Digital Dream NCH02 User manual

Handheld Motion Controller

For Engraving Machine

NCH02

User’s Manual

Digital Dream CNC Co,. Ltd.

www.ddcnc.com

The version of 20180915

1 NCH02 Motion Controller Introduction

1) Max. 5 Axis,3-5 Axis Optional;Max. 125Khz per axis;

2) 2-4 Axis linear interpolation,any 2 axis circular interpolation;

3) 5 opto isolated digital outputs,8 opto isolated digital inputs;

4) Analog spindle control 0-10V spindle control (can be modified as PWM output);

5) 24VDC power input, minimum 1A;

6) 3.5 inches TFT screen, resolution ratio: 480x320;19 user keys;

9) USB flash disk support for G code file input;

10) The control system can preview the process path before machining,and it makes the system more

steady,working smoothy and precise;

11) Support the Standa�rd MPG or the NVMPG which Digital dream made;

12) Acceleration/Deceleration Mode: S curve;

13) Support un-limited size file for machining;

14) Manual/Automatic machining function;

15) Support the operation to Start a G code from a specific line;

16) Support for “Power Cut” recovery. Data is automatically saved;

17) Support time-lock function;

18) Automatocally Probe function;

19) Supporting Homing,Go to Zero,workpiece origin position saving;

20) Supporting downloading and uploading all the parameter setting of the controller.

Digital Dream has a 10 years history in the numerical control industry, specializing in the research, devel-

opment and production of various CNC (Computer Numerical Control) systems. DigitalDream aims to combine

high quality and high reliability with affordability. We produce 1 axis to 6 axes CNC system.

Thank you for choosing digital dream’s motion controllers.With a lots of examples and charts,this manual

will describe the features,functions and every operations of our controllers.Pls read this manual carefully before

any assembling and using.Incorrect handling can result in injury and damage to persons and engraving

machine.Pls keep the manual carefully for convenient to read it at any time in need.

NCH02 is very professional 3-5 Axis CNC Motion Controller which is based on embedded system.NCH02

operates as a standalone system with handheld Pendant without the need of a computer,and with a pendant,it

makes users very convenient to opreate the machines.Our controller adopts Embedded Operating System,by

which the controller will never get virus-infected.And the controller adopts look-ahead algorithm by which the

the controller can read more ahead 30-lines G-code than the operating.All the features guarantees high preci-

sion,accuracy and reliability.And the size is very small,oepreation is very easy,very suitable for all size of

Engraving machines,Milling machines and cutting machines and so on.

1.1 Introduction of Product

1.2 Performance parameter of the NCH02

Page -1 NCH02 User’s ManualDigital Dream Motion Controller

The NCH02 motion controller contains the handheld motion controller,wiring board,and HDMI digital

high-definition transmission cable.

The handheld motion controller and wiring board are communicated by 2 Meter 37 pins HDMI digital

high-definition transmission cable which is shielding twisted-pair cable to avoid interference.

Picture 1-1 shows the appearance and size of NCH02 Pendant.

Picture 1-2 shows the appearance and size of NCH02 Wiring Board.

