Digitrax BDL16 Service manual

1

1.0 Introduction 2

2.0 Terminology 2

3.0 Track Wiring for Detection with BDL16 4

4.0 BDL16 Installation 4

5.0 Set up for Non-Digitrax layouts 8

6.0 Customizing Your BDL16 By Setting Up Option Switches 10

6.1 How to read back and change BDL16 Option Switches: 10

7.0 Power Management 11

8.0 Auto-Reversing 13

9.0 LED Occupancy Indicators 13

10.0 BDL16 Board Address 14

10.1 To set up the board address 14

11.0 Troubleshooting: Checklist 14

11.1 Packet Reception 14

11.2 Mode Indication 15

11.3 Occupancy Debug 15

11.4 LocoNet Debug 15

11.5 Analog Locomotives 15

12.0 Warranty and Repair Information 16

13.0 FCC Information 16

BDL16 LocoNet Occupancy Detector

with RX4 Installation Information

Manual

Digitrax, LocoNet, Genesis II, Empire Builder II, Chief II, Super Chief, and

others included in this manual are trademarks of various manufacturers includ-

ing Digitrax and others. There are many different manufacturers who build

products that work with Digitrax, those used in this manual are for example

only. U.S. & International Patents Pending for BDL16, RX4, transponding and

other Digitrax products & technologies

Copyright Digitrax, Inc. All rights reserved. Printed in USA. REV 02/01

Security element is the plant, including track, associated with any reporting,

interlocking and/or signaling for that track section.

Whole layout common rail is a method of wiring layouts where power dis-

tricts and their boosters are connected electrically by a common rail or com-

mon power bus return wire. This method is traditionally used for convention-

ally controlled layouts. The track feeds for one rail are connected together to

one output of the power pack. The other rail is gapped and the track feeds are

connected to the power pack through block control switches. Whole layout

common rail wiring has a disadvantage when it comes to detection systems

because detectors are not able to independently monitor whether zone power is

on or off. There is no way to tell whether occupancy detection is actually

working in any given detection section.

Detection Section is a section of track gapped on one or both rails and con-

nected to an occupancy detector so that the detector can sense the presence of a

loco (or other specially equipped cars) in that section of track.

Occupancy detector is a device that senses the presence of a locomotive (or

other specially equipped cars) in a section of track that is set up for occupancy

detection. Occupancy detectors also provide feedback to indicate occupancy.

This feedback may be in the form of a lamp on a control panel or it may be a

feedback message sent to the system that can be used by other layout devices.

Also called a block occupancy detector on conventional layouts. Detectors are

not covered by the DCC Standards or Recommended Practices.

Transponder is an electronic device with a transponder address that is

installed in rolling stock. Transponders provide information to transponder

detectors installed on the layout. This lets the system determine in which

detection section the transponder is currently located. Transponders are includ-

ed in many Digitrax premium decoders. TD1 (transponder) & TL1 (transpon-

der with light output) are available as separate units that can be added to locos

with existing decoders or to other rolling stock without decoders if you want to

use them for transponding only and don't need motor control.

Transponder detector is an electronic device installed in a detection section

on the layout that receives the information broadcast from a transponder. The

transponder detector sends feedback to the system that lets it determine the

detection section location of any given transponder at any time. RX4

Transponder detectors are hosted by the BDL16 and upgrade 4 detection zones

of the BDL16 to be transponder detection zones. In this case, each transpond-

ing zone encompasses 4 detection zones.

The BDL16 is divided into four Zones. Each Zone supports 4 detection sec-

tions and each zone can be run from a different booster.

3

1.0 Introduction

The BDL16 uses digital signal processing (DSP) to give you occupancy detec-

tion for 16 detection sections on your layout. The BDL16 can also host

transponder detectors to let you implement Digitrax transponding. The BDL16

reports detection section occupancy and transponder location information to the

system via its LocoNet connection. You can also install LEDs in an occupancy

display panel to report detection section occupancy and transponder location.

The BDL16 is split into 4 zones, A through D, each with 4 detection sections,

for a total of 16 detection sections. Each BDL16 zone can be run from a dif-

ferent booster.

On your Digitrax system, the BDL16 automatically detects the LocoNet con-

figuration it finds and initializes itself accordingly. This automatic detection

also lets BDL16’s be used for occupancy detection on DCC systems without a

Digitrax compatible LocoNet command station.

The BDL16 can operate with no connection to LocoNet, using only the

RailSync DCC signal from any Digitrax compatible DCC system, and report-

ing detection information via optional LED outputs.

2.0 Terminology

Following are some terms you might find useful as you work with the BDL16.

