Digital deep sea DSE5220 User manual

COMPLEX SOLUTIONS

MADE SIMPLE.

DEEP SEA ELECTRONICS PLC

DSE5220

AUTO MAINS FAILURE MODULE

OPERATING MANUAL

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

2 057-012 5220 OPERATING MANUAL ISSUE 5.1 18/06/2007 AM

Deep Sea Electronics Plc

Highfield House

Hunmanby

North Yorkshire

YO14 0PH

ENGLAND

Sales Tel: +44 (0) 1723 890099

Sales Fax: +44 (0) 1723 893303

E-mail: [email protected]

Website: www.deepseaplc.com

DSE Model 5220 Control and Instrumentation System Operators Manual

© Deep Sea Electronics Plc

All rights reserved. No part of this publication may be reproduced in any material form (including photocopying or storing in any

medium by electronic means or other) without the written permission of the copyright holder except in accordance with the

provisions of the Copyright, Designs and Patents Act 1988.

Applications for the copyright holder’s written permission to reproduce any part of this publication should be addressed to Deep

Sea Electronics Plc at the address above.

Any reference to trademarked product names used within this publication is owned by their respective companies.

Deep Sea Electronics Plc reserves the right to change the contents of this document without prior notice.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

5220 OPERATING MANUAL ISSUE 5.1 18-Jun-07 AM 3

TABLE OF CONTENTS

Section Page

1INTRODUCTION ..............................................................................................5

2CLARIFICATION OF NOTATION USED WITHIN THIS PUBLICATION.........5

3OPERATION ....................................................................................................6

3.1 AUTOMATIC MODE OF OPERATION...............................................................................6

3.2 MANUAL OPERATION.......................................................................................................8

3.3 TEST OPERATION..............................................................................................................9

4PROTECTIONS..............................................................................................10

4.1 WARNINGS .......................................................................................................................11

4.2 ANALOGUE PRE-ALARMS .............................................................................................11

4.3 HIGH CURRENT WARNING ALARM...............................................................................12

4.4 SHUTDOWNS....................................................................................................................13

4.5 HIGH CURRENT SHUTDOWN ALARM...........................................................................15

4.6 ELECTRICAL TRIPS.........................................................................................................15

5LCD INDICATORS AND LOGO INSERT.......................................................16

6DESCRIPTION OF CONTROLS ....................................................................17

6.1 TYPICAL LCD DISPLAY SCREENS................................................................................18

6.2 LCD DISPLAY AREAS......................................................................................................19

6.3 VIEWING THE INSTRUMENTS ........................................................................................20

6.4 VIEWING THE EVENT LOG..............................................................................................21

6.5 INDICATORS.....................................................................................................................22

6.6 CONTROLS.......................................................................................................................22

7FRONT PANEL CONFIGURATION...............................................................23

7.1 ACCESSING THE FRONT PANEL CONFIGURATION EDITOR ....................................23

7.1.1 ENTERING THE CONFIGURATION EDITOR PIN NUMBER...................................23

7.1.2 EDITING AN ANALOGUE VALUE .............................................................................24

7.1.3 EDITING THE CURRENT DATE/TIME......................................................................26

8INSTALLATION INSTRUCTIONS..................................................................27

8.1 PANEL CUT-OUT..............................................................................................................27

8.2 COOLING...........................................................................................................................27

8.3 UNIT DIMENSIONS...........................................................................................................27

8.4 FRONT PANEL LAYOUT..................................................................................................28

8.5 REAR PANEL LAYOUT....................................................................................................28

