Dimetix DLS-B 15 Product manual

Table of Contents

1 Introduction.................................................................................................................................................... 3

1.1 Product identification..................................................................................................................................................4

1.2 Components...............................................................................................................................................................4

1.3 Validity....................................................................................................................................................................... 4

1.4 easurement range....................................................................................................................................................5

1.5 Prevention of erroneous measurements...................................................................................................................... 5

2 Device setup................................................................................................................................................... 6

2.1 Connection.................................................................................................................................................................6

2.2 Controlled mode.........................................................................................................................................................7

2.3 Automatic mode.........................................................................................................................................................8

2.4 Display ode..............................................................................................................................................................9

2.5 External Trigger.........................................................................................................................................................10

3 Installation.................................................................................................................................................... 11

3.1 ounting................................................................................................................................................................. 11

3.2 Device wiring............................................................................................................................................................11

3.3 Alignment of the laser beam.....................................................................................................................................13

4 Technical data............................................................................................................................................... 14

4.1 easuring accuracy.................................................................................................................................................. 14

4.2 Specifications............................................................................................................................................................15

5 Electrical components................................................................................................................................... 16

5.1 ID switch...................................................................................................................................................................16

5.2 Reset switch..............................................................................................................................................................16

5.3 Digital output........................................................................................................................................................... 16

5.4 Digital Input..............................................................................................................................................................16

5.5 Analog output.......................................................................................................................................................... 16

5.6 Connector................................................................................................................................................................ 17

6 Physical dimensions....................................................................................................................................... 18

7 Factory settings............................................................................................................................................. 19

7.1 Operation................................................................................................................................................................. 19

7.2 Communication parameters......................................................................................................................................19

7.3 Analog outputs.........................................................................................................................................................19

7.4 odule ID.................................................................................................................................................................19

7.5 Digital output 1 (DOUT1).......................................................................................................................................... 19

7.6 Digital output 2 (DOUT2).......................................................................................................................................... 19

7.7 Digital input 1 (DI1)...................................................................................................................................................19

7.8 User distance offset.................................................................................................................................................. 19

8 Command set............................................................................................................................................... 20

8.1 General.....................................................................................................................................................................20

8.2 Operation commands............................................................................................................................................... 21

8.3 Configuration commands..........................................................................................................................................24

8.4 Digital Input..............................................................................................................................................................30

8.5 Special User Commands............................................................................................................................................31

8.6 Error codes............................................................................................................................................................... 34

9 Accessories................................................................................................................................................... 35

9.1 Viewfinder................................................................................................................................................................35

9.2 Target plates.............................................................................................................................................................35

9.3 Laser Glasses.............................................................................................................................................................35

9.4 Cables...................................................................................................................................................................... 36

9.5 Connector cover IP65................................................................................................................................................36

9.6 Connector with 90° cable exit IP65........................................................................................................................... 36

10 Safety instructions....................................................................................................................................... 37

10.1 Use of the instrument............................................................................................................................................. 37

10.2 Limits to use........................................................................................................................................................... 38

10.3 Areas of responsibility.............................................................................................................................................38

10.4 Hazards in use........................................................................................................................................................ 39

10.5 Laser classification...................................................................................................................................................40

10.6 Electromagnetic compatibility (E C).......................................................................................................................41

10.7 Producer Standards.................................................................................................................................................41

10.8 Disposal..................................................................................................................................................................41

10.9 Labeling..................................................................................................................................................................42

10.10 aintenance.........................................................................................................................................................43

10.11 Service..................................................................................................................................................................43

TE HNI AL REFEREN E MANUAL

1 Introduction

The DLS-B(H) is a powerful distance-measuring instrument for integration into industrial applications. It allows

accurate and contactless distance measurement over a wide range using the reflection of a laser beam:

Key features

•Compatible with DI ETIX DLS-A(H) Laser Distance Sensor

•easurement range 0.2 to 500 m

•Serial interface (RS232 and RS422)

•Connection of up to 10 modules on a single RS422 line

•Wide range power supply (9...30VDC), heating option (24...30VDC)

•Programmable analog output (0/4...20mA)

•Two programmable digital outputs (DO1 and DO2)

•Digital output for error signalization (DOE)

•One programmable digital input (DI1)

•ASCII protocol to control external displays

•D-Sub connector and screw terminal joint for easy connection

•IP65 (protected against ingress of dust and water)

•4 LEDs for status signaling

•Complementary configuration software available at Dimetix web site (www.dimetix.com)

•Optional: Internal heater for module operation down to -40°C

•Laser class II (<0.95mW)

•Accessories for easy use of the sensor

CAUTION

Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

For easy startup with the DLS-B(H) sensor, please use our free configuration software from our

web-page: www.dimetix.com

Distance Laser Sensor V1.02 Page 3/43

Fig. 1 Standard application

easured distance

Target

easuring

reference

DLS-B(H)