Direct home wiring is a layout wiring method where each power district and

its booster is electrically isolated. The track within each power district uses a

"common return" wiring method for occupancy detection and/or power man-

agement. Direct home wiring is the wiring method recommended by Digitrax

for safety reasons & also because it makes detection work more prototypically.

Power district is the power wiring, components and equipment attached to that

wiring, driven by a single properly isolated booster. Power districts are double

gapped on both ends. BDL16 is used to set up detection sections within one or

more power districts.

Power sub-district is the wiring, components and equipment that are con-

trolled from both power bus wires by their own power management device, for

example a reversing section controlled by an automated reversing device like

the PM4. Power sub-districts are gapped on both ends.

Detection common is the common return used within a properly electrically

isolated power district for implementing occupancy detection.

2

5

3.0 Track Wiring for Detection with BDL16

BDL16 comes from the factory set up for DCC operation on layouts that use

direct home wiring. Direct home wiring is the wiring method recommended by

Digitrax. With direct home wiring, each power district and its booster is elec-

trically isolated. This method of wiring has safety advantages and makes detec-

tion work more prototypically. The track within each power district can use

"common rail" wiring for detection or power management. In most cases, the

BDL16 will work as it comes from the factory with direct home wiring when

its 44 pin socket is wired to the layout and connections are made to a 12V AC

power supply (100mA minimum), booster power and ground. Figure 1:

Typical Direct Home Wiring, shows the typical usage of a BDL16 operating

all 4 zones from a single booster, i.e. in a single power district. A single

BDL16 can be operated by up to four different boosters.

With direct home wiring, the BDL16 can determine & indicate whether any of

its 4 zones is powered or not (possibly short-circuited) even when there is noth-

ing on the rails in the detection sections. The BDL16 default logic causes the

detection sections to show "occupied" if the associated zone's power is off

(because in this case, detection is not possible). This default matches prototype

detection safety practices.

Whole layout common rail is a method of wiring layouts where power districts

and their boosters are electrically connected using a common rail or common

power bus return wire. Whole layout common rail wiring is at a disadvantage

when it comes to detection systems since detectors cannot independently moni-

tor whether zone power is on or off so they can't tell whether occupancy detec-

tion is working or not in any given detection section. To get around this limita-

tion, the BDL16 uses option switch 10 to set up detection section 16 to be used

as a zone power detector for detection sections 1 through 15. Wire a 10K resis-

tor from detection section 16 (not connected to tracks) to the detection common

return for the whole BDL16. Then detection section 16 on the BDL16 will be

active when the BDL16 sees track power and you will be able to tell whether

detection is actually available in detection sections 1 through 15.

4.0 BDL16 Installation

TABLE I shows the pin-out for the BDL16's 44 pin connector. Be sure to wire

the BDL16 ground wire to the Digitrax Booster ground, common (or case) of

the boosters. Wire the track outputs to the appropriate detection section follow-

ing the example in Figure 1. The Zone common connections to the booster

should be as short as possible and relatively heavy gauge, since they are com-

mon to all four detectors in the zone. For example, a 12awg zone connection to

the booster should be less than 10 feet for best performance. For whole layout

4

12345678910111213141516171819202122

TOP ROW

AB

C

D

AUX1

AUX2

PS12

12 VAC

Power

Supply

Zone Common

(Heavy Wire)

Detection Common

Booster Ground to pin 11

Zone A

DS 1

DS 2

DS 3

DS 4

Zone B

DS 5

DS 6

DS 7

DS 8

Zone C

DS 9

DS 10

DS 11

DS 12

Zone D

DS 13

DS 14

DS 15

DS 16

Booster GND

Ext. Power

BDL16

Top View

Detection Section

1Detection Section

2Detection Section

3Detection Section

4

TRACK

STATUS

POWER

ON

OFF LINE

O/G

N

HO

MODE

MODE

O

RUN

LOCONET

A B

SCALE

SLEEP

SLEEPP

P

R

R

RAIL B

POWER INPOWER IN

RAIL A

POWER INPOWER IN

GROUND

LocoNet

to other LocoNet

Devices such as

(Throttles, Boosters,

UP3's Etc.)

12 VAC to Pin 12

12 VAC to Pin N

Note: BDL16 Zone A Wiring

shown for clarity. Zones B, C,

and D are wired similarly.