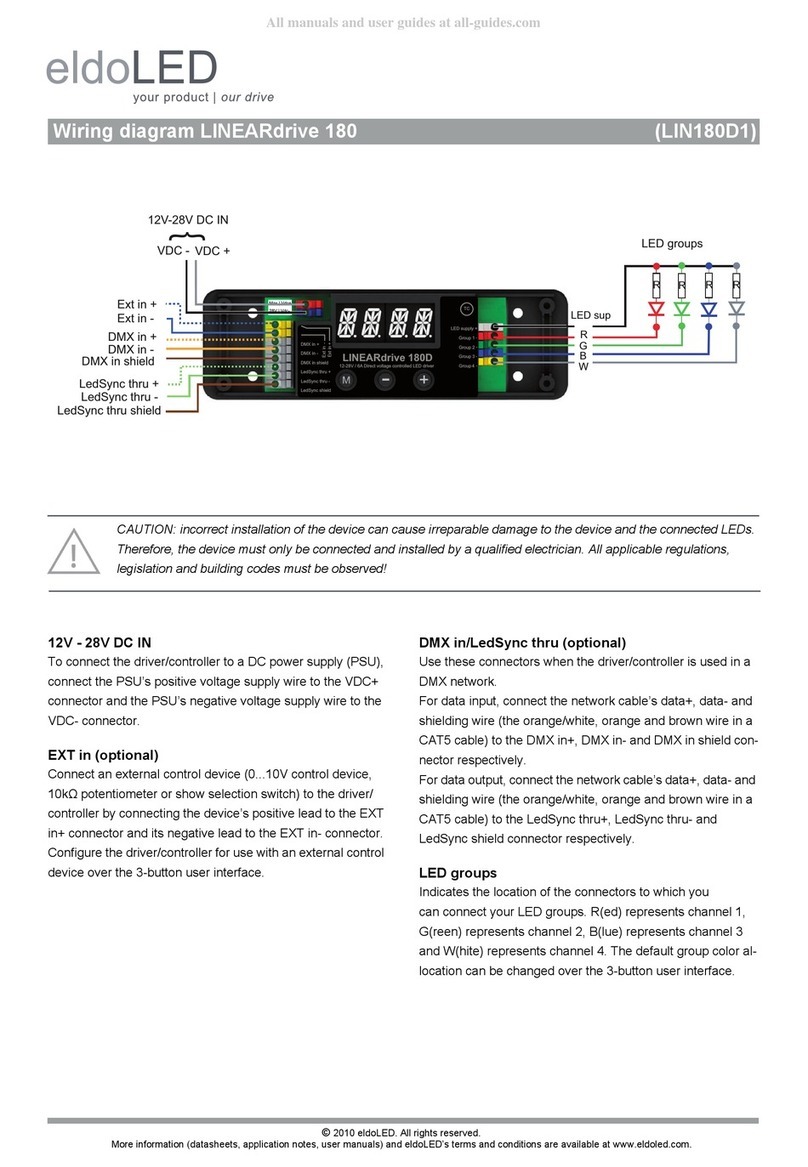

9ELECTRICAL CONNECTIONS......................................................................29

9.1 CONNECTION DETAILS...................................................................................................29

9.1.1 PLUG “A” 8 WAY........................................................................................................29

9.1.2 PLUG “B” 11 WAY......................................................................................................29

9.1.3 PLUG “C” 3 WAY (NOT FITTED)...............................................................................29

9.1.4 PLUG “D” 4 WAY (OPTIONAL)..................................................................................30

9.1.5 PLUG “E” 8 WAY........................................................................................................30

9.1.6 PLUG “F” 4 WAY ........................................................................................................30

9.1.7 PLUG “G” 5 WAY........................................................................................................30

9.1.8 PLUG “H” 4 WAY........................................................................................................31

9.1.9 PC CONFIGURATION INTERFACE CONNECTOR..................................................32

9.1.10 EXPANSION OUTPUT CONNECTOR.......................................................................32

9.2 CONNECTOR FUNCTION DETAILS................................................................................33

9.2.1 PLUG “A” 8 WAY........................................................................................................33

9.2.2 PLUG “B” 11 WAY......................................................................................................33

9.2.3 PLUG “C” 3 WAY (NOT FITTED)...............................................................................34

9.2.4 PLUG “D” 4 WAY (OPTIONAL)..................................................................................34

9.2.5 PLUG “E” 8 WAY........................................................................................................34

9.2.6 PLUG “F” 4 WAY ........................................................................................................34

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

4 057-012 5220 OPERATING MANUAL ISSUE 5.1 18/06/2007 AM

9.2.7 PLUG “G” 5 WAY........................................................................................................34

9.2.8 PLUG “H” 4 WAY........................................................................................................35

9.2.9 PURCHASING ADDITIONAL CONNECTOR PLUGS FROM DSE............................35

10 SPECIFICATION..........................................................................................36

11 COMMISSIONING .......................................................................................38

11.1.1 PRE-COMMISSIONING..............................................................................................38

12 FAULT FINDING..........................................................................................39

13 FACTORY DEFAULT CONFIGURATION...................................................40

14 TYPICAL WIRING DIAGRAM......................................................................43

15 APPENDIX...................................................................................................44

15.1 ALTERNATIVE WIRING TOPOLOGIES.......................................................................44

15.1.1 3 PHASE, 3 WIRE.......................................................................................................44

15.1.2 1 PHASE, 2 WIRE.......................................................................................................44

15.1.3 2 PHASE, 3 WIRE ( 2 PHASE CENTRE TAP NEUTRAL).........................................45

15.2 ICONS AND LCD IDENTIFICATION.............................................................................46

15.2.1 PUSH BUTTONS........................................................................................................46

15.2.2 STATUS / MEASUREMENT UNITS...........................................................................46

15.2.3 ALARM INDICATIONS................................................................................................46

15.3 5220 IDMT TRIPPING CURVES (TYPICAL).................................................................46

15.4 SENDER WIRING RECOMMENDATIONS....................................................................46

15.4.1 EARTH RETURN SENDERS .....................................................................................46

15.4.2 INSULATED RETURN SENDERS .............................................................................46

15.4.3 FUEL LEVEL SENDERS ............................................................................................46

15.5 5200 SERIES CONFIGURATION SOFTWARE AND P810 INTERFACE MODULE ...46

15.6 OUTPUT EXPANSION...................................................................................................46

15.6.1 RELAY OUTPUT EXPANSION (157).........................................................................46

15.6.2 LED OUTPUT EXPANSION (548)..............................................................................46

15.7 INPUT EXPANSION.......................................................................................................46

15.8 STANDBY GENERATING SET?...................................................................................46

15.9 ENCLOSURE CLASSIFICATIONS ...............................................................................46

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

5220 OPERATING MANUAL ISSUE 5.1 18-Jun-07 AM 5

1 INTRODUCTION

The DSE 5220 automatic mains failure module has been designed to allow the OEM to meet most of the industry’s

complex specifications. It has been primarily designed to monitor the mains (utility) supply, starting the generator

automatically should it fall out of limits. Transfer of the load is automatic upon a mains supply failure. If required the

generator and can be started and stopped manually, and if required, the user can transfer the load to the generator

either manually (via external push-buttons) or automatically. The user also has the facility to view all the system

operating parameters via the LCD display.

