Digitrax DN166I1C User manual

© 2014 Digitrax, Inc. www.digitrax.com— 1 —

Features:

▪FX3Function outputs for prototypical lighting eects and on/o control:

Constant Brightness Lighting with directional or independent control.

Optimized selectable LED or incandescent lamp operation

Realistic Eects like Ditch lights, Mars lights, strobes, and many more

Congurable Pulse Function available on all function outputs.

FX3 & Standard Function Qualiers operate functions based on direc-

tion, F0 on or o, direction and F0, and whether loco is moving.

Function Mapping for custom function setup.

Master Light Switch turns o all lights & functions with one keystroke.

Advanced Consist Function Controls.

▪Digitrax LocoMotion®System-Your locomotives look like the real thing.

The Digitrax LocoMotion System makes them run like the real thing, too!

Scaleable Speed Stabilization (Back EMF) with simple setup & 256

level resolution.

Torque Compensation.

128 Speed Step operation (14 or 28 steps can also be used).

Momentum with acceleration and deceleration.

Normal Direction of Travel is user selectable.

Switching Speed feature for easier and faster access to yard speeds.

3 Step Speed Tables set start, mid and max voltage for custom control.

28 Step Speed Tables with 256 level resolution for precise control.

▪Program CVs using any Digitrax Compatible Control system without having

to buy any extra equipment.

▪2 Digit and 4 Digit Addressing.

▪Basic, Advanced & UniVersal Consisting.

▪SuperSonic motor drive for silent operation.

▪Direct mode programming.

▪Decoder Reset CV with or without speed table reset.

▪Transponder Equipped ready for transponding on your Layout.

▪Motor Isolation Protection helps prevent damage to your decoder.

▪Automatic Analog Mode Conversion when running on DC layout.

▪Decoder Lock for individual programming of multiple decoders in one loco.

▪Digitrax “No Worries” Warranty.

