E6582112

VF-AS3

i

I

3

9

Contents

1 Introduction ............................................................................................................................................................. 1-1

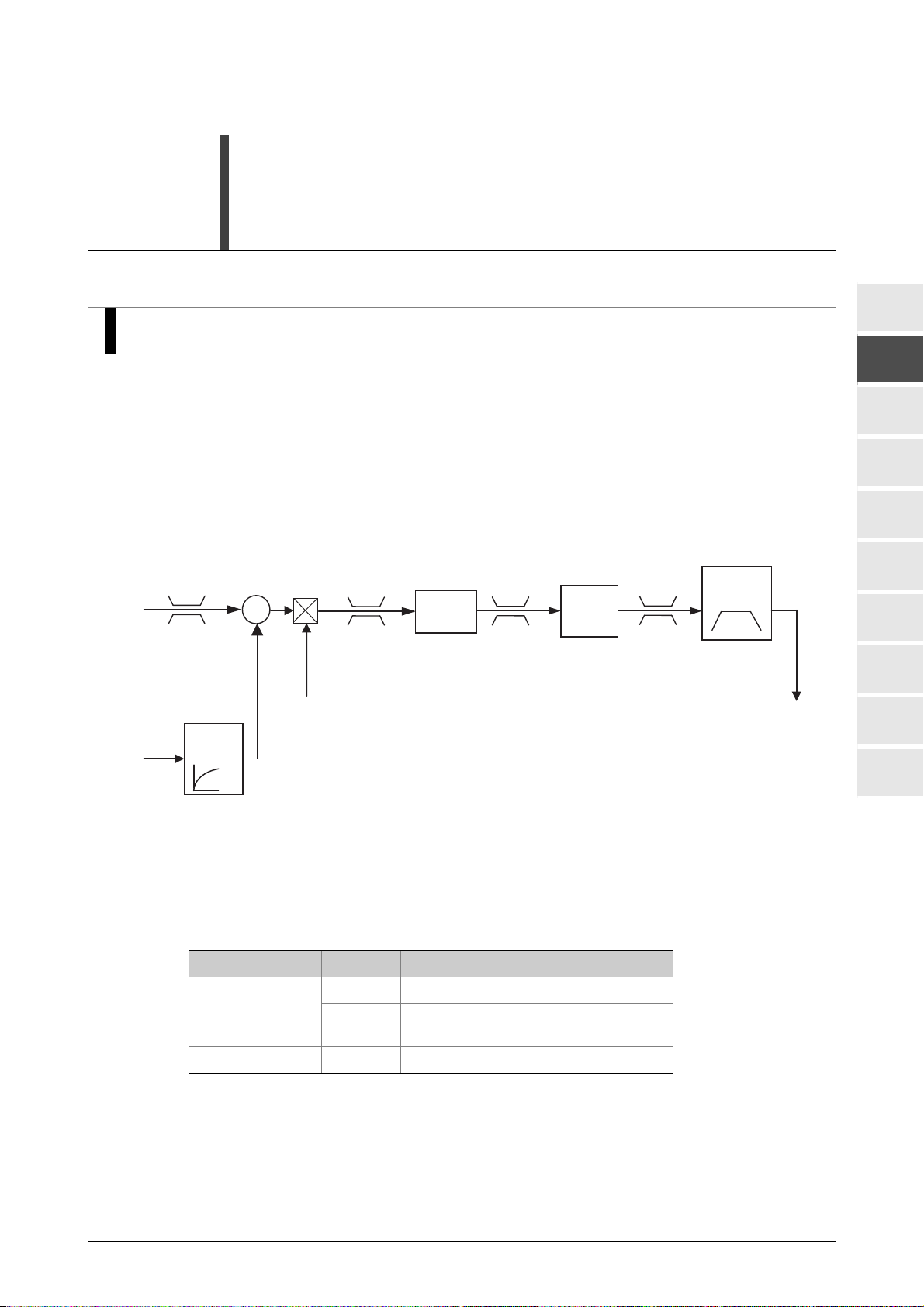

2 PID control selection ............................................................................................................................................... 2-1

2. 1 Process PID control ........................................................................................................................................ 2-1

2. 2 Speed PID control ........................................................................................................................................... 2-3

2. 3 Easy positioning PID control ........................................................................................................................... 2-5

2. 4 Dancer control ................................................................................................................................................ 2-8

3 Parameter list of PID control ................................................................................................................................... 3-1

4 Setting for PID control ............................................................................................................................................. 4-1

4. 1 Fundamental setting ....................................................................................................................................... 4-1

4. 1. 1 Feedback value ................................................................................................................................ 4-1

4. 1. 2 Set value ........................................................................................................................................... 4-5

4. 1. 3 Override function .............................................................................................................................. 4-9

4. 1. 4 Acceleration and deceleration time ................................................................................................ 4-10

4. 2 Set to suit the motor ...................................................................................................................................... 4-10

4. 3 Set to suit the system ................................................................................................................................... 4-11

4. 3. 1 Set if necessary .............................................................................................................................. 4-11

4. 3. 2 Switch PID characteristics .............................................................................................................. 4-11

4. 3. 3 Agreement between set value and feedback value ........................................................................ 4-12

4. 3. 4 Switch to frequency command operation ....................................................................................... 4-12

4. 3. 5 Deviation limit of PID control .......................................................................................................... 4-13

4. 3. 6 PID control with Sleep function ....................................................................................................... 4-13

4. 3. 7 Output power compensation function ............................................................................................. 4-15

4. 4 PID auto tuning function ............................................................................................................................... 4-16

5 PID control adjustment ........................................................................................................................................... 5-1

5. 1 Summary of adjustment .................................................................................................................................. 5-1

5. 2 Fundamental adjustment (common) ............................................................................................................... 5-1

5. 2. 1 Proportional (P) gain ......................................................................................................................... 5-2

5. 2. 2 Integral (I) gain ................................................................................................................................. 5-2

5. 2. 3 Differential (D) gain ........................................................................................................................... 5-2

5. 3 Applied adjustment (Common) ....................................................................................................................... 5-3

5. 3. 1 PID integral / differential reset .......................................................................................................... 5-3

5. 3. 2 PID control wait time ......................................................................................................................... 5-3

5. 4 Applied adjustment (for speed PID control) .................................................................................................... 5-3

5. 4. 1 Delay filter ......................................................................................................................................... 5-3

5. 4. 2 Set value increase time, decrease time ............................................................................................ 5-4

6 Analog input characteristics .................................................................................................................................... 6-1

7 PID2 control ............................................................................................................................................................ 7-1

8 Parameter list of PID2 control ................................................................................................................................. 8-1

9 External PID control ................................................................................................................................................ 9-1

10 Parameter list of external PID control ................................................................................................................... 10-1