Dimetix DLS-C 15 Product manual

TECHNICAL REFERENCE MANUAL

Ta le of Contents

1 Introduction...................................................................................................................................................................................................4

1.1 Product identification...........................................................................................................................................................................5

1.2 Components........................................................................................................................................................................................5

1.3 Validit .................................................................................................................................................................................................5

2 Application examples....................................................................................................................................................................................6

2.1 Serial interface RS-232 / RS-422...........................................................................................................................................................6

2.2 Analog and digital output....................................................................................................................................................................6

2.3 External displa ....................................................................................................................................................................................6

2.4 External trigger....................................................................................................................................................................................6

2.5 SSI connection.....................................................................................................................................................................................7

2.6 Positioning...........................................................................................................................................................................................7

3 Device overview and setup............................................................................................................................................................................8

3.1 Connection for configuration...............................................................................................................................................................8

3.2 Output interfaces.................................................................................................................................................................................9

3.2.1 Output configuration example...................................................................................................................................................9

3.3 Operation modes...............................................................................................................................................................................10

3.3.1 Controlled mode......................................................................................................................................................................10

3.3.2 Stand-alone mode....................................................................................................................................................................11

3.4 Measuring characteristics...................................................................................................................................................................12

3.4.1 Measuring characteristics overview..........................................................................................................................................12

3.4.2 Moving target characteristic.....................................................................................................................................................13

3.4.3 Error behavior...........................................................................................................................................................................14

3.5 Special user commands......................................................................................................................................................................15

3.5.1 Offset / Gain.............................................................................................................................................................................15

3.5.2 Output format..........................................................................................................................................................................15

3.6 Output value filter..............................................................................................................................................................................16

3.6.1 Moving average filter...............................................................................................................................................................16

3.6.2 Spike suppression filter.............................................................................................................................................................16

3.6.3 Error suppression filter..............................................................................................................................................................16

4 Installation...................................................................................................................................................................................................17

4.1 Mounting...........................................................................................................................................................................................17

4.1.1 Mounting of the device............................................................................................................................................................17

4.1.2 Mounting for the reflective plate..............................................................................................................................................17

4.1.3 Alignment of the laser beam....................................................................................................................................................17

4.1.4 Laser Life time consideration....................................................................................................................................................17

4.2 Device wiring.....................................................................................................................................................................................17

4.2.1 Power suppl ............................................................................................................................................................................17

4.2.2 Cable connection.....................................................................................................................................................................17

4.2.3 Shield and ground....................................................................................................................................................................17

4.2.4 Serial connection......................................................................................................................................................................18

4.2.5 Analog / Digital connection......................................................................................................................................................19

4.2.6 SSI connection..........................................................................................................................................................................19

4.2.7 External trigger connection......................................................................................................................................................20

5 Technical data.............................................................................................................................................................................................21

5.1 Measuring accurac definition...........................................................................................................................................................21

5.2 Measuring performance influences....................................................................................................................................................21

5.3 Prevention of erroneous measurements.............................................................................................................................................22

5.3.1 Rough surfaces.........................................................................................................................................................................22

5.3.2 Transparent surfaces................................................................................................................................................................22

5.3.3 Wet, smooth, or high-gloss surfaces........................................................................................................................................22

5.3.4 Inclined, round surfaces............................................................................................................................................................22

5.3.5 Multiple reflections...................................................................................................................................................................22

5.3.6 Influence of sun light................................................................................................................................................................22

5.4 Specifications.....................................................................................................................................................................................23

6 Electrical components.................................................................................................................................................................................24

6.1 ID switch............................................................................................................................................................................................24

6.2 Reset switch.......................................................................................................................................................................................24

6.3 Digital output.....................................................................................................................................................................................24

6.4 Digital input.......................................................................................................................................................................................24

6.5 Analog output...................................................................................................................................................................................25

6.6 RS-232 serial interfaces......................................................................................................................................................................25

6.7 RS-422 serial interface.......................................................................................................................................................................25

6.8 SSI output..........................................................................................................................................................................................26

6.8.1 SSI Specification.......................................................................................................................................................................26

6.8.2 SSI Timing................................................................................................................................................................................26

6.9 Connector..........................................................................................................................................................................................27

6.9.1 D-Sub connector......................................................................................................................................................................27

6.9.2 Screw terminal.........................................................................................................................................................................27

TECHNICAL REFERENCE MANUAL

7 Ph sical dimensions.....................................................................................................................................................................................28

8 Factor settings...........................................................................................................................................................................................28

8.1 Standard configuration......................................................................................................................................................................28

8.2 User configured measurement...........................................................................................................................................................28

9 Command set.............................................................................................................................................................................................29

9.1 General..............................................................................................................................................................................................29

9.1.1 Command termination <trm>..................................................................................................................................................29

9.1.2 Device identification N.............................................................................................................................................................29

9.1.3 Parameter separator.................................................................................................................................................................29

9.1.4 Set/Get commands...................................................................................................................................................................29

9.1.5 Startup sequence.....................................................................................................................................................................29

9.2 Operation commands........................................................................................................................................................................30

9.2.1 Distance measurement (sNg)....................................................................................................................................................30

9.2.2 Single sensor tracking (sNh)......................................................................................................................................................30

9.2.3 Single sensor tracking with timer(sNh).....................................................................................................................................30

9.2.4 Tracking with buffering – Start (sNf).........................................................................................................................................31

9.2.5 Read out - Tracking with buffering(sNq)...................................................................................................................................31

9.2.6 STOP/CLEAR command (sNc)....................................................................................................................................................31

9.2.7 Signal measurement (sNm).......................................................................................................................................................31

9.2.8 Temperature measurement (sNt)..............................................................................................................................................32

9.2.9 Laser ON (sNo).........................................................................................................................................................................32

9.2.10 Laser OFF (sNp).......................................................................................................................................................................32

9.3 Configuration commands..................................................................................................................................................................33

9.3.1 Set communication parameter (sNbr).......................................................................................................................................33

9.3.2 Measuring characteristic configuration (sNuc)..........................................................................................................................34

9.3.3 Set auto start configuration (sNA)............................................................................................................................................35