1.3 Appearance, Structure and Size of Product

NCH02 User’s ManualPage -2Digital Dream Motion Controller

Picture 1-2 The NCH02 wiring board Size

70 mm

23.5 mm

100 mm

Picture 1-1 NCH02 Pendant Size

108 mm

30 mm

168 mm

23 User’s Keys

3.5’’ (480*320 ) LCD

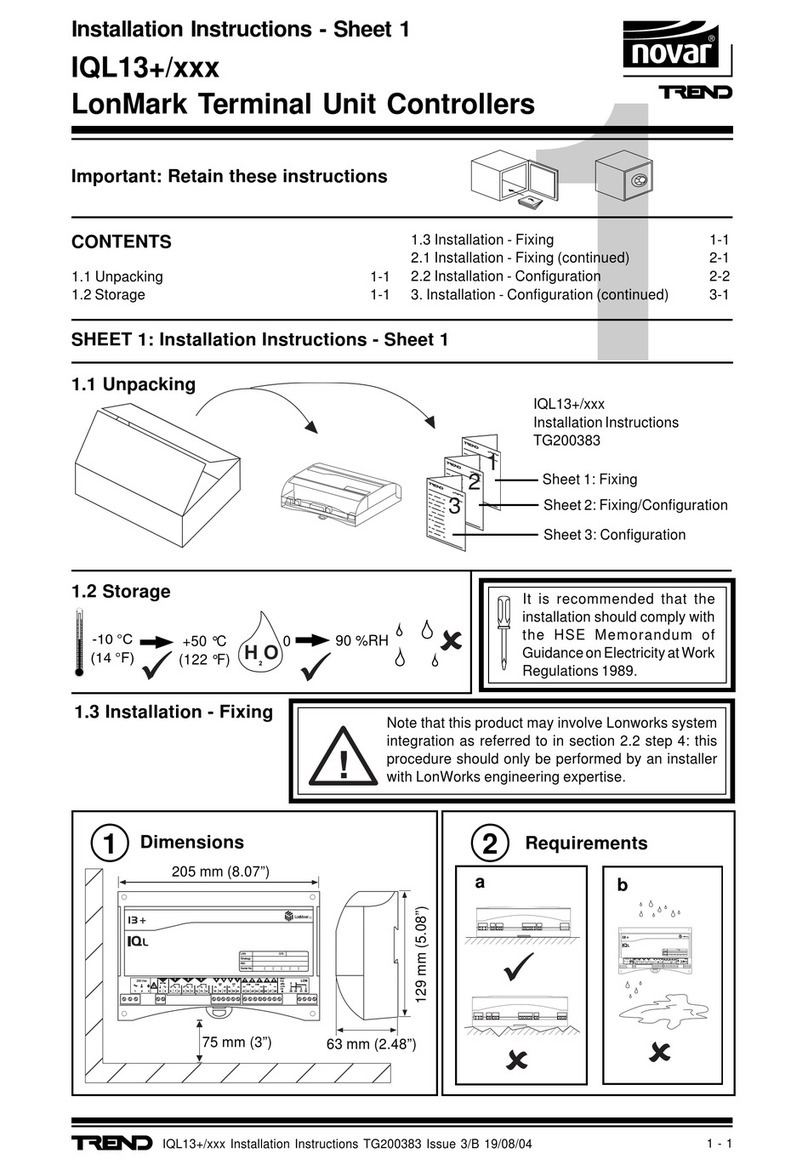

Picture 1-3 shows the Installation size of NCH02 Wiring Board.

Picture 1-4 shows the 2 side pictures of NCH Wiring Board.The one side is for the MPG interface;and the

other side is the LED indicators and USB port for the communication with the NCH02 Pendant Controller.

There are two LED indicatiors,the red one is for the power,the green one is for the communications with

the NCH Pendant controller.

NCH02 User’s ManualDigital Dream Motion Controller Page -3

Picture 1-3 The NCH02 wiring board Install Size

Picture 1-4 The NCH02 wiring board 2 Sides Picture

The LED Indicatior and USB Port for the pendant The MPG Port

65 mm

4 mm

65 mm

When operating the NCH02 Controller, the users will come across some English abbreviations. Here a list

with explanations:

FRO: Feed Rate Override

SRO: Spindle Rate Override

SRJ: Jog Speed Setting

F: Feed rate, unit is mm/min

S: Spindle Speed, unit rev/min.

X: The coordinate code of the X axis.

Y: The coordinate code of the Y axis.

Z: The coordinate code of the Z axis.

A: The coordinate code of the A axis

BUSY: The system is busy. You still can adjust FRO and SRO

READY: READY mode, any operation can be done

RESET: Reset mode, controller is in “OFF” mode, no operation can be performed

CONT: Continuous mode, each axis can be manually jogged with the arrow keys

Step :Manual Step Mode,each axis can be jogged in defined steps

MPG: MPG mode. Operate the machine with the MPG (Manual Pulse Generator)

AUTO: Run G code. Auto is showing when file is processing

Keep away from exposure to moisture or water. This product contains sophisticated electronics

and must not get wet.

Wiring warning: the IO input terminal of this controller supports equipment with source power (such as

Inductive Proximity Switch ). When using this kind of equipment, pay attention to the polarity. Avoid the

+terminal to be connect with GND. This controllers has analog output for spindle control (0-10V). Please avoid

this terminal to ever connect with GND as damage to the controller may occur.

Operation warning. Please observe all security measures when operating the machine. The ESTOP

must be connected and properly labelled. In case of a problem, press the E-stop at once to avoid

damage to humans, animals and the equipment.

