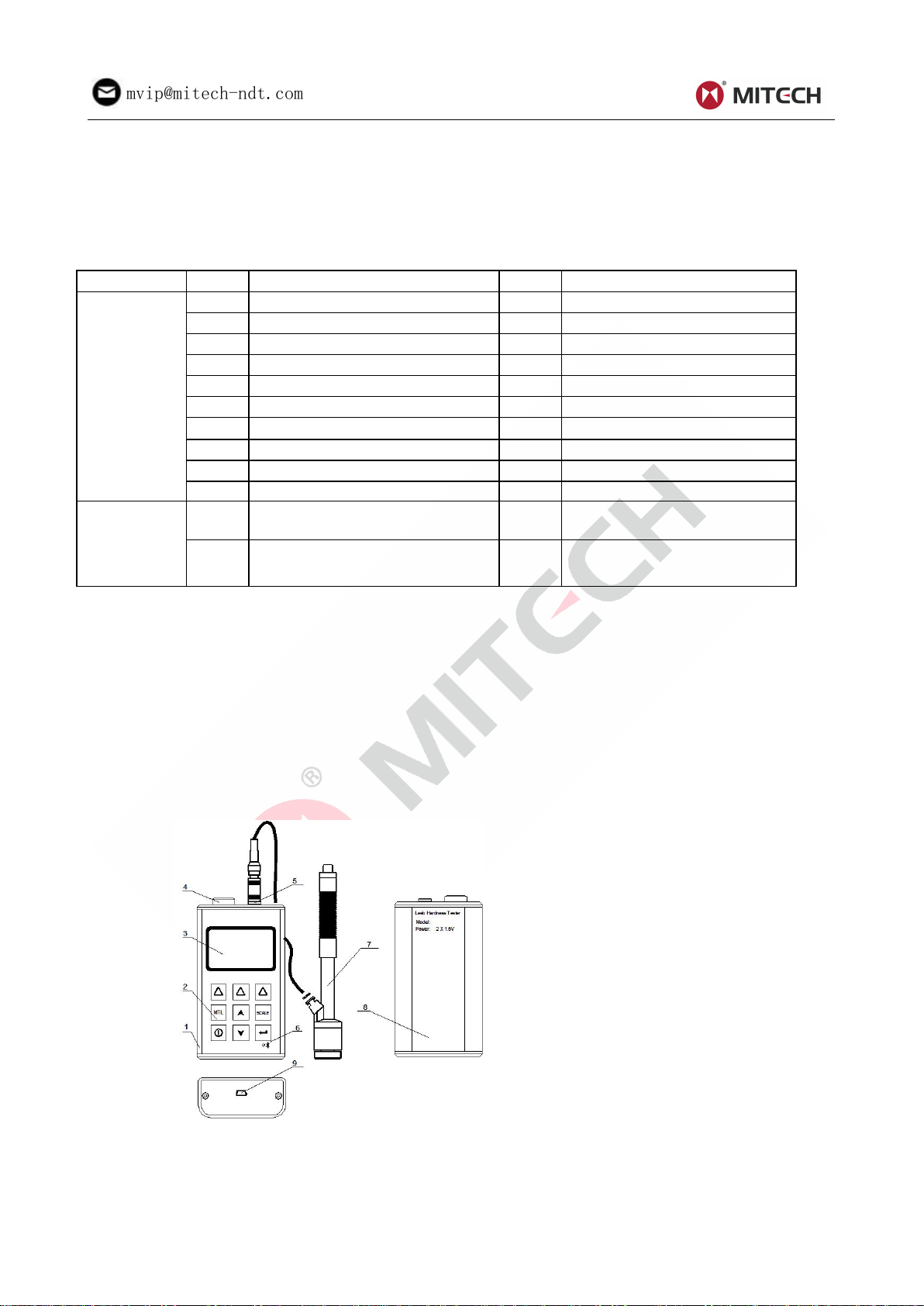

2 Product Feature.................................................................................................................................................... 4

2.1 Structure feature..........................................................................................................................................4