The DSE 5220 module monitors the mains (utility) supply indicating the status of the mains on the module’s

integral LCD display. Additionally the module monitors the engine, indicating the operational status and fault

conditions, automatically shutting down the engine and giving a true first up fault condition of an engine failure by a

flashing common alarm LCD indicator. The exact failure mode is indicated by combined “hidden ‘til lit” LEDs and

the LCD display on the front panel.

The powerful microprocessor contained within the module allows for a range of complex features to be

incorporated as standard:

•Graphical Icon based LCD display (excluding the need for translations and languages).

•Voltage, Current and Power monitoring.

•Engine parameter monitoring.

•Fully configurable inputs for use as alarms or a range of different functions.

•Extensive range output functions using built in relay outputs or relay expansion available.

Selective operational sequences, timers and alarm trips can be altered by the customer via a PC using the 5200

series configuration software and P810 interface. Additionally, a subset of this information can be adjusted from the

module’s front panel configuration editor.

The module is housed in a robust plastic case for front panel mounting. Connections to the module are via locking

plug and sockets.

2 CLARIFICATION OF NOTATION USED WITHIN THIS PUBLICATION.

NOTE:

Highlights an essential element of a procedure to ensure

correctness.

CAUTION!

Indicates a procedure or practice which, if not strictly observed,

could result in damage or destruction of equipment.

WARNING!

Indicates a procedure or practice, which could result in injury to

personnel or loss of life if not followed correctly.

©

Deep Sea Electronics Plc owns the copyright to this manual, which

cannot be copied, reproduced or disclosed to a third party without

prior written permission.

Compliant with BS EN 60950 Low Voltage Directive

Compliant with BS EN 50081-2 EMC Directive

Compliant with BS EN 50082-2 EMC Directive

Year 2000 Compliant

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

6 057-012 5220 OPERATING MANUAL ISSUE 5.1 18/06/2007 AM

3 OPERATION

The following description details the sequences followed by a module containing the standard ‘factory

configuration’. Always refer to your configuration source for the exact sequences and timers observed by any

particular module in the field.

FIG 1

3.1 AUTOMATIC MODE OF OPERATION

NOTE:- If a digital input configured to panel lock is active, the LCD will display the

icon. When in panel lock, changing module modes will not be possible. Viewing the instruments and

event logs is NOT affected by panel lock.

This mode is activated by pressing the pushbutton. An LED indicator beside the button confirms this

action.

Should the mains (utility) supply fall outside the configurable limits for

longer than the period of the mains transient delay timer, the mains

(utility) failure indicator will illuminate and the mains (utility) available

GREEN indicator LED extinguishes. Additionally, while in AUTO

mode, the remote start input (if configured) is monitored. If active, the

Remote Start Active indicator (if configured) illuminates.

V

Overvoltage V

Undervoltage

Overfrequency

Underfrequency

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

5220 OPERATING MANUAL ISSUE 5.1 18-Jun-07 AM 7

Whether the start sequence is initiated by mains (utility failure) or by remote start input, the follow sequence is

followed :

To allow for short term mains supply transient conditions or false remote start signals, the Start Delay timer is

initiated. After this delay, if the pre-heat output option is selected then the pre-heat timer is initiated, and the

corresponding auxiliary output (if configured) will energise.

NOTE:- If the mains supply returns within limits, ( or the Remote Start signal is removed if the start

sequence was initiated by remote start) during the Start Delay timer, the unit will return to a stand-by

state.

After the above delays the Fuel Solenoid is energised, then one second later, the Starter Motor is engaged.

The engine is cranked for a pre-set time period. If the engine fails to fire during this cranking attempt then the

starter motor is disengaged for the pre-set rest period. Should this sequence continue beyond the set number of

attempts, the start sequence will be terminated and

Fail to Start fault will be displayed accompanied by a flashing shutdown symbol.

When the engine fires, the starter motor is disengaged and locked out at a pre-set frequency from the Alternator

output. Alternatively a Magnetic Pickup mounted on the flywheel housing can be used for speed detection (This is

selected by PC using the 5200 series configuration software). Rising oil pressure can also be used to disconnect

the starter motor, however it cannot be used for underspeed or overspeed detection.

After the starter motor has disengaged, the Safety On timer is activated, allowing Oil Pressure, High Engine

Temperature, Under-speed, Charge Fail and any delayed Auxiliary fault inputs to stabilise without triggering the

fault.

Once the engine is running, the Warm Up timer, if selected is initiated, allowing the engine to stabilise before

accepting the load.