External LED

Connectors (pin 1)

(See

Figure 4)

Figure 1: Typical Direct Home Wiring

Direct Home Booster (Digitrax standard)

ID LED (green)

Option LED (red)

Detection Section

16

~

~~

~

7

6

Pin

#

Name

Connect To

1

Zone A

Connection to booster for Zone A

2

Detection

Section 1

(DS 1)

Isolated track section for Detection Section 1

3

DS 2

Isolated track section for Detection Section 2

4

DS 3

Isolated track section for Detection Section 3

5

DS 4

Isolated track section for Detection Section 4

6

Zone B

Connection to booster for Zone B

7

DS 5

Isolated track section for Detection Section 5

8

DS 6

Isolated track section for Detection Section 6

9

DS 7

Isolated track section for Detection Sectio n 7

10

DS 8

Isolated track section for Detection Section 8

11

Ground**

LocoNet/BDL16 ground to Booster

case/common ground

12

AC Power 1*

Power input to BDL16 : AC 12V to 15V, or

+DC 12V to 15V

13

Zone C

Connection to booster for Zone C

14

DS 9

Isolated track section for Detection Section 9

15

DS 10

Isolated track section for Detection Section 10

16

DS 11

Isolated track section for Detection Section 11

17

DS 12

Isolated track section for Detection Section 12

18

Zone D

Connection to booster for Zone D

19

DS 13

Isolated track section for Detection Section 13

20

DS 14

Isolated track section for Detection Section 14

21

DS 15

Isolated track section for Detection Section 15

22

DS 16

Isolated track section for Detection Section 16

Pin

#

Name

Connect To

A

Zone A

Connection to booster for Zone A

B

Detection

Section 1

Isolated track section for Detection Section 1

C

DS 2

Isolated track section for Detection Section 2

D

DS 3

Isolated track section for Detection Section 3

E

DS 4

Isolated track section for Detection Section 4

F

Zone B

Connection to booster for Zone B

H

DS 5

Isolated track section for Detection Section 5

J

DS 6

Isolated track section for Detection Section 6

K

DS 7

Isolated track section for Detection Section 7

L

DS 8

Isolated track section for Detection Section 8

M

LocoNet

LocoNet network, connect to RED/GREEN

wires if not using RJ12 jacks

N

AC Power 2*

Power input to BDL16: AC 12V to 15V, or

DC 12V to 15V return

P

Zone C

Connection to booster for Zone C

R

DS 9

Isolated track section for Detection Section 9

S

DS 10

Isolated track section for Detection Section 10

T

DS 11

Isolated track section for Detection Section 11

U

DS 12

Isolated track section for Detection Section 12

V

Zone D

Connection to booster for Z one D

W

DS 13

Isolated track section for Detection Section 13

X

DS 14

Isolated track section for Detection Section 14

Y

DS 15

Isolated track section for Detection Section 15

Z

DS 16

Isolated track section for Detection Section 16

TABLE I: BDL 16 Connector Printed Circuit Bboard Component Side TABLE I: BDL 16 Connector Printed Circuit Board Solder Side

Note that all connector pins except 11/M and 12/N are paired top (com-

ponent side) and bottom(solder side) of the PCB(printed circuit board).

For 6A current rating with 3A connector pins, track/zone wires must be

connected to both pin pairs: e.g., Zone A = pins 1 & A.

Note some letters are not used on connector.

*These AC1/AC2 power connections should be made to supply only used by

BDL16(s).

**The Ground connection must be made to booster for correct BDL16 opera-

tion.

9

common rail wiring, refer to Figure 2:Common Rail Wiring and be sure to

change option switch 10 to "closed".

If you are using a Digitrax system, connect LocoNet via one of the BDL16's

LocoNet jacks. If you are using another DCC system, connect the leftmost pin

of the RJ12 socket (called the RailSync pin) to a reliable source of the DCC

signal that matches the DCC signal being sent by the booster to the detection

sections handled by the BDL16. It is best if this signal stays active even when

the booster output is shorted or disconnected from the BDL16 zone inputs, for

example by a PM4 Power Manager.

Connect a 12VAC power supply to the AC1 and AC2 terminals of the BDL16's

44 pin connector. This powers the BDL16(s). Multiple BDL16 units can be

supplied by a single shared supply as long as you provide at least 100mA for

each BDL16. This supply should not power or be shared by any devices other

than BDL16’s.

Set up the BDL16 to operate on your layout: The BDL16's option switches are

set at the factory for default values that will work for most direct home wired

layouts. You can fine-tune the BDL16's characteristics using its option switch-

es. The BDL16's option switches can be set using a Digitrax compatible throt-

tle or a PC with LocoNet compatible software that can control turnouts. See

"Customizing your BDL16 By Setting Up Option Switches below".

5.0 Set up for Non-Digitrax layouts

To make set up simpler and to make it easier for non-Digitrax layouts to use

the BDL16, there are two quick configuration buttons that let you set up your

unit to work with either direct home or whole layout common rail without

using a Digitrax throttle or computer.