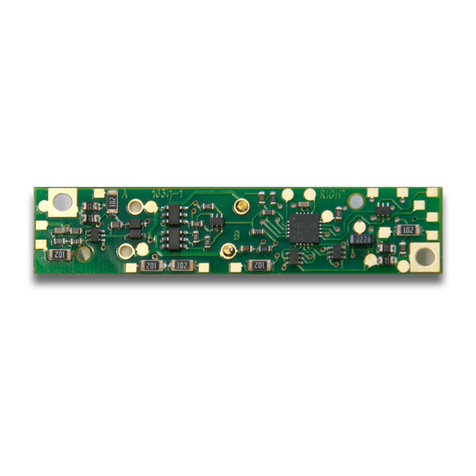

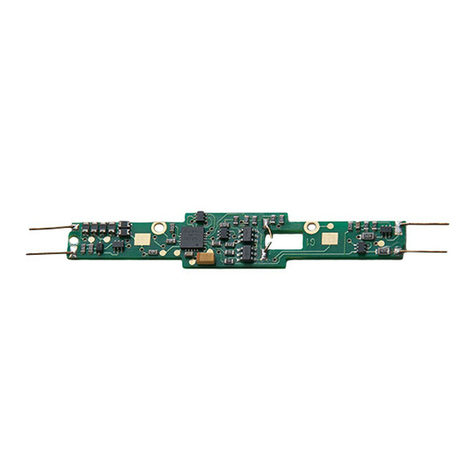

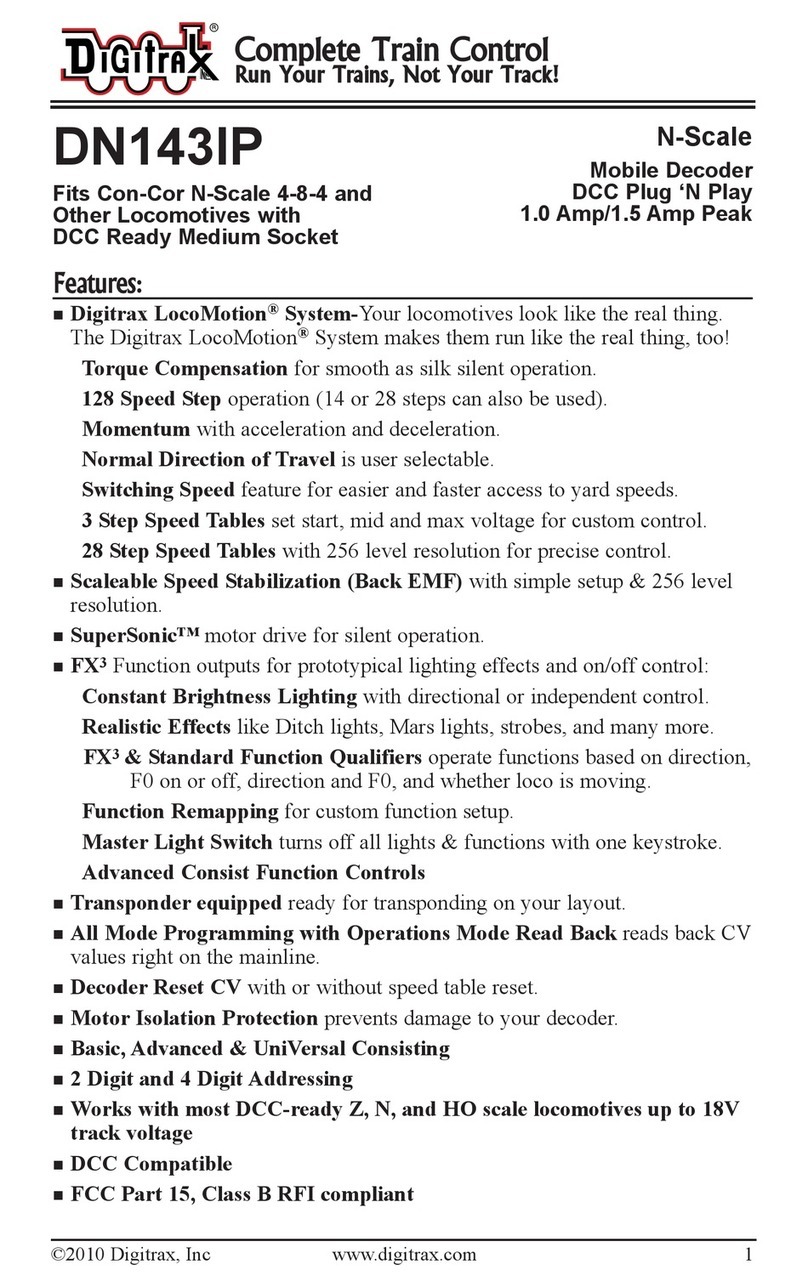

DN166I1C

Fits InterMountain N Scale F3 and F7

A & B units

.472” x 2.165” x .098”

11.98mm x 54.99mm x 2.4mm

N Scale

Mobile Decoder

Board Replacement

1.5 Amp/2.0 Amps Peak

6 FX3 Functions, 0.5 Amp

Complete Train Control

Run Your Trains, Not Your Track!

© 2014 Digitrax, Inc. www.digitrax.com— 2 —

Parts List

1 DN166I1C Mobile Decoder 1 Instruction Sheet

Installation Information

See the Digitrax Decoder Manual for complete decoder test procedures, instal-

lation instructions, programming and technical information. Digitrax manuals

and instructions are updated periodically. Please visit www.digitrax.com for the

latest versions, technical updates and additional locomotive-specic installation

instructions. CAUTION: Programming and layout track must not exceed

16V when using this decoder.

Installation Instructions

1. Carefully remove the locomotive’s

shell from the frame by inserting

two toothpicks under the unit’s

ladders as shown.

2. Once you’ve positioned the tooth-

picks, grasp the frame and tooth-

picks with one hand and the loco-

motive’s shell with the other hand

and carefully separate the two.

3. Once the shell is o, remove the

existing light board by removing the

two screws located on the diagonal

corners of the board. The nal step

in removing the light board is to

carefully unsolder the two wires

leading from the headlight assem-

bly.

4. Take the new DN166I1C decoder

and place it on top of the frame.

Note proper orientation. The decod-

er’s brass motor contacts should t

in the frame slot as shown.