If an auxiliary output has been selected to give a load transfer signal, this would then activate.

NOTE:-A load transfer will not be initiated until the Oil Pressure has risen. Thus preventing

excessive wear on the engine.

On the return of the mains supply, (or removal of the Remote Start signal if the set was started by remote signal) ,

the Stop delay timer is initiated, once it has timed out, the load Transfer signal is de-energised, removing the load.

The Cooling timer is then initiated, allowing the engine a cooling down period off load before shutting down. Once

the Cooling timer expires the Fuel Solenoid is de-energised, bringing the generator to a stop.

Should the mains supply fall outside limits again (or the Remote Start signal is re-activated) during the cooling

down period, the generating set will return to a on load condition.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

8 057-012 5220 OPERATING MANUAL ISSUE 5.1 18/06/2007 AM

3.2 MANUAL OPERATION

NOTE:- If a digital input configured to panel lock is active, the LCD will display the icon. When in

panel lock, changing module modes will not be possible. Viewing the instruments and event logs

is NOT affected by panel lock.

To initiate a start sequence in MANUAL, press the pushbutton. When the controller is in the manual mode

(indicated by an LED indicator beside the button), pressing the START (I) button will initiate the start sequence.

NOTE:- There is no Start Delay in this mode of operation.

If the pre-heat output option is selected this timer is then initiated, and the auxiliary output selected is energised.

The Fuel Solenoid is energised, then the Starter Motor is engaged.

The engine is cranked for a pre-set time period. If the engine fails to fire during this cranking attempt then the

starter motor is disengaged for the pre-set rest period. Should this sequence continue beyond the set number of

attempts, the start sequence will be terminated and Fail to Start fault will be displayed accompanied by a

flashing shutdown indicator.

When the engine fires, the starter motor is disengaged and locked out at a pre-set frequency from the Alternator

output. Alternatively a Magnetic Pickup mounted on the flywheel housing can be used for speed detection (This is

selected by PC using the 5200 series configuration software). Rising oil pressure can also be used to disconnect

the starter motor, however it cannot be used for underspeed or overspeed detection.

After the starter motor has disengaged, the Safety On timer is activated, allowing Oil Pressure, High Engine

Temperature, Under-speed, Charge Fail and any delayed Auxiliary fault inputs to stabilise without triggering the

fault.

Once the engine is running, the Warm Up timer, if selected, is initiated, allowing the engine to stabilise before it

can be loaded.

The generator will run off load, unless the mains supply fails or a Remote Start on load signal is applied. If Close

generator has been selected as a control source, the appropriate auxiliary output will then activate.

The generator will continue to run On load regardless of the state of the mains supply or remote start input until the

Auto mode is selected.

If Auto mode is selected, and the mains supply is healthy with the remote start on load signal not active, then the

Remote Stop Delay Timer begins, after which, the load is disconnected. The generator will then run off load

allowing the engine a cooling down period.

Selecting STOP (O) de-energises the FUEL SOLENOID, bringing the generator to a stop.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

5220 OPERATING MANUAL ISSUE 5.1 18-Jun-07 AM 9

3.3 TEST OPERATION

NOTE:- If a digital input configured to panel lock is active, the LCD will display the icon. When in

panel lock, changing module modes will not be possible. Viewing the instruments and event logs

is NOT affected by panel lock.

To initiate a start sequence in TEST, press the pushbutton. When the controller is in the test mode (indicated

by an LED indicator beside the button), pressing the START (I) button will initiate the start sequence.

NOTE:- There is no Start Delay in this mode of operation.

If the pre-heat output option is selected this timer is then initiated, and the auxiliary output selected is energised.

After the above delay the Fuel Solenoid is energised, then the Starter Motor is engaged.

The engine is cranked for a pre-set time period. If the engine fails to fire during this cranking attempt then the

starter motor is disengaged for the pre-set rest period. Should this sequence continue beyond the set number of

attempts, the start sequence will be terminated and Fail to Start fault will be displayed accompanied by a

flashing shutdown indicator.

When the engine fires, the starter motor is disengaged and locked out at a pre-set frequency from the Alternator

output. Alternatively a Magnetic Pickup mounted on the flywheel housing can be used for speed detection (This is

selected by PC using the 5200 series configuration software). Rising oil pressure can also be used to disconnect

the starter motor, however it cannot be used for underspeed or overspeed detection.

After the starter motor has disengaged, the Safety On timer is activated, allowing Oil Pressure, High Engine

Temperature, Under-speed, Charge Fail and any delayed Auxiliary fault inputs to stabilise without triggering the

fault.

Once the engine is running, the Warm Up timer, if selected, is initiated, allowing the engine to stabilise before it

can be loaded.

The generator will continue to run On load regardless of the state of the mains supply or remote start input until the

Auto mode is selected.

If Auto mode is selected, and the mains supply is healthy with the remote start on load signal not active, then the

Remote Stop Delay Timer begins, after which, the load is disconnected. The generator will then run off load

allowing the engine a cooling down period.

