Dings 70 Series User manual

70 Series

Double “C” Face

Brake Instructions

IMPORTANT

Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself

and others by observing all safety information. Failure to

comply with instructions could result in personal injury

and/or property damage! Retain instructions for future

reference. When unpacking the brake, inspect it carefully

for damage that may have occurred during transit.

Bulletin No. BK4620 (2/18)

4740 WEST ELECTRIC AVENUElMILWAUKEE, WI 53219lP ONE 414/672-7830 lFAX 414/672-5354 lwww. dingsbrakes.com

ARNING

Brake performance and features must be carefully matched to the

requirements of the application.

Consideration must be given to torque requirements, especially where

an overhauling condition exists, as well as thermal capacity, ambient

temperature, atmospheric explosion hazards, type of enclosure and

any other unusual conditions.

Improper selection and installation of a brake and/or lack of mainte-

nance may cause brake failure which could result in damage to prop-

erty and/or injury to personnel.

If injury to personnel could be caused by brake failure, additional

means must be provided to insure safety of personnel.

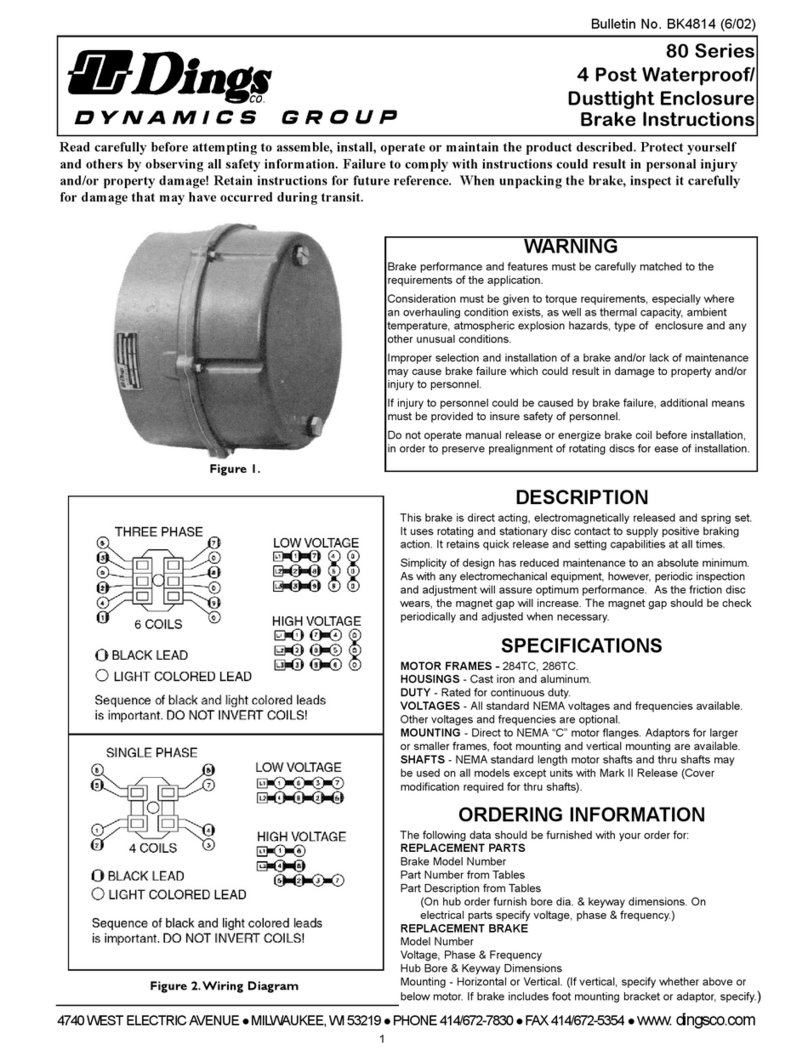

DESCRIPTION

This brake is direct acting, electromagnetically released and spring set.

It uses rotating and stationary disc contact to supply positive braking

action. It retains quick release and setting capabilities at all times.

Simplicity of design has reduced maintenance to an absolute minimum.

As with any electromechanical equipment, however, periodic inspection

and adjustment will assure optimum performance. As the friction disc

wears, the magnet gap will increase. The magnet gap should be checked

periodically and adjusted when necessary. This brake is offered in 2

housing styles: Standard (NEMA 2) and Enclosed (NEMA 4).