TE HNI AL REFEREN E MANUAL

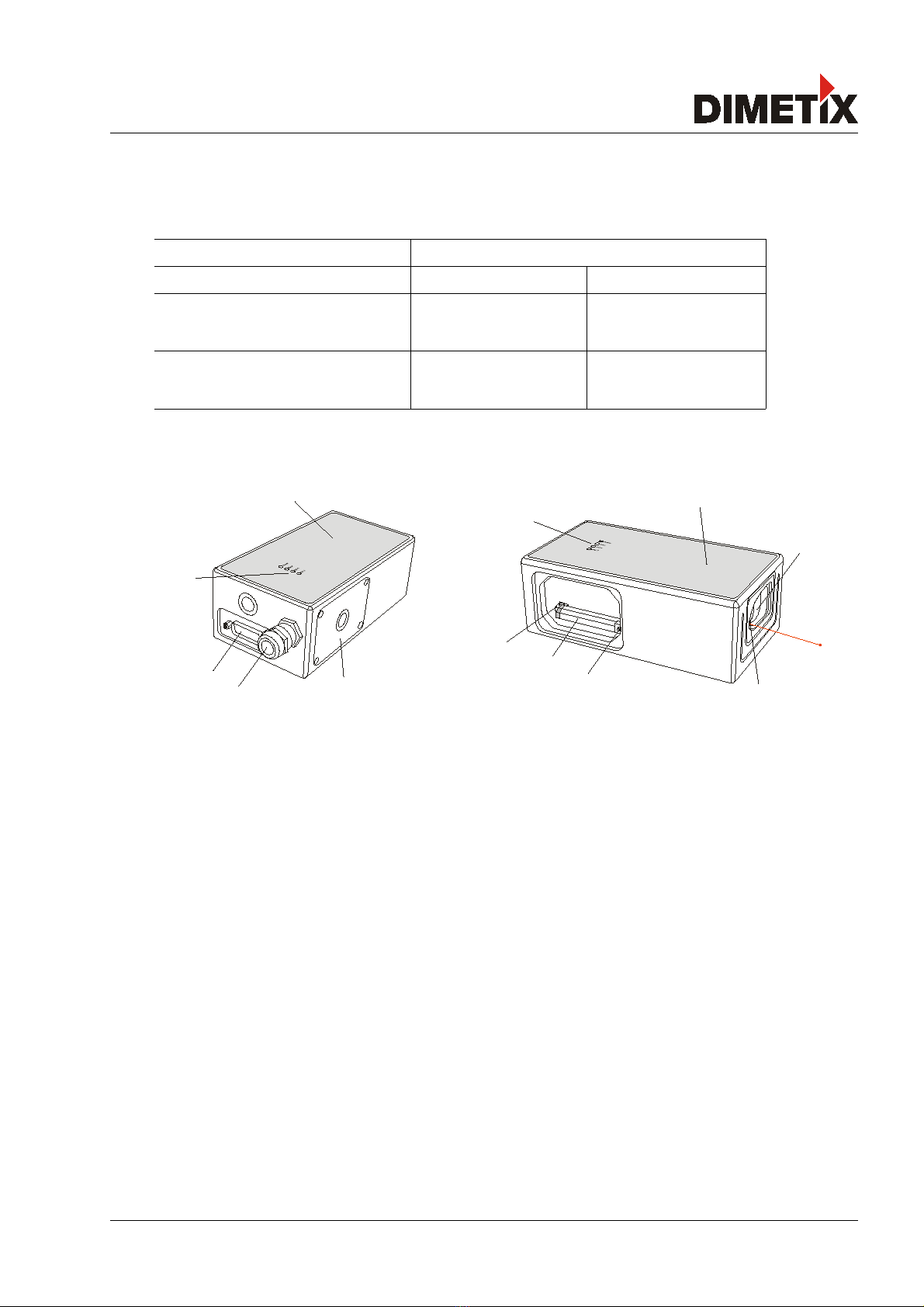

1.1 Product identification

The product is identified by the label on the top of the enclosure:

Version Typical Accuracy

1.5mm 3.0mm

Standard version DLS-B 15

Part No.: 500602

DLS-B 30

Part No.: 500601

Extended temperature range DLS-BH 15

Part No.: 500612

DLS-BH 30

Part No.: 500611

1.2 omponents

1 Status LEDs

status signaling

2 15-Pin D-Sub connector

RS422, RS232, analog, digital output

3 able gland (M16 x 1.5mm)

for connection cable insertion

4 over

provides access to electrical components

5 Reset switch

resets the DLS-B(H) to default settings

6 Screw terminal

RS422, RS232, analog, digital output

7 ID switch

defines the module ID for RS422 operation

8 Laser beam outlet

9 Receiver optics

10 Product label

see 10.9 Labeling on page 42

1.3 Validity

This manual is valid for DLS-B(H) devices with the following software version:

Interface software version: 0100 or later

odule software version: 0100 or later

To get the software version for the DLS-B(H) use the command described in8.3.9 Get Software Version (sNsv) on

page 28

Distance Laser Sensor V1.02 Page 4/43

7

6

5

9

1

8

10

1

2

1

10

4

3

TE HNI AL REFEREN E MANUAL

1.4 Measurement range

The DLS-B(H) is an optical instrument, whose operation is influenced by environmental conditions. Therefore,

the measurement range achieved in use may vary. The following conditions may influence the measurement

range:

Key Factors increasing range Factors reducing range

Target surface Bright and reflective surfaces such as the

target plates (See 9 Accessories on page 35)

att and dark surfaces

Green and blue surfaces

Airborne particles Clean air Dust, fog, heavy rainfall, heavy snowfall

Sunshine Darkness Bright sunshine on the target

The DLS-B(H) does not compensate for the influence of the atmospheric environment, which may be relevant

when measuring long distances (e.g. > 150m). These effects are described in:

B.Edlen: “The Refractive Index of ir, Metrologia 2”, 71-80 (1966)

1.5 Prevention of erroneous measurements

1.5.1 Rough surfaces

On a rough surface (e.g. coarse plaster), measure against the center of the illuminated area. To avoid measuring

to the bottom of gaps in the surface use a target plate (see accessories) or board.

1.5.2 Transparent surfaces

To avoid measuring errors, do not measure against transparent surfaces such as colorless liquids (such as water)

or (dust-free) glass. In case of unfamiliar materials and liquids, always carry out a trial measurement.

Erroneous measurements can occur when aiming through panes of glass,

or if there are several objects in the line of sight.

1.5.3 Wet, smooth, or high-gloss surfaces

1 Aiming at an “acute“ angle deflects the laser beam. The DLS-B(H) may receive a signal that is

too weak (error message 255) or it may measure the distance targeted by the deflected laser beam.

2 If aiming at a right angle, the DLS-B(H) may receive a signal that is too strong (error message 256).

1.5.4 Inclined, round surfaces

easurement is possible as long as there is enough target surface area for the laser spot.

1.5.5 Multiple reflections

Erroneous measurements may occur if the laser beam is reflected by other objects than the target. Avoid any

reflective object along the measurement path.

Distance Laser Sensor V1.02 Page 5/43

TE HNI AL REFEREN E MANUAL

2 Device setup

We recommend that you carry out the configuration steps in an office before mounting the device, especially if

you are not familiar with the DLS-B(H).

The DLS-B(H) supports two types of operating modes:

•Controlled mode

•Automatic mode (for use in stand-alone operation)

The first decision to be taken is the type of operating mode that will be used to transmit the distance

measurement data. While the controlled mode provides maximum flexibility and accuracy, it is often not suitable

for integration into existing PLCs or analog environments. In such cases the automatic mode might be preferred.

Key controlled mode automatic mode

(with analog and/or digital outputs

Accuracy aximum measurement accuracy Accuracy depends on signal scaling

(see 8.3.5 Set/Get distance range (sNv) on page

26)

Flexibility Access to full command set Limited

Integration Requires protocol implementation Wiring of AO and/or DO signals

Connection Connection of up to 10 DLS-B(H)s to a

single RS-422 line.

Point-to-point connection

The following two sections describe the configuration of the DLS-B(H) for the controlled and automatic modes.

