Digital Dream EC500 User manual

Mach3 Ethernet Motion Controller

EC500

User’s Manual

The version of 20180925

Contents

1. Brief Description of the EC500 Motion Controller

2. Safety Notes

5.2 Stepper/Servo Motor Control Interface Connection

5.3 Spindle Control Output Port

3. Physical Installation of the device

5. Wiring and Ports Description

4. Controller EC500 Power Solution

5.8 Power Supply for Controller System and Power Supply for IO Port

5.5 Function Switch for MPG and Connection for MPG

1

1

2

4

5

7

8

9

11

12

12

15

15

16

16

17

18

19

22

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

3

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●

16

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●

●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●●

6.2 Open Mach3 Software and connect with right PlugIn file

6.6 MPG Settings

6.5 Port and Pins Setup

6. Mach 3 Configuration

6.1 PlugIn

6.3 Check EC500 Plug-In in the Mach3 software

5.4 General output interface

5.6 Serial extend port

5.7 Input Ports

5.9 LEDs Indicator for Power and communication with Mach 3 software

6.4 Motor Tuning and Setup

5.1 Ethernet Communication Interface to PC

1. Description of the EC500 Motion Controller Device:

For firstly of all we thank you for your interesting in our product and for reading this user’s guide.

The EC500 is a high-performace external motion controller for Mach3, with ethernet interface,supporting

standard MPG pendant.The device can communicate with a connection to a control computer’s network.The

network connection can be built with direct connection or via router/Swith devices.

The computer connects to the EC500 via a standard Ethernet cable.The cable may be shielded or unshield-

ed.An advantage of the Ethernet compared to a USB is that the cable length maybe as long as 100 meters.The

maximum length for a USB cable is 5 meters,and that is pushing it in a noisy working environment.Another

advantages is that Ethernet uses transformers for coupling the data signals,which galvanically isolates the

computer from the downstream electronics.

The device can be used to control machine tools with stepper or servo motor controls with pulse and direc-

tion interfaces;the controller can output a maximum of 460kHz stepping frequency for each axes and can work

with upto 6-axes.The Controller is 3-6 Axis for user’s options.

This user’s guide describes how to establish connection between the device and controler computer,the

device and stepper/Servo drives and spindle motor,how to setup the LAN network and the device for the

communication.This document also describs the inputs and outputs,the electrical parameters and properties of

the motion controller.It guides the users how to run the device with Mach3 software,and how to set the parame-

ters in the software.

Here is the brief description for the device:

1) Motion control 3-6 Axis(X,Y,Z,A,B,C) for option,max frequency output 460Khz/Axis;

2) Main power supply 24VDC,Current should higher than 1A;

3) IO Power is 24VDC power supply input,current should higher than 1A;

4) IO Power is 24VDC power supply input,current should higher than 1A. (By the IO power supply,system

already supply the power for IO ports.So no need the external power supply for IO port anymore.);

5) 18 opto-isolated digital input ports,16 opto-isolated digital output ports;

6) 1 analog output port of 0-10V adjustable speed for spindle (can change to PWM output port);

7) ARM motion control chip;

8) Compatible with Standard MPG and also Digital Dream MPG

Accessories:

Beside the main products,in our package,there are accesories:1pcs 1.5meter Ethernet cable.

2. Safety Notes:

Moving objets like machine tool axes and automatical equipments can be very dangerous.Always make

sure to keep all machines safety standards.Always install E-stop switches and the required safety equipments to

your control system and make sure that the equipment controlled by our device meets all the safety standards.

Always keep the controller dry and away from falling chips and dust,protect the device from taint

damage.Avoid conneciton mistakes,avoid high voltage damage,avoid operation errors.

Protect the device from direct intensive sunshine beams and from extreme temperature levels and from

extra high humidity weather.

We cannot take the responsibility for any persernal injury and financial loss caused by any device failure

or caused by following an error in this documentation.