If the “ID” switch behind the green ID LED is held down when AC power is

first applied, the BDL16 will operate on direct home layouts(the default as

shipped from factory). When DCC packets are supplied to the RJ12 connector

the ID LED will be lit and “wink” off once every 2 seconds to indicate direct

home operation is selected.

If the “OPTION” switch behind the red option LED is held down when AC

power is first applied, the BDL16 will operate on whole layout common rail

layouts. When DCC packets are supplied to the RJ12 connector the ID LED

will be lit and “wink” off twice every 2 seconds to indicate whole layout com-

mon rail operation is selected.

If either switch is pressed when the BDL16 is first powered up, the BDL16

will be re-configured.

8

12345678910111213141516171819202122

TOP ROW

AB

C

D

AUX1

AUX2

PS12

12 VAC

Power

Supply

Common

Rail Return

Detection Common

Booster Ground

to pin 11

Zone A

DS 1

DS 2

DS 3

DS 4

Zone B

DS 5

DS 6

DS 7

DS 8

Zone C

DS 9

DS 10

DS 11

DS 12

Zone D

DS 13

DS 14

DS 15

DS 16

Booster GND

Ext. Power

BDL16

Top View

Detection Section

1Detection Section

2Detection Section

3Detection Section

15

TRACK

STATUS

POWER

ON

OFF LINE

O/G

N

HO

MODE

MODE

O

RUN

LOCONET

A B

SCALE

SLEEP

SLEEPP

P

R

RAIL B

POWER INPOWER IN

RAIL A

POWER INPOWER IN

GROUND

LocoNet

to other LocoNet

Devices such as

(Throttles, Boosters,

UP3's Etc.)

12 VAC to Pin 12

12 VAC to Pin N

External LED

Connectors (pin 1)

See Fig. 4

Figure 2: Common RailWiring

Opto-Isolated Booster

DS 16 Used as

Zone Power Detector

For Zones 1 thru 15

To other Common Rail

Sections

To other

Common Rail

Sections

Track Detection

uses the Layout

Common Rail

ID LED (green)

Option LED (red)

(Heavy Wire)

Digitrax Special Order or

Other Digitrax Compatible Booster

~

~~

~

10 kohm

Resistor

Note: For this example,

BDL16 OPSW 10 must

be set to "c".

7.0 Power Management

The BDL16 is designed to operate “downstream” of the Digitrax boosters and

power management devices. The BDL16 is the "last" device in the chain from

booster to power manager to BDL16. It is connected directly to the track

detection section. There should be no other connections to any detection sec-

tion that will draw track power or the detection section will always show occu-

pied.

If a device is used to switch off power feeding the BDL16 and the track it is

connected to, for example, a PM4 Power Manager, it should break the track

power to both the zone and detection common rail. If a device only switches

off a single leg, then it must be placed in the detection common rail wiring.

11

6.0 Customizing Your BDL16 By Setting Up Option

Switches

TABLE II, below, details the option switches & settings you can use to cus-

tomize your BDL16. These option switches are set up using your Digitrax

throttle's SWITCH commands. SWITCH mode is normally used for operating

turnouts by issuing closed ("c") or thrown ("t") commands. In the case of your

BDL16, each switch address is a BDL16 option switch.

6.1 How to read back and change BDL16 Option Switches:

1. Power up your BDL16.

2. Press the switch behind the red option LED for about 1 second, then release

it. The red option and green ID LEDs will flash alternately to let you know

that you are in option switch setup mode.

3. Connect a DT or UT series Digitrax throttle to the BDL16's LocoNet con-

nector.

4. Go into SWITCH mode. Dial up the switch number that corresponds to the

OPSW you want to change and issue a closed "c" or thrown "t" command to

set the OPSW to the desired setting. The OPSW is changed as soon as you

issue the SWITCH command. See below for instructions for specific Digitrax

throttles.

5. When BDL16 OPSWs are set up as desired, press the switch behind the red

option LED for about 1 second and release it, the BDL16 will exit option

switch set up mode. You can also exit option switch set up mode by turning

off the power to the BDL16 and then turning it back on.

DT100 or DT200 series throttle, press “MODE/DISP” on the throttle to enter

SWITCH mode. Use the throttle to read back each OPSW in TABLE II by

dialing it up on the throttle and looking at it's setting (c or t). If you need to

make a change to the OPSW simply press c or t to make the change you want.

Once you are finished reading back and changing settings, simply wait 6 sec-

onds for the throttle to time out and return to LOCO mode. Be sure to com-

plete step 5 above when finished setting OPSWs.