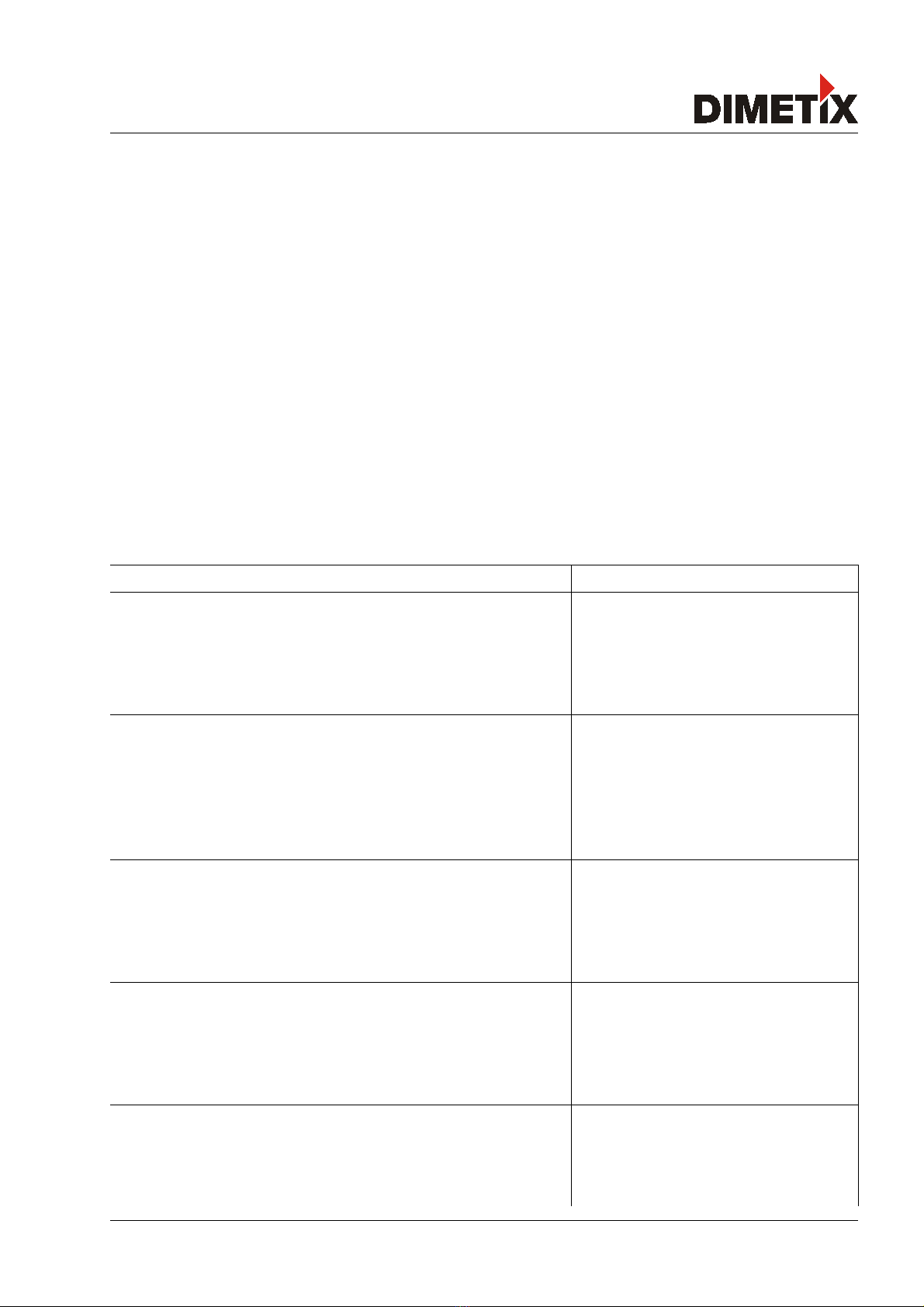

2.1 onnection

To be able to configure the DLS-B(H), it must be powered and connected to a PC. Figure 2 shows the necessary

connections. On the PC, any terminal program can be used to communicate with the module. A configuration

utility is also available on the web page www.dimetix.com.

Distance Laser Sensor V1.02 Page 6/43

Fig. 2 Connection for DLS-B(H) configuration

DLS-B(H)

9 pin

D-Sub

Tx

Gnd

2

5

3

Tx

Rx

2

1

GND

V+

Rx

15 pin

D-Sub

9..30VDC

24..30VDC for Heating option

+-

14,15

7,8

Default setting:

Baud:

Bit:

Parity:

Stop:

19200

7

even

1

CO 1 or CO 2

TE HNI AL REFEREN E MANUAL

2.2 ontrolled mode

In controlled mode, each operation of a DLS-B(H) is triggered by a command sent from a host system over a

serial line. While a single device can be connected to the host system using the RS232 interface, up to 10

devices can be connected to a single serial RS422 line. The related command set is described in Chapter 8 on

page 20.

2.2.1 onfiguration

After connecting the module, the steps below are necessary to configure the DLS-B(H) for the controlled

interface mode.

No. Action Comment Command

1 Set ID switch Changes to the module ID are activated

after a power cycle.

Example for module 0:

Change the ID Switch to position 0

Set ID switch to position 0

Power OFF; Wait 10s; Power ON

2

Set controlled mode Set the DLS-B(H) to the controlled

mode, if not already in controlled

mode.

Example for module 0:

Set to controlled mode by means of the

stop command.

s0c<trm>1)

3

Set communication

parameters

If necessary, change the settings for the

serial interface.

Example for module 0:

Set serial interface to 19200 Baud, 8

Bit, no Parity

s0br+2<trm>1)

Power OFF; Wait 10s; Change settings

on the host; Power ON

1) Commands are described in 8 Command set on page 20

Note: If the communication parameters of the module are lost, please reset the configuration to the

factory settings (7 Factory settings on page 19) using the reset button (5.2 Reset switch on page

16). Please note that the ID switch must be reset manually.

2.2.2 Host software

Host software is required for operation of the DLS-B(H) in controlled mode. When connecting multiple devices

to a single serial line (RS422), strict aster-Slave communication must be implemented (DLS-B(H) operates as

slave). For software sample-code or application-notes please consult our web site www.dimetix.com.

Careful testing of the host software together with the devices prior to installation is strongly recommended.

Distance Laser Sensor V1.02 Page 7/43

TE HNI AL REFEREN E MANUAL

2.3 Automatic mode

A automatic mode is provided for host-less operation of the DLS-B(H). The analog and digitals outputs are

updated according the configuration described below as soon as the unit is powered up.

nalog Output

The analog output is configurable and works with two ranges:

–0..20mA

–4..20mA

Digital Outputs

Three digital outputs are included in the DLS-B(H). Two are programmable, while the third is used to

signal an error state of the device.

2.3.1 onfiguration

After connecting the module, the following steps are necessary to configure the DLS-B(H) for automatic mode.

No. Action Comment Command

1

Set current output

range

Defines the current output range

from 0 to 20mA or from 4 to 20mA.

Example for module 0:

Set current output range from 4mA

to 20mA.

s0vm+1<trm>1)

2

Set distance range Defines minimum distance (Dmin)

and the maximum distance (Dmax)

for the distance range of the analog

output.

Example for module 0:

Set distance range from 0m to 10m

s0v+00000000+00100000<trm>1)

3

Set analog output in

case of an error

Sets the current that should be

applied in case of an error.

Example for module 0:

Set current to 0mA in case of an

error.

s0ve+000<trm>1)

4

Configure digital

output

Set the ON and OFF level for the

digital outputs.

Example for module 0:

DO 1: off=2000mm on=2005mm

DO 2: off=4000mm on=4005mm

s01+00020000+00020050<trm>1)

s02+00040000+00040050<trm>1)

5

Save settings The changed configuration must be

saved to make it permanent.