High voltage danger. The NCH02 is connected to 24VDC. Obey and follow the electricity safety rules

of your country when connecting this equipment.

1.4 Explanation of Abbreviations

1.5 Notes and Warnings

NCH02 User’s ManualDigital Dream Motion Controller Page -4

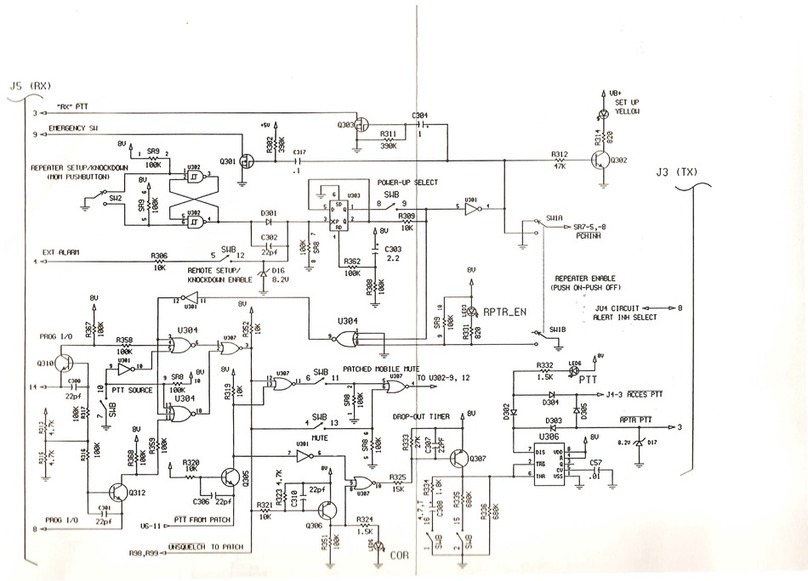

2 Wiring Board

NCH02 User’s ManualPage -5

The circuit switching wiring board provides screw terminals for power (24VDC), input signals, spindle

control, pulse and direction for X/Y/Z/A/B stepper/ servo drives, MPG, input and output ports as well as an USB

input. Please see the reference picture 2-1 in detail.

Input Ports Output Ports

Spindle Ports

X/Y/Z/A/B Stepper/

Servo Ports

MPG Ports

Power Supply

24VDC

USB Port

Picture 2-1 Wiring Board Rear view

Picture 2-2 Board Power Structure

As the picture shows, the wiring section of the controller has Stepper/Servo Ports,Spindle Control

Ports,MPG ports,Output and Input Ports,and Power supply Ports,as well as USB ports.

The Inside power solution in the field of the Industrial automation is always very complicated, there is a

lot of the GND, now we descript the structure of the power structure as below:

The power structure as the Picture 2-2,main power supply input ,MPG module and Power and USB port

share common GND, stepper control module and Input&Output module and Spindle control module share

common GND, between the two sector there is photoelectric isolation. Inside of the board, there is GND as

common-, no need to connect external power supply.

NCH02 User’s ManualDigital Dream Motion Controller Page -6

Picture 2-1 USB port

Picture 2-2 The Input Ports definition

As the following picture showed,by the USB terminal block is USB port, you can connect with handheld

controller.

As the Picture 2-1 showed, The power supply port.The Input voltage is 24VDC, and the power is not less

than 20W. The positive and negative connection of the power supply see as the silk printing.

2.1 USB Port

2.2 Main power supply port

2.3 The Input Ports

USB Port

GND

INP1

INP2

INP3

INP4

INP5

INP6

INP7

INP8

GND

12V

Picture 2-4 Probe/Estop/ ordinary fretting switch input connection

Picture 2-5 2 Lines Proximity Switch Connection Method

Picture 2-3 Internal structure diagram of the input port

NCH02 User’s ManualDigital Dream Motion Controller Page -7

As the Picture 2-2 showed,Inputs ports has already defined.The Users can use them as E-stop,Probe,limit-

ed/Home functions and so on.The ports is a common negative interface,which can be connected with a micro

switch,a 2 line proximity switch or a NPN type 3 line proximity switch.All the ports are isolated.And the

internal structure is as following Picture 2-3.

And the E-stop,Micro switch,2 line proximity switch connection methods refered to Picture 2-4.