9.3.4 Set/Get analog output min level (sNvm)...................................................................................................................................35

9.3.5 Set/Get analog output value in error case (sNve)......................................................................................................................35

9.3.6 Set/Get analog output distance range (sNv).............................................................................................................................36

9.3.7 Set/Get digital output levels (sNn)............................................................................................................................................37

9.3.8 Configure digital input (sNDI1).................................................................................................................................................38

9.3.9 Read digital input (sNRI)...........................................................................................................................................................38

9.3.10 Interface 2 configuration (RS-422 / SSI)..................................................................................................................................39

9.3.11 Set/Get error value on SSI output...........................................................................................................................................40

9.3.12 Set/Get measurement filter configuration (sNfi).....................................................................................................................40

9.3.13 Save configuration parameters (sNs)......................................................................................................................................40

9.3.14 Set configuration parameters to factor default (sNd)............................................................................................................41

9.3.15 Get software version (sNsv)....................................................................................................................................................41

9.3.16 Get serial number (sNsn)........................................................................................................................................................41

9.3.17 Get device generation and t pe (dg)......................................................................................................................................42

9.3.18 Get device t pe (dt)................................................................................................................................................................42

9.4 Special user operation commands.....................................................................................................................................................43

9.4.1 User distance measurement (sNug)..........................................................................................................................................43

9.4.2 User single sensor tracking (sNuh)............................................................................................................................................43

9.4.3 User single sensor tracking with timer(sNuh)............................................................................................................................44

9.4.4 User tracking with buffering – Start (sNuf)...............................................................................................................................44

9.4.5 Read out – User tracking with buffering (sNuq)........................................................................................................................44

9.5 Special User configuration commands...............................................................................................................................................45

9.5.1 Set user auto start configuration (sNuA)...................................................................................................................................45

9.5.2 Set/Get user distance offset (sNuof).........................................................................................................................................45

9.5.3 Set/Get user distance gain (sNuga)...........................................................................................................................................45

9.5.4 User output protocol (sNuo).....................................................................................................................................................46

9.6 Error codes.........................................................................................................................................................................................47

10 Safet instructions.....................................................................................................................................................................................48

10.1 Use of the instrument......................................................................................................................................................................48

10.2 Limits to use....................................................................................................................................................................................48

10.3 Areas of responsibilit ......................................................................................................................................................................49

10.4 Hazards in use.................................................................................................................................................................................49

10.5 Laser classification...........................................................................................................................................................................50

10.6 Electromagnetic compatibilit (EMC)...............................................................................................................................................51

10.7 Producer Standards..........................................................................................................................................................................51

10.8 Disposal...........................................................................................................................................................................................51

10.9 Labeling...........................................................................................................................................................................................52

10.10 Laser Specification.........................................................................................................................................................................52

10.11 Maintenance..................................................................................................................................................................................52

10.12 Service...........................................................................................................................................................................................52

TECHNICAL REFERENCE MANUAL

1 Introduction

The DLS-C(H) and FLS-C(H) are powerful distance-measuring instruments for integration into industrial applications. The allow accurate and

contactless distance measurement over a wide range using the reflection of a laser beam:

Ke features

•Compatible with DIMETIX DLS-B(H) and DLS-A(H) Laser Distance Sensor

•Measurement range 0.05 to 500 m

•Serial interface (RS-232 and RS-422)

•SSI interface (FLS-C(H) onl )

•Connection of up to 10 modules on a single RS-422 line

•Wide range power suppl (9...30VDC), heating option (24...30VDC)

•Programmable analog output (0/4...20mA)

•Two programmable digital outputs (DO1 and DO2)

•Digital output for error signalization (DOE)

•One programmable digital input (DI1)

•ASCII protocol to control external displa s

•D-Sub connector and screw terminal joint for eas connection of DLS-C(H) / FLS-C(H)

•IP65 (protected against ingress of dust and water)

•4 LEDs for status signaling

•Complementar configuration software available at Dimetix web site (www.dimetix.com)

•Optional: Internal heater for device operation down to -40°C

•Laser class II (<0.95mW)

•Accessories for eas use of the sensor

Use of controls or adjustments or performance of procedures other than those specified in this

Technical Reference Manual may result in hazardous radiation exposure.

For easy startup with the DLS / FLS sensor, please use our free

configuration software from our we -page:

www.dimetix.com/Utilit SW

Distance Laser Sensor Page 4/53

Fig. 1 Standard application

Measured distance

Target

Measuring

reference

DLS-C(H)

FLS-C(H)

TECHNICAL REFERENCE MANUAL

1.1 Product identification

The product is identified b the label on the top of the sensor:

DLS-C Version with a measurement rate of up to 6 Hz and a maximum measuring distance of 150m

Typical Accuracy

1.5mm 3.0mm

Standard version DLS-C 15

Part No.: 500622

DLS-C 30

Part No.: 500621

Extended temperature range DLS-CH 15

Part No.: 500624

DLS-CH 30

Part No.: 500623

FLS-C Version with a measurement rate of up to 250 Hz and a maximum measuring distance of 500m