Page -1Digital Dream Mach3 Motion Controller EC500 User’s Manual

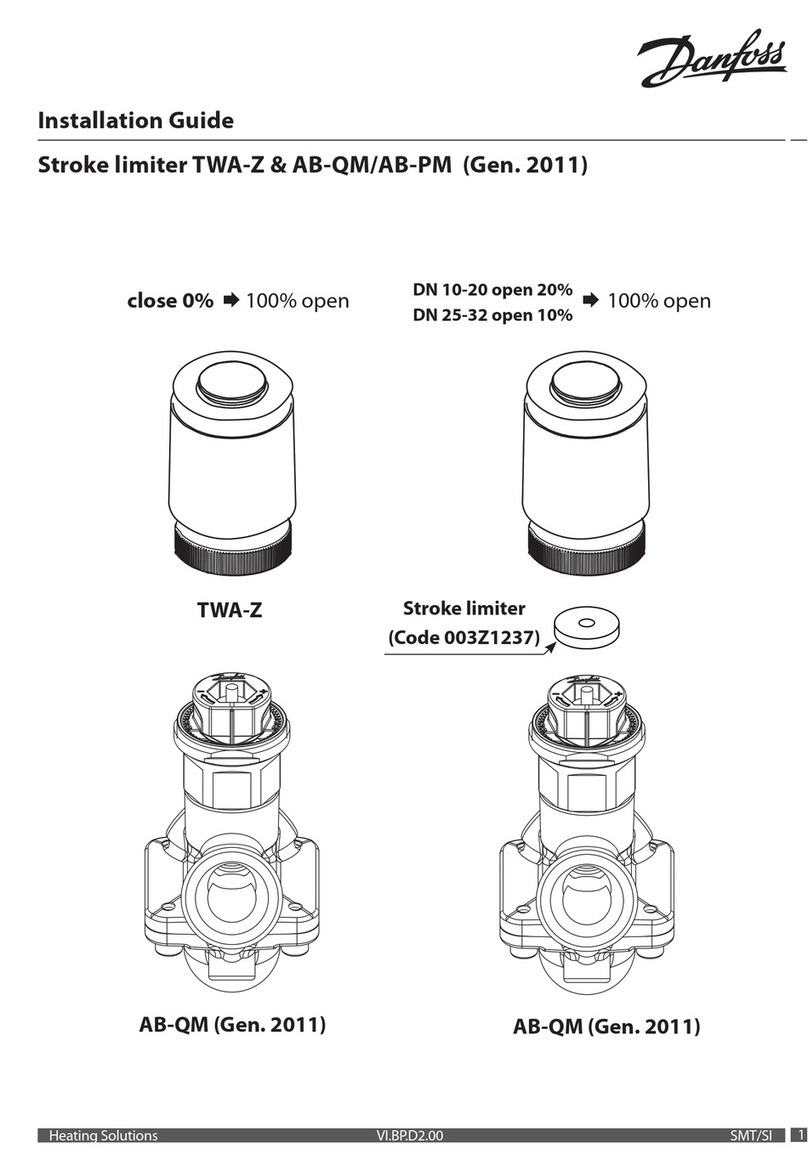

3. Physical Installation of the device(Unit:mm)

The EC500 motion controller is with the sealed shell structure,there are 4pcs mounting holes around the

controller.We can fix 4pcs 4mm diameter holes at the cabinet,and install the controller into the cabinet.