NCH02 User’s ManualDigital Dream Motion Controller Page -8

3 lines Proximity Switch connection method as following Picture 2-6 shows. Brown cable connect with

12V,Black cable connect channel, blue cable connect with GND1.

3 lines proximity switch only NPN type is avaiable for the NCH02.

Picture 2-6 NPN 3 lines Proximity Switch connection drawing

Picture 2-7 NPN 3 lines Proximity Switch example

NCH02 User’s ManualDigital Dream Motion Controller Page -9

Picture 2-8 The Output Ports definition

Picture 2-9 General Output Port Connect with a Relay

As the Picture 2-8 shows,the interface is an open-ground interface,which can be absorbed not more than

50mA current.The relay with a absorption current of no more than 50mA can be driven directly. If it's more than

50mA, and it is recommended to use a current amplification, for example ULN2803 chip.

The Picture 2-9 is for external power relay method.

2.3 The Output Ports

OUP5

OUP4

OUP3

GND

NCH02 User’s ManualDigital Dream Motion Controller Page -10

Picture 2-9 The MPG Port

The MPG interface Pin order as following:

2.4 The MPG Ports

Pin No. Definition Notes

T1OUT TXD of Serial Port

VMPG

WHA+

WHB+

XIN

ZIN

X100IN

1

Power supply Positive Terminal (5V)2

MPG A phase differential input positive terminal

MPG B phase differential input positive terminal

MPG A phase differential input negative terminal

MPG B phase differential input negative terminal

X axis selection input

A axis selection input

Y axis selection input

Z axis selection input

100 Rate Selection Input

10 Rate Selection Input

EP ESTOP port

R1IN RXD of Serial Port

GND Ground and common end

3

4

5

6

7

8

9

10

WHA-11

WHB-12

YIN13

AIN14

X10IN15

NCH02 User’s ManualDigital Dream Motion Controller Page -11

Picture 2-10 The Spindle Control Port

Picture 2-11 The Spindle Control Port definition and wiring

The Picture 2-10 showed interface definition is VSO/GND/OT1/OT2. The VSO is the 0-10V analog

output, OT1/OT2 digital signal output, spindle control output interface and spindle inverter connection methods

as Picture 2-11. VSO/GND/OT1/OT2 are respectively connected with the inverter AIN1/COM/X1/X2, where

AIN1 is the input speed signal;COM is Comman Ground;X1 and X2 are configured to forward and reverse

revolution.

2.5 The Spindle Control Port

OT2

OT1

GND

VSO

NCH02 User’s ManualDigital Dream Motion Controller Page -12

The following Picture 2-12 shows the definition of Servo/Stepper Ports.There are 5 axis X/Y/Z/A/B,each

axis connection is common anode.Output signal voltage is 5V.

DIR is Direction Signal Output;

PUL is Pulse Signal Output.

2.6 The Servo/Stepper Port

X Axis/COM+

X Axis/PUL-

X Axis/DIR-

Y Axis/COM+

Y Axis/PUL-

Y Axis/DIR-

Z Axis/COM+

Z Axis/PUL-

Z Axis/DIR-

A Axis/COM+

A Axis/PUL-

A Axis/DIR-

B Axis/COM+

B Axis/PUL-

B Axis/DIR-

Picture 2-12 Definition of Servo/Step Ports

Picture 2-13 The wiring method with Stepper driver

3 Handheld Controller Keyboard Definition

NCH02 User’s ManualDigital Dream Motion Controller Page -13

1: Mode of Step/Continuous/MPG Selection

2: Data . Input

Spindle manual Start/Close

Page Left

Page Right

RESET

1: Cancel;

2: Exit

Shift,This key will activate 2nd Mode

Keys Icon Keys IconDefinition Definition

1: A axis rotates in forward direction;

2: A axis select;

3: Data 7 Input

1: B axis rotates in forward direction;

2: B axis select;

3: Data 8 Input

1: Z axis Up;

2: Z axis select;

3: Data 9 Input

1: Z axis Down;

2: Home;

3: Data 6 Input

1: A axis rotates in reserve direction;

2: 0-clearing;

3: Data 4 Input

1: B axis rotates in reserve direction;

2: Go To Zero funciton;

3: Data 5 Input

1: X axis moves left;

2: Probe;

3: Data 1 Input.