UT series throttle, press RUN/STOP and DISP/OPSW at the same time to

enter SWITCH mode. With a UT throttle, you won't be able to read back the

BDL16 OPSW settings but you can change them by dialing up the OPSW

number you want to modify and pressing the c key. When the LED under the c

key is on the OPSW is set to closed, when it is off, the OPSW is set to thrown

(the factory default setting). When you are finished setting up BDL16 OPSWs,

return to LOCO mode by pressing RUN/STOP and DISP/OPSW at the same

time to exit SWITCH mode. Be sure to complete step 5 above when finished

setting OPSWs.

10

OPSW

t=thrown (factory default)

c=closed

01

Set up for operation with

direct home wired layouts

(Digitrax recommended

wiring)

Set up for whole layout

common rail wired layouts

09

Detection sections show

occupied when zone power

is off

no forced occupied

detection when zone power

is off

10

Use detection section 16 as

a normal detection section.

Use detection section 16 as

zone power ON qualifier

for whole layout common

rail wiring

11

Allow this BDL16 to be the

master.

Do not allow this BDL16

to be master

12

Allow this BDL16 to

terminate LocoNet

Do not allow this BDL16

to terminate LocoNet

13

Power up delay 5 seconds

for DB150 compatibility

Power up delay 1/2 second

19

Use regular threshold sense

DCC occupancy. (approx 22

kohms minimum)

Use high threshold sense

DCC occupancy (approx

10 kohms minimum)

25

16 LEDs show occupancy

Drive 16 occupancy LEDs

from SWITCH commands

(not occupancy)

26

Occupancy LEDs decoded

from track DCC switch

commands

Occupancy LEDs decoded

from LocoNet SWITCH

commands

40

Direct home wiring

compatible

Make all option switches

factory default

TABLE II: BDL16 Option Switches (OPSWs)

BDL16 option switches (OPSWs) have a default of “t” or thrown. The

following table shows what each OPSW is used for when it is set for

thrown or closed.

8.0 Auto-Reversing

Note that an auto-reverse section can only use detection sections that are con-

tained in a BDL16 zone that is correctly set up for auto-reversing , see Figure

3: Reverse Section Wiring for a wiring example.

9.0 LED Occupancy Indicators

9.1 LT5 Tester

Each BDL16 comes with an LT5 that will help you with layout wiring and

troubleshooting for transponding & detection with Digitrax BDL16 LocoNet

Occupancy Detector. The LT5 plugs onto the LED Connections of BDL16 and

the LEDS on the LT5 light when detection sections are occupied. The status of

power to each zone is also shown.

9.2 Panel Indicator Wiring

For a front panel display of status with user supplied LED’s, connect to the

four 0.1” 2x5 headers, and wire up LEDs as shown in Figure 4: LED Panel

Indicators Wiring. DigiKey (1-800-DigiKey) part number M1AXA-1036R-

ND is a convenient plug and cable assembly that you can use to wire LED

indicators. Header “A” includes the 4 detection indicators for detection sec-

tions 1 to 4 and the zone power indicator for zone A that includes these four

12345678910

AB

C

D

Zone A

DS 1

DS 2

DS 3

DS 4

Zone B

DS 5

DS 6

DS 7

DS 8

BDL16 (PartialTop View)

LED for First Detection Section (1,5,9, or 13)

LED for Second Detection Section (2,6, 0, or 14)

LED for Third Detection Section (3,7,11, or 15)

LED for Fourth Detection Section (4,8,12, or 16)

LED for Power Zone (A, B, C, or D)

Socket

Plug LT5 Tester in to External LED Connectors A,B,C, or D

with LED's facing the edge of the BDL16 as shown.

LT5Tester

External LED

Connectors

LocoNet

Connectors

LT5Tester

13

12

12345678910111213141516171819202122

TOP ROW

AB

C

D

AUX1

AUX2

PS12

12 VAC

Power

Supply

Zone A

DS 1

DS 2

DS 3

DS 4

Zone B

DS 5

DS 6

DS 7

DS 8

Zone C

DS 9

DS 10

DS 11

DS 12

Zone D

DS 13

DS 14

DS 15

DS 16

Booster GND

Ext. Power

BDL16

Top View

LocoNet

to other LocoNet

Devices such as

(Throttles, Boosters,

UP3's Etc.)

12 VAC to Pin 12

12 VAC to Pin N

External LED

Connectors (pin 1)

See Fig. 4

Figure 3: Reverse Section Wiring

ID LED (green)

Option LED (red)

These 2 wires come

from a reversing device

such as a PM4 Reverse

Section, a separate

auto-reversing booster,

a DPDT toggle switch,

or other reversing

device.