Selecting STOP (O) removes the Close Generator output (if configured) and de-energises the FUEL SOLENOID,

bringing the generator to a stop.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

10 057-012 5220 OPERATING MANUAL ISSUE 5.1 18/06/2007 AM

4 PROTECTIONS

The module will indicate that an alarm has occurred in several ways;

The LCD display will indicate a ‘common alarm’ either :

(warning), (shutdown) or

(electrical trip)

If appropriate, the LCD display or LED indicators will display the

appropriate alarm icon i.e. for battery charging failure :

NOTE:- Alarm icons in the LED display area are ‘hid until lit’. This means that the display area

appears totally clear, and ‘free from clutter’. The advantage of this is that when an alarm does occur,

the respective LED icon will illuminate on the otherwise blank fascia. This makes alarm identification

much clearer.

If no alarms are present the LCD

will extinguish any alarm icons.

In the event of a warning alarm the LCD will display the appropriate icon. If a shutdown then occurs the module

will display the appropriate icon. The original warning alarm icon will remain displayed.

Example:-

Low battery volts warning (all symbols steady)

Followed by….

Low battery volts warning indicator still

present, common alarm indicator has

changed to a shutdown symbol and is

now flashing.

Also present is the flashing underspeed

LED.

Underspeed and Shutdown alarm Icons are displayed flashing. The original warning will remain displayed as long

at the triggering conditions remain. Any subsequent warnings or shutdowns that occur will be displayed steady,

therefore only the first-up shutdown will appear flashing.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

5220 OPERATING MANUAL ISSUE 5.1 18-Jun-07 AM 11

4.1 WARNINGS

Warnings are non-critical alarm conditions and do not affect the operation of the generator system, they serve to

draw the operators attention to an undesirable condition.

In the event of a warning alarm the LCD will display:-

BATTERY CHARGE FAILURE, if the module does not detect a voltage from the warning light terminal on the

auxiliary charge alternator the icon will illuminate.

BATTERY LOW VOLTAGE, if the module detects that the plant DC supply has fallen below the low volts setting

level, the module will display:-

V

The Battery Low Voltage alarm is delayed by the Low DC Volts Delay timer.

BATTERY HIGH VOLTAGE, if the module detects that the plant DC supply has risen above the high volts setting

level, the module will display:-

V

The Battery High Voltage alarm is delayed by the High DC Volts Delay timer.

FAIL TO STOP, If the module detects the engine is still running when the ‘Fail to stop timer’ expires, then the

module will display:-

NOTE:- ‘Fail to Stop’ could indicate a faulty oil pressure sender - If engine is at rest check oil sender

wiring and configuration.

AUXILIARY INPUTS, if an auxiliary input has been configured as a warning the appropriate LCD segment will be

displayed:-

!

LOW FUEL LEVEL. If the fuel level detected by the fuel level sender falls below the low fuel level setting, a

warning will occur.

The icon will illuminate.

4.2 ANALOGUE PRE-ALARMS

The following alarms are termed ‘pre-alarms’ as they pre warn the operator of a potentially more serious alarm

condition. For instance, if the engine temperature rises past the pre alarm level, a warning condition will occur to

notify the operator. If the temperature falls below this level, then the alarm ceases, and the set will continue to run

as normal. However if the temperature continues to rise until the coolant temperature trip point is reached, the

warning is escalated and a high coolant temperature shutdown is initiated.

During a pre-alarm condition, the warning symbol is displayed on the LCD display, along with the appropriate

icon:

LOW OIL PRESSURE, if the module detects that the engine oil pressure has fallen below the low oil pressure pre-

alarm setting level after the Safety On timer has expired, a warning will occur.

The icon will illuminate.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

12 057-012 5220 OPERATING MANUAL ISSUE 5.1 18/06/2007 AM

HIGH ENGINE TEMPERATURE if the module detects that the engine coolant temperature has exceeded the high

engine temperature pre-alarm setting level after the Safety On timer has expired, a warning will occur.

The icon will illuminate.

OVERSPEED, if the engine speed exceeds the pre-alarm trip a warning is initiated.

The icon will illuminate.

Overspeed is not delayed, it is an immediate warning.

UNDERSPEED, if the engine speed falls below the pre-set pre-alarm after the Safety On timer has expired, a

warning is initiated.

The icon will illuminate.

GENERATOR HIGH FREQUENCY if the module detects a generator output frequency in excess

of the pre-set pre-alarm, a warning is initiated.

The icon will illuminate.

Generator High Frequency is not delayed, it is an immediate warning.

GENERATOR LOW FREQUENCY, if the module detects a generator output frequency below the

pre-set pre-alarm after the Safety On timer has expired, a warning is initiated.

The icon will illuminate.

GENERATOR HIGH VOLTAGE if the module detects a generator output voltage in excess of the pre-set trip a

shutdown is initiated.

The Vicon will illuminate.

High voltage is not delayed, it is an immediate shutdown.

GENERATOR LOW VOLTAGE if the module detects a generator output voltage below the below the pre-set pre-

alarm after the Safety On timer has expired, a warning is initiated.

The Vicon will illuminate.

4.3 HIGH CURRENT WARNING ALARM

GENERATOR HIGH CURRENT, if the module detects a generator output current in excess of the pre-set trip a

warning is initiated.