Typical Accuracy

1.0mm 3.0mm

Standard version FLS-C 10

Part No.: 600502

FLS-C 30

Part No.: 600501

Extended temperature range FLS-CH 10

Part No.: 600504

FLS-CH 30

Part No.: 600503

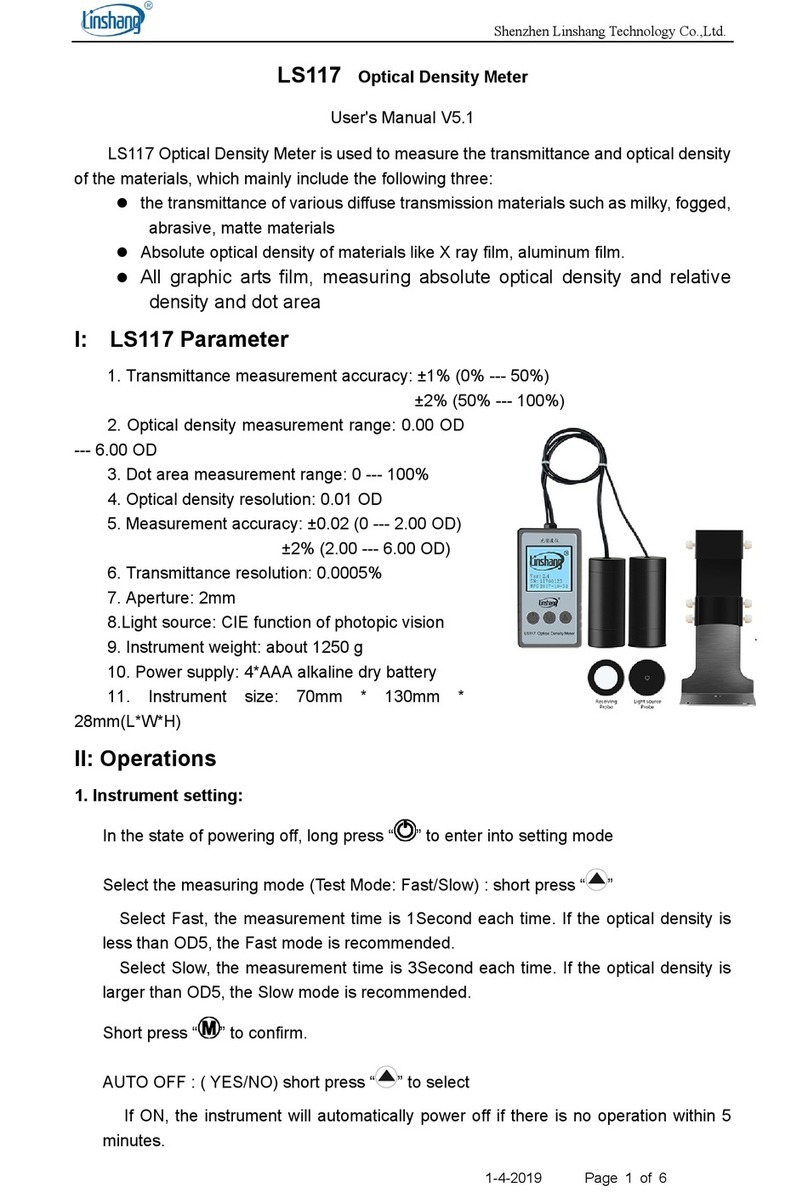

1. Components

1 Status LEDs

status signaling

2 15-Pin D-Su connector

RS-422, RS-232, SSI , analog, digital output

3 Ca le gland (M16 x 1.5mm)

for connection cable insertion

4 Cover

provides access to the screw terminal,

Screwdriver-t pe is Torx T9

5 Reset switch

resets the DLS-C(H)/FLS-C(H) to default settings

6 Screw terminal

RS-422, RS-232, SSI, analog, digital output

7 ID switch

defines the Device ID for RS-422 operation

8 Laser eam outlet

9 Receiver optics

10 Product la el

see 10.9 Labeling on page 52

1.3 Validity

This manual is valid for DLS-C(H) and FLS-C(H) devices with the following software version:

Interface software version: 0500 or later

Module software version: 0400 or later

To get the software version use the command described in 9.3.15 Get software version (sNsv) on page 41

Distance Laser Sensor Page 5/53

7

6

5

9

1

8

10

1

2

1

10

4

3

TECHNICAL REFERENCE MANUAL

Application examples

Since the configuration of the DLS-C(H)/FLS-C(H) is ver flexible the device is usable in various situations. The following application examples

give an idea of possible applications. Please visit www.dimetix.com for a detailed description of the mentioned application examples and

check for additional application examples.

.1 Serial interface RS- 3 / RS-4

While the RS-232 should be used for the configuration of the device (See

3.1 Connection for configuration on page 8) the RS-422 is made for

communication in industrial environment (See 3.3.1 Controlled mode on

page 10 and 4.2.4 Serial connection on page 18).

Fig. 2 shows the connection of multiple DLS-C(H)/FLS-C(H) devices to a

Siemens S7 PLC. A detailed application note can be found on

www.dimetix.com.

For RS-422 connections use twisted pair cables onl !.

. Analog and digital output

Activate the stand-alone mode (3.3.2 Stand-alone mode on page 11) and the

device is read to use. It starts measuring after power on and updates the analog

and digital output according to the configuration. See 9.3.4 and the following

chapters for the configuration commands.

.3 External display

If Displa Mode is enabled, the DLS-C(H)/FLS-C(H) formats the measured distance

as ASCII string, which is understood b External Displa s with a serial interface.

Since the DLS-C(H)/FLS-C(H) transfers this formatted string automaticall on the

serial interface after completing a measurement. Measurement results can be

displa ed on an external displa without an additional controller.

Check www.dimetix.com for a detailed application note.

.4 External trigger

The DLS-C(H)/FLS-C(H) includes the option of triggering measurements with an

external switch or push button on Digital Input 1 (DI 1). Using the Digital Input DI 1

disables the Digital Output DO 1.

Please refer to 3.3.2.2 Manual start configuration on page 11

Distance Laser Sensor Page 6/53

Fig. 5: Use digital input as external trigger

12

13

AO

AGND

DO/DI 1

V+

7,8

9

1k

Fig. 4: External displa connection

DO/DI 1

V+

7,8

9

1k

2

1

R

T

m

GND

14,15

RS232 or RS422

Fig. 2: RS-422 connection to S7 PLC

R+

R-

T+

T-

ID switch

Position 0

CP 340 Zusatzkarte

5

4

6

3

14,1 5

7,8

V+

R+

R-

T+

T-

ID switch

Position 1

5

4

6

3

14,1 5

7,8

V+

R+

R-

T+

T-

ID switch

Position 9

5

4

6

3

14,1 5

7,8

V+

Vcc

0V

(slave) (slave) (slave)

CP3 40-RS 4 22/485;

6ES7 340-1CH 00-0A E0

Pin 2

Pin 9

Pin 4

Pin 11

Pin 8

Sub -D

Buch se 15pol

Siemens S7

DLS-C(H)/FLS-C(H) DLS-C(H)/FLS-C(H) DLS-C(H)/FLS-C(H)

DLS-C(H)

FLS-C(H)

DLS-C(H)

FLS-C(H)

Fig. 3: AO and DO connection

DLS-C(H)

FLS-C(H)

12

14,15

13

24V=

9..30VDC

24..30VDC for Heating Option

0V

AO

AGND

DO 1

DO 2

V+

GND

7,8

9

10

TECHNICAL REFERENCE MANUAL

.5 SSI connection

Set the FLS-C(H) in stand-alone mode (3.3.2 Stand-alone mode on page 11) and

connect it to a SSI master as shown in Fig. 6. The measured distances are

immediatel available at the SSI output. See 9.3.10 Interface 2 configuration (RS-

422 / SSI) on page 39 for the detailed command description.

