INSTALLATION INSTALLATION

SECTION 3

Plumbing

Fit an isolation valve in the cold mains supply

preceding the installation point of the

handyman unit to allow the unit to be serviced.

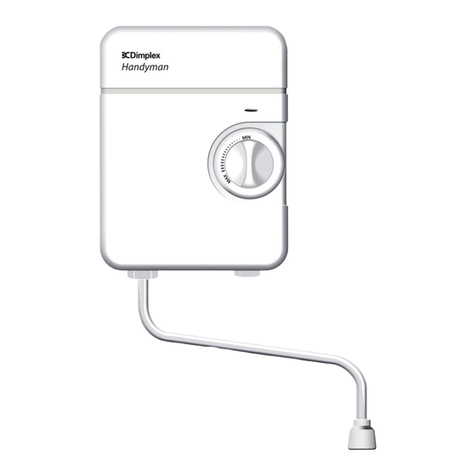

Turn the temperature Control so that it is set to

‘MIN’.

Remove the front cover by unscrewing the

screw at the bottom of the unit and lifting the

cover, complete with control knob, off the

handwash unit.

Place the handwash unit on the wall, ensuring

it is level, and mark the location of the fixing

screws through the backplate.

The following procedure assumes installation

onto a sound masonry surface, if installing

onto other surfaces the procedure and fixings

may need to be modified.

Carefully drill the holes using a 5.5mm

masonry drill-bit and insert the rawl plugs into

the holes.

Place the unit on the wall and secure it using

the screws provided.

Run the water supply to the unit using 15mm

copper or stainless pipe and flush the

pipework for several seconds to remove any

flux and debris within the pipe, before

connecting to the unit.

Connect the mains water supply to the blue

water inlet on the handwash unit using the

compression nut and olive provided. Take

care not to use excessive force when

tightening the compression nut.

Fit the swivel arm to the end outlet of the

handwash unit.

With the unit fully plumbed in turn on the

mains water supply and check the system for

leaks.

SECTION 4

Electricity Supply

Warning this appliance must be earthed!

The unit is suitable for connection to

~230-240V/50Hz supply only

The wiring must conform to with I.E.E. wiring

regulations. If in doubt seek professional advice.

The unit may be supplied from a ring circuit

via a fused spur with a double pole linked

isolating switch fitted with a 13A fuse. The

supply cable should be 3 core and of 1.5

–2.5mm diameter.

The cable should be routed to the handwash

unit so that it enters either via the cable entry

point at the top right hand side of the unit or

through the break-out hole at the rear of the

unit.

The cable grommet should be inserted at the

entry point and the wire routed into the unit.

Connect the Live wire to the terminal

marked L.

Connect the Neutral wire to the terminal

marked N.

Connect the Earth wire to the terminal

marked E.

Ensure that the terminal screws are fully tightened

and good electrical continuity is achieved.

Secure the cable to the unit using the cable

clamp.

Do no switch on the electricity supply to

the unit!

SECTION 5

Final Assembly

Ensuring the temperature control knob is set to

‘MIN’, place the cover carefully onto the

handwash unit and secure using the fixing

screws.

SECTION 6

Commissioning

Turn the temperature control knob

anti-clockwise to its ‘MAX’ setting and allow

water to flow through the unit until a

continuous stream of water, free of air bubbles

is achieved.

Switch on the electrical supply at the isolating

switch. The Power indicator should light.

After a few seconds check that the water from

the unit is beginning to get warm. Adjust the

temperature control clockwise and check that

after a few seconds the water becomes

hotter.

Turn off the unit by turning the temperature

control knob fully clockwise. Switch off the

electricity supply at the isolation switch

SECTION 7

Operation

Switch on

1) Turn on the electricity supply at the isolating

switch. The power indicator should light.

2) Turn the temperature control knob anti-

clockwise to its ‘MAX’ position – indicating

maximum water flow.

3) After a few seconds the water should run

warm, ready for use.

4) If the temperature is required to be increased

turn the knob slowly clockwise, wait a few

seconds until the water temperature

stabilises and adjust again if necessary.

5) To reduce the water temperature turn the

knob anti-clockwise.

Do not under any circumstances restrict or

cover the sprayhead or try to prevent water

exiting the handwash unit as this will cause

the safety cut-out to operate.

Turn off

1) To turn the unit off, turn the temperature

knob fully clockwise until the water stops

flowing. Note: some water may continue

to drip from the unit for a few minutes

as excess water drains from the unit.

2) Switch off the electricity supply at the

isolating switch.

Note: variation in water temperature is

achieved by varying the flow of water through

the unit, hence for higher temperatures you

will notice a reduction in the flow of water

from the handwash unit.