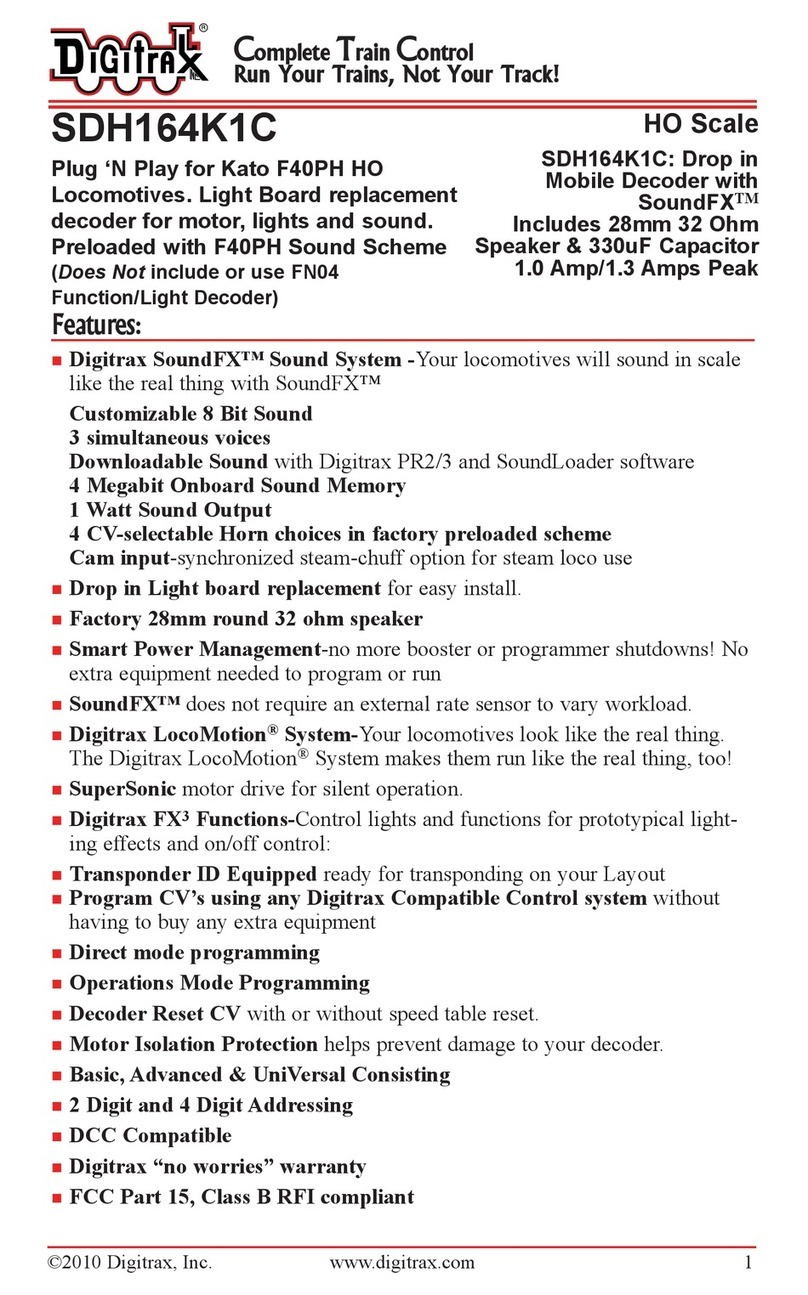

Digitrax DZ123MK0 User manual

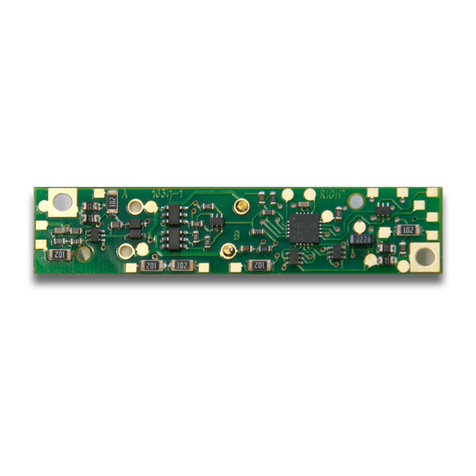

D 123MK0

Fits Marklin Mini Club 88455

*&896*7

nDigitrax LocoMotion®System-Your locomotives look like the real thing.

The Digitrax Loco otion System makes them run like the real thing, too!

Torque Compensation for smooth as silk silent operation.

128 Speed Step operation (14 or 28 steps can also be used).

Momentum with acceleration and deceleration.

Normal Direction of Travel is user selectable.