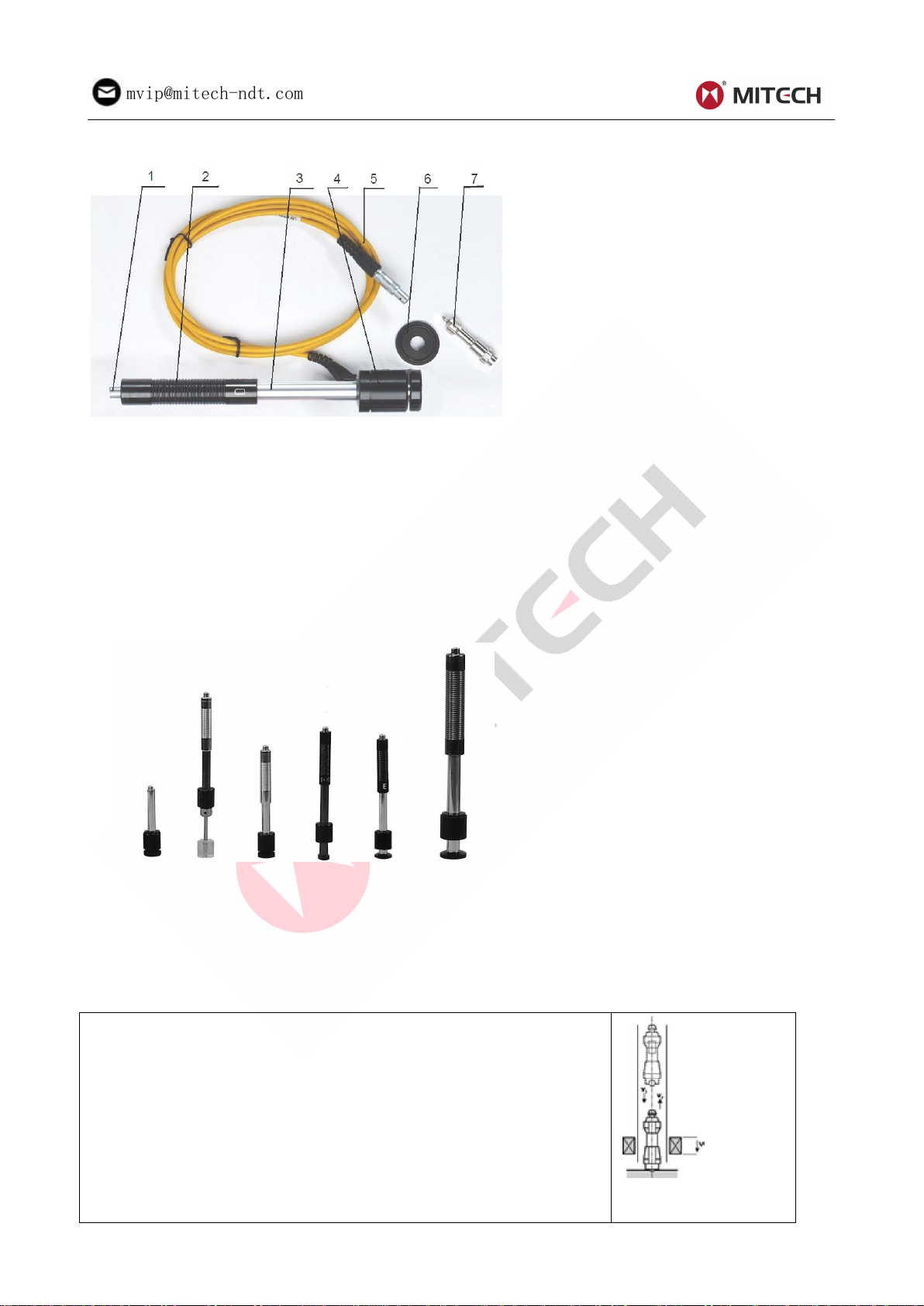

2.2 Impact device D........................................................................................................................................... 5

2.3 Other impact devices.................................................................................................................................. 5

2.4 Leeb rebound principle for hardness testing.......................................................................................... 5

2.5 Screen display............................................................................................................................................. 6

2.6 Keypad.......................................................................................................................................................... 6

2.7 Measuring conditions..................................................................................................................................7