Never connect the SSI master before the FLS-C(H) interface 2 is configured as SSI

interface.

.6 Positioning

The figure on the left shows a t pical positioning application. In this

application the SSI interface of the FLS-C(H) is directl connected to a

position input of a motor drive. The drive controls the motor In such a

wa , that the sledge moves to the position given as set point b the

PLC.

The encoder is used for securit reasons to double check the movement

b the Drive.

In this applications the FLS-C(H) uses the SSI interface (4.2.6 SSI

connection on page 19) and the moving target characteristic (3.4.2

Moving target characteristic on page 13.

Please check on www.dimetix.com for detailed application notes.

Distance Laser Sensor Page 7/53

Fig. 7: Positioning application

Possition

SSI

Field bus

PLC

Drive

Fig. 6: SSI connection example

Cl oc k+

SS I c loc k

SS I data

R+

R-

T+

T-

5

4

6

3

7, 8

V+

(SSI Clock in +)

(SSI Clock in -)

(SSI da ta out + )

(SSI da ta out - )

14 , 1 5

0V

V c c

shielded twisted pair

connection

GND

SSI master

(i.e. controller)

SSI slave

FLS-C(H)

Cl oc k-

Dat a+

Dat a-

Te rm in a l

Shield

TECHNICAL REFERENCE MANUAL

3 Device overview and setup

We recommend that ou carr out the configuration steps in an office before mounting the device, especiall if ou are not familiar with

the DLS-C(H)/FLS-C(H).

Configure the outputs first and second do the configuration of the operation mode. The following sections describe the configuration steps

and give an example.

3.1 Connection for configuration

To be able to configure the DLS-C(H)/FLS-C(H), it must be powered and connected to a PC. Figure 8 shows the necessar connections. On

the PC, an terminal program can be used to communicate with the module. A configuration utilit is also available on the web page

www.dimetix.com.

Distance Laser Sensor Page 8/53

Fig. 8 Connection for DLS-C(H)/FLS-C(H) configuration

DLS-C(H)

9 pin

D-Sub

T

Gnd

2

5

3

T

R

2

1

GND

V+

R

15 pin

D-Sub

9..30VDC

24..30VDC for Heating option

+-

14,15

7,8

Default setting:

Baud:

Bit:

Parity:

Stop:

19200

7

even

1

COM1 or COM2

DLS-C(H)

FLS-C(H)

TECHNICAL REFERENCE MANUAL

3. Output interfaces

The DLS-C(H)/FLS-C(H) contains different interfaces. Measurement results and errors are signaled at the outputs as described below.

RS-232 The RS-232 is meant for the configuration of the device, however measurement can also be taken using the RS-232

interface. Measurement results and/or error codes are sent corresponding to the command description. To use this

interface host s stem is needed as described in 3.3.1 Controlled mode on page 10.

RS-422 The RS-422 operates like the RS-232, but it is an industrial interface and therefore not onl usable for configuration

but also for controlled measurement as described in 3.3.1 Controlled mode on page 10.

The RS-422 can not be used simultaneous with the SSI interface since it uses the same signal lines.

SSI Output The SSI Interface is onl implemented in the FLS t pe. The SSI interface is updated after each successful measurement

as well as after an error occurs. If the interface is activated, it is updated in all operation modes.

Binar and Gra code as well as error signalization is supported. (See 4.2.6 SSI connection on page 19)

Analog Output The analog output is updated in controlled and stand-alone mode. It is configurable and works with two ranges:

- 0..20mA

- 4..20mA

Digital Outputs Three digital outputs are included in the DLS-C(H)/FLS-C(H). Two of them are programmable, while the third is used

to signal an error state of the device. The digital outputs are updated in all operation modes.

3.2.1 Output configuration example

After connecting the DLS-C(H)/FLS-C(H), the following steps are necessar to configure the output behavior.

No. Action Comment Command

1

Set current output range Defines the current output range from 0 to

20mA or from 4 to 20mA.

Example for device 0:

Set current output range from 4mA to 20mA.

s0vm+1<trm>1)

2

Set distance range Defines the minimum distance (Dmin) and the

maximum distance (Dmax) for the current

range of the analog output.

Example for device 0:

Set distance range from 0m to 10m

s0v+00000000+00100000<trm>1)

3

Set analog output in case of

an error

Sets the current that should be applied in

case of an error.

Example for device 0:

Set current to 0mA in case of an error.

s0ve+000<trm>1)

4

Configure digital output Set the ON and OFF level for the digital

outputs.

Example for device 0:

DO 1: off=2000mm on=2005mm

DO 2: off=4000mm on=4005mm

s01+00020000+00020050<trm>1)

s02+00040000+00040050<trm>1)

5

Configure SSI Output Activate SSI output (RS-422 is deactivated)

Example for device 0:

Set SSI configuration

Set output value in error case to 12345

s0SSI+1<trm>1)

s0SSIe+12345<trm>1)

6

Save settings The changed configuration must be saved to

make it permanent.

Example for device 0:

Save settings for device 0

s0s<trm>1)

1) Commands are described in 9 Command set on page 29

Note: If the serial line settings of the device have been lost, please reset the configuration to the factor settings (8 Factor settings on

page 28) using the reset button (6.2 Reset switch on page 24). Please note that the ID switch must be reset manuall .