Switching Speed feature for easier and faster access to yard speeds.

3 Step Speed Tables set start, mid and max voltage for custom control.

28 Step Speed Tables with 256 level resolution for precise control.

nScaleable Speed Stabilization (Back EMF) with simple setup & 256 level

resolution.

nSuperSonic motor drive for silent operation.

nFX3Functions for prototypical lighting effects:

Constant Brightness Lighting with directional or independent control.

Dynamic and Static Qualifiers operate functions based on direction,

F0 on or off, loco direction and F0, and whether loco is moving.

Function Remapping of 14 functions for custom function setup.

Master Light Switch turns off all lights & functions with one keystroke.

Advanced Consist Function Controls

nTransponder equipped ready for transponding on your layout.

nAll Mode Programming with Operations Mode Read Back-read back CV

values right on the mainline.

nDecoder Factory C Reset with or without speed table initialize.

nMotor Isolation Protection prevents damage to your loco and decoder.

nBasic, Advanced & Uni ersal Consisting

n2 Digit and 4 Digit Addressing

nDCC Compatible

©2012 Digitrax, Inc www.digitrax.com 1

3140*8*!6&.2328630

92%396!6&.2738%396!6&(/

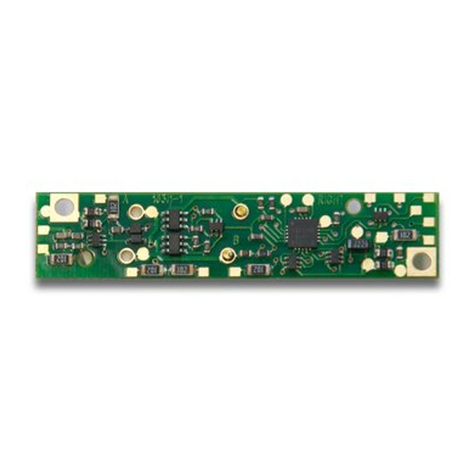

Scale

Mobile Decoder

DCC Board Replacement

1 Amp/1.25 Amp Peak

2 FX3Functions, 0.5 Amp

©2012 Digitrax, Inc www.digitrax.com 2

&687.78

1 DZ123 K0 Decoder 1 Instruction sheet

278&00&8.322+361&8.32

For ost Z Scale layouts, Digitrax recommends using 8V DC or less for opera-

tion to avoid damage to locomotive motors & shells. See the Digitrax Decoder

anual for complete decoder test procedures, installation instructions, pro-

gramming and technical information. Digitrax manuals and instructions are

updated periodically. Please visit www.digitrax.com for the latest versions,

technical updates and additional locomotive-specific installation instructions.

