Dings 70 Series User manual

BULLETINNO.BK4603

DATE8/94

4740WESTELECTRICAVENUEŸMILWAUKEE,WI53219Ÿ(414)6727830 ŸFAX(414)6725354

1

DIRACTBRAKES

70&80SERIES

INSTRUCTIONS

IMPORTANT

Readthisbulletincarefullybeforeinstallingoroperating

this brake. Failure to comply with these instructions

cancelsallwarrantiessincethesafetyoftheunitmaybe

endangered by improper installation or operating

procedures.

DESCRIPTION

Thisbrake is direct acting, electromagneticallyreleased

and spring set. It uses rotating and stationary disc

contact to supply positive braking action. It retains

quickreleaseandsettingcapabilitiesataltimes

Simplicity of design has reduced maintenance to an

absolute minimum. As with any electromechanical

equipment,however,periodicinspectionandadjustment

willassure optimumperformance. Asthe friction disc

wears, the magnet gap will increase. The magnet gap

should be checked periodically and adjusted when

necessary.

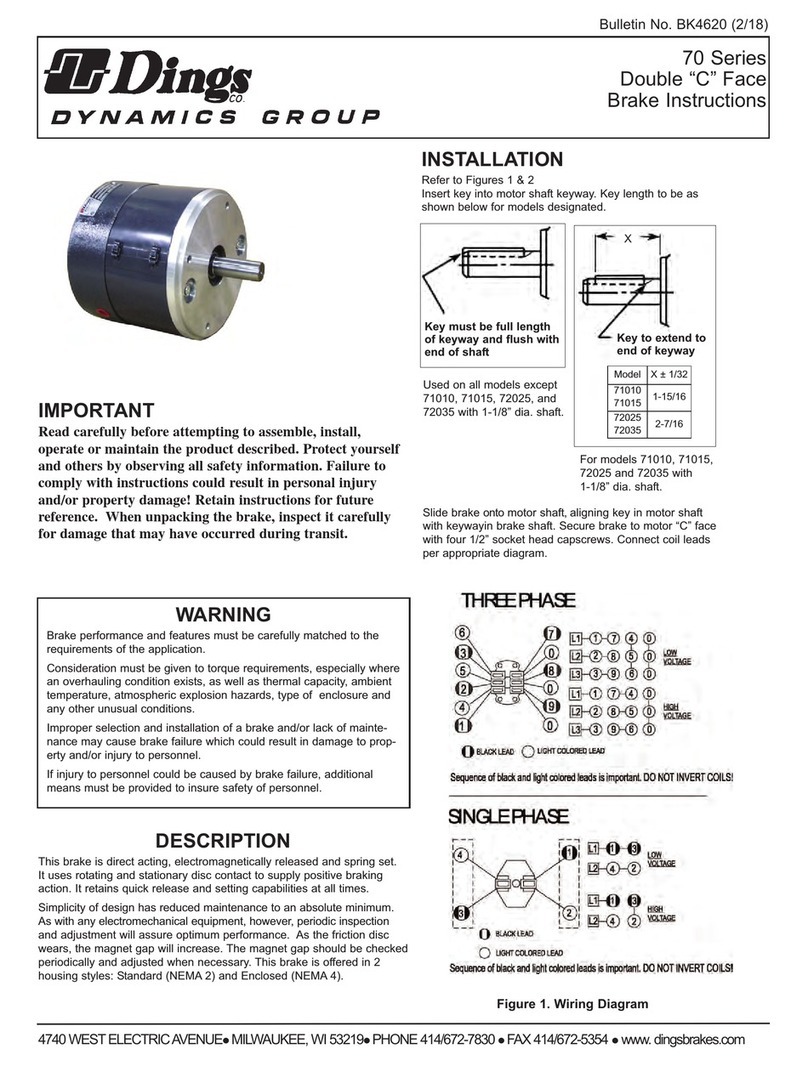

INSTALLATION

RefertoFigures3&5,Tables1,2&4

Figure1illustratesDiractbrakeswithastandardmanual

release.Thisreleaseconsistsoftworodsvisiblethruthe

cover. An optional release, the Mark II, has a single

leverasshowninFigure4.

1. Remove hub (1) from brakeand position on motor

shaft with key according to dimension “N”.

Stampedpartnumberonhubshouldfaceawayfrom

motor. Tighten hub set screws with 12 ft. lbs.

torque. On Mark II release models, motor shaft

shouldnotextendbeyondhub.

2. Removecoverscrews(24)andcover(23),plus“O”

ring (28) and gasket (32) on enclosed housing

models. OnMarkII models, moverelease lever to

horizontalposition.Removecover.

3. Place brake on motor, guiding discs on hub. On

MarkIImodels,thereleaselevershouldhangdown.

Thereleasemechanism isresetbygravity.

4. Boltbrake to motor “C” face withfoursockethead

cap screws. See Tables 1 and 2, and Figure 3 for

screwsize.

