TECH STT-869 User manual

user’s manual

stt-869

user’s manual

stt-869

SERWIS 32-652 Bulowice,

ul. Skotnica 120

Tel. +48 33 8759380, +48 33 3300018

+48 33 8751920, +48 33 8704700

Monday - Friday

7:00 - 16:00

Saturday

9:00 - 12:00

TECH STEROWNIKI

Spółka z ograniczoną odpowiedzialnością SP.k.

Biała Droga 31

34-122 Wieprz

Safety

Before using the device for the fi rst time the user should read the

following regulations carefully. Not obeying the instructions included in

this manual may lead to personal injuries or controller damage.

The user’s manual should be stored in a safe place for further reference.

In order to avoid accidents and errors it should be ensured that every

person using the device has familiarized themselves with the principle of

operation as well as security functions of the controller. If the device is

to be sold or put in a diff erent place, make sure that the user’s manual

is there with the device so that any potential user has access to essential

information about the device.

The manufacturer does not accept responsibility for any injuries or

damage resulting from negligence; therefore, users are obliged to take

the necessary safety measures listed in this manual to protect their lives

and property.

WARNING

• The device should be installed by a qualifi ed electrician.

We are committed to protecting the environment.

Manufacturing electronic devices imposes an obligation

ofproviding for environmentally safe disposal of used

electronic components and devices. Hence, we have

been entered into a register kept by the Inspection For

Environmental Protection. The crossed-out bin symbol

on a product means that the product may not be

disposed of to household waste containers. Recycling

of wastes helps to protect the environment. The user is

obliged to transfer.

WARRANTY CARD

TECH company ensures to the Buyer proper operation of the device for the period of 24 months from the date of

sale. The Guarantor undertakes to repair the device free of charge if the defects occurred through the manufacturer’s fault.

The device should be delivered to its manufacturer. Principles of conduct in the case of a complaint are determined by the Act

on specifi c terms and conditions of consumer sale and amendments of the Civil Code (Journal of Laws of 5 September 2002).

THE DEVICE IS NOT INTENDED TO BE OPERATED BY CHILDREN.

Activities related to setting and regulation of the controller parameters described in the Instruction Manual and

parts wearing out during normal operation, such as fuses, are not covered by warranty repairs. The warranty does not cover

damages arising as a result of improper operation or through the user’s fault, mechanical damage or damage created as a

result of fi re, fl ood, atmospheric discharges, overvoltage or short-circuit. The interference of an unauthorized service, wilful

repairs, modifi cations and construction changes cause the loss of Warranty. TECH controllers have protective seals. Removing

a seal results in the loss of Warranty.

The costs of unjustifi able service call to a defect will be borne exclusively by the buyer. The unjustifi able service call

is defi ned as a call to remove damages not resulting from the Guarantor’s fault as well as a call considered unjustifi able by the

service after diagnosing the device (e.g. damage of the equipment through the fault of the client or not subject to Warranty),

or if the device defect occurred for reasons lying beyond the device.

In order to execute the rights arising from this Warranty, the user is obliged, at his own cost and risk, deliver the

device to the Guarantor along with a correctly fi lled-in warranty card (containing in particular the sale date, the seller’s

signature and a description of the defect) and sales proof (receipt, VAT invoice, etc.). The Warranty Card is the only basis for

repair free of charge. The complaint repair time is 14 days.

When the Warranty Card is lost or damaged, the manufacturer does not issue a duplicate.

...................................... ......................................