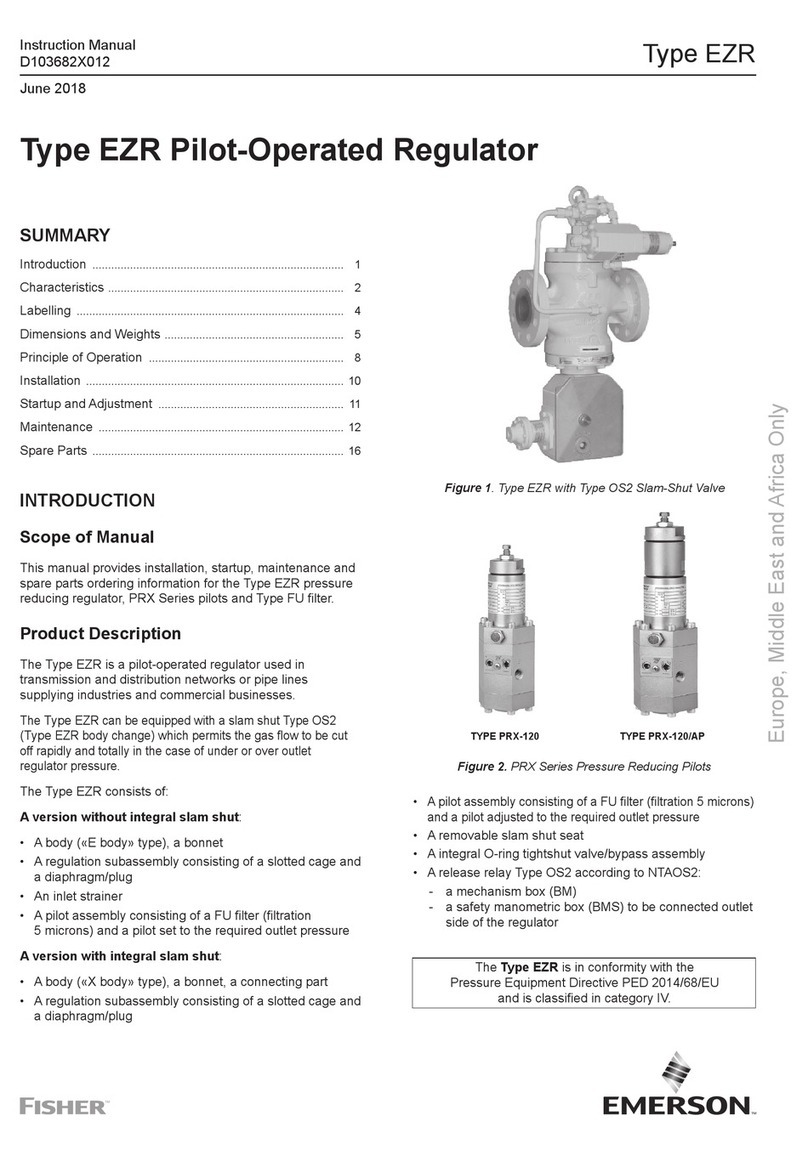

278&00&8.3227869(8.327&6/0.2.2.09'

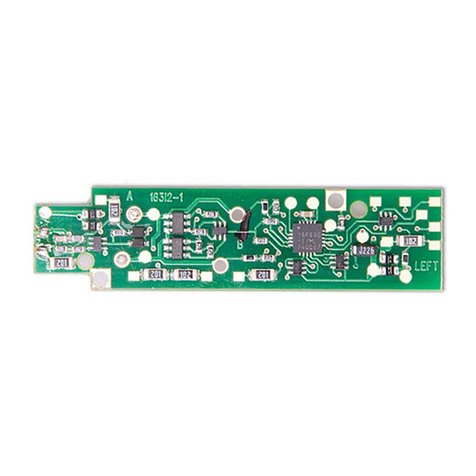

1. Carefully remove the locomo-

tive’s shell from the frame by

prying the edges of the shell

away from the frame and

allowing it to slide free.

Notice the orientation of the

shell for reinstallation later.

Figure 1.

2. Remove the two screws hold-

ing the factory light board in

place and remove the light

board. Be sure to save the

screws for reinstallation of the

DZ123 K0. Figure 2.