1: Y axis moves forward;

2: Y Axis Select

3: Data 2 Input

1: X axis moves right;

2: X Axis Select

3: Data 3 Input

1: Increase the number clockwise;

2: Decrease the number Counter-clockwise

3: Push the button to Confirm

1: Y axis move backward;

2: Data 0 Input

Start operation

Pause operation

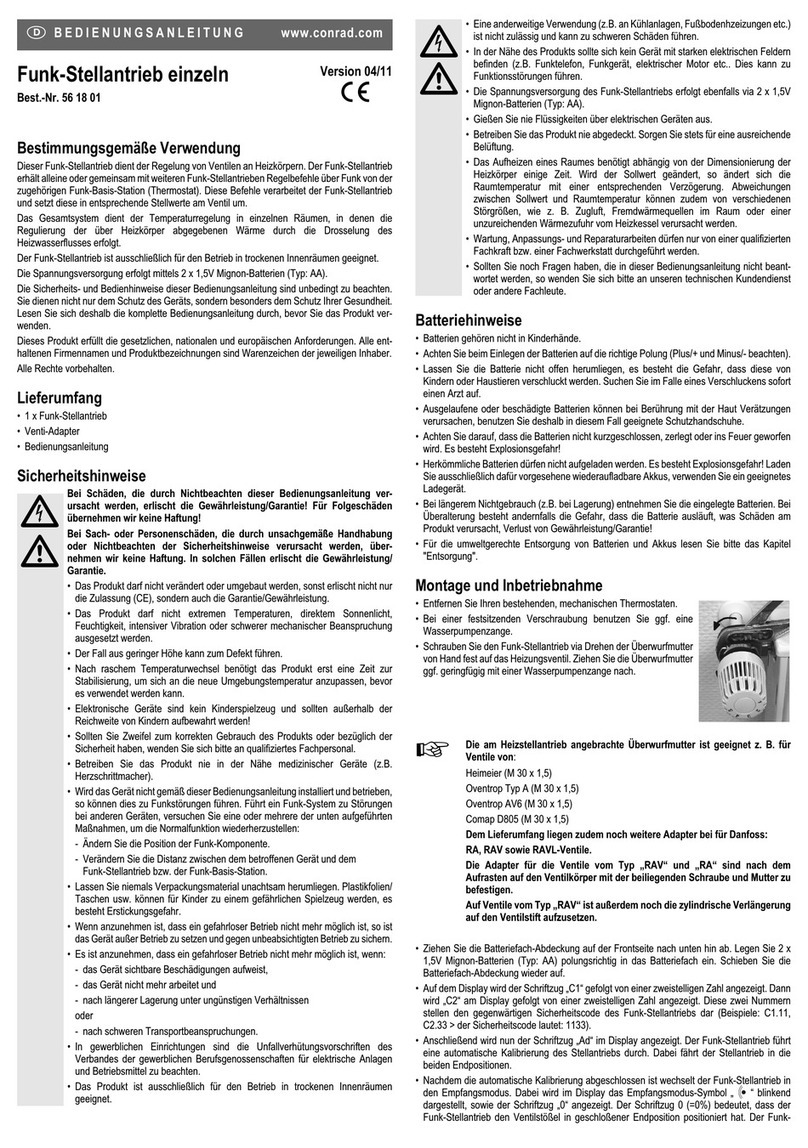

4. Motion Controller Software Description

NCH02 User’s ManualDigital Dream Motion Controller Page -14

Picture 4-1 Main Page of NCH02

4.1 Main Page Description

NCH02 Motion Controller software has 4 main parts:Main Page,File Management,Configuration Page,and

Test&Diagnosis Page.

We will describe them one by one as below.

The Picture 4-1 shows the Main Page of NCH02.It is divided into status column, coordinate display

column, basic parameter column, and notification column. In total, it is divided into 20 sections in detail. Here

the detailed description of the 20 sections :

The Picture 4-1 shows the main page in CONT mode,which is continuous mode.There are Continuous

mode,Step Mode and MPG mode for options by pressing the key to shift the 3 different mode.

By Pressing ,The controller status shift between READY and RESET status;

Only When in READY status,By Pressing , the controller will start to run a G-code,then the

status turn to “RUN”.And during the operation by handheld controllers of Jog operation,the status turns to

“JOG”MODE.