seller’s stamp date of sale

en

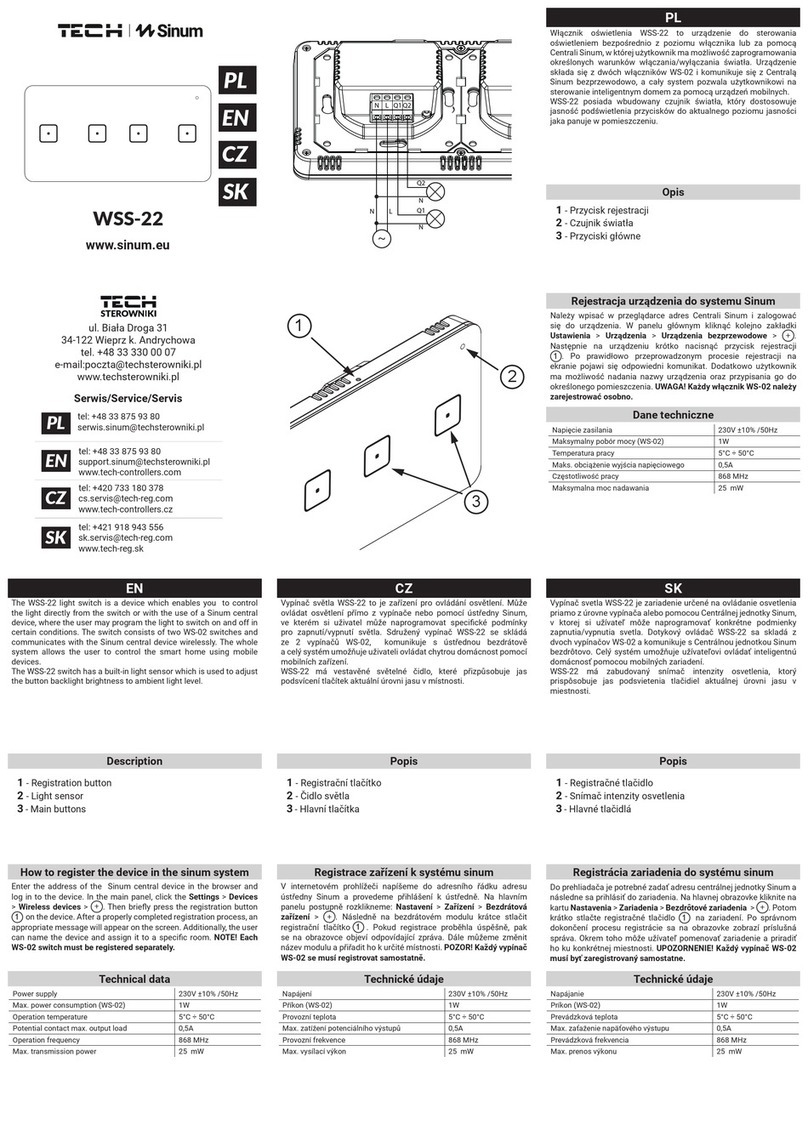

Description

STT-868 wireless electric actuator allows the user to easily and effi ciently

manage the temperature in particular heating zones of a building. The system

controlling the actuator ensures optimum heating comfort and contributes to

signifi cant energy saving. This type of actuator may be used in heating systems.

It is compatible with such controllers as EU-WIFI 8S, EU-L-8, EU-8S etc.

Technical data

Output – M30x1,5 nut

Communication – wireless

Frequency 868MHz

Power supply – 2x AA 1,5V batteries –

it is advisable to use high volume batteries

(over 2500mAh).

How to register the actuator

In order to register the actuator in a given zone, select <Registration> in

the main controller (see: instruction manual of the device) and press the

communication button.

Release it and observe the control light:

- if the green light fl ashes twice, it indicates successful registration

- if the red light goes on for a while, it indicates registration failure - it is

necessary to conduct registration again.

NOTE

If you press the communication button and the control light does not fl ash, it

means that the actuator motor is still working. Wait until it stops.

How to install the actuator

Follow these steps while installing the device:

1. Insert the batteries. The actuator moves into mounting position making it

easier for the user to screw it. Once the actuator is in mounting position, the

control light fl ashes green. The actuator remains in mounting position for 2

minutes.

NOTE

Depending on settings, it may take the actuator even 1,5 minutes to get into

the mounting position.

2. Screw the actuator to the radiator. Actuator calibration is initiated after

pressing the button or automatically after 2 minutes.

How to replace

batteries

1. Remove the cover

2. Remove the batteries

3. Press the communication button in order to

release the residual electricity

4. Insert new batteries

NOTE

Always use two new batteries of the same

brand.

Registration in mounting position

When the actuator is in mounting position, select <Registration> in the main

controller (see: instruction manual of the device) and hold the communication

button until the control light changes from green to red.

Connectivity test

In order to check the connection with the main controller, press the

communication button and hold it until the control light fl ashes twice. Release

the button and observe the control light:

- if the green light fl ashes twice, it indicates successful communication

- if the red light goes on for a while, there is no connection with the main

controller.

Connectivity test enables the user to identify the controller and the zone in

which a given actuator is registered. The main controller displays appropriate

message.

How to reset the actuator

In order to reset the actuator, press the communication button and hold it until

the control light fl ashes three times. Release the button and the actuator will

move to mounting position. Press the button or wait 2 minutes - the actuator

will reset. It is not necessary to register the actuator again.

Installation with Danfoss valve

1. Danfoss RAN (click) or RTD-N valve

2. Valve pressure pin

3. Pressure pin cap

4. Danfoss RAN (click) or RTD-N adapter

5. STT-869 actuator

It is necessary to put the cap on the valve pressure pin if we want ST-869 and

Danfoss valve to work properly.

