Dimetix FLS-C Installation and operating instructions

Application Note

AN2019

Moving Target Characteristic with SSI

FLS-C

Abstract

The “Moving target characteristic” is made for fast position measuring on continuous moving targets. This

document describes the necessary settings of the FLS-C sensor for the "Moving target characteristic" as well as

the configuration of the SSI and Analog interface.

V1.00

Please check www.dimetix.com

for the latest version

This application note is provided as is without any warranty for any problems this sample may cause.

Dimetix AG, Degersheimerstrasse 14, CH-9100 Herisau, Switzerland

Phone: +41 71 353 0000, Fax: +41 71 353 0001, E-mail: info@dimetix.com

©

Copyright by Dimetix AG

www.dimetix.com

Laser Distance Sensors

Table of Contents

1 Introduction...................................................................................................................................................................................................3

1.1 Feedback positioning...........................................................................................................................................................................3

1.2 Usable sensors.....................................................................................................................................................................................3

2 Preparation....................................................................................................................................................................................................4

2.1 Connect DLS/FLS UtilitySW with the FLS-C...........................................................................................................................................5

3 Measurement characteristic configuration.....................................................................................................................................................6

4 Interface setup..............................................................................................................................................................................................7

4.1 General................................................................................................................................................................................................7

4.2 SSI........................................................................................................................................................................................................7

4.2.1 Configuration of the SSI output..................................................................................................................................................7

4.2.2 Wiring........................................................................................................................................................................................8

4.3 Analog / Digital....................................................................................................................................................................................9

4.3.1 Configuration of the analog output............................................................................................................................................9

4.3.2 Configuration of the digital output...........................................................................................................................................10

4.3.3 Wiring......................................................................................................................................................................................10

5 Measurement mode....................................................................................................................................................................................11

5.1 Auto start..........................................................................................................................................................................................11

5.2 Manual start......................................................................................................................................................................................12

5.2.1 Digital input connection...........................................................................................................................................................12

Moving Target Characteristic with SSI AN2019 Page 2 of 12

Laser Distance Sensors

1Introduction

Different measurement characteristics are implemented into the FLS-C. This measurement characteristics provide

the necessary flexibility to configure the FLS-C for various applications.

The FLS-C laser distance sensor is able to measure continuous moving targets with a speed of 200Hz, as long as

there are no distance jumps. While the FLS-C is measuring with 200Hz the “SSI” interface is the best choice to

transfer the measured results to the host system. This digital interface is fast and has no additional noise.

In addition the analog output is updated with 200Hz also.

The disadvantage of the analog interface is the accuracy, that depends on the configured distance range. In

addition noise will be added to the analog signal.

This document describes the configuration and connection of the FLS-C for the use with the “Moving target

characteristic” with SSI. While this document provides step by step configuration instructions, the Technical

Reference Manual gives a more detailed description.

1.1 Feedback positioning

Fig. 1 shows a typical positioning application, that uses “Moving target characteristic”. In this application, the

FLS-C laser distance sensor measures absolute distances, that can be used as real time feedback for the position

controller implemented in the drive.

Ensure that no distance jumps occur in order to use the “Moving target characteristic”.

1.2 Usable sensors

The following sensors can be used for such kind of applications.

Sensor Part No Short description

FLS-C 10 600502 Distance sensor with an accuracy of +/-1mm, max Distance 500m, Temperature range -10..+50°C

FLS-C 30 600501 Distance sensor with an accuracy of +/-3mm, max Distance 500m, Temperature range -10..+50°C

FLS-CH 10 600504 Distance sensor with an accuracy of +/-1mm, max Distance 500m, Temperature range -40..+50°C

FLS-CH 30 600503 Distance sensor with an accuracy of +/-3mm, max Distance 500m, Temperature range -40..+50°C

Moving Target Characteristic with SSI AN2019 Page 3 of 12

Laser Distance Sensors

Fig. 1: Positioning application with feedback controller

Position

SSI

Field

bus

PLC Drive

Encoder

2 Preparation

1. The following items are needed to do the configuration of the FLS-C.

•RS-232 Configuration cable FLS / DLS (Part no. 500200)

•24V DC Power supply

2. Download the DLS/FLS UtilitySW from the website http://www.dimetix.com/UtilitySW/ and install it on a PC.

3. Connect the FLS-C sensor to the PC and to the 24V DC Power supply as shown in Fig 2.

4. Start the DLS/FLS UtilitySW on the PC.

Moving Target Characteristic with SSI AN2019 Page 4 of 12

Laser Distance Sensors

Fig. 2: Configuration connection

9 pin

D-Sub

Tx

Gnd

2

5

3

Tx

Rx

2

1

GND

V+

Rx

15 pin

D-Sub

9..30VDC

24..30VDC for Heating option

+

-

14,15

7,8

Defaultsetting:

Baud:

Bit:

Parity:

Stop:

19200

7

even

1

COM1 or COM2

2.1 Connect DLS/FLS UtilitySW with the FLS-C

After start-up of the DLS/FLS UtilitySW the window shown in Fig. 3 is visible. Set the “Communication

parameters” corresponding to the connection of the FLS-C sensor and press the “CHECK CONNECTION”

button.