1. Feed status:Manually Position the machine at any position:

The Operation Status column displays the working status of the controller.There are 4 different status:

RESET/READY/JOG/RUN

2. Operation Status: It shows the working status of Controller :

NCH02 User’s ManualDigital Dream Motion Controller Page -15

Before the description from No.5,we’d like to explain the Rotary&Push Button.Pls note the Picture 4-2 as

above.By this button,it can decrease or increase the values by turnning the button,and push it to confirm.

When we need to edit a value,for example,FRO or SRO or SJR value and so on,firstly select it and push

the button,we can see the orignal values color is white and background is black,then we start to edit it by turning

the button,the values’ background color becomes to Blue.After we edited the value,and we push the button to

confirm it,the background turns to black color.Then Push the button again to exit the editting state.

This is the operation method for all the value editing.

There will be 4 Status at File Status:No file Loaded;U-Disk Detected;U-Disk Removed;G-code file name:

No File Loaded:When the controller cannot detect a U-disk and cannot load a file;

U-Disk Detected:When the U-disk is inserted and controller can detect the U-disk;

U-Disk Removed:When the U-disk is removed;

G-code file name:When the G-code file is selected and the controller is running the G-code file,it will

display the name of the G-code file.

3. File status:It shows the G-code file information and U-disk

4. Time display:This column shows the processing time of the G code operation.

Time keeping is halted during Pause.

5. FRO: FRO controls the Feed Speed.

The adjustment range is 0%~200%.By turnning the rotary button,adjust the value in 10% increments by

each click.

6. SRO:SRO controls the Spindle Speed.

The adjustment range is 0%~200%.By turnning the rotary button,adjust the value in 10% increments by

each click.The current spind speed #S=SRO*S(The fixed Spindle speed value)

7. SJR: SJR controls the jogging of the machine.

The adjustment range is 0%~100%.By turnning the rotary button,adjust the value in 10% increments by

each click.The Current Jog Speed #HF=SJR*HF(The fixed Jog Speed)

Picture 4-2 Rotary&Push Button On Handheld Controller of NCH02

- Rotary Button +

Push Button

NCH02 User’s ManualDigital Dream Motion Controller Page -16

8: Manual Jog Distance in Step Mode:

Each Axis can be jogged in defined distance.In Step Mode,you can define the increments by

0.01mm,0.1mm or 1mm.By turning the button,the values can be decrease or increase.

default Spindle Speed. The Default Spindle Speed can be changed, use the A- key to modify.

9: Feedrate:F stands for Feed Speed:

It is the minimum Feed speed value of the controller,can be adjust by Rotary button also.

If there is no F values in G-code file,the controller will run the file at the speed of Feedrate value,if there

is F value in G-code file,the controller just run as the G-code file.

10: Real time Feed Speed:

F Real-time Feed Speed Value shows the current feeding speed when running a G-code.

F Real-time Feed Speed Value=FRO*F(The Feed speed fixd by G-code or controller)

11: Speed of spindle:

It is the Default Spindle speed value of the controller,can be adjust by Rotary button also.

If there is no S values in G-code file,the controller will run the file at the speed of Feedrate value,if there

is S value in G-code file,the controller just run as the G-code file.

12: Real time Spindle Speed:

S Real-time Spindle Speed Value shows the current Spindle speed when running a G-code.

F Real-time Feed Speed Value=SRO*S(The Spindle speed fixd by G-code or controller).

13: M10/M11: Start/Stop of Lubrication

M10/M11 can adjust by rotaty button,or can run as the directive from G-code file.

14: M8/M9 : Start/Stop of Cooling

M8/M9 can adjust by rotaty button,or can run as the directive from G-code file.

15: M3/M4/M5: forward-rotating/Reverse-Rotating/Stop Spindle

M3/M4/M5 can adjust by rotaty button,or can run as the directive from G-code file.

16: Coordinate System

The Coordinate System Range is G54-G59,can adjust by rotaty button,or can run as the directive from

G-code file.

17: Controller System Status

There are 7 different kinds status of the controller.Here we explain them as below:

1

3

4

5

6

7

2

No. Display Definition

System Ready The Controller is Ready for Any Operation.

System Reset Controller is in Reset Status.