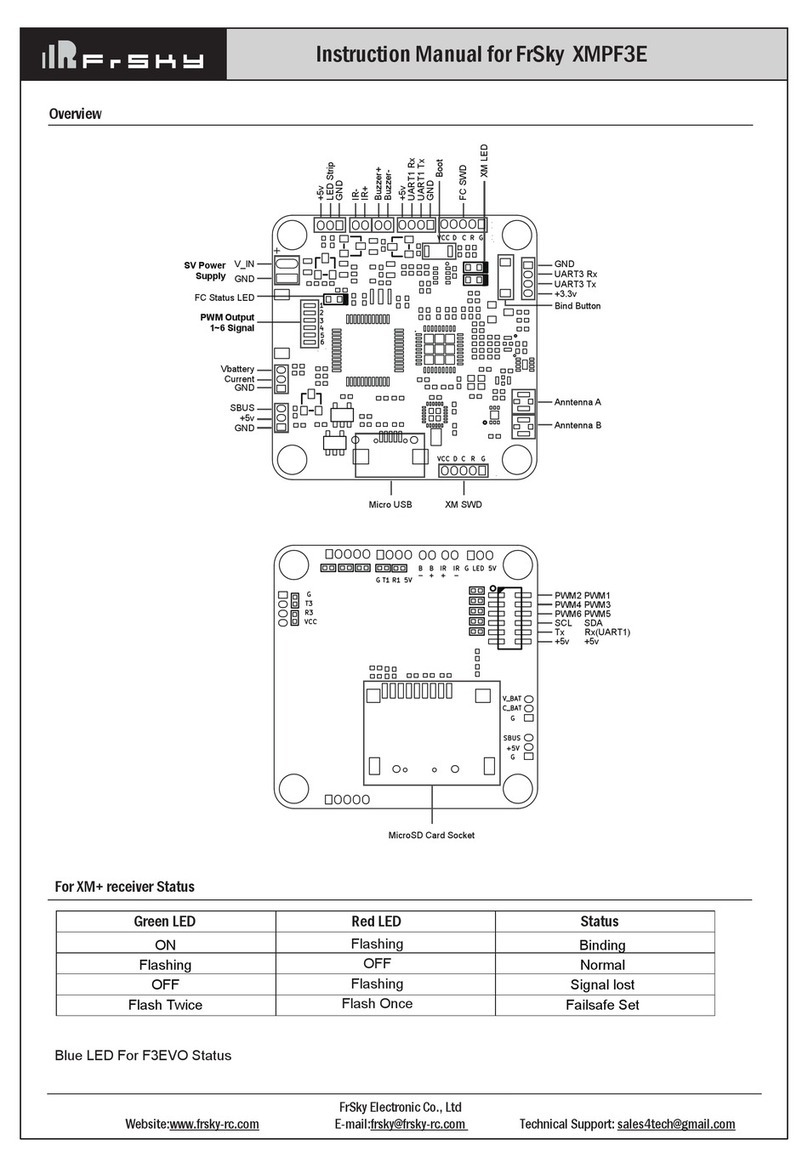

3. Prepare the DZ123 K0 for

installation by using a pair of

needle nose pliers to bend the

motor contacts and light pick-

ups into the proper shape. The

motor contacts should be bent

downwards at a 30 or 45

degree angle through the open

space in the board. The light

pickups should be bent accord-

ing to the bend guide at right,

Figure 3. It may be helpful to

compare the bends to those on

the factory light board and

attempt to match the shape.

Be gentle with bending the

leads to avoid any breakage.

3140*8*!6&.2328630

92%396!6&.2738%396!6&(/

Figure 1:

Remove loco shell

Figure 2: Remove the two screws holding the

factor light board in place.

Figure 3

Actual size

Bend

Guide

©2012 Digitrax, Inc www.digitrax.com 3

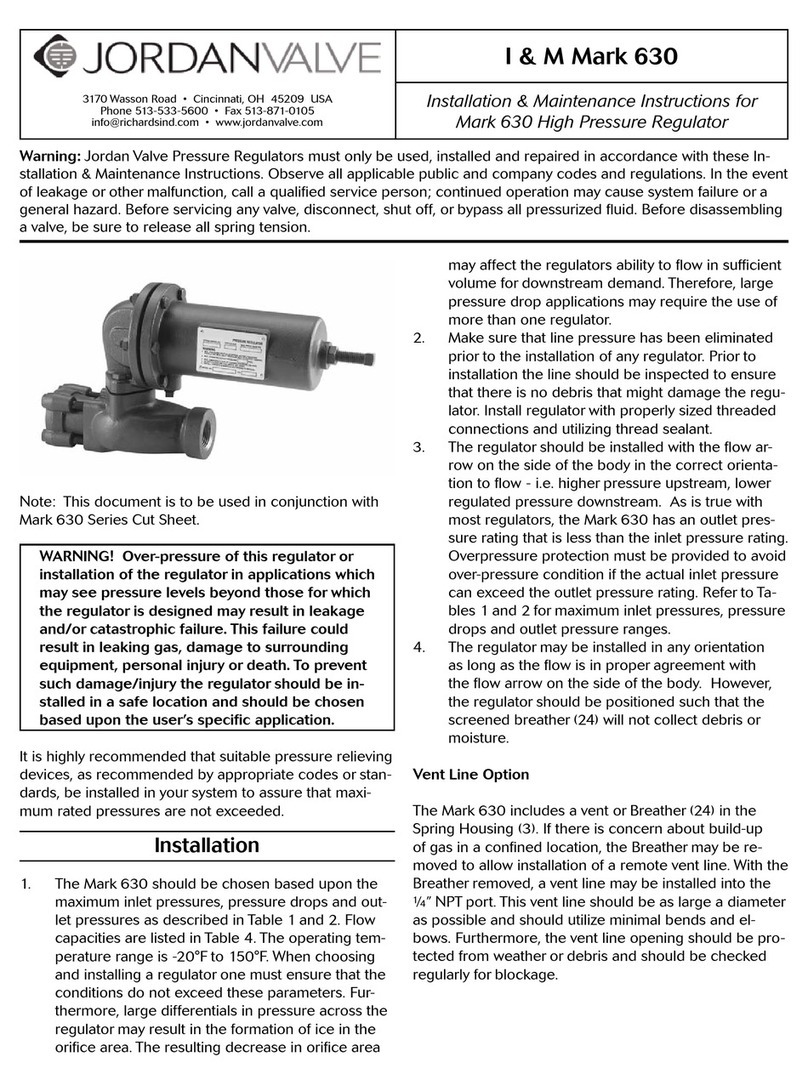

4. Install the DZ123 K0 such

that the square open space in

the center of the board and

motor pickups are positioned

over the resistor. Reinstall the

two screws removed in step

two, insert them through the

DZ123 K0 and tighten them

to the frame. The motor pick-

ups must make contact with

each side of the resistor leads.

This may require additional

bending of the pickup leads to

achieve. If possible, it is rec-

ommended to check for conti-

nuity between the resistor

leads and the motor pickup

using a quality multimeter.