Example for module 0:

Save settings for module 0

s0s<trm>1)

Distance Laser Sensor V1.02 Page 8/43

TE HNI AL REFEREN E MANUAL

No. Action Comment Command

6

Set automatic mode Set the DLS-B(H) to the automatic

mode with the desired update rate.

Example for module 0:

Set measurement rate to fastest

possible speed.

s0A+0<trm>1)

1) Commands are described in 8 Command set on page 20

Node: If the serial line settings of the module have been lost, please reset the configuration to the factory

settings (7 Factory settings on page 19) using the reset button (5.2 Reset switch on page 16). Please

note that the ID switch must be reset manually.

2.4 Display Mode

If Display ode is enabled, the DLS-B(H) formats the measured distance as ASCII string, which is understood by

External Displays with a serial interface. Since the DLS-B(H) outputs this formatted string automatically on the

serial interface after completing a measurement. easurement results can be displayed on an external display

without an additional controller.

For a detailed description of this mode, please contact Dimetix or your dealer.

Distance Laser Sensor V1.02 Page 9/43

2

1

Rx

Tx

m

GND

14,15

RS232 or RS422

TE HNI AL REFEREN E MANUAL

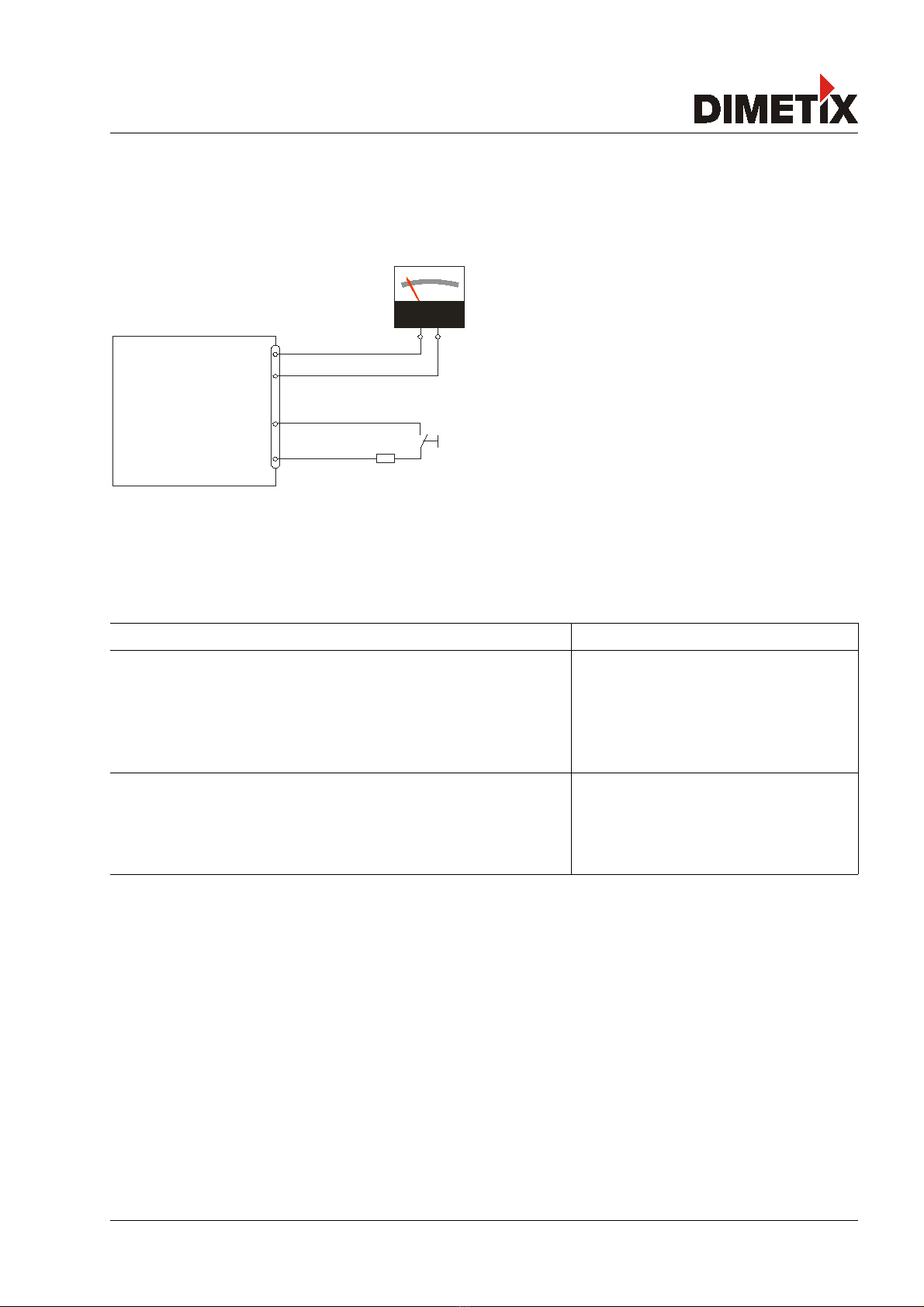

2.5 External Trigger

The DLS-B(H) includes the option of triggering measurements with an external switch or push button on Digital

Input 1 (DI 1). Using the Digital Input DI 1 disables the Digital Output DO 1.

The command to activate the external trigger option is described in 8.4 Digital Input on page 30.

2.5.1 onfiguration

After connecting the DLS-B(H), the following steps are necessary to activate the external trigger. The example

shows the configuration for triggering a single distance measurement.

No. Action Comment Command

1

Activate digital input

DI1

Defines the action for a trigger

event on DI1.

Example for module 0:

Configure DI1 to trigger a single

distance measurement.

s0DI1+2<trm>1)

5

Save settings The changed configuration must be

saved to make it permanent.

Example for module 0:

Save settings for module 0

s0s<trm>1)

1) Commands are described in 8 Command set on page 20

Distance Laser Sensor V1.02 Page 10/43

12

13

AO

AGND

DO/DI 1

V+

7,8

9

1k

DLS-B(H)

TE HNI AL REFEREN E MANUAL

3 Installation

3.1 Mounting

Three 4 threaded holes in the bottom of the DLS-B(H) make it easy to mount the device.

Always obey all applicable safety regulations and never use the device outside the specifications stated under

4 Technical data on page 14

3.2 Device wiring

3.2.1 Power Supply

For trouble-free operation use a separate power supply for the DLS-B(H).

DLS-B: 9...30V, 0.5A DC

DLS-BH: 24...30V, 2.5A DC

3.2.2 able connection

A ferrite core must be fitted to the connecting cable. Use a ferrite core with an impedance of 150 Ω to 260 Ω

at 25 Hz and 640 Ω to 730 Ωat 100 Hz. For example you can use KCF-65 from KE Kitagawa.