The Aicon will illuminate.

If this high current condition continues for an excess period of time, then the alarm is escalated to a shutdown

condition. For further details of the high current alarm, please see High Current Shutdown Alarm.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

5220 OPERATING MANUAL ISSUE 5.1 18-Jun-07 AM 13

4.4 SHUTDOWNS

Shutdowns are latching and stop the Generator. The alarm must be cleared, and the fault removed to reset the

module.

In the event of a shutdown alarm the LCD will display:-

(flashing).

The appropriate icon will also be displayed flashing

NOTE:- The alarm condition must be rectified before a reset will take place. If the alarm condition

remains it will not be possible to reset the unit (The exception to this is the Low Oil Pressure alarm and

similar ‘delayed alarms’, as the oil pressure will be low with the engine at rest). Any subsequent

warnings or shutdowns that occur will be displayed steady, therefore only the first-up shutdown will

appear flashing.

FAIL TO START, if the engine does not fire after the pre-set number of attempts has been made a shutdown will

be initiated.

The icon will illuminate.

EMERGENCY STOP, removal of the positive DC Supply from the Emergency Stop input initiates the following

sequence, firstly it will initiate a controlled shutdown of the Generator and prevent any attempt to restart the

Generator until the Emergency Stop push-button has been reset. Secondly it removes the positive DC supply from

both the Fuel Solenoid and Starter Solenoid.

The icon will illuminate.

NOTE:- The Emergency Stop positive signal must be present otherwise the unit will shutdown.

LOW OIL PRESSURE, if the module detects that the engine oil pressure has fallen below the low oil pressure trip

setting level after the Safety On timer has expired, a shutdown will occur.

The icon will illuminate.

HIGH ENGINE TEMPERATURE if the module detects that the engine coolant temperature has exceeded the high

engine temperature trip setting level after the Safety On timer has expired, a shutdown will occur.

The icon will illuminate.

OVERSPEED, if the engine speed exceeds the pre-set trip a shutdown is initiated.

The icon will illuminate.

Overspeed is not delayed, it is an immediate shutdown.

NOTE:-During the start-up sequence the overspeed trip logic can be configured to allow an extra

trip level margin. This is used to prevent nuisance tripping on start-up - Refer to the 5200 series

configuration software manual under heading ‘Overspeed Overshoot’ for details.

UNDERSPEED, if the engine speed falls below the pre-set trip after the Safety On timer has expired, a shutdown is

initiated.

The icon will illuminate.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

14 057-012 5220 OPERATING MANUAL ISSUE 5.1 18/06/2007 AM

GENERATOR HIGH FREQUENCY if the module detects a generator output frequency in excess

of the pre-set trip a shutdown is initiated.

The icon will illuminate.

Generator High Frequency is not delayed, it is an immediate shutdown.

GENERATOR LOW FREQUENCY, if the module detects a generator output frequency below the

pre-set trip after the Safety On timer has expired, a shutdown is initiated.

The icon will illuminate.

GENERATOR HIGH VOLTAGE if the module detects a generator output voltage in excess of the pre-set trip a

shutdown is initiated.

The Vicon will illuminate.

High voltage is not delayed, it is an immediate shutdown.

GENERATOR LOW VOLTAGE if the module detects a generator output voltage below the below the pre-set trip

after the Safety On timer has expired, a shutdown is initiated.

The Vicon will illuminate.

OIL PRESSURE SENDER OPEN CIRCUIT, if the module detects a loss of signal from the oil pressure sender

(open circuit) a shutdown is initiated. The LCD will indicate:-

(Steady) (And ‘-----‘ on the engine oil pressure instrument). Sender failure is not delayed, it is an immediate

shutdown.

AUXILIARY INPUTS, if an auxiliary input has been configured as a shutdown the appropriate LCD segment will be

displayed:-

!

LOSS OF SPEED SIGNAL, if the speed sensing signal is lost during cranking, a shutdown is initiated.

The icon will illuminate. (Steady) (And ‘-----‘ on the engine RPM instrument).

NOTE:- This will only occur if the speed sensing signal is lost during cranking or during the safety

on timer. If the signal is lost during normal operation the Generator will shutdown with an Under-speed

alarm.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

5220 OPERATING MANUAL ISSUE 5.1 18-Jun-07 AM 15

4.5 HIGH CURRENT SHUTDOWN ALARM

GENERATOR HIGH CURRENT, if the module detects a generator output current in excess of the pre-set trip a

warning is initiated. This warning will continue for a period of time depending upon the level of overload that the

generator is subjected to, and the configuration setting for Generator High Current in the 5200 series configuration

software.

For instance the factory default settings for Generator High Current allow for a loading of the generator to 110% for

one hour. That is to say if the generator load level exceeds the trip point by 10%, a warning alarm will occur while

the overload condition exists. If the load level does not drop to normal levels within one hour, the set is stopped,

the 5220 module displaying either shutdown alarm or electrical trip alarm depending upon module configuration.

Additionally, the Aicon will illuminate.

NOTE:- Higher overload levels will result in a faster acting shutdown condition. For instance with

the factory default configuration, an overload level twice that of the trip level ( typically 200%) will result

in a Generator High Current shutdown condition after 36 seconds.