Figure 4.

5. Reinstall the shell, making

sure it is in the proper orienta-

tion. The catenary selector

hole should be oriented over

the top of the DZ123 K0’s

CPU. The first fit will be tight

as the light pickup leads are

further bent into place.

Figure 5.

6. Place the loco on the track and select the default address “03”. Ensure that

the motor runs and that the lights function. If the motor or lights do not

work remove the shell and adjust the pickup wires so that they are making

proper contact.

97831.>.2,%396*(3)*6

Your Digitrax decoder is ready to run and will operate using address 03 with no

additional programming. For a more prototypical railroading experience, your

decoder can be customized for your specific locomotive by programming some

of the Configuration Variables, or CVs, available. See the Digitrax Decoder

anual or the Digitrax web site for more information.

!6&271.88*6) "!8*(-7944368).,.86&<(31

&2&1&.8=" 6*4&.6).,.86&<(31

;;;).,.86&<(31

Figure 4

Figure 5: Reinstall the shell.

©2012 Digitrax, Inc www.digitrax.com 4

-&2,.2,8-**(3)*6))6*77

The first CV most people change is the decoder address. This allows you to

independently control each loco with a unique address. Digitrax decoders are

shipped with CV01 (AD2), the two digit address, set to 03. Following is a brief

description of how to change the decoder address with a Digitrax DT series

throttle. See your Starter Set anual for complete programming instructions.

1. Place the loco on the programming track. Go into Program ode on your system.

On DT400/DT402 press PROG. On DT300, DT100 & DT200 press RUN/STOP &

FN/F0.

2. Choose AD2 for 2 digit addressing or AD4 for 4 digit addressing (DT400/DT402

and DT300). (Ad for DT100 & DT200, see set manual for 4 digit instructions).

3. Choose the address you want to set up for the decoder.

4. Complete address programming. On DT400/DT402 press ENTER. On DT300,

DT100 & DT200 press SEL.

Note: CV29 must also be programmed to enable 4 digit addressing, this is

done automatically by the DT400/DT402 & DT300 but not on earlier throttles.

.,.86&<3(338.32? =78*1

Your locomotives look like the real thing, now you can make them run like the

real thing, too. Digitrax decoders incorporate torque compensation for smooth

as silk operation. You can also program CVs that control momentum, 3 step

and 128 step speed tables, switching speed, normal direction of travel,

scaleable speed stabilization and more to take full advantage of the Digitrax

Loco otion®System.

31*2891##

omentum is part of the Loco otion®System. Acceleration is controlled by

CV03 and deceleration by CV04. Both come from the factory set to 000. A

range of 000 to 031 is available for both accel and decel. Try CV03:003 and

CV04:000 as a starting point for experimenting with momentum.

3140*8*!6&.2328630

92%396!6&.2738%396!6&(/

©2012 Digitrax, Inc www.digitrax.com 5

4**)!&'0*73;8-*3(3*7432)7838-*!-63880*

With Digitrax Loco otion®, there are two types of speed tables: 3 Step Tables

and High Resolution 28 Step Tables. Please see your Decoder anual for a

discussion of the 28 Step Tables. The 3 Step Tables are set up by programming 3

CVs: Start Voltage (CV02), id point Voltage (CV06) and ax Voltage

(CV05). These values are set at 000 at the factory. All have a range of values

from 000 to 255. We recommend the following CV values as a starting point for

experimenting with speed tables.

8-*63(338.32

®

*&896*7 ;.8(-.2, 4**)361&0.6*(8.323+

!6&:*0 (&0*&'0* 4**) 8&'.0.>&8.32&(/*&896*7

Switching speed is controlled by CV54. The factory setting is 000 for OFF. To

turn on the switching speed feature, program CV54 to a value of 001. When

this feature is on, use F6 to activate and deactivate switching speed. With the

feature on the throttle’s target speed is effectively reduced by about 50% and

the effects of accel and decel programmed into the decoder are reduced by 1/4.

This is useful for yard switching operations.

Normal Direction of Travel is controlled by CV29. See your decoder manual

for additional information on the settings for CV29.

Loco Type V Start V Mid V Max

CV02 CV06 CV05

Switcher

Concentrated low speed. Limited top 002 038 064

speed

Road Switcher

Prototypical top speed w/evenly 002 048 098

distributed curve from 0 to top speed

Mainline Loco

Quick increase to cruising speed then 002 128 154

levels off to prototypical top speed.