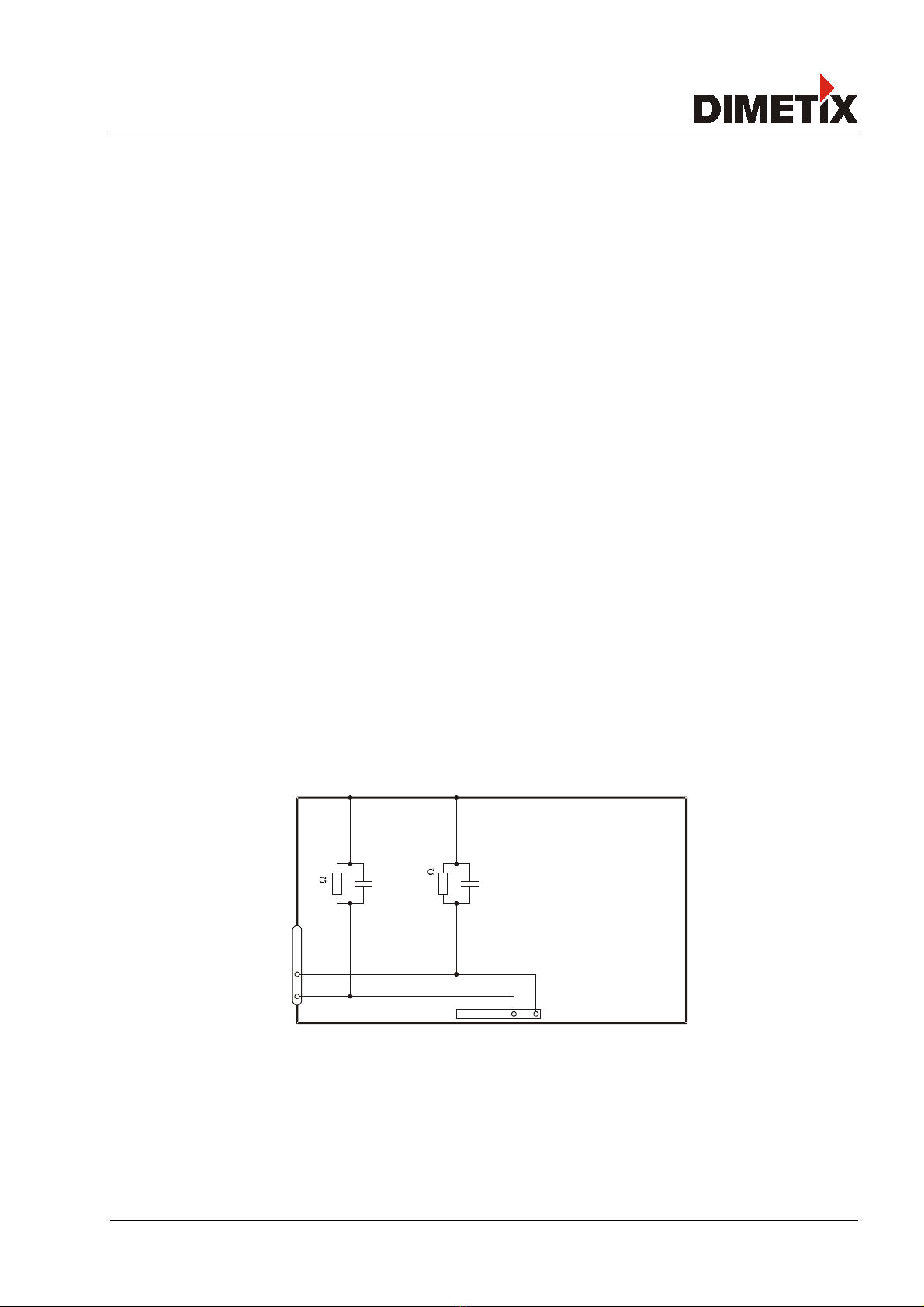

3.2.3 Shield and Ground

The DLS-B(H) contains two electrically isolated grounds, the general ground (GND) and the analog ground

(AGND). GND and AGND are connected to the housing by a RC element. Please see figure 5

Distance Laser Sensor V1.02 Page 11/43

DLS-B(H)

Screw terminal

GND

AGND

15 pin D-Sub

GND

AGND

20nF

1

10nF

500k

TE HNI AL REFEREN E MANUAL

3.2.4 ontrolled mode

RS232

Only point-to-point communication is possible when using the RS232 interface.

❢Never connect multiple DLS-B(H)s on a RS232 serial line

RS422

It is possible to connect multiple devices on a single RS422 line. To ensure proper operation, strict aster-Slave

communication must be applied. It is important, that the aster has full control of the communication and

never initiates a new communication before termination of the previous communication (answer from the DLS-

B(H) or timeout).

❢Ensure, that all DLS-B(H)s are set to different ID numbers

Distance Laser Sensor V1.02 Page 12/43

Tx

Host

(PC or PLC)

Rx

TxRx

2

7,8

1

14,15

V+

9..30VDC

24..30VDC with Heating

0V

R+

R-

T+

T-

ID switch

Position 0

A

B

A

B

Host

(PC or PLC)

R

t

R

t

5

4

6

3

14,15

R

t

R

t

7,8

V+

R+

R-

T+

T-

ID switch

Position 1

5

4

6

3

14,15

7,8

V+

R+

R-

T+

T-

ID switch

Position 9

5

4

6

3

14,15

7,8

V+

9..30VDC

24..30VDC with Heating

0V

(slave) (slave) (slave)

(master)

DLS-B(H)

DLS-B(H) DLS-B(H) DLS-B(H)

TE HNI AL REFEREN E MANUAL

3.2.5 Automatic mode

The analog interface of the DLS-B(H) is isolated from the rest of the device. When using the analog interface,

connect the analog ground (AGND).

ake sure, that the total resistance in the analog path is lower than 500 Ω.

3.3 Alignment of the laser beam

Alignment of the laser beam is often difficult when the target is far away, as the laser spot is not visible. An

optional telescopic viewfinder is available which simplifies alignment significantly. Please refer to chapter 9

ccessories on page 35 for a description of the viewfinder.