Picture 3-1 EC500 Front Appearance and size

Picture 3-2 EC500 Installation Dimensions

190 mm

32 mm

113 mm

21 mm

7 mm

4 mm

116 mm

119 mm

Page -2Digital Dream Mach3 Motion Controller EC500 User’s Manual

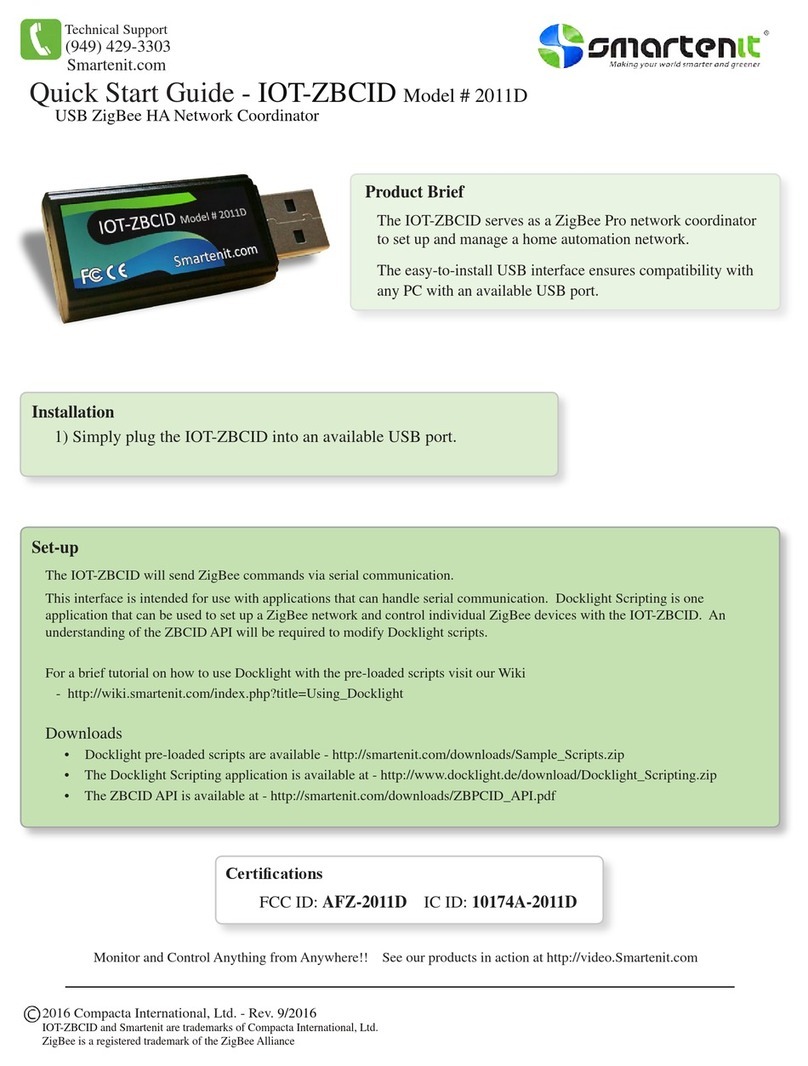

4. Controller EC500 Power Solution

Picture 4-1 EC 500 Power supply structure

Page -3Digital Dream Mach3 Motion Controller EC500 User’s Manual

The power supply solution in the field of the Industrial automation is always very complicated, there is a

lot of the GND, now we descript the structure of the power structure as below:

The power structure as the Picture 4-1,Power supply input and Ethernet port share common GND, stepper

control module,Input&Output module,Spindle control module and MPG Port share common GND, between the

two sector there is photoelectric isolation. Inside of the board, there is GND as common-, no need to connect

external power supply.

The following drawing shows the main connections of our device.We will descrip one by one in next

pages.Here are:

1 : Ethernet Communication Interface to PC

2 : Stepper/Servo motor Driver connection port

3 : Spindle Control Output Port

4 : Gerneral Output Interface

5 : MPG Port

6 : Functional Switch for MPG:Standard MPG or Digital Dream MPG

7 : Serial Extend Port

8 : Input Port:Limit/Home/Probe and so on

9 : IO Power Port

10 : Main Power Port

11 : Power and Communication LED Indicator

Picture 5-1 EC500 Wiring Over-view

10:Main Power Port

2: Stepper/Servo Driver

1: Ethernet Interface 11: LED Indicator

4: Genernal Output

9:IO Power Port

5: MPG

8:Input Port 7:Serial Extend Port

6: Optionanl Swirtch for MPG

3: Spindle Control

Page -4Digital Dream Mach3 Motion Controller EC500 User’s Manual

5. Wiring and Ports Description

5.1 Ethernet Communication Interface to PC

5.1.1 Setup with direct connection to a LAN network card.

To setup the network on the computer side there are two ways for our device:

1) Setup with direct connection to a LAN network card;

2) Setup with connection via switch/router.

Firstly connect the EC500 controller to PC by the ethernet cable.

To Setup the connection with direct cable connection click on the name of the connection and on the pop-up

window press the Properties button.Please note that for this action to work the user must have administrator

rights inWindows account.Control Panel -> Network and Internet -> Network Connections.

Pls remember to shut down the firewall of the computer before the connection.

Picture 5-2 EC500 Ethernet Commnication Setup

Page -5Digital Dream Mach3 Motion Controller EC500 User’s Manual

5.1.2 Setup with direct connection via switch/router.

To Setup the connection with connection via a switch or router device click on the name of the connection and

on the pop-up window press the Properties button.Please note that for this action to work the user must have

administrator rights in Windows account.On the popup window find and select the ‘Internet Protocol Version

4(TCP/IPv4)’ row and click the Properties button.Find and click ‘Obtain an IP address automatically’ and

system will setup the connection.

Picture 5-3 EC500 Ethernet Communication Setup IP No.

Picture 5-4 EC500 Ethernet Communication via switch/router

IP range from

192.168.1.1 to 192.168.1.255

Subnet Mask:

255.255.255.0

Page -6Digital Dream Mach3 Motion Controller EC500 User’s Manual

5.2 Stepper/Servo Motor Control Interface Connection

The device can be used to control machine tools with stepper

or servo motor controls with pulse and direction interfaces

upto 6-axes.