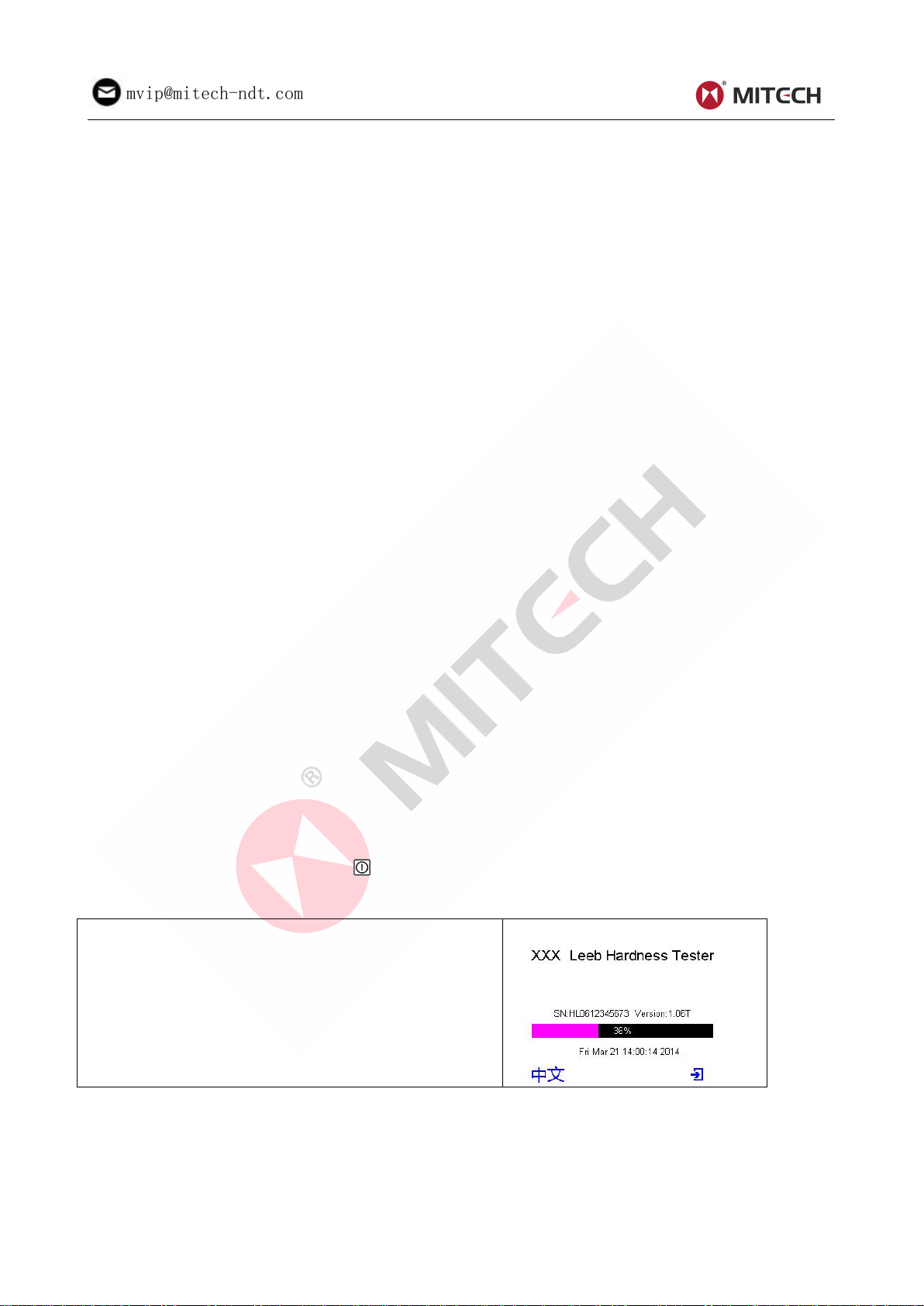

3 Startup..................................................................................................................................................................... 7

3.1 Power supply................................................................................................................................................7

3.2 Connecting the instruments.......................................................................................................................7

3.3 Starting the instrument............................................................................................................................... 7

3.4 Configuration of the standby settings...................................................................................................... 8