5. Solder headlight leads to the new

decoder board as shown If you were

sitting in the cab, the yellow lead

would be on your left and the green

lead would be on your right. The

nal step is to secure the decoder

with the original screws. Note: the locomotive’s frame halves may have to be

loosened slightly to achieve proper alignment.

Figure 1: Insert

toothpicks as

shown

Tooth-

picks

inserted

under

center of

body

Figure 3: Unscrew, unsolder

and remove standard lightboard

Figure 2:

Remove shell

from frame.

Board shown

partially

removed.

© 2014 Digitrax, Inc. www.digitrax.com— 3 —

CAUTION: When

attaching head-

light wires, be very

careful that the

wires you attach

do not come into

contact with any

other pads or

components on

the board where

they might create

a short circuit.

Installation

Notes

1. Do not exceed

the decoder’s

500mA total

function output

rating.

2. We recommend that the Blue wire, also called +Common or Lamp Common,

be connected as shown. If you wish to omit the Blue wire in your installation,

consult the Digitrax Decoder Manual for more information.

3. The head lamp should be hooked up using the Blue/+Common wire for opti-

mal Digitrax transponding operation.

4. To use a function output with an inductive (coil) type load, see the Digitrax

Decoder Manual for more information to avoid damage to the decoder.

5. See the Digitrax Decoder Manual for full details of wiring 12-16V lamps, 1.5V

lamps, and LEDs. Lamps that draw more than 80 mA when running require

a 22 ohm 1/4 watt resistor in series with the directional light function lead to

protect the decoder.

6. Some locomotives employ lter capacitors for RFI suppression in the loco-

motive wiring. These may cause problems with Supersonic decoders and

non-decoder analog operation on DCC. This capacitor should be removed for

safe operation.

Customizing Your Decoder

Your Digitrax decoder is ready to run and will operate using address 03 with no

additional programming. For a more prototypical railroading experience, your

decoder can be customized for your specic locomotive by programming some of

the Conguration Variables, or CVs, available. See the Digitrax Decoder Manual

or the Digitrax web site for more information.

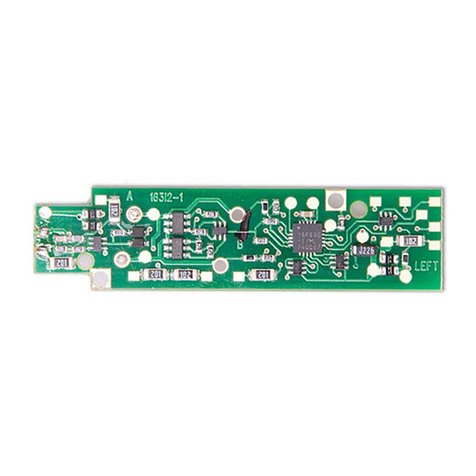

Figure 4: Solder headlight wires, secure new decoder with

original screws

Yellow Wire

Green Wire

© 2014 Digitrax, Inc. www.digitrax.com— 4 —

Changing the Decoder Address

The rst CV most people change is the decoder address. This allows you to inde-

pendently control each loco with a unique address. Digitrax decoders are shipped

with CV01 (AD2), the two digit address, set to 03. Following is a brief description

of how to change the decoder address with a Digitrax DT4XX series throttle. See

your Starter Set Manual for complete programming instructions.

1. Place the loco on the programming track not to exceed 16V. Go into

Program Mode on your system. On DT4XX throttle press PROG.

2. Choose AD2 for 2 digit addressing or AD4 for 4 digit addressing.

3. Choose the address you want to set up for the decoder.

4. Complete address programming by pressing ENTER.

Note: CV29 must also be programmed to enable 4 digit addressing, this is done

automatically by the DT4XX throttles. See your Digitrax Decoder Manual or the

Digitrax Toolbox App for how to set up CV29.

Digitrax LocoMotion®System

Your locomotives look like the real thing, now you can make them run like the

real thing, too. Digitrax decoders incorporate torque compensation for smooth

as silk operation. You can also program CVs that control momentum, 3 step and

128 step speed tables, switching speed, normal direction of travel, scalable speed

stabilization and more to take full advantage of the Digitrax LocoMotion System.