Zone Common

Detection Common

Booster Ground to pin 11

For non-reversing

Detection Sections

For non-reversing Detection

Sections

All 4 Detection Sections

in this zone can only be

used in this

reverse section

Reverse

Section Non-reversing

part of layout

{

Using 4

Detection Sections

address. The board address is changed as soon as you issue the SWITCH com-

mand. See below for instructions for specific Digitrax throttles.

DT100 or DT200 series throttle, press “MODE/DISP” on the throttle to enter

SWITCH mode. Use the throttle dial up the board address you would like to

assign to the BDL16. When the address is in the display, press "c" to issue a

closed command. This will set the board address for the BDL16. The green

LED will then go steady green to indicate BDL16 Power on.

UT series throttle, press RUN/STOP and DISP/OPSW at the same time to

enter SWITCH mode. With a UT throttle, dial up the board address you would

like to assign to the BDL16. Press the "c" key until the corresponding LED is

lit. This will set the board address for the BDL16. The green LED will then go

steady green to indicate BDL16 Power ON. When you are finished setting up

BDL16's board address, return to LOCO mode by pressing RUN/STOP and

DISP/OPSW at the same time to exit SWITCH mode.

11.0 Troubleshooting: Checklist

11.1 Packet Reception

Be sure the green ID LED is ON & is “winking” off about every 2 seconds.

This means that correctly formatted DCC packets are being decoded from the

left most (Railsync) pin of the RJ12 LocoNet socket. For DCC detection, the

same DCC packet signal that drives the booster must be connected to the RJ12

socket's leftmost pin. If you are using LocoNet, and you do not see the green

LED blinking pattern described, check to be sure that the system is powered up

and that your LocoNet cable connections are good. You can use your LT-1 to

test the LocoNet cables if you suspect there is a problem with them. If the

green LED on the BDL16 is not lit, check the external power connections.

11.2 Mode Indication

The winking on the green ID LED indicates the primary BDL16 mode. A sin-

gle wink indicates standard Digitrax compatible Direct Home track wiring and

detection logic will be used, a double wink indicates Common Rail wiring and

detection logic is to be used. For Common Rail, all 4 BDL16 zone connections

must be made to the System Common ground point. Be sure the BDL16 con-

figuration is appropriate for your usage.

11.3 Occupancy Debug

Use the LT5 provided with your BDL16 as described in Section 9.1. You can

also build a simple LED display debugger as follows. Use a 10 pin plug and

cable such as DigiKey (1-800-DigiKey) part number M1AXA-1036R-ND that

will plug into one of the 4 occupancy LED headers on the BDL16 and solder

LEDs to the wires to create an array of LEDs. By plugging this display array

15

detection sections.

The BDL16 incorporates current setting resistors to set the LED current typi-

cally about 3mA. If you use higher LED drive currents you can external tran-

sistors etc to amplify the LED current.

The LED drive from the BDL16 is active high at about +5 volts above the

BDL16 ground pin, via a 1 kilo-ohm resistor. Note that the ribbon cable

includes separate ground return conductors for each LED that allow a 10 con-

ductor ribbon cable to be split into 5 pairs to conveniently route to individual

LEDS. Be sure to connect the +ve active output leads to the LED anodes.

10.0 BDL16 Board Address

When the BDL16 is connected to LocoNet, it will communicate coded detec-

tion information to the system. If you wish to report BDL16 status to LocoNet

and attached devices or computers that can interpret these messages, you will

probably want to set up a unique board address for each BDL16.

10.1 To set up the board address

1. Power up your BDL16.

2. Press the switch behind the green ID LED for about 1 second, then release

it. The green ID LED will blink. The red option LED will not light. This let's

you know that you are in board address set up mode.

3. Connect a DT or UT series Digitrax throttle to the BDL16's LocoNet con-

nector.

4. Go into SWITCH mode. Dial up the switch number that corresponds to the

board address you want to set and issue a closed "c" command to set the board

Figure 4: LED Panel IndicatorsWiring

Pin 1

GND

GND

GND

GND

GND

Detection Section

1, 5, 9, 13

Detection Section

2, 6, 10, 14

Detection Section

3, 7, 11, 15

Detection Section

4, 8, 12, 16

Zone A, B, C, D

Power

Front Panel LEDs

External LED

Connector

Ribbon Cable & Plug

(DigiKey #M1AXA-1036R-ND)

Edge of PC Board

Note: Connect active output leads to LED anode

& ground leads to LED cathode.

14

dance with the manufacturer's specifications, any and all warranties either

expressed or implied are void. Except to the extent expressly stated in this

section, there are no warranties, express or implied, including but not lim-

ited to any warranties of merchantability or fitness for a particular purpose.

Digitrax, Inc. reserves the right to make changes in design and specifi-

cations and/or to make additions or improvements in its products without

imposing any obligations upon itself to install these changes, additions or

improvements on products previously manufactured.