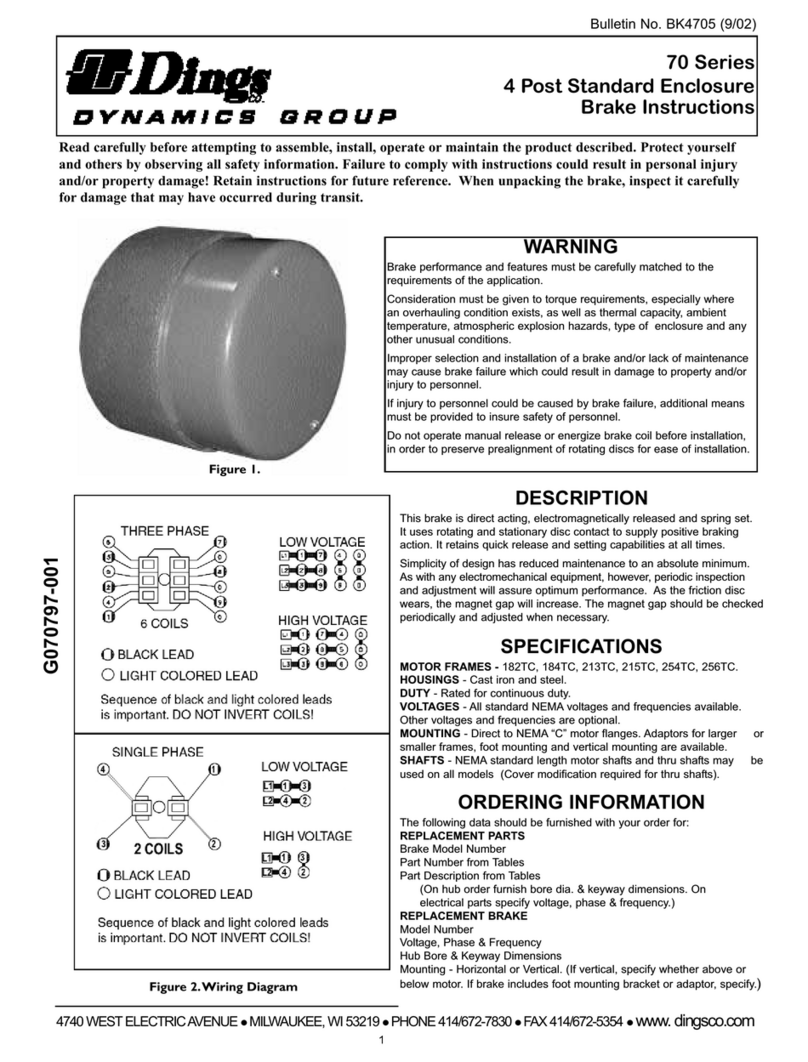

Figure 1. iring Diagram

INSTALLATION

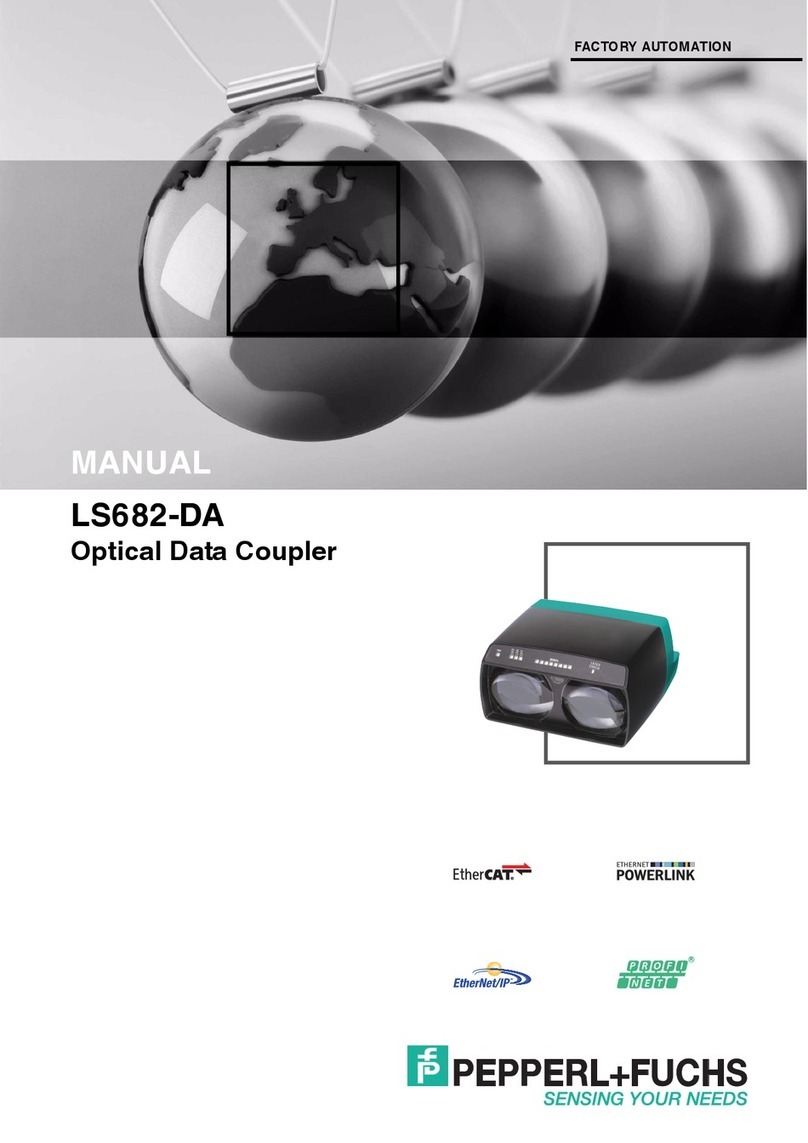

Refer to Figures 1 & 2

Insert key into motor shaft keyway. Key length to be as

shown below for models designated.

Used on all models except

71010, 71015, 72025, and

72035 with 1-1/8” dia. shaft.

For models 71010, 71015,

72025 and 72035 with

1-1/8” dia. shaft.

Slide brake onto motor shaft, aligning key in motor shaft

with keywayin brake shaft. Secure brake to motor “C” face

with four 1/2” socket head capscrews. Connect coil leads

per appropriate diagram.