Distance Laser Sensor V1.02 Page 13/43

DLS-B(H)

Analog Input

0..20mA

12

14,15

13

Digital Input

24V=

9..30VDC

24..30VDC for Heating Option

0V

PLC

AO

AGND

DO 1

DO 2

V+

GND

7,8

9

10

TE HNI AL REFEREN E MANUAL

4 Technical data

4.1 Measuring accuracy

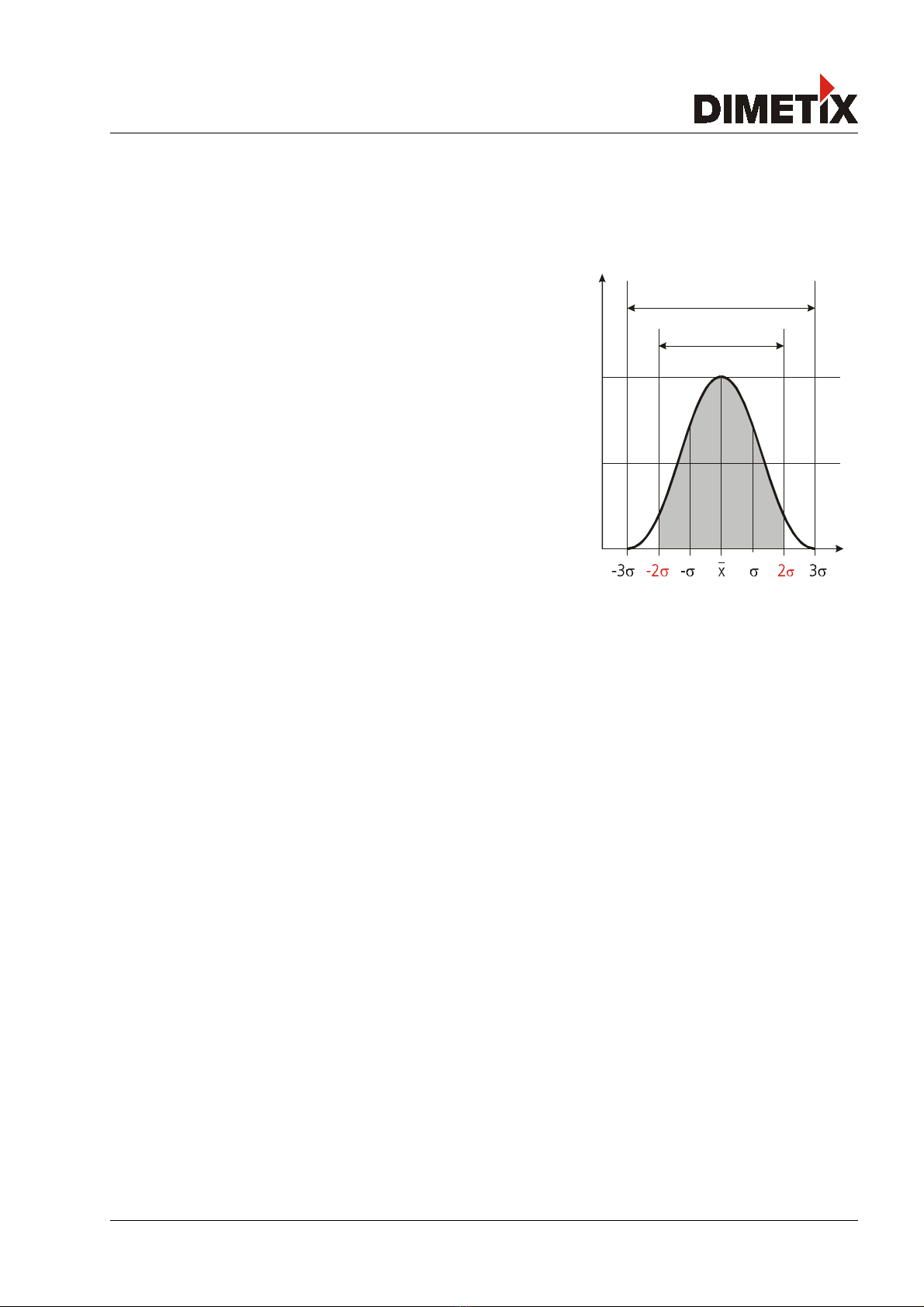

The measuring accuracy corresponds to the ISO-recommendation ISO/R

1938-1971 with a statistical confidence level of 95.4% (i.e. ± twice the

standard deviation σ, refer to diagram on the right). The typical

measuring accuracy relates to average conditions for measuring. It is

±1.5mm for the DLS-B(H) 15 and ± 3.0mm for the DLS-B(H) 30 valid in

the tracking mode

The maximum measuring error relates to unfavorable conditions such

as:

- Highly reflective surfaces (e.g. reflector tapes)

- Operation at the limits of the permitted temperature range,

adaptation to ambient temperature canceled

- Very bright ambient conditions, strong heat shimmer

and can be up to ± 2 mm for DLS-B(H) 15 and ± 5 mm for DLS-B(H) 30. The DLS-B(H) does not compensate

changes of atmospheric environment. These changes can influence the accuracy if measuring long distances

(>150m) under conditions very different from 20°C, 60% relative humidity and 953 mbar air pressure. The

influences of the atmospheric environment are described in

B.Edlen: “The Refractive Index of ir, Metrologia 2”, 71-80 (1966)