PIN Mark Description

XP+

XP-

XD+

XD-

YP+

YP-

YD+

YD-

ZP+

ZP-

ZD+

ZD-

X Axis Direction Output -

X Axis Direction Output +

X Axis Pulse Output -

X Axis Pulse Output +

Y Axis Direction Output -

Y Axis Direction Output +

Y Axis Pulse Output -

Y Axis Pulse Output +

Z Axis Direction Output -

Z Axis Direction Output +

Z Axis Pulse Output -

Z Axis Pulse Output +

AP+

AP-

AD+

AD- A Axis Direction Output -

A Axis Direction Output +

A Axis Pulse Output -

A Axis Pulse Output +

BP+

BP-

BD+

BD- X Axis Direction Output -

B Axis Direction Output +

B Axis Pulse Output -

B Axis Pulse Output +

CP+

CP-

CD+

CD-

Motor Driver Connection(5V)

Picture 5-5 EC500 Stepper/Servo Mark and description

B Axis Direction Output -

C Axis Direction Output +

C Axis Pulse Output -

C Axis Pulse Output +

C Axis Direction Output -

Page -7Digital Dream Mach3 Motion Controller EC500 User’s Manual

As Picture 5-1 showed,No.3 terminal block is for Spindle control output. We define the interface from

left are COM-,VSO,COM-,OUT1,OUT2,OUT3,OUT4,OUT5. They are Ground of output, Speed adjusting

voltage, Ground of output, Digital output1, Digital output2, Digital output3, Digital output4, Digital output5.

Take Nowforeuer inverter as the example. Spindle control output and the inverter connection showed as

Picture 5-6.X1 control spindle Clockwise RUN and STOP, AIN1 modify spindle's speed. if we need to control

spindle anti-clockwise RUN and STOP, we need to connect X2 to OUT2.

5.3 Spindle Control Output Port

Picture 5-6 EC500 Spindle Control Setup

COM

AIN1

X1

X2

VSO connects to Speed adjustment which defined by voltage 0-10V.

The relationship Max. Spindle speed and current spindle speed is as below:

VSO(Output Voltage)=10*current spindle speed(S)/Maximum Spindle Speed(Max.S).

For example if we set the Max Speed is 24000,and we need the current spindle speed is 18000,then

VSO=10*18000/24000=7.5V.

The following picture 5-7 is the setting method of Max. speed in Mach3 software.

Page -8Digital Dream Mach3 Motion Controller EC500 User’s Manual

As the Picture 5-1 showed. the marked No. 4 is General output interface. This is a DB15 port.

5.4 General output interface

PIN No. DefinitionMark

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

COM+ IO power +

OUTPUT 6

IOUTPUT 8

OUTPUT 10

Common Ground for output

Common Ground for output

OUTPUT13

OUTPUT15

IO power +

OUTPUT 7

OUTPUT 9

OUTPUT 11

OUTPUT 12

OUTPUT 14

OUTPUT 16

VCCIO

OUT6

OUT8

OUT10

OUT7

OUT9

OUT11

OUT12

OUT14

OUT16

COM-

GND

OUT13

OUT15

Picture 5-7 EC500 Spindle Motor Max Speed Setting

Picture 5-8 General Output DB15 Pin No.

Page -9Digital Dream Mach3 Motion Controller EC500 User’s Manual

The general output interface has a built-in relay drive circuit, which can be directly connected to less than the

100mA relay. Reference Picture 5-10. for wiring with relay, using output 6(Pin No.2).

Picture 5-9 OUTPUT port internal structure

Picture 5-10 Solid Replay Connection

OUT6

COM+

Page -10Digital Dream Mach3 Motion Controller EC500 User’s Manual

5.5 Function Switch for MPG and Connection for MPG

As the Picture 5-1 showed, the marked No.6 is the switch for the options of two type MPG.For EC500,it

can supply both standard MPG and NV-MPG which is made by our company Digital Dream. The Marked No.

5 is the interface for the connection of MPG.

The difference connection for Standard MPG and NV-MPG is from the Pin1 and Pin 2.Pls check the

following table.Pls don’t also forget when you need standard MPG turns the switch to STD,and when you

need NV-MPG,switch it to NV.Then wiring the connections of MPG interface.