Key must be full length

of keyway and flush with

end of shaft

Key to extend to

end of keyway

X

Model X ± 1/32

71010

71015 1-15/16

72025

72035 2-7/16

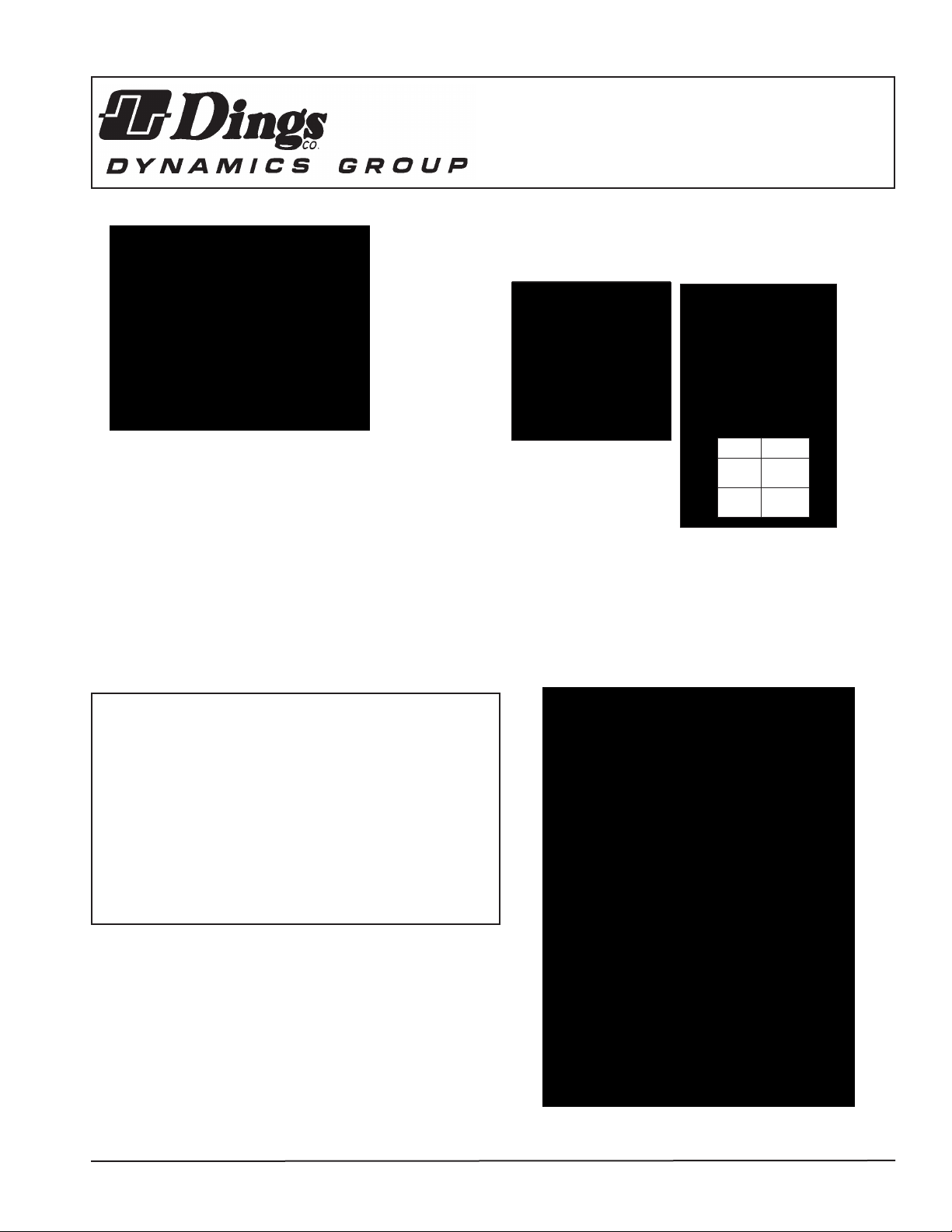

MANUAL RELEASE

(See Figure 4)

To operate release, rotate two nuts (16) clockwise until stop

screw (14) hits pin. Brake will remain in released position until rods

are manually returned to original position, or until electrical power

is restored, automatically resetting the brake.

TORQUE ADJUSTMENT

(See Figures 2 & 4–Table 1)

Brake is factory set for rated torque per spring length “ ”. To increase

stopping time and lower torque, turn two locknuts (9) counterclockwise,

increasing dimension “ ”. Both springs must be set to the same length.

Do not decrease spring length “ ” as this may cause coil to burn out.

MAINTENANCE AND SERVICE

EAR ADJUSTMENT

(See Figures 2 & 4– Table 1)

Magnet gap “D” increases as friction discs wear. When gap approaches

“D” max., adjust gap to “D” min. dimension by turning nuts (23 and 24).

Magnet gap can vary from nominal + .005” between corners. After

setting gap, readjust torque spring length “ ”.

CAUTION: MAGNET GAP MUST NOT EXCEED

“D” MAXIMUM.

FRICTION DISC REPLACEMENT

(See Figure 4 & Table 1)

When the rotating friction disc (4) wears down to a thickness of 7/32”,

replace disc. Remove brake from its associated equipment (reducer-

motor-etc.). Remove retaining ring (28) and press shaft (1) out of bear-

ing in brake case (25). A wheel puller, utilizing openings in side of

case, can be used. Continue disassembling in this order: two nuts (26),

brake case (25), roll pins (17), manual release knobs (16), manual

release screws (14), manual release washers (12), manual release

shims(13), two nuts (24), magnet mounting plate assembly (18), two

nuts (23), two nuts (9), torque spring washers (8), torque springs (7),

pressure plate assembly (6) and discs (4) (5).

Lay bracket (2) on a flat table. Place shaft (1) in center of bracket, with

a spacer under hub. Spacer thickness to be 13/16”. Replace worn

friction discs (4) and reassemble disc pack. Continue reassembling in

reverse order, setting torque spring dimension “ ,” and magnet gap “D”

min. (Table 1.). When assembling manual relase, turn release rod (10)

counter-clockwise until screw (14) strikes pin. Wind torsion spring (11)

about 1/4 turn and hook spring over pin.