!6&271.88*6) "!8*(-7944368).,.86&<(31

&2&1&.8=" 6*4&.6).,.86&<(31

;;;).,.86&<(31

©2012 Digitrax, Inc www.digitrax.com 6

94*6 32.( .0*284*6&8.32&2)!3659*314*27&8.32

The factory settings in the decoder provide silent, smooth operation of your

locomotive under most conditions. For more information about these settings,

please see the Digitrax Decoder anual or our website.

.,.86&<!6&27432).2,#

Digitrax Transponding is controlled by CV61. The initial factory set value is

000 for OFF. To turn on transponding, program CV61 to a value of 002. This

allows you to use Digitrax transponding to keep track of your rolling stock.

When transponding is enabled, the front light of the locomotive will flicker

slightly to indicate transponding signal is being communicated.

*(3)*6*7*8#

Decoder reset lets you reset all CV values to the initial factory settings. To

reset all CV values, program CV08 to a value of 008. You also have the option

of resetting all values except the 28 speed step tables. To do this,

program CV08 to a value of 009.

&78*6.,-8 ;.8(-

Each of the six function outputs can be programmed to turn on and off with the

F0 ON/OFF key on your throttle, creating a aster Light Switch. The CV

values for creating this effect are listed in the Digitrax Decoder anual in the

section: Setting up FX & FX3Effects On Function Outputs.

92(8.32*1&44.2,

Function remapping allows you to program the function outputs of your

decoder to be controlled by selected function keys on your throttle. Please

consult the Digitrax Decoder anual or website for information on function

remapping.

$&66&28=*4&.6

Digitrax gives a one year “No Worries" Warranty against manufacturing defects and

accidental customer damage on all Digitrax products.

That's it! A simple, straightforward warranty with no tricky language!

Visit www.digitrax.com for complete warranty details and instructions for returning

items for repair.

Damaged decoders should be returned directly to Digitrax for repair.

3140*8*!6&.2328630

92%396!6&.2738%396!6&(/

©2012 Digitrax, Inc www.digitrax.com 7

Caution: To prevent damage to your decoder and locomotive, track voltage

used during operation must not exceed the operating parameters of the

locomotive and its lighting system in which the decoder is installed (typi-

cally this is 12 DC). For most N scale layouts, Digitrax recommends using

14 volts DC or less for operation to avoid damage to the locomotive shell,

lamps and decoder. For Most Z Scale layouts, Digitrax recommends using

8 DC or less for operation to avoid damage to locomotive motors &

shells.

Digitrax, Inc. is not responsible for unintentional

errors or omissions in this document.

!6&271.88*6) "!8*(-7944368).,.86&<(31

&2&1&.8=" 6*4&.6).,.86&<(31

;;;).,.86&<(31

Made in U.S.A.

307-DZ123MK0

!6&271.88*63&)