Distance Laser Sensor Page 9/53

TECHNICAL REFERENCE MANUAL

3.3 Operation modes

The first decision to be taken is the t pe of operating mode that will be used to perform distance measurements. While the controlled mode

provides maximum flexibilit and accurac , it is often not suitable for integration into existing drives, PLCs or analog environments. In such

cases the Stand-alone mode might be preferred.

controlled mode stand-alone mode

Auto start Manual start

The measurement is controlled b a host with

commands such as

- sNg

- sNh

- sNuf

The measurement starts after power

on. This must be configured with the

command

- sNA

- sNuA

After configuring the DO1 as DI1, the

measurement can be triggered b an

external signal. Use the following

command

- sNDI

See 9.2 Operation commands starting on page 30 See 9.3.3 Set auto start

configuration (sNA) on page 35

See 9.3.8 Configure digital input (sNDI1)

on page 38

After each measurement all outputs are updated corresponding to the configuration (See 9.3 Configuration commands on page 33).

3.3.1 Controlled mode

In controlled mode, each operation of a DLS-C(H)/FLS-C(H) is triggered b a command sent from a host s stem over a serial line. While a

single device can be connected to the host s stem using the RS-232 interface, up to 10 devices can be connected to a single serial RS-422

line. The related command set is described in Chapter 9 on page 29.

3.3.1.1 Configuration

After connecting the module, the steps below are necessar to configure the DLS-C(H)/FLS-C(H) for the controlled interface mode.

No. Action Comment Command

1 Set ID switch Changes to the Device ID are activated after a

power c cle.

Example for device 0:

Change the ID Switch to position 0

Set ID switch to position 0

Power OFF; Wait 10s; Power ON

2

Set controlled mode Set the DLS-C(H)/FLS-C(H) to the controlled

mode, if not alread in controlled mode.

Example for device 0:

Set to controlled mode b means of the stop

command.

s0c<trm>1)

3

Set communication

parameters

If necessar , change the settings for the serial

interface.

Example for device 0:

Set serial interface to 19200 Baud, 8 Bit, no

Parit

s0br+2<trm>1)

Power OFF; Wait 10s; Change settings on the

host; Power ON

1) Commands are described in 9 Command set on page 29

Note: If the communication parameters of the device are lost, please reset the configuration to the factor settings (8 Factor settings

on page 28) using the reset button (6.2 Reset switch on page 24). Please note that the ID switch must be reset manuall .

3.3.1.2 Host software

Host software is required for operation of the DLS-C(H)/FLS-C(H) in controlled mode. When connecting multiple devices to a single serial

line (RS-422), strict Master-Slave communication must be implemented (DLS-C(H)/FLS-C(H) operates as slave). For software sample-code or

application-notes please consult our web site www.dimetix.com.

Careful testing of the host software together with the devices prior to installation is strongl recommended.

Distance Laser Sensor Page 10/53

TECHNICAL REFERENCE MANUAL

3.3.2 Stand-alone mode

Before starting the stand-alone mode, output configuration must be done (See 3.2 Output interfaces on page 9)

3.3.2.1 Auto start configuration

The following steps are necessar to configure the DLS-C(H)/FLS-C(H) for stand-alone mode with auto start.

No. Action Comment Command

1

Set auto start Set the DLS-C(H)/FLS-C(H) to the stand-alone

mode with auto start and with the desired

sample rate.

Example for device 0:

Set sample rate to fastest possible speed.

s0A+0<trm>1)

1) Commands are described in 9 Command set on page 29

Note: If the serial line settings of the device have been lost, please reset the configuration to the factor settings (8 Factor settings on

page 28) using the reset button (6.2 Reset switch on page 24). Please note that the ID switch must be reset manuall .

3.3.2.2 Manual start configuration

Configure the Digital Input (see 9.3.8 Configure digital input (sNDI1) on page 38) to activate the external trigger to start measurements.

No. Action Comment Command

1

Activate digital input DI1 Defines the action for a trigger event on DI1.

Example for device 0:

Configure DI1 to start and stop tracking. If

DI1 is high, distances are measured and the

result is transferred to the output at all

interfaces. If DI1 goes to low, the

measurement stops

s0DI1+3<trm>1)

2

Save settings The changed configuration must be saved to

make it permanent.

Example for device 0:

Save settings for device 0 s0s<trm>1)

1) Commands are described in 9 Command set on page 29

Note: If the serial line settings of the device have been lost, please reset the configuration to the factor settings (8 Factor settings on

page 28) using the reset button (6.2 Reset switch on page 24). Please note that the ID switch must be reset manuall .

Distance Laser Sensor Page 11/53

TECHNICAL REFERENCE MANUAL

3.4 Measuring characteristics

Multiple measuring characteristics are available in the FLS-C measuring devices to meet different requirements for various applications. With

these measuring characteristics measuring rate and accurac can be optimized for special requirements.

The FLS-C measuring device at factor settings has an accurac of ±1 mm (FLS-C(H) 10) respectivel ±3 mm (FLS-C(H) 30) at 2σ. Measuring

rate depends on environmental conditions such as target surface, distance, background light (e.g. sun light), etc. Good environmental

conditions increase measuring rate (e.g. white target surface or orange reflective target plate and dark environment).

3.4.1 Measuring characteristics overview

Availa le in DLS-C(H)

Availa le in FLS-C(H)

Measuring

character-

istic

Measuring

rate

Typical accuracy @

2σ

Description

Error ehavior1)

User Commands2)

FLS-C(H)

10

FLS-C(H)

30

Normal Commands2)

Normal

(factory

setting)

max. 10

Hz3)1) ±1 mm ±3 mm Measuring range on natural surface: typical 65 m

Configuration command: sNuc+0+04) A

Fast max. 20 Hz1) ±2 mm ±6 mm Increased measuring rate up to 20 Hz.

Configuration command: sNuc+0+14) A

Precise max. 6 Hz1) ~±0.8 mm ~±2.4 mm

Increased accurac of ±0.8 mm

Surveying applications, short range applications etc.

Configuration command: sNuc+0+24)

A

Natural

surface

max. 6Hz,

can drop to

0.25Hz @ up

to approx.