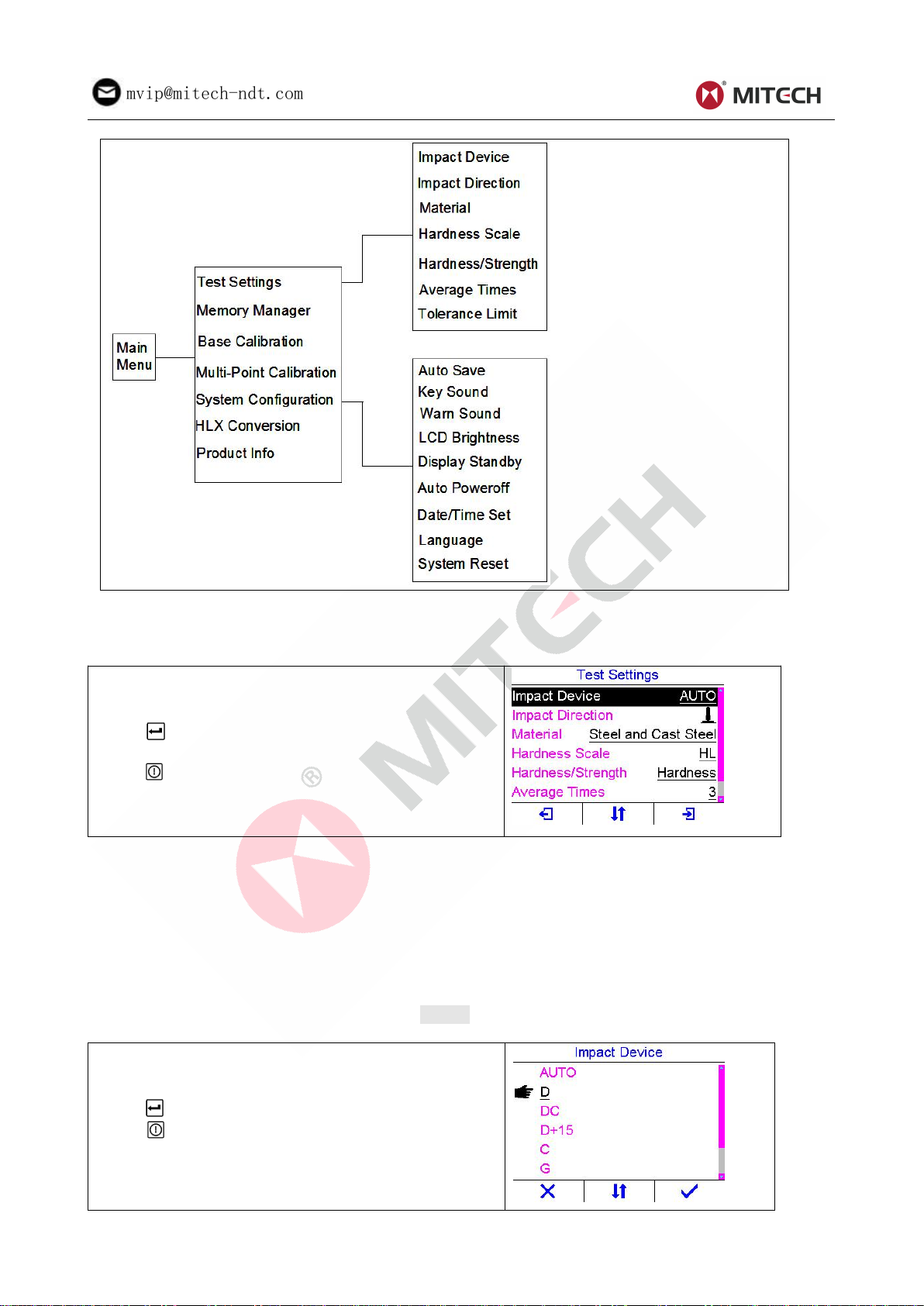

4 Settings................................................................................................................................................................... 8

4.1 Test settings................................................................................................................................................. 9

4.2 Memory manager...................................................................................................................................... 12

4.3 Base calibration (Impact device calibration).........................................................................................12

4.4 Multi-point calibration............................................................................................................................... 13

4.5 System configuration................................................................................................................................ 14

4.6 HLX conversion function..........................................................................................................................16

4.7 Product information...................................................................................................................................17

4.8 Replace the batteries............................................................................................................................... 17

4.9 Communication..........................................................................................................................................17

4.10 Print via Bluetooth...................................................................................................................................17

5 Operation.............................................................................................................................................................. 18

5.1 Preparation of the sample....................................................................................................................... 18

5.2 Triggering the impact................................................................................................................................ 20

5.3 Conversion Deviations............................................................................................................................. 20

Number of impacts per measuring area...................................................................................................... 21

6 Fault and Troubleshooting.............................................................................................................................. 22

7 Maintenance, storage and care...................................................................................................................... 22

7.1 Performance check (before each use).................................................................................................. 22

7.2 Maintenance.............................................................................................................................................. 23

7.3 Transport and storage conditions...........................................................................................................23

7.4 Cleaning (after each use)........................................................................................................................ 24

7.5 Warranty..................................................................................................................................................... 24

7.6 Tips on safety.............................................................................................................................................24

Appendix.................................................................................................................................................................. 25

Table 1...................................................................................................................................... 25

Table 2...................................................................................................................................... 26

Table 3...................................................................................................................................... 27

Table 4...................................................................................................................................... 28

User Notes................................................................................................................................................................29