Momentum-CV03 & CV04

Momentum is part of the LocoMotion System. Acceleration is controlled by CV03

and deceleration by CV04. Both come from the factory set to 000. A range of 000

to 031 is available for both accel and decel. Try CV03:003 and CV04:000 as a

starting point for experimenting with momentum.

Speed Tables-How the Loco Responds to the Throttle

With Digitrax LocoMotion, there are two types of speed tables: 3 Step Tables and

High Resolution 28 Step Tables. Please see your Decoder Manual for a discussion

of the 28 Step Tables. The 3 Step Tables are set up by programming 3 CVs: Start

Voltage (CV02), Mid point Voltage (CV06) and Max Voltage (CV05). These values

are set at 000 at the factory. All have a range of values from 000 to 255. We rec-

ommend the following CV values as a starting point for experimenting with speed

tables.

© 2014 Digitrax, Inc. www.digitrax.com— 5 —

Loco Type V Start

CV02

V Mid

CV06

V Max

CV05

Switcher

Concentrated low speed. Limited top

speed

002 038 064

Road Switcher

Prototypical top speed w/evenly

distributed curve from 0 to top speed

002 048 098

Mainline Loco

Quick increase to cruising speed then

levels o to prototypical top speed.

002 128 154

Other LocoMotion®Features: Switching Speed, Normal

Direction of Travel & Scalable Speed Stabilization

(Back EMF) Features

Switching speed is controlled by CV54. The factory setting is 000 for OFF. To

turn on the switching speed feature, program CV54 to a value of 001. When this

feature is on, use F6 to activate and deactivate switching speed. With the feature

on the throttle’s target speed is eectively reduced by about 50% and the eects

of accel and decel programmed into the decoder are reduced by 1/4. This is useful

for yard switching operations.

Normal Direction of Travel is controlled by CV29. See your decoder manual

or the Digitrax Toolbox App for additional information on the settings for CV29.

The intensity, or droop, of Scaleable Speed Stabilization (Back EMF) is

controlled by CV57. The factory setting for this feature is 006 which is suitable for

most locos. You can adjust this value in the range of 000 for OFF to 015 for the

maximum eect. Consult your Digitrax Decoder Manual for info about CVs 55 &

56 and their eects on scaleable speed stabilization.

SuperSonic Silent Operation and Torque Compensation

The factory settings in the decoder provide silent, smooth operation of your loco-

motive under most conditions. For more information about these settings, please

see the Digitrax Decoder Manual or our website.

© 2014 Digitrax, Inc. www.digitrax.com— 6 —

Function Outputs on the DN166I1C

The DN166I1C is set up at the factory to control six functions. The unit has two

sets of outputs for directional lighting. Pads F0F/F0F+ are for the front light and

F0R/F0R+ for the rear light. Functions F1 , F2 , F3 and F4 can be used by sol-

dering a wire from the pad for the function you wish to use to the lamp (or other

function) you wish to control.

1. Forward or Reverse direction of travel, or

2. Whether F0 is on or o, or

3. Both direction of travel and whether F0 is on or o, or

4. Whether the locomotive is stopped or moving.

Function Remapping

Function remapping allows you to program the function outputs of your decoder

to be controlled by selected function keys on your throttle. Please consult the

Digitrax Decoder Manual or website for information on function remapping.

F2+ F1 F2 F4

F3

F0R+

F0R

F0F

F0F+

F4+ F1+ F3+

© 2014 Digitrax, Inc. www.digitrax.com— 7 —

Digitrax Transponding CV61

Digitrax Transponding is controlled by CV61. The initial factory set value is 000

for OFF. To turn on transponding, program CV61 to a value of 002. This al-

lows you to use Digitrax transponding to keep track of your rolling stock. When

transponding is enabled, the front light of the locomotive will icker slightly to

indicate transponding signal is being communicated. For optimal transponding

operation, we recommend that you hook up the forward and rear lights as shown

above.

Decoder Reset CV08

Decoder reset lets you reset all CV values to the initial factory settings. To reset all

CV values, program CV08 to a value of 008. You also have the option of resetting

all the CV values except the 28 speed step tables. To do this program CV08 to a

value of 009.

