1 DDCS V2.1 Controller Introduction

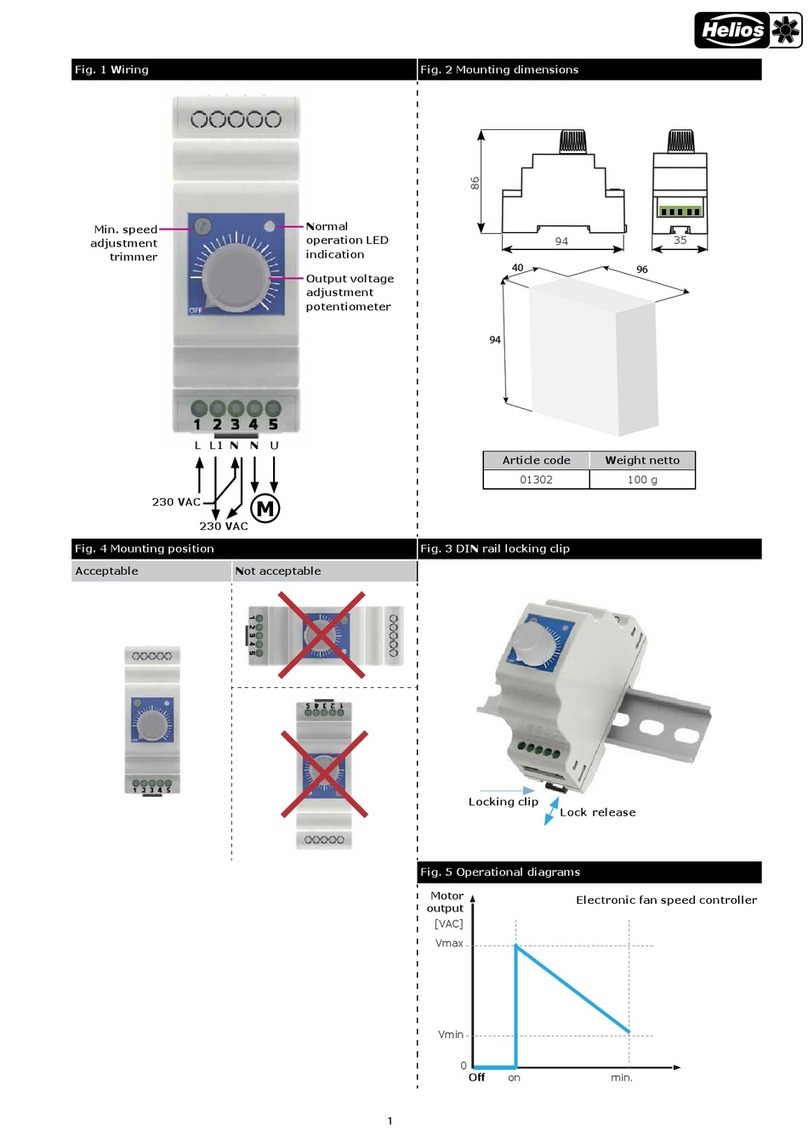

1) 16 opto isolated digital inputs

2) 3 opto isolated digital outputs

3) Analog spindle control 0-10V spindle control (can be modified as PWM output)

4) 4 axis motor control, max 500KHz per axis

5) ARM9 main control chip

6) FPGA core algorithm chip

7) 4.3 inches TFT screen, resolution ratio: 480x272

8) 17 operation keys

9) 18V-32V power input, minimum 0.5A

10) USB flash disk support for G code file input

11) 1GB internal memory

12) MPG port for our MPG with digital display. Many other MPG’s also supported

13) Jog function for each axis (continuous, step, defined distance

14) Support the operation of quickly specify the running position

15) Support for “Power Cut” recovery. Data is automatically saved.

Digital Dream has a 20 years history in the numerical control industry, specializing in the research, devel-

opment and production of various CNC (Computer Numerical Control) systems. Digtital Dream aims to

combine high quality and high reliability with affordability. We produce 1 axis to 6 axes CNC system.

The DDCS V2.1 is a 4 axis motion controller for stepper and servo systems. We are very proud of this

product, it combines great power with a tiny footprint and is easy to use. After a very short time you will be

familiar with the functions and this manual will help you. The highest output pulse per axis is 500KHz. The

pulse width is adjustable (refer to driver manual). The control period of each position is only 4 milliseconds.

This provides high control precision for stepper motors and servo motors.

The DDCS V2.1 numerical control system adopts the ARM+FPGA design framework. ARM controls the

human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the

control pulse. This guarantees reliable control and easy operation. The internal operating system is Linux based.

The panel layout structure of the DDCS V2.1 is very rational to save space. All operations are controlled

by only 17 keys and a comprehensive G code set is supported.

The DDCS V2.1 can be used for many styles and types of CNC machines. Lathes, Routers, Pick&Place and

Mills are just a few examples. The DDCS V2.1 operates as a Stand Alone system without the need of a comput-

er. This guarantees high precision, accuracy and reliability. The interface, even very comprehensive, can be

learned in a very short time.

1.1 Introduction of Product

1.2 Performance parameter of the Digtital Dream DDCS V2.1

Page -1Digtital Dream 4 Axis Motion Controller DDCS V2.1 User’s Manual