Distance Laser Sensor V1.02 Page 14/43

99.7%

95.4%

TE HNI AL REFEREN E MANUAL

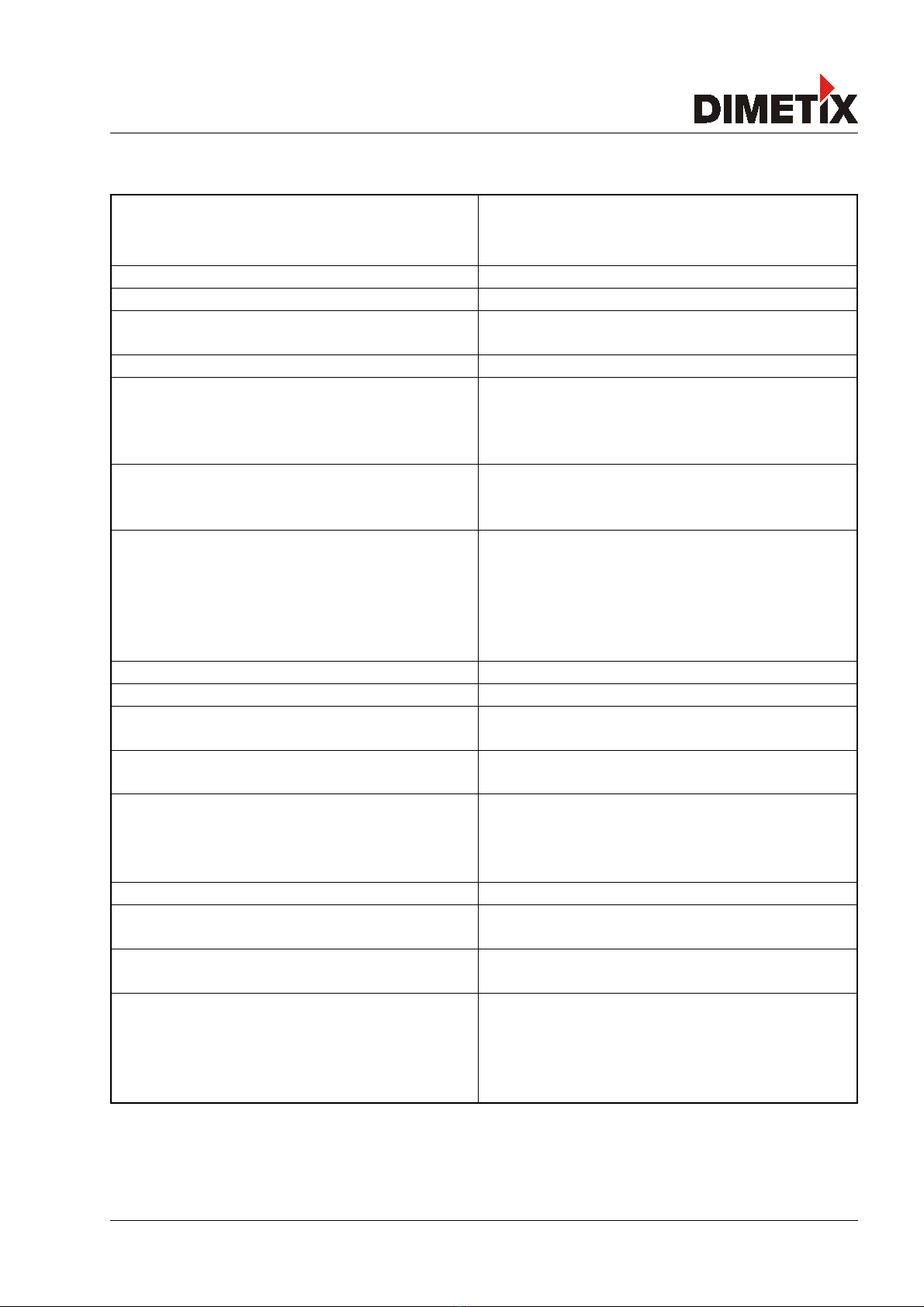

4.2 Specifications

Typical measuring accuracy for

DLS-B 15 / DLS-BH 15 1)

DLS-B 30 / DLS-BH 30 1)

± 1.5 mm @ 2σ

± 3.0 mm @ 2σ

Smallest unit displayed 0.1 mm

easuring range on natural surfaces 0.05 to approx. 65 m

easuring range on orange (reflective) target plate.

See chapter 9.2 Target plates on page 35.

0.05 to 500 m

easuring reference from front edge (See 6 Physical dimensions)

Diameter of laser spot at target at a distance of 4mm @ 5 m

8mm @ 10m

approx. 28mm*14mm @ 50m

approx. 40mm*25mm @ 100 m

Time for a measurement

Single measurement

Tracking

0.15 to approx. 4 sec

0.15 to approx. 4 sec

Light source Laser diode 620-690 nm (red)

IEC 60825-1:2001; Class 2

FDA 21CFR 1040.10 and 1040.11

Beam divergence:0.16 x 0.6 mrad

Pulse duration: 0.45x10-9 s

aximum radiant power: 0.95 mW

Laser Life Time > 50'000h @ 20°C

ESD IEC 61000-4-2 : 1995 +A1 +A2

E C EN 61000-6-4

EN 61000-6-2

Power supply 9 ... 30V DC 0.5A for DLS-B

24 ... 30V DC 2.5A for DLS-BH (Heating option)

Dimensions 150 x 80 x 55 mm

Temperature range during operation 2)

DLS-B 15 / DLS-B 30

DLS-BH 15 / DLS-BH 30

-10 °C to +50 °C

-40 °C to +50 °C

Temperature range during storage -40 °C to +70 °C

Degree of Protection IP65; IEC60529 (protected against ingress of dust and

water)

Weight DLS-B(H): 665 g

DLS-B(H): 690 g

Interface 1 serial asynchronous interface (RS232/RS422)

1 programmable analog output 0/4 .. 20mA

2 programmable digital outputs

1 programmable digital input

1 digital output for error status

1) See 4.1 easuring accuracy on page 14.

2) In case of permanent continuous measurement (tracking mode) the max. temperature is reduced to 45°C

Distance Laser Sensor V1.02 Page 15/43

TE HNI AL REFEREN E MANUAL

5 Electrical components

5.1 ID switch

This switch is used to set the module ID and can be set from 0 to 9. Default setting is 0.

5.2 Reset switch

To reset the module to factory settings do the following:

•Switch OFF the power for the module

•Press the reset button and keep it pressed

•Switch on the power for the module

•Keep the reset button pressed until all LEDs on the module are illuminated

•Release the reset button.

•Switch the power OFF and wait 5 seconds.

•Switch on the power and wait until the green power LED is on.

5.3 Digital output

The DLS-B(H) contains two digital outputs for level monitoring (DO 1 and DO 2)

and one digital output for error signalization (DO E). These outputs are open drain

outputs as shown in figure 7 and can drive up to 200mA. aximum switching

voltage is 30V DC. In the ON state, the FET transistor is electro conductive.

5.4 Digital Input

The Digital Output (DO 1) can be configured as a Digital Input (DI 1). This is useful for triggering measurements

by means of an external switch or push button. Please refer to chapter 8.4 Digital Input on page 30.

Low Level is: U DI1 < 2VDC

High Level is: U DI1 > 9VDC and U DI1 < 30VDC

5.5 Analog output

The analog output of the DLS-B(H) is a current source (0..20mA or 4..20mA). It is capable of driving loads up to

500Ω. The analog output has an accuracy of +/- 1% Full scale.

e.g. The configured measurement range is 0...20m and the actual measured distance is 14m. This results in a

measurement uncertainty of ± 0.2m (1% of 20m), which includes all parameters (temperature drift,

sensor accuracy, linearity, target color etc.). The uncertainty decreases, if the ambient temperature is

stable.