80m

~±5 mm

@ up to

approx.

80m

~±15 mm

@ up to

approx.

80m

Increased measuring range on natural surfaces:

t pical 80 meters

Measuring against far awa natural surfaces or bad reflective

surfaces such as black s nthetic granules, etc.

Configuration command: sNuc+0+34)

A

Timed

user

programmed

DLS: ≤ 6Hz,

FLS: ≤ 35Hz

variable variable

The device does not check the signal condition to ensure the

specified accurac is reached, a measurement value is transferred

to the output at a defined measuring rate.

This mode serves for applications where the accurac is not

important but the reaction time is critical

Configuration command: sNuc+1+14)

A

Moving

Target

250Hz,

SSI can poll

with up to

500Hz

±1 mm ±3 mm

The device measures to a continuously moving target and the

distance changes without any jumps.

This measurement characteristic supervises the ma speed,

checks for distance jumps and includes a special filter to

eliminate errors occurring for only a very short time.

Configuration command: sNuc+2+04) (with error freezing)

sNuc+2+14) (without error freezing)

B

1) The behavior in case of an error depends on the configuration. See 3.4.3 Error behavior on page 14

2) Changed characteristics do not influence all commands

3) Good environmental conditions (e.g. white target surface or orange reflective target plate and dark environment).

4) For the description of the command see 9.3.2 Measuring characteristic configuration (sNuc) on Page 34

Distance Laser Sensor Page 12/53

TECHNICAL REFERENCE MANUAL

3.4.2 Moving target characteristic

For continuous movements of a target which t picall appears in positioning applications like automatic warehouses there is a special

measurement characteristic built into the FLS-C (H) called “Moving target”(See 2.6 Positioning on page 7 for a sample application)

To operate the FLS-C(H) in this measurement characteristic

successfull , distance jumps must not occur. The laser beam

must alwa s hit the target.

This measurement characteristic combines a fast measurement rate with the unique accurac of the FLS-C(H). The measurement rate is

fixed and does not change during operation.

For RS-232, RS-422, analog and digital outputs, the output rate is 250Hz. The SSI interface can return reliable measurement data at up to

500Hz read out rate corresponding to the clock received from the master.

When measuring to a stopped target, the resulting distance will sta at a single value, it does not occur an deviation of the distance. This is

necessar if the sensor is used for positioning in closed looped applications.

An optimized error handling suppresses short errors, that ma occur b a short break of the laser beam. In addition an over speed detector

(>10m/s) detects improper situations, which results in an error. This ensures robust operation in positioning applications.

The behavior of the device in case of a severe error can be defined b the operator (See 3.4.3 Error behavior on page 14).

For a description of the configuration command see 9.3.2 Measuring characteristic configuration (sNuc) on page 34.

Distance Laser Sensor Page 13/53

Fig. 9: Condition for moving target characteristic

V

VV

> 150mm

distance jump

moving target jumping target

TECHNICAL REFERENCE MANUAL

3.4.3 Error ehavior

The device has different error behaviors depending on the measuring characteristics and on the start operation.

3.4.3.1 A - Behavior

In case the device detects an error, this error is signalized at the outputs. On the serial and SSI output the error code will be visible

depending on the configuration. The error will be visible at the output until the device performs a successful measurement and outputs the

new distance value or the device will be reset b command (sNc) or b a power c cle.

3.4.3.2 B – Behavior (in moving target characteristic)

This error behavior is onl relevant when using the moving target measurement characteristic.

Configuration with error freezing

sNuc+2+01)

without error freezing

sNuc+2+11)

Situation

Temporar error The temporar error is converted into a

permanent error. This error must be reset as

described below.

The temporar error disappears as soon as the error

condition is cleared (a successful measurement is

done).

Permanent error The permanent error must be reset as described

below.

The permanent error must be reset as described

below.

The error reset function depending on the start condition. The following diagram shows the error reset for the different start configurations.

Stand-alone mode: Auto start configuration

(3.3.2.1 Auto start configuration on page 11)

In this operation the measurement starts automaticall at power on.

A signalized error is reset automaticall after 5 seconds. The reset is

done b an automatic restart of the device. This restart maximal

takes about 4 seconds.

Stand-alone mode: Manual start configuration

(3.3.2.2 Manual start configuration on page 11)

In this operation the measurement is started with a digital input. In

case of an error, the reset of a signalized error is done b restarting

the measurement with the digital input.

1) For the description of the command see 9.3.2 Measuring characteristic configuration (sNuc) on Page 34

Distance Laser Sensor Page 14/53

t < 4 sec

Initialization *

t = min. 1 sec

Error

DO Error

Digital

Input

Output

SSI

Output

RS-232/422

ON

HIGH

OFF

LOW

Start

measuring

Stop

measuring

Measuring values Measuring values

Measuring valuesMeasuring values Error value

Configured Error value

(s SSIe)NValue = 0

no output

Value = 0

no output

t = 5 sec

Error time

t < 4 sec

Initialization*

DO Error

Output

SSI

ON

OFF

Error

Automatic

restart

Measuring values Measuring values

Configured Error value

(s SSIe)NValue = 0

TECHNICAL REFERENCE MANUAL

3.5 Special user commands

The standard command set is extended b a special user command set, which makes it possible to change the output format and appl a

offset and gain.

User command configuration do not influence Analog, Digital and SSI outputs.

3.5.1 Offset / Gain

The user can set an individual user gain and offset to create user defined output values. The output value is calculated as follows.

ValueUser =(Distance+Offset User )⋅GainNumUser

GainDenUser

See 9.5.2 Set/Get user distance offset (sNuof) and

9.5.3 Set/Get user distance gain (sNuga) on page 45

With the offset and gain the result of the user commands (See 9.4 Special user operation commands on page 43) are changed onl .

Analog, Digital and SSI output values are not affected.

3.5.2 Output format

The DLS-C(H)/FLS-C(H) is able to format the output value on the serial interface (RS-232/RS-422) in order to fit it to an ASCII displa . B the

command sNuo the length of the output value can be defined as well as the position of the decimal point. This command in combination

with a gain and offset allows the direct connection of an external displa as described under 2.3 External displa on page 6.