PIN No. DefinitionMark

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

T1OUT TXD of Serial port

Power supply + for MPG(5V)

A phase positive of the encoder

B phase negative of the encoder

X axis select input

Estop port

Z axis select input

100 rate select input

RXD of Serial port

Ground and common end

A phase positive of the encoder

B phase negative of the encoder

Y axis select input

A axis select input

10 rate select input6

R1IN

VMPG

WHA+

WHB+

GND

WHA-

WHB-

YIN

AIN

X10IN

XIN

EP

ZIN

X100IN

DescriptionDescription

STD(STANDARD MPG) NV(NVMPG)

1

TXD

BIN

MPG serial communication Output Port For the digital display

PIN NO. Mark Definition Mark Definition

MPG TYPE

9CIN

Select Axis B

Select Axis C

T1OUT

R1IN

OUT for serial port

IN for serial port

MPG

Page -11Digital Dream Mach3 Motion Controller EC500 User’s Manual

Picture 5-11 Extended Serial Port

As the Picture 5-1 show, The marked No. 7 port is Serial extend port. The interface is mainly used for

extended serial devices, such as IO extensions or HMI interface extensions.

5.6 Serial extend port

PIN No. DefinitionMark

1&6

2

3

5&9

4&7&8

VCC5 5V Power+

Receive for serial port

Transmit for serial port

Ground

Reserved

RXD

TXD

GND

NC

As the Picture 5-1 showed, Marked No. 8 position is for Input ports.They are the optical isolated

Input interface. The Mark information from left to right

is:IN1,COM-,IN2,COM-,IN3,IN4,IN5,IN6,IN7,IN8,COM-,COM+,IN9,IN10,IN11,IN12,IN13,IN14,COM

-,COM+,IN15,COM-,IN16,IN17,COM-,IN18.

Internal structure see as Picture 5-12.

2 lines Proximity Switch/ordinary fretting switch / drawing see as Picture 5-13.

3 lines Proximity Switch connection Picture 5-14 and Picture 5-15, brown cable for Proximity

switch connect with 12V,Black cable connect channel, blue cable connect with GND1. Pls note Only

support NPN typel 3 lines proximity switch.

5.7 Input Ports

1

5

6

9

Page -12Digital Dream Mach3 Motion Controller EC500 User’s Manual

Picture 5-12 Internal structure of Input interface

Picture 5-13 Probe/Estop/ and other switch input connection

Page -13Digital Dream Mach3 Motion Controller EC500 User’s Manual

Picture 5-14 NPN 3 lines Proximity Switch connection drawing

Picture 5-15 NPN 3 lines Proximity Switch Connection Example

Page -14Digital Dream Mach3 Motion Controller EC500 User’s Manual

As the Picture 5-1 show, The marked No. 9 port is the power supply port for IO port,and Marked No. 10

is for the power supply for Controller System. The access voltage range is 24VDC, and the power demand is

not less than 20W. As shown in the picture, the left terminal is power - and the right terminal is power + ,they

shared one common GND.See the Picture 5-16 as below:

5.8 Power Supply for Controller System and Power Supply for IO Port

Picture 5-16 Power supply for Controler System and for IO Port

As the Picture 5-1 show, There are 3 Indicator LEDs for the controller power,IO Power and communicai-

ton with Mach3 respectively.

If the controller and IO power supply are configurated in right way,the Main Power LED and IO Power

LED turn to Red.

The LED marked “CONN” represents the status of the communicaton with Mach3 software.If a link has

not been established,the LED will not light.

5.9 LEDs Indicator for Power and communication with Mach 3 software

Page -15Digital Dream Mach3 Motion Controller EC500 User’s Manual

6.2 Open Mach3 Software and connect with right PlugIn file

Double-click the icon mach3mill .Enter into Mach3 software. Pop-up the plug-in box as

below left picture.Then Click “Create Profile” and name it to “DigitalDream”,click “Default profile values” and

confirm it by “OK”

6. Mach 3 Configuration

When you purchase our product, we will supply a software package in the U-disk, which contains “Digit-

alDream” PlugIn,and the EC500 Manual.

In your computer which you will run the EC500 controller,you must already installed the Mach 3 Software,and

now pls copy the PlugIn in to C:\Mach3\PlugIn.(If the user install the Mach 3 software in C-disk.)

6.1 PlugIn

Page -16Digital Dream Mach3 Motion Controller EC500 User’s Manual

After Click “OK”,it will popup a window for the options of DLL file as below,pls choose “Digital Dream” as

below.Then press OK. If you do not want to the dialog box to show again any more, select ‘Don’t ask me this

again’.If connect successfully,Status bar will show “EC500 device is connected to your computer”.