13.0 FCC Information

Radio or TV Interference: (this information is MANDATED by the FCC) This equip-

ment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a residential

environment. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. However, there is no guarantee that inter-

ference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and the receiver.

-Connect the equipment into an outlet on a circuit different form that

to which the receiver is connected.

-Consult the dealer or an experienced radio/TV technician for help.

Note that any modifications to the equipment not expressly approved by Digitrax voids

the user's authority to operate under and be in compliance with CFR 47 rules, as

administered by the Federal Communication Commission. Digitrax believes any

conscientiously installed equipment following guidelines in this manual would be

unlikely to experience RFI problems.

17

into one of the 4 occupancy LED headers, you can see the state of the zone and

occupancies for that header. This allows you to easily check the zone sensitivi-

ty (typically 22K ohms to give detection). This also aids in the determination

of detection number and activity for a track detection section. Many detection

problems are related to wiring problems or poor connections to the detection

section rather than to the actual BDL16. By using the display array, you can

eliminate the wiring issues from the equation and be sure that the BDL 16 is

set up correctly.

Remember, if the zone power is OFF, the occupancy LEDs should be set up so

that they will be on to be sure that signaling systems or a CTC/dispatcher will

see the detection section in its most restricted aspect.

11.4 LocoNet Debug

If you are using LocoNet for reporting, be sure that the configuration is correct

for your usage. In normal operations the red “option” LED will blink ON

briefly when valid LocoNet messages are seen confirming a good LocoNet net-

work connection.

11.5 Analog Locomotives

The motor inductance of analog locomotives may in some installations cause

cross talk among the BDL16 detection sections. The addition of a 220ohm

3watt power wire wound resistor between the booster track terminals (Rail A

and Rail B on Digitrax boosters) will typically reduce the effect of this cross

talk. Simply use a leaded resistor as a jumper between the booster's two track

terminals.

12.0 Warranty and Repair Information

Digitrax guarantees the BDL16 to be free from manufacturing defects

for five years from the date of purchase. These units are not user service-

able. If a defect occurs, return the unit to Digitrax for service. Digitrax

will repair or replace BDL16s at our discretion at no charge to you for one

year from purchase date. This warranty excludes damage due to abuse,

such as failure to properly protect against input over current with a fuse or

circuit breaker or applying excessive input voltage to the unit.

Digitrax will make non-warranty repairs needed because of physical

damage or electrical abuse at fair and reasonable rates.

All warranties on Digitrax products are limited to refund of purchase

price or repair or replacement of Digitrax products at the sole discretion of

Digitrax.