Distance Laser Sensor V1.02 Page 16/43

Fig. 7 Open drain output

uMax=max. uncertainty

Conf MaxDist =DDistance programmed for the maximum output current

Conf MinDist =DDistance programmed for the minimum output current

uMax=Range

100 =Conf MaxDist−Conf MinDist

100

DOUT

On

TE HNI AL REFEREN E MANUAL

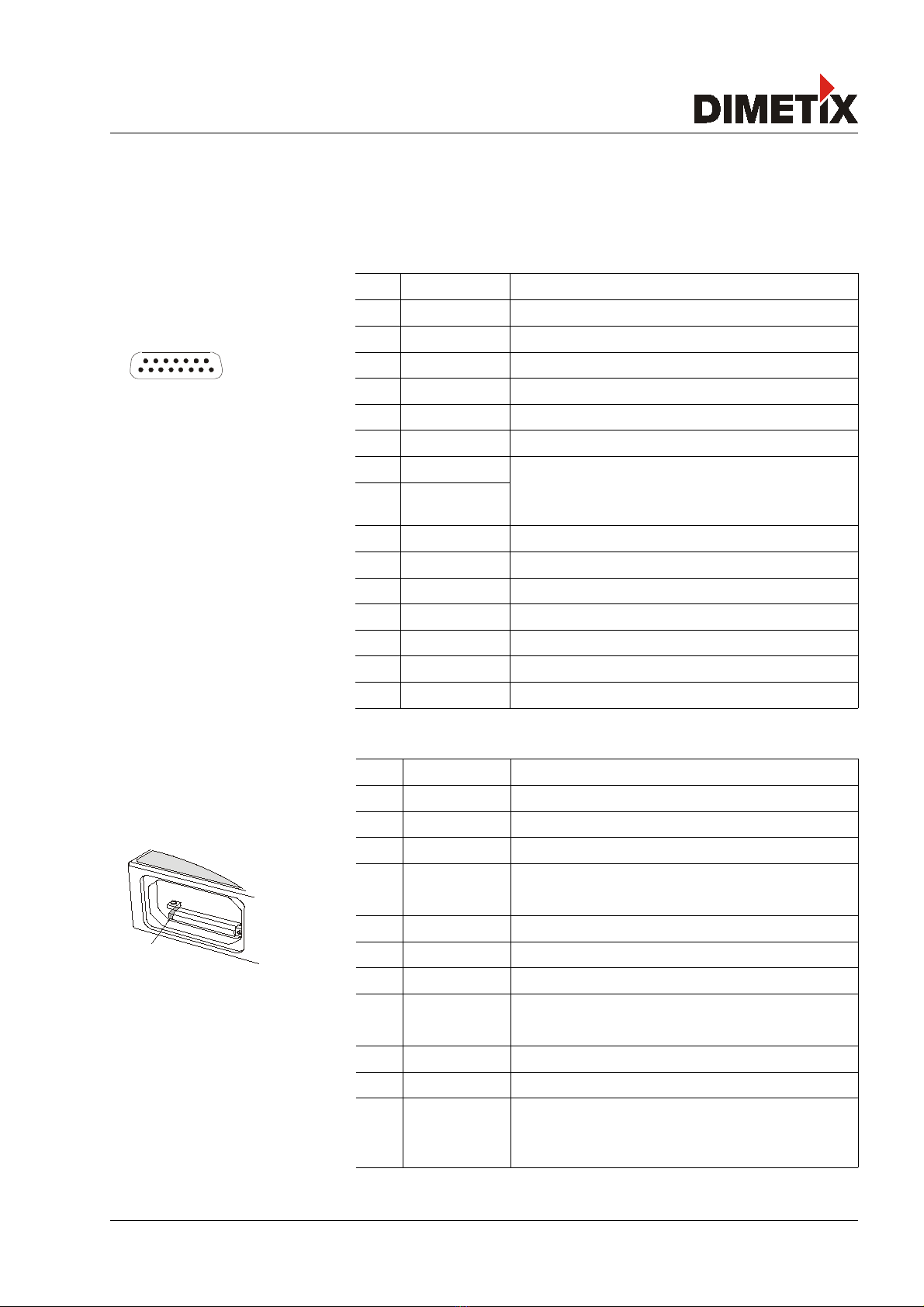

5.6 onnector

5.6.1 D-Sub connector

Pin Designator Description

1 Rx RS232 receive line

2 Tx RS232 send line

3 T- RS422 send line negative

4 T+ RS422 send line positive

5 R- RS422 receive line negative

6 R+ RS422 receive line positive

7 PWR

8 PWR

DC Power

+ 9V…+30V for DLS-B

+24V…+30V for DLS-BH (Heating option)

9 DO 1 Digital output 1 (Open Drain) or Digital input 1

10 DO 2 Digital output 2 (Open Drain)

11 DO E Digital output for error signalization (Open Drain)

12 AGND Analog ground

13 AO Analog output (0/4..20mA)

14 GND Ground line

15 GND Ground line

5.6.2 Screw terminal

Pin Designator Description

1 R+ RS422 Receive line positive

2 R- RS422 Receive line negative

3 T+ RS422 Send line positive

4 T- RS422 Send line negative

5 Tx RS232 Transmit line

6 Rx RS232 Receive line

7 AGND Analog ground

8 AO Analog output (0/4..20mA)

9 DO E Digital output for error signalization (Open Drain)

10 DO 2 Digital output 2 (Open Drain)

11 DO 1 Digital output 1 (Open Drain) or Digital input 1

12 GND Ground line

13 PWR Power DC

+9V...+30V DLS-B

+24...+30V DLS-BH (Heating option)

Distance Laser Sensor V1.02 Page 17/43

No.1

1

9

15

8

TE HNI AL REFEREN E MANUAL

6 Physical dimensions

All dimension in mm

Distance Laser Sensor V1.02 Page 18/43

150.0

38.5

88.5

easuring reference

= =

3 x 4 x 5

54.0

80.0

16 x 1.5

40.0

= =

152.5

80.0

Laser Beam

32.2

28.5

36.0

14.5

TE HNI AL REFEREN E MANUAL

7 Factory settings

7.1 Operation

ode: Controlled ode

7.2 ommunication parameters

Baud: 19200

Data bit: 7

Parity: Even

Stop bit: 1

7.3 Analog outputs

in output: 4mA

Range min: 0m

Range max: 10m

Error output: 0mA

7.4 Module ID

ID Number: 0

7.5 Digital output 1 (DOUT1)

ON: 2m + 5mm = 2005mm

OFF: 2m - 5mm = 1995mm

7.6 Digital output 2 (DOUT2)

ON: 1m – 5mm = 995mm

OFF: 1m + 5mm = 1005mm

7.7 Digital input 1 (DI1)

Inactive, configured as output

7.8 User distance offset

User distance offset = 0mm

Distance Laser Sensor V1.02 Page 19/43

TE HNI AL REFEREN E MANUAL

8 ommand set

8.1 General

8.1.1 ommand termination <trm>

All commands for the DLS-B(H) are ASCII based and terminated <trm> with <cr><lf>.

8.1.2 Module identification N

Since the module can be addressed with the ID switch, the ID is represented in the commands by N. At the

location of the N insert the odule ID.

8.1.3 Parameter separator

The command syntax uses the '+' sign as parameter separator. The '+' sign can be replaced by the minus '-'

sign if applicable by the command.

8.1.4 Set/Get ommands

All configuration commands that are used to set configuration values can also be used to read the currently set

value by omitting the parameter. The command syntax is described as follows:

Set ommand Get ommand

Command sNuof+xxxxxxxx<trm> sNuof<trm>

Return successful gNof?<trm> gNuof+xxxxxxxx<trm>

Return Error gN@Ezzz gN@Ezzz

Parameters Nodule ID

xxxxxxxx Offset in 1/10 mm; + positive / - negative

zzz Error code

8.1.5 Startup sequence

After power on the DLS-B(H) does all the initializations and sends a start sequence gN?. On this sequence, the

N stands for the odule ID. After sending this start sequence, the DLS-B(H) is ready to use.

Distance Laser Sensor V1.02 Page 20/43

This manual suits for next models

3

Table of contents

Other Dimetix Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Levitronix

Levitronix LEVIFLOW LFSC-D Series user manual

Teledyne

Teledyne HASTINGS 2002 instruction manual

Michelin

Michelin 12290 Operation instructions

Anritsu

Anritsu MS9740B Operation manual

ADS

ADS Intrinsically-Safe TRITON+ Installation, operation and maintenance manual

Cocraft

Cocraft HD400 Original instructions