For details of the relationship between the overload and the shutdown time, please see the Appendix

section of this manual.

4.6 ELECTRICAL TRIPS

Electrical trips are latching and stop the Generator but in a controlled manner. On initiation of the electrical trip

condition the module will de-energise the ‘Close Generator’ Output to remove the load from the generator. Once

this has occurred the module will start the Cooling timer and allow the engine to cool off-load before shutting down

the engine. The alarm must be accepted and cleared, and the fault removed to reset the module.

In the event of an electrical trip alarm the icon will illuminate.

Additionally, During the cooling timer the warning symbol is displayed followed by the flashing shutdown

symbol when the cooling timer has expired.

AUXILIARY INPUTS, if an auxiliary input has been configured as an electrical trip the appropriate LCD segment

will be displayed:-

!

GENERATOR HIGH CURRENT. If the module detects a generator output current in excess of the pre-set trip a

warning is initiated.

The Aicon will illuminate.

If this high current condition continues for an excess period of time, then the alarm is escalated to either a

shutdown or electrical trip condition (depending upon module configuration). For further details of the high current

alarm, please see High Current Shutdown Alarm.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

16 057-012 5220 OPERATING MANUAL ISSUE 5.1 18/06/2007 AM

5 LCD INDICATORS AND LOGO INSERT

USER CONFIGURABLE LCD indicators

These indicators can be configured by the user to indicate any one of 100+ different functions

based around the following:-

•INDICATIONS - Monitoring of a digital input and indicating associated functioning user’s

equipment - Such as Battery Charger On or Louvre Open, etc.

•WARNINGS and SHUTDOWNS - Specific indication of a particular warning or shutdown

condition, backed up by LCD indication - Such as Low Oil Pressure Shutdown, Low

Coolant level, etc.

•STATUS INDICATIONS - Indication of specific functions or sequences derived from the

modules operating state - Such as Safety On, Pre-heating, Panel Locked, Generator

Available, etc.

These indicators are annunciated using a removable insert card. Additionally the module’s logo

can be changed to suit generator manufacturer’s requirements. This can be used for instance to

give custom branding to the module, or even include the service telephone number.

DSE have produced the ‘insert card creator’ software, shipped with the DSE Software CD to ease

the production of text and logo insert cards to suit your application.

Removal and insertion of the text insert card

Removal and insertion of the Logo insert card

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

5220 OPERATING MANUAL ISSUE 5.1 18-Jun-07 AM 17

6 DESCRIPTION OF CONTROLS

The following section details the function and meaning of the various controls on the module.

FIG2

Stop Manual Test

A

uto Start

Scroll

Configure

/ log

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

18 057-012 5220 OPERATING MANUAL ISSUE 5.1 18/06/2007 AM

6.1 TYPICAL LCD DISPLAY SCREENS

INSTRUMENTS

The LCD displays the various engine parameters such as

‘ENGINE SPEED’,‘OIL PRESSURE’, ‘HOURS RUN’, etc.

Each instrument is displayed with the appropriate units of measure.

In this example, the values being displayed are Generator

phase to neutral L1-N, AC voltages V.

STATUS ICONS

The LCD also displays the status of the controller by showing (for

example) an hourglass symbol when a timer is in progress or by

displaying a common alarm symbol. This display is indicating that a

timer is in progress and a warning alarm is present. See the

‘Protections’ section of this manual for details of the alarms.

In this example the values being displayed are the three

generator AC currents A

USER DEFINED

INDICATIONS

The LCD displays the user-defined indications when configured

and active. The icons will illuminate and point to the appropriate

text insert label. These indications can be used to indicate the

operation of external equipment (i.e. ‘Battery Charger On’, ‘Breaker

Closed’ etc) or to indicate internal states (i.e. Engine Running,

Safety On, etc).

USER DEFINED ALARMS

The LCD displays the user-defined alarms when configured and

active. The icons will illuminate and point to the appropriate text

insert label. These alarms can be used to indicate the operation of

external alarms (i.e. ‘Low Fuel Level’, ‘Low Coolant level’ etc) or to

indicate internal alarms (i.e. Fail to Stop, MPU fault, etc).

HOURS RUN COUNTER

The LCD displays the generator hours run time while both the

generator symbol and the clock symbol are present.

In this example the hours run time would read 21 hours and 35

minutes.

HOURS RUN (100 hrs +)

The hours run up to and including 99 are displayed on the third line

of the display. Minutes run are displayed after the decimal point.

All hours above 99, (i.e. the hundreds, thousands and tens of

thousands units) are displayed on the second line of the display.

In this example the hours run time would read 221 hours and 35

minutes.

HOURS RUN (1000 hrs +)

All hours above 99, (i.e. the hundreds, thousands and tens of

thousands units) are displayed on the second line of the display.