NOTE: When assembling manual release mechanism, add only

enough shim washers (13) to obtain proper release action.

With too many shim washers, brake will not automatically reset when

electrical power is applied. With too few shim washers, motor shaft will

not turn freely with brake in manually released position.

IMPORTANT: Make sure release is working properly

before proceeding.

Place case (25) over shaft (1). Release brake by turning two nuts (16)

clockwise. Press bearing (in case) onto shaft by applying pressure to

bearing inner race. Complete assembly in this order: snap ring (28)

and two nuts (26).

NOTE::Units with 1-3/8” dia. output shafts–remove brake case by

first removing outside retaining rin (41) and two nuts (26).

Then press shaft (1) out of bearing. Next remove remaining retaining

ring (41) and pull shaft out of brake.

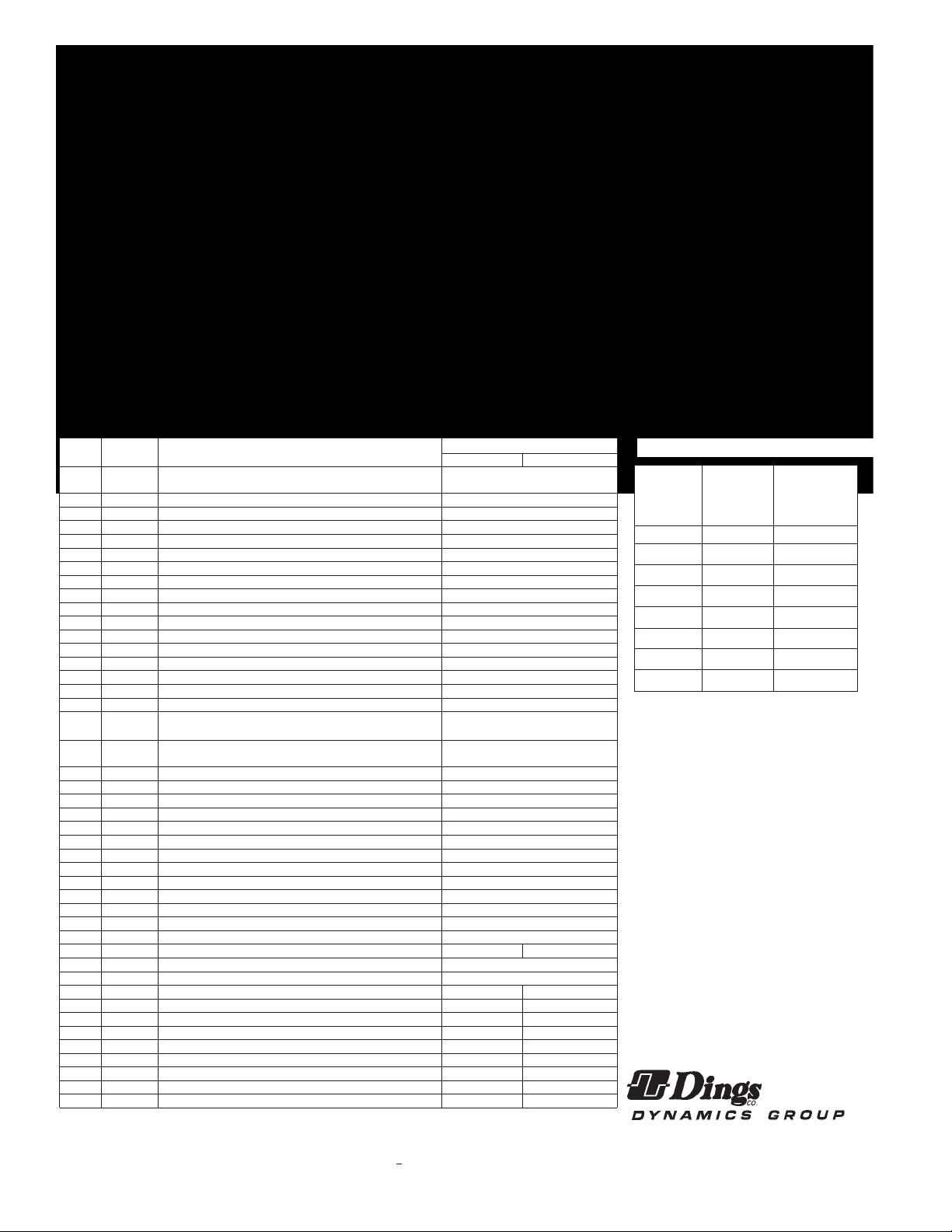

MODEL

NUMBER

NEMA 2

MODEL

NUMBER

NEMA 4

# of

friction

discs

Torque

Lb-Ft

Weight

lbs.