Click config plugins in the software main menu,in the pop-down menu select ‘PluginConfig’,it will show the

DigitalDream Plug-In is enabled:

6.3 Check EC500 Plug-In in the Mach3 software

Page -17Digital Dream Mach3 Motion Controller EC500 User’s Manual

Mach3's Menu -> Config -> Motor Tuning (and Setup).

The Step Pulse and Direction Pulse fields are used for a Ethernet Port connection from your computer to

your hardware.

The Steps per Unit, Velocity (Units per Minute) and Acceleration fields are critical for tuning your

motors. The Steps per Unit is determined by your hardware for each axis. The velocity is the maximum

speed you want your axis to move. The acceleration is the maximum acceleration rate your motors should run

at (to prevent stalling or missed steps). This needs to be done for each of your axes.

Don’t forget to save the data when you finished the data setting of every axis.For example,you click Z

Axis,and save all the datas into the column,then you must click “SAVE AXIS SETTING”,then the datas can

be saved.

6.4 Motor Tuning and Setup

Click Main Menu ‘Config’,select the ‘Motor Tuning’ from its pop-down menu:

Then the screen display as below:

Page -18Digital Dream Mach3 Motion Controller EC500 User’s Manual

Table of contents

Other Digital Dream Controllers manuals

Digital Dream

Digital Dream DM500T3 User manual

Digital Dream

Digital Dream DM500 User manual

Digital Dream

Digital Dream NCH02 User manual

Digital Dream

Digital Dream DDCS V2.1 User manual

Digital Dream

Digital Dream UC300 User manual

Digital Dream

Digital Dream DDCS V3.1 User manual

Digital Dream

Digital Dream DDCS-Expert User manual

Popular Controllers manuals by other brands

controlair

controlair 350 Series Installation, operation and maintenance instructions

Emulex

Emulex MD21/S2 Technical manual

Mitsubishi Electric

Mitsubishi Electric MELDAS MDS-B-SVJ2 Series Specifications and Instruction Manual

LG

LG PBACNBTR1A installation manual

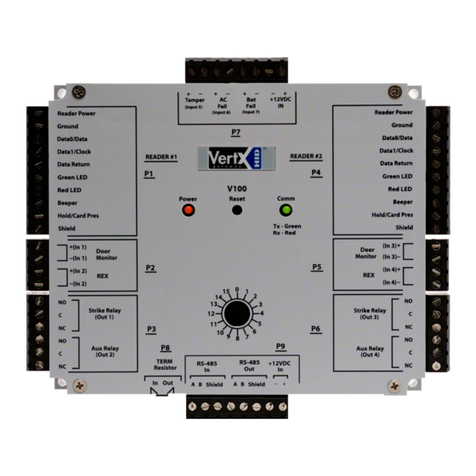

HID

HID VertX EVO Series quick start guide

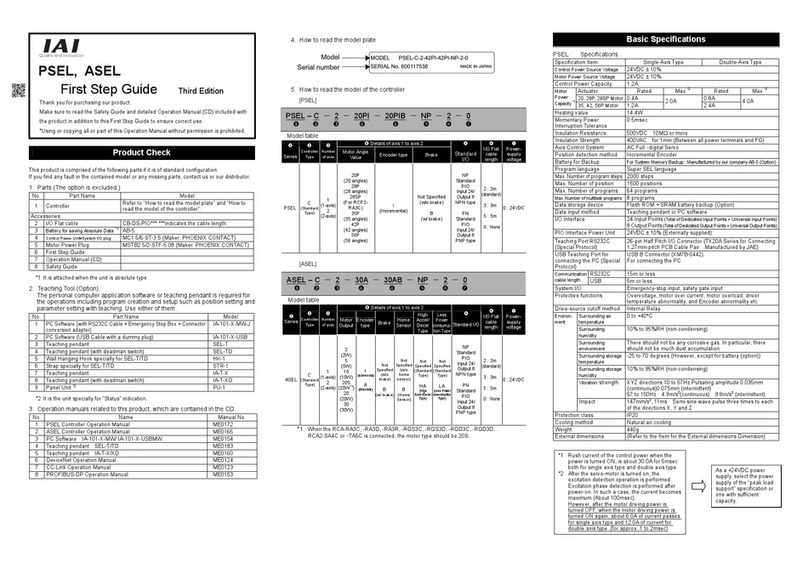

IAI

IAI PSEL series First step guide