&2&1&.8=

;;;).,.86&<(31

"!8*(-7944368).,.86&<(31

6*4&.6).,.86&<(31

D 123MK0

Fits Marklin Mini Club 88455

Available

Computer InterfaceComputer Interface

Decoder ProgrammerDecoder Programmer

Sound ProgrammerSound Programmer

TM

E

EMPIREMPIRE B

BUILDER

UILDER

Super

Super

TM

0

00

00

00

0

Table of contents

Other Digitrax Controllers manuals

Digitrax

Digitrax DN166I2 User manual

Digitrax

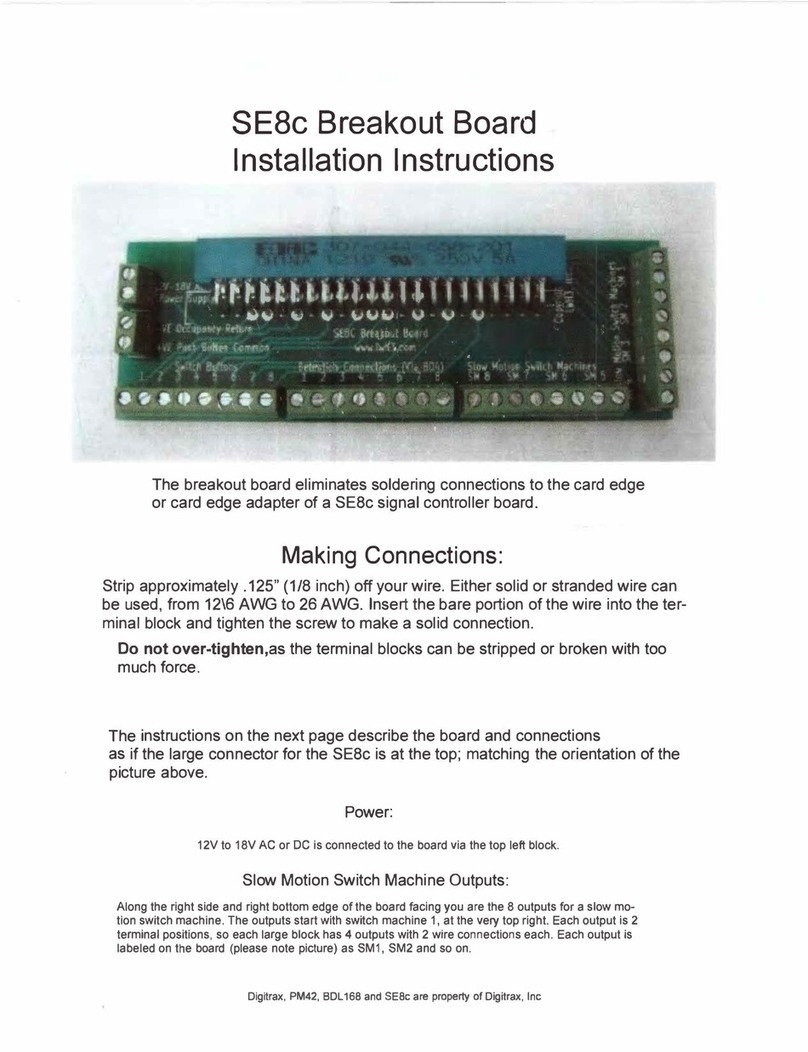

Digitrax SE8C User manual