Thermal

Capacity

PS/Min

Inertia

WK2

LB-FT2

DIMENSIONS

AC C

D

A (Motor Shaft Length)

Max. Min. 1-1/8” Dia. 1-3/8” Dia.

Max. Min. Max. Min.

71010-38 71010-46 1 10 45 11 .069 1.19 6.84 .070 .030 1.31

2.81 2.50

*1.81 *1.69

71015-38 71015-46 1 15 45 11 .069 .070 .030 1.31

72025-38 72025-46 2 25 49 12 .110 1.63 7.47 .070 .035 1.31 *2.44 *2.31

73025-38 73025-46 3 25 53 13 .150 2.25 8.09 .070 .040 1.25 3.13 2.94

72035-38 72035-46 2 35 49 12 .110 1.63 7.47 .070 .035 1.21 *2.44 *2.31

73035-38 73035-46 3 35 53 13 .150 2.25 8.09 .070 .040 1.27 3.13 2.94

73050-38 73050-46 3 50 53 13 .150 2.25 8.09 .070 .040 1.25 3.13 2.94

74075-38 74075-46 4 75 57 14 .190 2.88 8.72 .070 .040 1.21 3.25 3.00

Figure 2. Outline Drawing

Table1. List of Models and Dimensions *Std. NEMA Motor Shafts will have to be shortened.

2

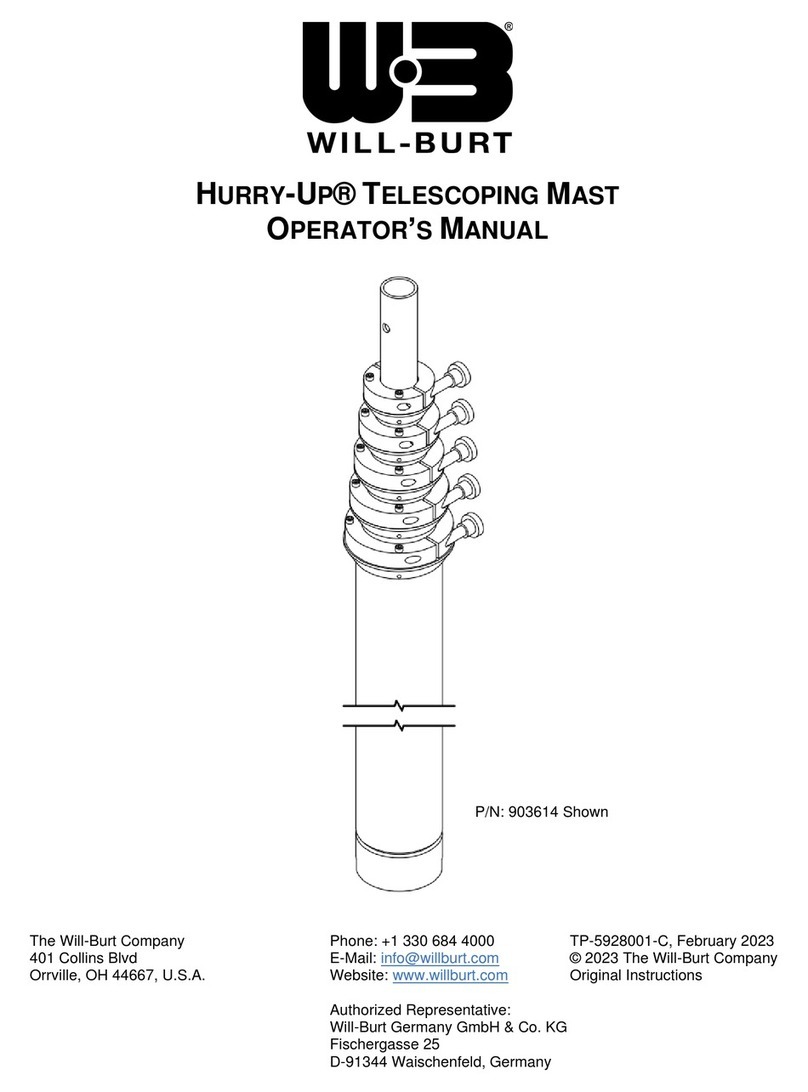

MAGNET COIL REPLACEMENT

(See Figures 1, 3 & 4)