The command is described under 9.5.4 User output protocol (sNuo) on page 46

Distance Laser Sensor Page 15/53

TECHNICAL REFERENCE MANUAL

3.6 Output value filter

The DLS-C(H)/FLS-C(H) contains a filter for the measurement value, which can be activated and offers different configurations. This filter is

available in the following Measuring characteristics (see 3.4 Measuring characteristics) on the DLS-C(H) and the FLS-C(H):

- Normal

- Fast

- Precise

- Natural Surface

- Timed

The output value filter is made of a moving average, a spike suppression as well as an error suppression filter. These filters are all

configurable to offer most possible flexibilit for the adaption of the DLS-C(H)/FLS-C(H) device to various applications.

This filter is inactive for the moving target characteristic.

3.6.1 Moving average filter

The moving average filter averages a specified number of measurements.

Maximum 32 measurement values can be averaged. If a new measurement

value is present, this value will be added to the filter values, while the last

value will be removed. The sum of all measurement values divided b the

size of the filter is transferred to all outputs.

3.6.2 Spike suppression filter

The spike suppression eliminates pairs of min max values inside the filter values (Number of

filter values can be defined). Alwa s the smallest and largest values are removed from the

average calculation.

3.6.3 Error suppression filter

A maximum number of errors inside the filtered values can be suppressed. If the number of

errors inside the filtered values is less as the specified value, no error is shown at the output

See 9.3.12 Set/Get measurement filter configuration (sNfi) on page 40

Distance Laser Sensor Page 16/53

Fig. 10 Moving average filter

New Measurement Value

filtered result

n

Filter

Fig. 11: Spike suppression filter

10

8

4

5

3

2

9

7

6

17

18

13

12

11

115

16

14 19

Fig. 12: Error suppression

Error

Error

10

8

4

5

3

2

9

7

6

17

18

13

12

11

115

16

14 19

TECHNICAL REFERENCE MANUAL

4 Installation

4.1 Mounting

4.1.1 Mounting of the device

Three M4 threaded holes in the bottom of the DLS-C(H)/FLS-C(H) make it eas to mount the device.

Alwa s obe all applicable safet regulations and never use the device outside the specifications stated under 5 Technical data on page 21.

4.1.2 Mounting for the reflective plate

Measuring to the reflective plate ma generate erroneous measurements, if the reflective plate is

mounted exactl at an angle of 90° to the laser beam. Therefore mount the reflective plate like shown

in figure 13.

Avoid direct sunlight on the reflective plate to increase measurement performance.

4.1.3 Alignment of the laser eam

Alignment of the laser beam is often difficult when the target is far awa , as the laser spot is not visible. An optional telescopic viewfinder

and an alignment jig is available to simplif the alignment procedure. (See www.dimetix.com for additional accessories and further details).

4.1.4 Laser Life time consideration

since the life time of the laser is limited, operate the device in a wa , that the laser is switched on onl when necessar . The laser life time

stated under 5 Technical data on page 21 relates to the time while the laser is on.

4. Device wiring

4.2.1 Power supply

For trouble-free operation use a separate power suppl for the DLS-C(H)/FLS-C(H).

FLS-C, DLS-C: 9...30V, 0.5A DC

FLS-CH, DLS-CH: 24...30V, 2.5A DC

4.2.2 Ca le connection

A ferrite core must be fitted to the connecting cable. Use a ferrite core with an impedance of 150 Ω to 260 Ω at 25MHz and 640 Ω to 730

Ω at 100MHz. For example ou can use KCF-65 from KE Kitagawa.

4.2.3 Shield and ground

The DLS-C(H)/FLS-C(H) contains two electricall isolated grounds, the

general ground (GND) and the analog ground (AGND). GND and

AGND are connected to the housing b a RC element. Please see

figure 19.

Distance Laser Sensor Page 17/53

Fig. 13: Reflective Plate mounting

Sensor

Laser Beam 1-3°

Reflective plate

Fig. 14 Connection between shield and ground

Screw terminal

GND

AGND

15 pin D-Sub

GND

AGND

20nF

1M

10nF

500k

DLS-C(H)

FLS-C(H)

TECHNICAL REFERENCE MANUAL

4.2.4 Serial connection

This connection is mainl used for the controlled mode or to configure the device.

RS-232

Onl point-to-point communication is possible when using the RS-232 interface.

Never connect multiple DLS-C(H)/FLS-C(H)s on a RS-232 serial line

RS-422

It is possible to connect multiple devices on a single RS-422 line. To ensure proper operation, strict Master-Slave communication must be

applied. It is important, that the Master has full control of the communication and never initiates a new communication before termination

of the previous communication (answer from the DLS-C(H)/FLS-C(H) or timeout).

For RS-422 connections, use shielded twisted pair cables onl ! For detailed information following the RS-422 guidelines.

Ensure, that all DLS-C(H)/FLS-C(H)s are set to different ID num ers.

The RS-422 interface cannot e used simultaneous with the SSI interface.

Distance Laser Sensor Page 18/53

Fig. 16: Connecting multiple devices with RS-422

DLS-B(H)

Fig. 15 Point-to-point connection with RS-232

DLS-C(H)

FLS-C(H)

T

Host

(PC or PLC)

R

TR

2

7,8

1

14,15

V+

9..30VDC

24..30VDC with Heating

0V

DLS-C(H) / FLS-C(H) DLS-C(H) / FLS-C(H) DLS-C(H) / FLS-C(H)

R+

R-

T+

T-

ID switch

Position 0

Host

(PC or PLC)

R

t

R

t

5

4

6

3

14,15

R

t

R

t

7,8

V+

R+

R-

T+

T-

ID switch

Position 1

5

4

6

3

14,15

7,8

V+

R+

R-

T+

T-

ID switch

Position 9

5

4

6

3

14,15

7,8

V+

9..30VDC

24..30VDC with Heating

0V

(slave) (slave) (slave)

(master)

TECHNICAL REFERENCE MANUAL

4.2.5 Analog / Digital connection

This connection is mainl used with the stand-alone mode. The analog interface of the DLS-C(H)/FLS-C(H) is isolated from the rest of the

device (See 4.2.3 Shield and ground on page 17). When using the analog interface, connect the analog ground (AGND).