In this example the hours run time would read 3221 hours and 35

minutes.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

5220 OPERATING MANUAL ISSUE 5.1 18-Jun-07 AM 19

6.2 LCD DISPLAY AREAS

Instrument values

Display information &

units of measure

Alarm icons

Status icons

User configurable display

icons

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

DSE Model 5220 Automatic Mains Failure & Instrumentation System Operators Manual

20 057-012 5220 OPERATING MANUAL ISSUE 5.1 18/06/2007 AM

6.3 VIEWING THE INSTRUMENTS

It is possible to manually scroll to display the different instruments by repeatedly operating the scroll button. Once

selected the instrument will remain on the LCD display until the user selects a different instrument or after a period

of inactivity the module will revert to the initial display (Hz/RPM).

Instrument Page Order:-

•Generator RPM / Frequency (Hz)

•Generator AC Voltage Line-Neutral

•Generator AC Voltage Line-Line

•Oil Pressure

•Coolant temperature

•Fuel level (%)

•Engine Hours Run

•DC Battery Voltage

•AC Line Current

•Total kW

•Total VA

•AC phase angle (cos

∅

)

•Mains (Utility) Frequency (Hz)

•Mains (Utility) AC Voltage Line-Neutral

•Mains (Utility) AC Voltage Line-Line

Manually Selecting an Instrument

Initial display (Hz/RPM)

Pressing the DOWN button the LCD will

then show (Generator L-N voltages)

Pressing the DOWN button the LCD will

then show (Generator L-L voltages)

Pressing the button again will scroll through each individual instrument eventually returning to the original

instrument displayed.

NOTE:-Once selected the instrument will remain on the LCD display until the user selects a different

instrument or after a period of inactivity the module will revert to the initial display.

CALL US TODAY

1-888-POWER-58

REQUEST A QUOTE

SHOP ONLINE

www.genpowerusa.com

Table of contents

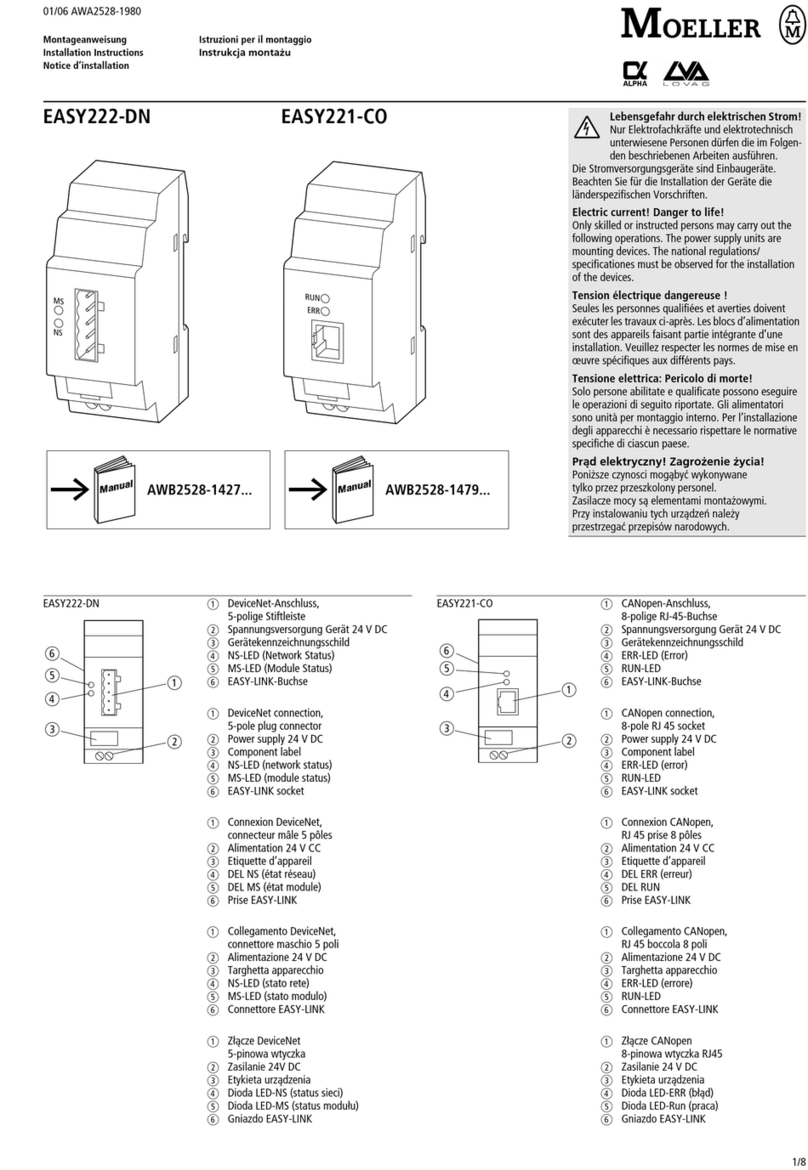

Popular Control Unit manuals by other brands

Moeller

Moeller EASY221-CO installation instructions

Georg Fischer

Georg Fischer Signet 9900 instruction sheet

Light O Rama

Light O Rama Easy Light Linker RF-V4 user manual

Fortinet

Fortinet FortiGate-7000E Series Guide

Johnson Controls

Johnson Controls CKM-MR51E Hardware installation manual

Honeywell

Honeywell Braukmann RV 284 installation instructions