Remove magnet assembly as outlined under FRICTION DISC

REPLACEMENT.

Coils (21) are held in place with epoxy cement. Force coil off

magnet mounting plate and remove excess epoxy from all surfaces.

Replacement coils should be held in place with new epoxy cement.

The epoxy cement should be heat resistant and shock resistant.

Place an insulating washer (20) below the coils. Order insulating wash-

ers when ordering coils. An insulating washer can be cut to

suit when replacing only one coil on a multiple coil assembly.

When installing coils, it is very important to follow EXACTLY the

sequence of black and light colored leads as shown in wiring

diagram (Figure 1). The brake will not operate properly unless coils

are all in the correct position.

Reassemble all parts in reverse order.

TROUBLE SHOOTING

A. IF BRAKE DOES NOT RELEASE:

1. Check brake visually for broken or damaged parts.

2. Check for broken leadwire or bad electrical connection.

3. Check for correct voltage. Line voltage must correspond to

the voltage for which the brake coils are connected. If the

line voltage is more than 10% below the voltage for which

the brake coils are connected, the magnet will not pull in,

causing the coils to burn out within minutes. If the line voltage

is more than 10% above the voltage for which the brake coils

are connected, the coils will overheat and burn out.

4. Check for burned-out coils (coils may be charred or burned).

5. Check for excessive magnet gap. (See WEAR ADJUST

MENT.)

6. Check for failure or power supply to brake.

B. IF BRAKE DOES NOT STOP:

1. Check brake visually for broken or damaged parts.

2. Make certain hub has not shifted position on the motor shaft

and that all rotating discs are fully engaged on the hub.

3. Check that the manual release is in the normal position.

4. Check disc wear. (See WEAR ADJUSTMENT.)

C. IF BRAKE C ATTERS OR UMS:

1. See that magnet faces are clean. To remove dirt, insert a

clean sheet of paper between magnet faces and energize

brake. Move paper around between faces to dislodge dirt,

then remove paper.

2. Check for low voltage. Magnet will not pull in, and coils will

burn out if line voltage is beyond 10% below the voltage the

brake coils are connected for.

3. See that magnet faces are parallel within tolerance.

Readjust magnet gap to “D” min.

(See WEAR ADJUSTMENT.)

4. Check if shading coil (22) is cracked, broken or out of

position (single phase only).

D. IF MANUAL RELEASE DOES NOT WORK:

1. Check for broken or damaged parts.

2. Check return spring (11). Brake will not reset automatically if

this spring is broken.

3. Check quantity of shim washers (13) under release stop

screws. (See Manual Release Assembly under

“FRICTION DISC REPACEMENT”.)

Figure 3. Fastening of Replacement Magnet Coils

SPECIFICATIONS

MOTOR FRAMES - 182TC, 184TC, 213TC, 215TC, 254TC, 256TC.

ENCLOSURES - NEMA 2 or NEMA 4

(material: aluminum and cast iron)

DUTY - Rated for continuous duty.

VOLTAGES - All standard NEMA voltages and frequencies available.

Other voltages and frequencies are optional.

MOUNTING - Direct to NEMA “C” face, with one additional “C” face for

mounting of equipemnt to brake. Some standard motor shafts may

need modification, see Table 1.

orizontal or vertical mounting with modifications.

ORDERING INFORMATION

The following data should be furnished with your order for:

REPLACEMENT PARTS

Brake Model Number

Part Number from Tables

Part Description from Tables

ub Bore & Keyway. Shaft Extension Diameter & Keyway.

For electrical parts specify voltage, phase, and frequency.