System is running The controller is running a G-code file

X(Y/Z)++ LIMITED

X(Y/Z)-- LIMITED

X(Y/Z)++ SOFT LIMITED

X(Y/Z)-- SOFT LIMITED Negative soft limit of X(Y/Z) is Triggered

Positive soft limit of X(Y/Z) is Triggered

Negative Limit of X(Y/Z) is Triggered

Positive Limit of X(Y/Z) is Triggered

NCH02 User’s ManualDigital Dream Motion Controller Page -17

4.2 The File Management Page

18: The G-code Line that the Controller is Running

In the column,it shows the current G-code Line No. and G-code content.To Shift the G-code line,the users

can can edit Line Value here.

19: The coordinate values of each axis under the current coordinate

The coordinate values of each axis under the current coordinate are displayed here.

20: The coordinate values of each axis under the mechanical coordinate

The coordinate values of each axis under the mechanical coordinate are displayed here.

When the U-disk is inserted in to the controller USB port,The File management page can be entered by

pressing under the main page. The file management page is shown in Picture 4-3 as below.

The displays will show all folders and files in the Root directory. The Name of folders and files, the size

of files and the time and date of manipulation. The blue strip indicates the current valid target location.

By turnning the rotary&push button to select the G-code file and press it to confirm the selection.Then

the controller system will load the selected file.After the loading is finished,the controller software will shift

to Main Page Automatically.

Picture 4-3 File management page

NCH02 User’s ManualDigital Dream Motion Controller Page -18

4.3 The CONFIG(Configuration) Page

As Picture 4-4 showed as above,the Motor Parameter configuration Page has a lot of column.There is a lot

of the paramenter need to set up,also by rotary&push button.We marked the column from 1-17 and will decribe

them one by one as following table.

Picture 4-4 Motor Parameter Configuration Page(MOTOR)

When in the File Management Page,press to enter into the CONFIG Page.And the CONFIG

Page has 4 Sub-Page:

Motor Configuration

Input configuration

Spindle/Output

Other

By Pressing we can shift between the 4 sub-pages.

4.3.1 Motor Parameter Configuration(Motor)

NCH02 User’s ManualDigital Dream Motion Controller Page -19

Picture 4-5 Input Parameter Configuration (INPUT)

4.3.2 Input parameter configuration (INPUT)

1

3

4

5

6

7

8

9

2

No. Mark Definition Range

Stepsper 100-20000

50-20000

50-5000

10-200

0-100%

1/0

1/0

1/0

0-10

The number of pulses required for each 1mm feeding

The Max. Speed for Manually operation or the G-code file running.The unit is mm/min.

The Max. Acceleration for manual operation or G-code file running.The unit is mm/min2.

Z Axis Safety Height.The Unit is mm.

Backlash Speed

Backlash Enable,1=Enabe,0=disable.

Backlash Length,The unit is mm.

The Pulse Signal ELectric Level.0=Low,1=High

The Direction Signal ELectric Level.0=Low,1=High

Velocity

Accel

Safe-Z

BL SEPPD

Step Level

Dir Level

BL Enable

BL Length

1

3

4

5

6

7

8

2

No. Mark Definition Range

Limit++

L++ Level

Limit--

L-- Level

Home

Home Level

Home Dir

HKB Length

0-8

1/0

0-8

0-8

1/0

1/0

1/0

0-100

The Hard Limit at forward direction Pin setting.0=close the limit;1=IN1,2=IN2...8=IN8.

The Hard Limit at backward direction Pin setting.0=close the limit;1=IN1,2=IN2...8=IN8.

Active Level of forward direction limit.0=disable,1=enable

Active Level of backward direction limit.0=disable,1=enable

Home Pin Setting.0=Disable;1=IN1,2=IN2...8=IN8.

Back off distance after Home,the unit is mm

HOME direction.0=Backward,1=forward.

The HOME Signal ELectric Level.0=Low,1=High

The Picture 4-5 showed above it is the Input Parameter configuration page.At the chart below we explain

each column setting.By turning the rotary&push button,the user can select and edit the values and confirm.

Table of contents

Other Digital Dream Controllers manuals

Digital Dream

Digital Dream DDCS V2.1 User manual

Digital Dream

Digital Dream DDCS-Expert User manual

Digital Dream

Digital Dream DDCS V3.1 User manual

Digital Dream

Digital Dream EC500 User manual

Digital Dream

Digital Dream UC300 User manual

Digital Dream

Digital Dream DM500 User manual

Digital Dream

Digital Dream DM500T3 User manual