Make sure, that the total resistance in the analog path is lower than 500 Ω.

4.2.6 SSI connection

Connect a SSI master according to the connection diagram in Fig. 18. It is compulsor to use a twisted pair cable. See 6.8 SSI output on

page 26 and 6.8 SSI output on page 26 for additional information on the SSI interface.

Typical ca le length

The maximum transmission rate depends on the cable length as shown in the following table. For detailed cable specification use the SSI

guidelines. The transmission rate must be specified at the SSI master.

Max. cable length (t pical) max. transmission rate (t pical)

< 12.5 m < 810 kBaud

< 25 m < 750 kBaud

< 50 m < 570 kBaud

< 100 m < 360 kBaud

< 200 m < 220 kBaud

< 400 m < 120 kBaud

< 500 m < 100 kBaud

The RS-422 interface cannot e used simultaneous with the SSI interface.

The SSI Interface is implemented in the FLS-C(H) only.

Distance Laser Sensor Page 19/53

Fig. 17: Connection of an instrument and a PLC

Analog Input

0..20mA

12

14,15

13

Digital Input

24V=

9..30VDC

24..30VDC for Heating Option

0V

PLC

AO

AGND

DO 1

DO 2

V+

GND

7,8

9

10

DLS-C(H)

FLS-C(H)

Fig. 18: Connection of a SSI Master

Cloc k +

SSI c loc k

SSI data

R+

R-

T+

T-

5

4

6

3

7, 8

V+

(SSI Cloc k in + )

(SSI Cloc k in - )

(SSI data out + )

(SSI data out - )

1 4, 1 5

0V

V c c

shielded twisted pair

connection

G ND

SSI master

(i.e. controller)

SSI slave

FLS-C(H)

Cloc k -

Data+

Data-

Ter m in al

Shield

TECHNICAL REFERENCE MANUAL

4.2.7 External trigger connection

The DO1 (Digital Output 1) can also be used as digital input. For safet

reasons, alwa s use a resistor to protect the connection terminal.

The function of digital input can be configured b the command sNDI1

(see 9.3.8 Configure digital input (sNDI1) on page 38)

Distance Laser Sensor Page 20/53

Fig. 19: Connection for external triggering

DO/DI 1

V+

7,8

9

1k

DLS-C(H)

FLS-C(H)

Other manuals for DLS-C 15

2

This manual suits for next models

15

Table of contents

Other Dimetix Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

CIAT

CIAT GeoCIAT instruction manual

SenseAir

SenseAir eSENSE installation manual

Sensus

Sensus FieldLogic FL6500 Series quick guide

Shenzhen Linshang Technology

Shenzhen Linshang Technology LS117 user manual

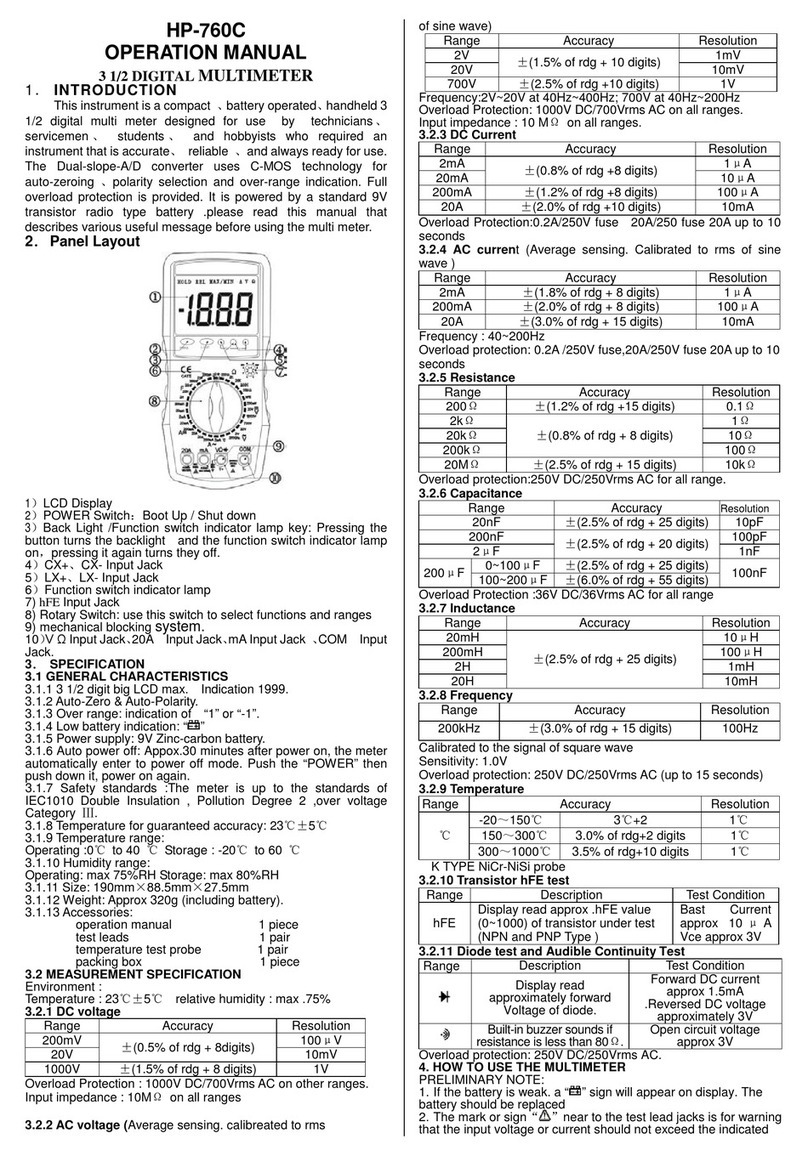

AEMC instruments

AEMC instruments MA194-24-BK user manual

AIC WAIKATO

AIC WAIKATO Presto Master Installation & operating manual