REPLACEMENT BRAKE

Model Number

Voltage, Phase & Frequency

ub Bore & Keyway Dimensions. Shaft Extension Diameter & Keyway.

Mounting - orizontal or Vertical. (If vertical, specify whether above or

below motor.

3

Table 2. Parts List

* Number of rotating discs is designated by model number; example:72025-38 has two rotating discs.

Also see table 1 for number of rotating discs.

** Number of stationary discs is one less than the number of rotating discs.

4740 WEST ELECTRIC AVENUE

MILWAUKEE, WI 53219

P ONE 414/672-7830 FAX 414/672-5354

www. dingsbrakes.com

ITEM

NO.

PCS.

REQ’D DESCRIPTION PART NUMBER

NEMA 2 NEMA 4

1 1 ub & shaft assembly

(Specify both diameters & keyways) Consult Factory

2 1 Bracket (Specify brake model no.) L070203

3 2 Studs (Specify brake model no.) 070180

4 * Rotating friction disc 070103-008

5 ** Stationary disc K070485-001

6 1 Pressure plate assembly K070045-001

7 2 Torque spring See torque spring table

8 2 Torque spring washer W004004-001

9 2 Torque adjusting nut W003001-022

10 2 Manual release rod G070472-001

11 2 Manual release spring G060010-001

12 2 Manual release washer W004004-003C

13 As Req’d Manual release shims- .006” thick W004004-004C

14 2 Manaul release stop screw G060029-001

15 2 Manual release lockwasher W004007-007

16 2 Manual release knob G070471-001

17 2 Roll pin, 3/32 x 9/16 lg. W005003-039

18 1 Magnet mounting plate assembly

for 3-Phase magnets (Includes items 19-20) K070097

18 1 Magnet mounting plate assembly

for 1-Phase magnets (Includes items 19-22) K070335

19 1 Roll pin, 5/32 x 1/-18 lg. W005003-109

20 2 Coils-single phase (See ordering info.) 070013

20 6 Coils-three phase (See ordering info.) 020003

21 2 Insulating washers, 1-Phase coils G070029-001

22 2 Shading coil (single phse only) G070032-001

23 2 ex jam nut 1/2-20 W003003-023

24 2 ESNA locknut 1/2-20 W003001-020

25 1 Adapter housing (1-1/8 output shaft) L070202-002

25 1 Adapter housing (1-3/8 output shaft) L070212-002

26 1 ESNA locknut 1/2-20 W003001-020

27 1 Ball bearing-double seal (1-1/8 output shaft) W009001-002

28 1 Retaining ring (1-1/8 output shaft) W006004-001

29 1 Retaining ring (1-1/8 output shaft) W006002-002

30 1 Wrap cover K070278-001 K070279-001

31 1 Nameplate with two drive screws K060473-001

32 1 Cap plug W008003-001

33 1 Pipe plug - 1/8 NPT W010002-001

34 1 “O” ring W006001-010

35 2 Gasket for brake mounting K070250

36 2 Gasket W011004-001

37 2 RD. D. screw, #10-32 x 1” lg. W001051-126 W001051-126

38 2 ex nut #10-32 W003021-008 W003021-008

39 1 Ball bearing-double seal (1-3/8 output shaft) W009001-003

40 1 Retaining ring (1-3/8 output shaft) W006002-003

41 2 Retaining ring (1-3/8 output shaft) W006007-003

Model

Number

NEMA 2

Model

Number

NEMA 4

Torque

Spring P/N

71010-38 71010-46 G070011-001

71015-38 71015-46 G070012-001

72025-38 72025-46 G070019-001

73025-38 73025-46 G070525-001

72035-38 72035-46 G070012-001

73035-38 73035-56 G070011-001

73050-38 73050-46 G070012-001

74075-38 74075-46 G070012-001

Torque spring (Item 7) table

This manual suits for next models

16

Other Dings Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Cannon

Cannon CT-500 instruction & operation manual

Doosan

Doosan 7/124 Operation & maintenance manual

Global Industrial

Global Industrial B237006 Assembly instructions

Mitsubishi Electric

Mitsubishi Electric M800VW Series Connection and set up manual

ABB

ABB DressPack product manual

Toshiba

Toshiba TOSVERT VF-AS3 instruction manual