Fig. 3: Start window of the DLS/FLS UtilitySW

After the DLS/FLS UtilitySW connected successfully to the FLS-C sensor, the “Software version and serial

number” section is updated as shown in Fig. 4. Further the “Status:” field at the bottom will show “OK”. If the

DLS/FLS UtilitySW does not show the described information, the connection with the FLS-C is not done properly.

If the connection is not done properly, press the reset button and follow the description to reset the sensor. Then

make sure that the Port setting is correct and press the “CHECK CONNECTION” Button again.

Fig. 4: Start window after "CHECK CONNECTION" procedure

Moving Target Characteristic with SSI AN2019 Page 5 of 12

Laser Distance Sensors

3 Measurement characteristic configuration

Activate the “Moving target characteristic” to be able to measure with 200Hz. To do so, change to the

“Configuration” tab and select the “Measurement characteristic” sub tab on the left, check “Moving target”

and press the “DOWNLOAD TO DEVICE” button. Fig. 5 shows the mentioned settings.

Moving Target Characteristic with SSI AN2019 Page 6 of 12

Laser Distance Sensors

Fig. 5: Configuration of the “Moving target characteristic”

4 Interface setup

4.1 General

While the FLS-C measures with “Moving target characteristic” the measured distances are available on all

interfaces. The following examples show the use of different interfaces.

4.2 SSI

The FLS-C device contains a SSI interface, that operates as SSI slave. This interface shares the connection pins

with the integrated RS422 interface. Hence the RS422 and the SSI interface can not be used at the same time.

While the FLS-C device is a SSI-slave the host has to be the SSI-master, which generates the clock.

Never connect the FLS-C to a SSI master before the interface is configured as SSI.

Always configure the interface before connecting to the master.

4.2.1 Configuration of the SSI output

On the “Configuration” tab, select the “SSI” sub tab on the left. In the “4-pole serial port usage sNSSI” area

select SSI to deactivate the RS-422 interface and activate the SSI interface and set the SSI configuration

corresponding to the configuration of the SSI master.

Further define the output value in case of an error as shown in Fig. 6. After configuring all options press the

“DOWNLOAD TO DEVICE” button to save the settings in the FLS-C.

Data format

The following figure shows the format of the output with the maximum length. Error code and Error bit can be

switched of and the data can be reduced to 23 bit. The data can be either binary or gray coded.

Data (24 Bit binary/gray)

Error code (binar

y/g

ray)

Error bit

MSB ff LSB MSB LSB

23222120191817161514131211109876543210765432100

Error behavior

In case of an error the data field contains a replacement value, the last valid distance or the error code,

depending on the configuration.

Moving Target Characteristic with SSI AN2019 Page 7 of 12

Laser Distance Sensors

Fig. 6: SSI interface configuration

SSI configuration

4.2.2 Wiring

Never connect the FLS-C to a SSI master before the interface is configured as SSI.

Always configure the interface before connecting to the master.

Connect the SSI interface to the SSI master as shown in Fig. 7. As soon as the master activates the clock, the FLS-

C returns the SSI data. For more detailed information about the SSI interface see the Technical Reference Manual

and AN2002 FLS-C SSI Interface.

Moving Target Characteristic with SSI AN2019 Page 8 of 12

Laser Distance Sensors

Fig. 7: SSI interface connection

Clock+

SSI clock

SSI data

R+

R-

T+

T-

5

4

6

3

7,8

V+

(SSI Clock in +)

(SSI Clock in -)

(SSI data out +)

(SSI data out -)

14,15

0V

Vcc

twisted pair

connection

GND

SSI master

(i.e. controller)

SSI slave

FLS-C(H)

Clock-

Data+

Data-

Terminal

4.3 Analog / Digital

The analog and digital outputs are updated after each measurement executed by the FLS-C. The scaling of the

analog output and the switching limits of the digital outputs can be configured with the DLS/FLS UtilitySW.

4.3.1 Configuration of the analog output

In the DLS/FLS UtilitySW select the “Configuration” tab and open the “Analog output” sub tab on the left. Fig. 8

shows the configuration of the analog output for the following settings.

Distance Current Situation Current

10m 20mA Error 2mA

0m 4mA Cable break 0mA

After setting the values as shown in Fig 8 press the “DOWNLOAD TO DEVICE” button to save the configuration

in the FLS-C.

Moving Target Characteristic with SSI AN2019 Page 9 of 12

Laser Distance Sensors

Fig. 8: Analog output configuration

4.3.2 Configuration of the digital output

Fig. 9 shows a possible configuration of the digital outputs. In this example, the digital output 2 will switch off, if

the distance is over 1005mm and switch on if below 995mm, hence the hysteresis is 10mm.

On the “Configuration” tab, select the “Digital output” sub tab on the left and set the values as shown in Fig. 9.

After configuring all options press the “DOWNLOAD TO DEVICE” button to save the settings in the FLS-C.

If you use manual start (see 5.2 Manual start), digital output 1 can not be used, since this pin will be used as

digital input to trigger the measurement.