Digitrax

Digitrax UT6 Series User manual

Digitrax

Digitrax DN166PS User manual

Digitrax

Digitrax SoundFX SDXH186MT User manual

Digitrax

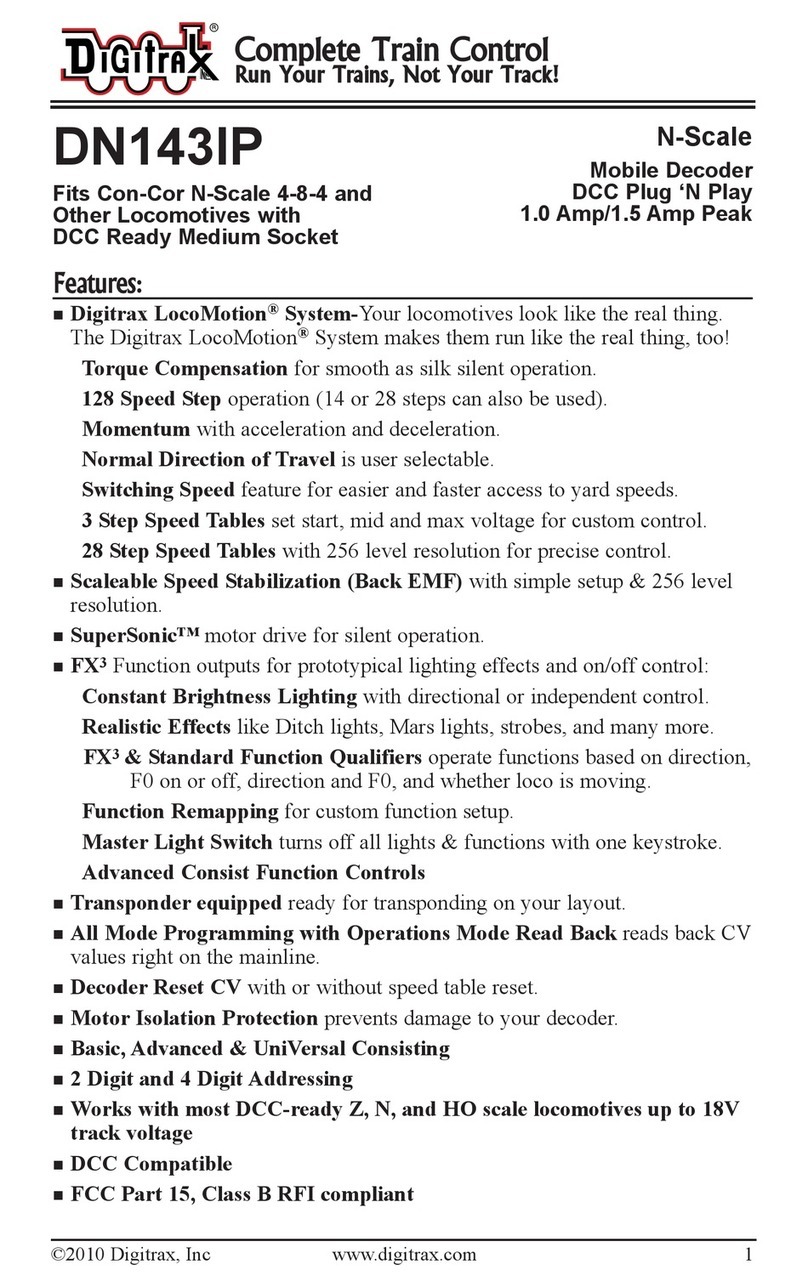

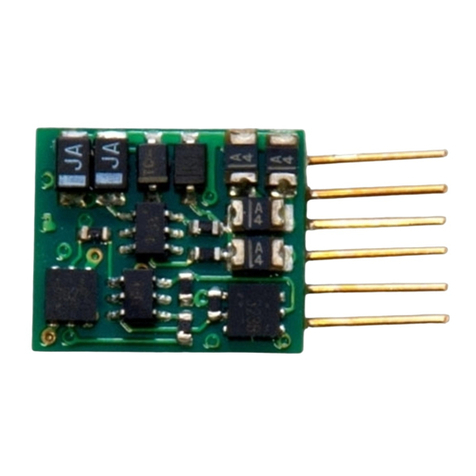

Digitrax DN143IP User manual

Digitrax

Digitrax DZ126IN User manual

Digitrax

Digitrax DT400 User manual

Digitrax

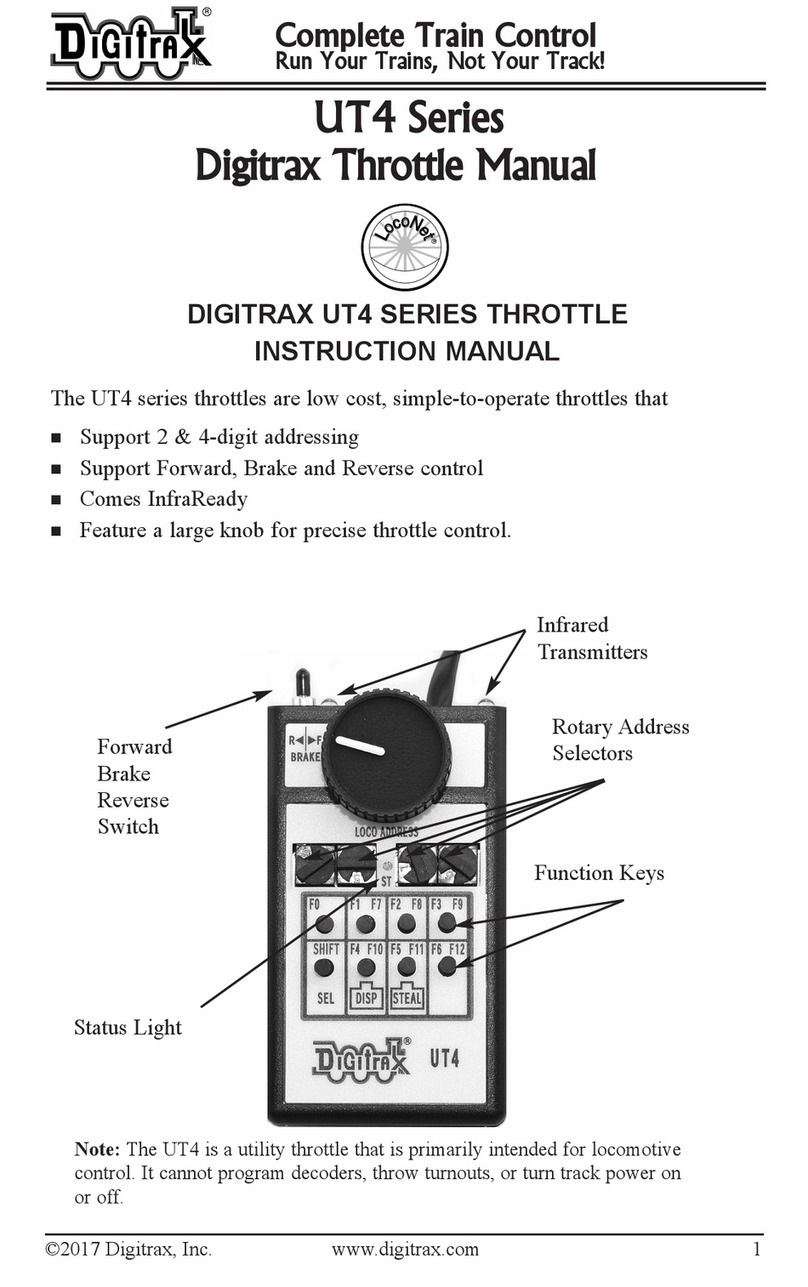

Digitrax UT4 Series User manual

Digitrax

Digitrax DN166I1B User manual