In the event that Digitrax products are not installed or used in accor-

16

Table of contents

Other Digitrax Security Sensor manuals

Popular Security Sensor manuals by other brands

Aparton

Aparton SPT-3B user manual

SATO

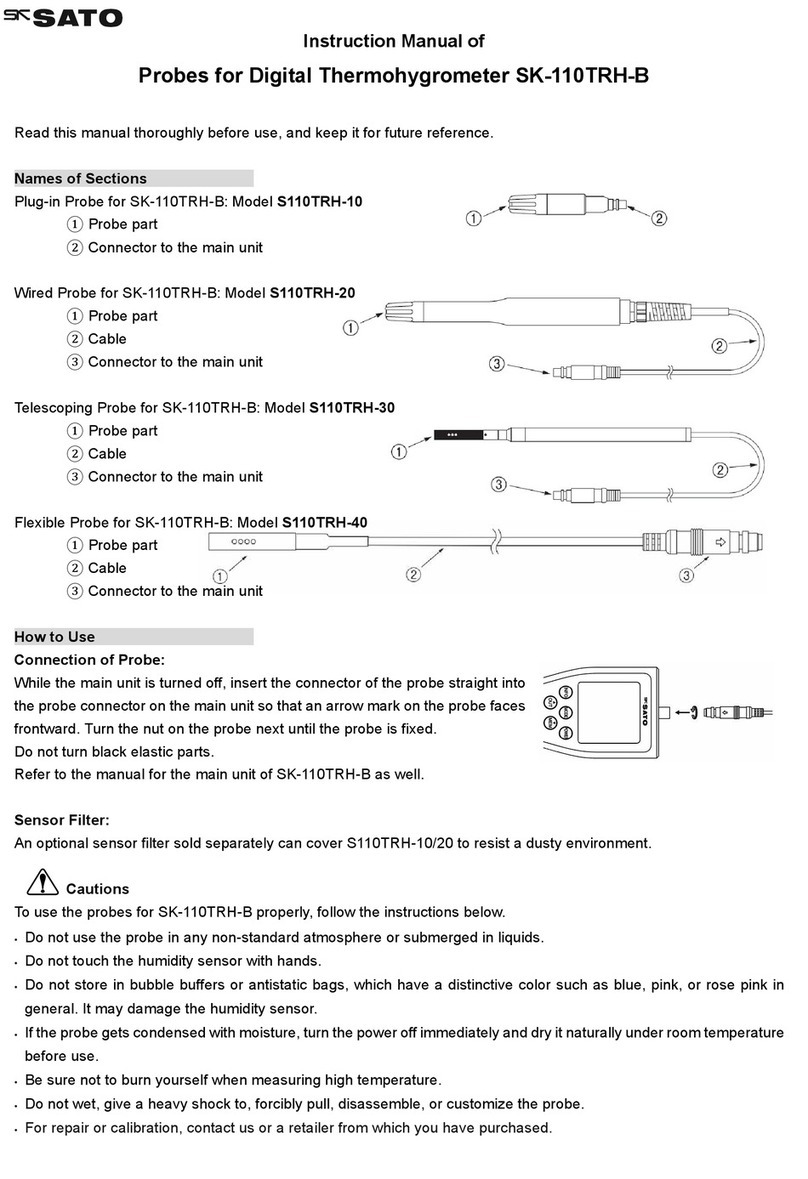

SATO S110TRH-10 instruction manual

MD

MD mXion RBM user manual

Honeywell

Honeywell Ex-Or MR2500D Installation and commissioning instructions

STIF

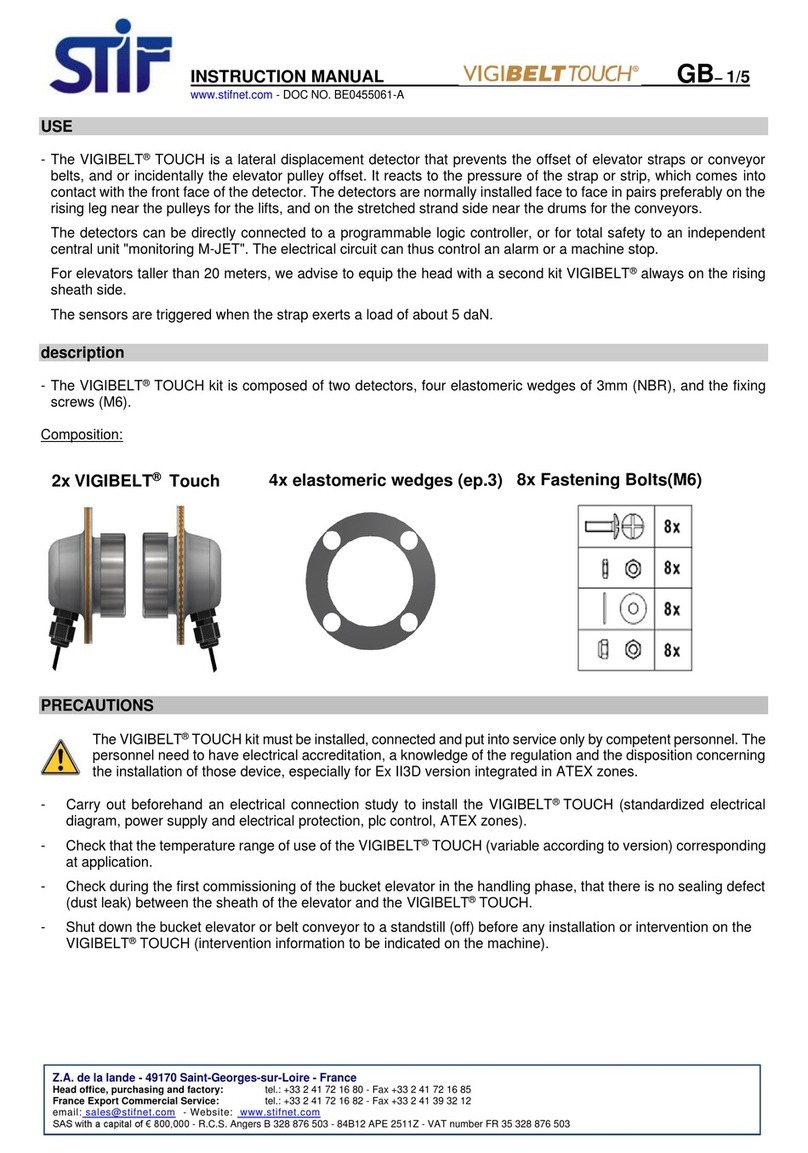

STIF VIGIBELT TOUCH instruction manual

Niko

Niko Swiss Garde 360 DALI Secondary A-Comfort high ceiling... installation instructions