Main controller alarms connected with actuator operation

If the main controller supporting STT-869 actuator informs about one of the following alarms, follow the steps described in the table below:

Type of alarm Possible cause How to fi x it

Error #1 - Calibration error 1 – Moving the

screw to the mounting position took too

much time

- The limit switch sensor is damaged - Call the service staff

Error #2 - Calibration error 2 – The screw

is maximally pulled out. No resistance

while pulling out

- The actuator has not been screwed to the valve or has not been

screwed completely

- The valve stroke is too big or the valve dimensions are not typical

- Actuator current sensor is damaged

- Check if the controller has been

installed properly

- Replace the batteries

- Call the service staff

Error #3 - Calibration error 3 -

The screw has not been pulled out enough

- the screw meets resistance too early

- The valve stroke is too small or the valve dimensions are not typical

- Actuator current sensor is damaged

- Low battery level

- Replace the batteries

- Call the service staff

Error #4 - No feedback - The master controller is switched off

- Poor range or no range in the master controller

- Radio module in the actuator is damaged

- Turn on the master controller

- Reduce the distance from the master

controller

- Call the service staff

Error #5 - Low battery level - The battery is fl at - Replace the batteries

Error #6 - Encoder is locked - The encoder is damaged - Call the service staff

Error #7 - To high voltage - Unevenness of the screw, the thread etc. may cause excessive resistance

- Too high resistance of gear or motor

- Current sensor is damaged

- Call the service staff

Error #8 - Limit switch sensor error - Limit switch sensor damaged - Call the service staff

EU DECLARATION OF CONFORMITY

Hereby, we declare under our sole responsibility that STT-869 room

regulator manufactured by TECH, headquartered in Wieprz Biała Droga

31, 34-122 Wieprz, is compliant with:

• Directive 2014/53/EU of the European parliament and of the

Council of 16 April 2014. on the harmonisation of the laws of the

Member States relating to the making available on the market of

radio equipment;

• Directive 2009/125/EC establishing a framework for the setting of

ecodesign requirements for energy-related products;

• the regulation by the Ministry of Economy of May 8, 2013

‘concerning the essential requirements as regards the restriction of

the use of certain hazardous substances in electrical and electronic

equipment’, implementing provisions of ROHS directive 2011/65/

EU.

For compliance assessment, harmonized standards were used:

PN-EN 60730-2-9 :2011 par. 3.1a Safety of use ETSI EN 301 489-1

V2.1.1 (2017-02) par.3.1b Electromagnetic compatibility ETSI EN 301

489-3 V2.1.1 (2017-03) par.3.1 b Electromagnetic compatibility ETSI EN

300 220-2 V3.1.1 (2017-02) par.3.2 Eff ective and coherent use of radio

spectrum ETSI EN 300 220-1 V3.1.1 (2017-02) par.3.2 Eff ective and

coherent use of radio spectrum

Wieprz, 17.08.2018

Control light

1. Danfoss RAN (click) or RTD-N valve

Communication button

Table of contents

Other TECH Controllers manuals

TECH

TECH ST-22 User manual

TECH

TECH ST-77 Assembly instructions

TECH

TECH WiFi RS User manual

TECH

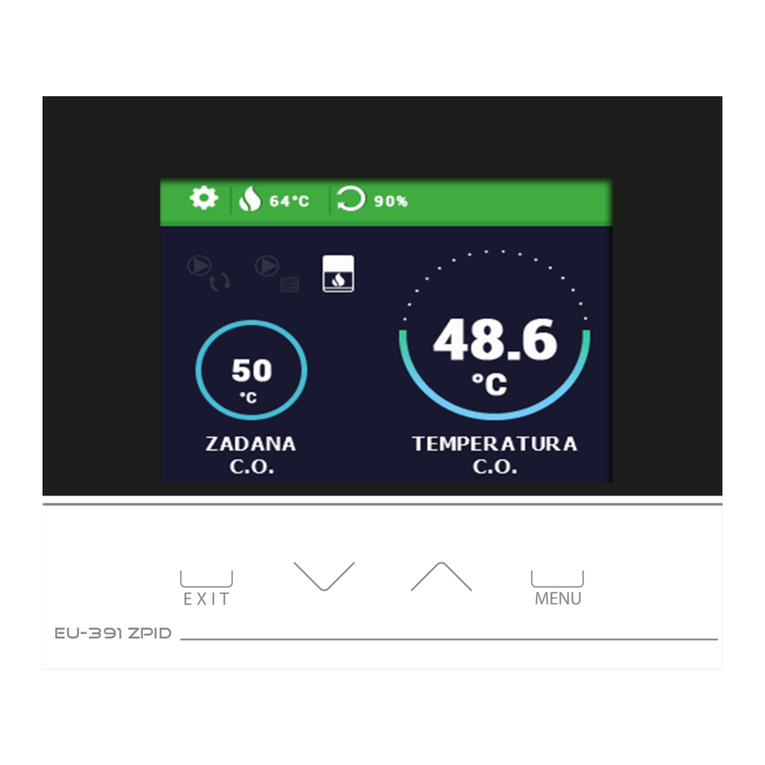

TECH EU-391 ZPID User manual

TECH

TECH EU-RP-3 User manual

TECH

TECH SINUM PS-10 230 User manual

TECH

TECH EU-21DHW User manual

TECH

TECH ST-402N PWM User manual

TECH

TECH ST-21D5 User manual

TECH

TECH ST-81 User manual