Warranty & Repair

Digitrax gives a one year “No Worries” Warranty against manufacturing defects

and accidental customer damage on all Digitrax command stations, boosters,

throttles, decoders, power supplies and layout control devices.

That’s it! A simple, straightforward warranty with no tricky language!

Visit www.digitrax.com for complete warranty details and instructions for

returning items for repair.

Please return warranty items directly to Digitrax - DO NOT return items

to place of purchase.

Available

Computer Interface

Decoder Programmer

Sound Programmer

TM

E

MPIRE

B

UILDER

Super

TM

0 0 0 0

2443 Transmitter Road

Panama City, FL 32404

www.digitrax.com

Contact: www.digitrax.com/contact

Support: [email protected]

Repair: [email protected]

DN166I1C

Fits InterMountain N Scale F3 and F7 A & B units

Made in the USA

TM

Part 15, Class B

RFI Compliant

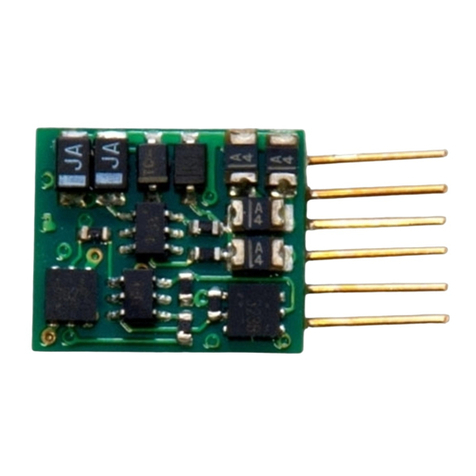

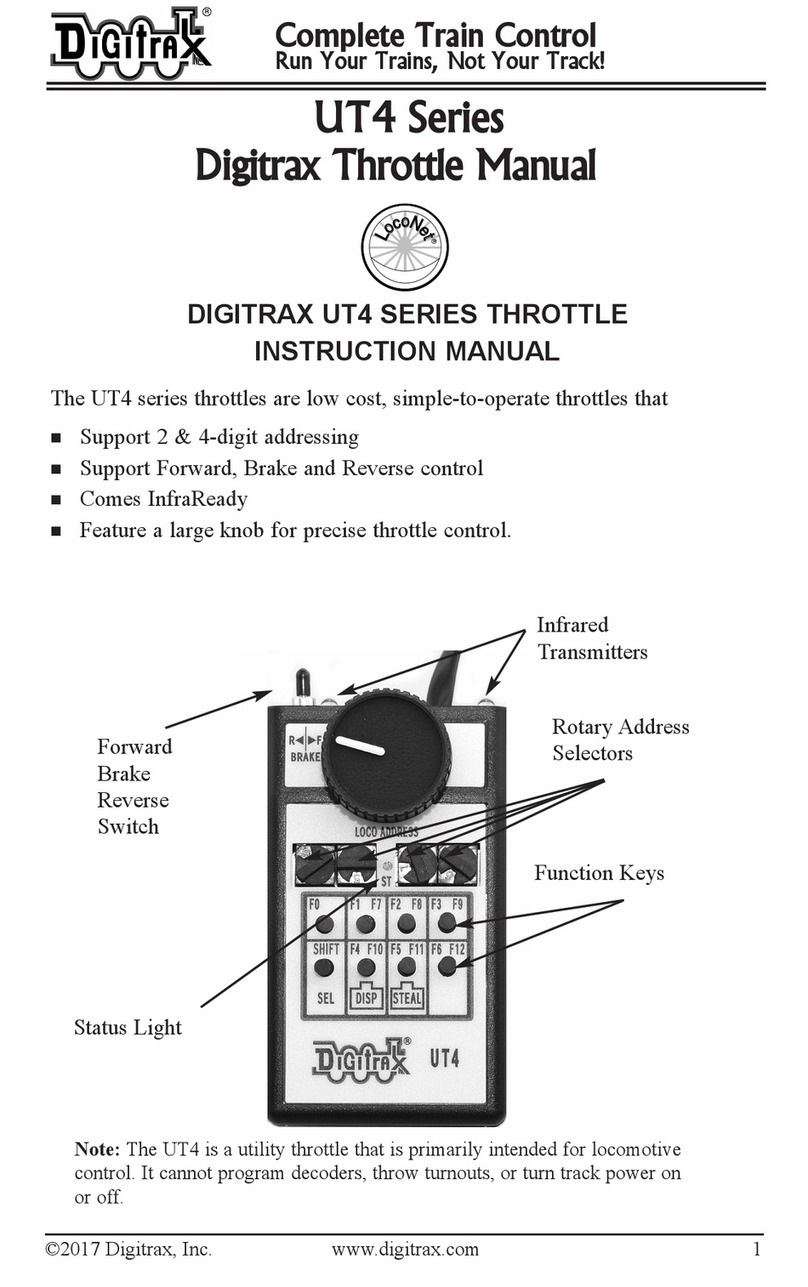

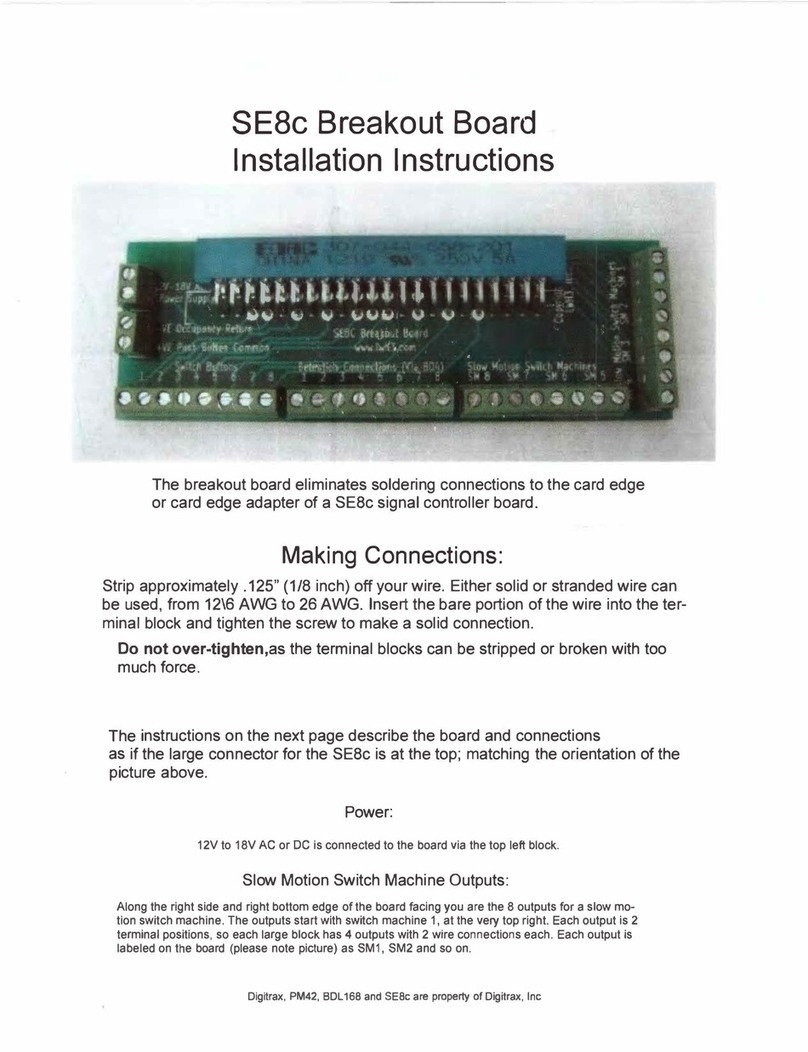

Table of contents

Other Digitrax Controllers manuals

Digitrax

Digitrax DZ123MK0 User manual

Digitrax

Digitrax DN166I2 User manual

Digitrax

Digitrax DN143IP User manual

Digitrax

Digitrax DZ126IN User manual

Digitrax

Digitrax DN166PS User manual

Digitrax

Digitrax UT4 Series User manual

Digitrax

Digitrax UT6 Series User manual

Digitrax

Digitrax SE8C User manual

Digitrax

Digitrax SDH164K1C User manual

Digitrax

Digitrax DH126MT User manual