4.3.3 Wiring

Fig 10 shows how to connect the analog and digital output.

If you use “Manual start” configuration (see 5.2 Manual start) do not use DO1 as output.

Moving Target Characteristic with SSI AN2019 Page 10 of 12

Laser Distance Sensors

Fig. 10: Analog and digital output connection

Fig. 9: Digital output configuration

12

14,15

13

24V=

9..30VDC

24..30VDC for Heating Option

0V

AO

AGND

DO 2

V+

GND

7,8

10

FLS-C

5 Measurement mode

After the configuring the “Measurement characteristic” and the interfaces, the start for the measurement must

be set up. The table below outlines the two different possibilities.

Auto start Manual start

The FLS-C is configured to start measuring after power

on automatically.

The FLS-C is configured to start measuring depending

on the signal on the digital input.

5.1 Auto start

Use this configuration if the sensor should start measuring automatically after every power on.

In the “Stand-alone Mode” tab, select “Auto start configuration” sub tab on the left. As shown in Fig. 11, check

the “ON” box and set the “Sample time” input field to 0 sec for fastest possible measurement.

As soon as you press the “DOWNLOAD TO DEVICE” button, the device starts to measure. Now the FLS-C is

configured to start measuring every time after power on.

Moving Target Characteristic with SSI AN2019 Page 11 of 12

Laser Distance Sensors

Fig. 11: Auto start configuration

5.2 Manual start

In Manual start operation, the measurement is controlled be the digital input of the FLS-C. The function of the

digital input can be configured with the DLS/FLS UtilitySW as shown in Fig. 12.

On the “Stand-alone Mode” tab, select the sub tab “Manual start configuration”, select “Active” in the “Digital

input DI1 sNDI1” area. Additionally select “Start / Stop single sensor tracking”. Then press the “DOWNLOAD TO

DEVICE” button. Now the sensor starts measuring when the digital input goes to high level and stops measuring

if the digital input goes to low level.

5.2.1 Digital input connection

After the digital input is configured and connected as shown in Fig. 13, the measurement of the sensor can be

controlled with an external switch or relays.

Moving Target Characteristic with SSI AN2019 Page 12 of 12

Laser Distance Sensors

Fig. 13: Digital input wiring

Fig. 12: Manual start configuration (Digital input)

DO 1/DI

V+

7,8

9

1kW

FLS-C

Table of contents

Other Dimetix Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Chopin

Chopin AlveoPC Maintenance manual

Binding Union

Binding Union METER 44 Technical manual

Keysight

Keysight N7744A user guide

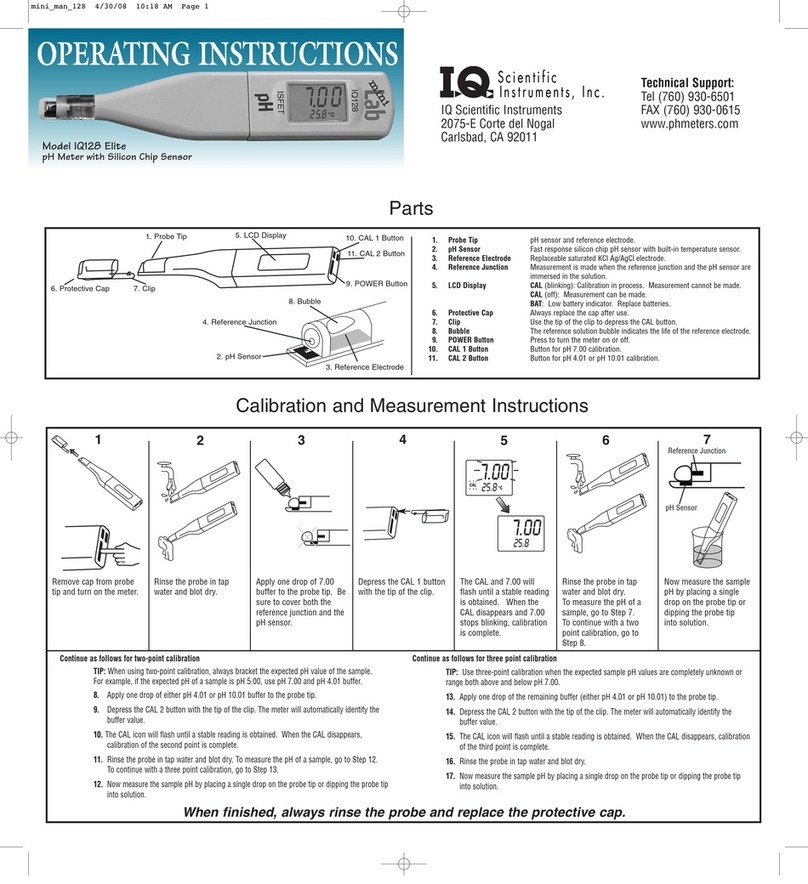

IQ Scientific Instruments

IQ Scientific Instruments miniLab IQ128 Elite operating instructions

Fluidwell

Fluidwell F014-P user manual

Hanna Instruments

Hanna Instruments HI781 user manual