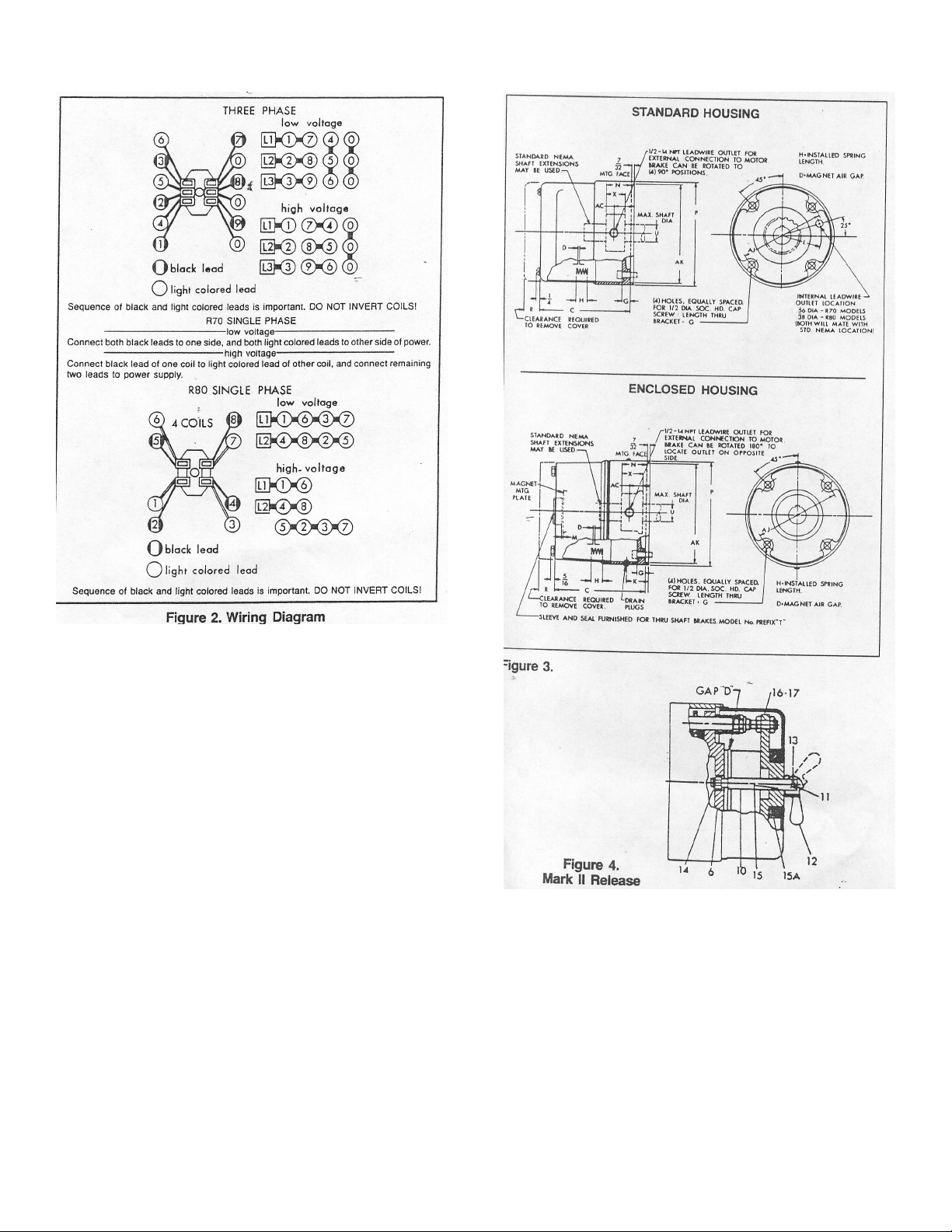

5. Connectcoilleadsperappropriatewiringdiagramin

Figure2andreplacecover.

WARNING

Brake performance and features must be carefully

matchedtotherequirementsoftheapplication.

Considerationmustbegiventotorquerequirements,

especially where an overhauling condition exists, as

well as thermal capacity, ambient temperature,

atmosphericexplosionhazards,typeofenclosureand

anyotherunusualconditions.

Improperselectionandinstallationofabrakeand/or

lack of maintenance may cause brake failure which

could result in damage to property and/or injury to

personnel.

If injury to personnel could be caused by brake

failure,additional means must beprovidedtoinsure

safetyofpersonnel.

Donotoperatemanualreleaseorenergizebrakecoil

beforeinstallation,inorderto preserveprealignment

ofrotatingdiscsforeaseofinstallation.

BULLETINNO.BK4603

DATE8/94

4740WESTELECTRICAVENUEŸMILWAUKEE,WI53219Ÿ(414)6727830 ŸFAX(414)6725354

2

MANUALRELEASEOPERATION

RefertoFigures4&5

To operate standard release (Figure 5), rotate two rods

(10)clockwiseuntilstopscrew(14)hitspin.Tooperate

Mark II release (Figure 4), push lever (12) to upward

position.Brakewillremaininrelease position untilrods

or lever are manually returned to original position, or

until electrical power is restored which automatically

resetsthebrake.

TORQUEADJUSTMENT

RefertoFigures3&5,Tables1or2

Brake is factory set for rated torque per spring length

“H”. To increase stopping time and lower torque, turn

two locknuts (9) counterclockwise, increasing

dimension “H”. Both spring lengths should be equal.

Donotdecreasespringlength “H”asthismaycausecoil

toburnout.

BULLETINNO.BK4603

DATE8/94

4740WESTELECTRICAVENUEŸMILWAUKEE,WI53219Ÿ(414)6727830 ŸFAX(414)6725354

3

MAINTENANCEANDSERVICE

WEARADJUSTMENT

Referto Figures3&5,Tables1or2

Magnet gap “D” increases as the rotating friction discs

wear. Whengapapproaches“D”max.,adjustgaptothe

“original setting” listed under “D” by turning nuts (21)

and (22). The “original setting” is also the minimum

allowed.

Too small a gap will not provide the proper running

clearance, and will cause excessive wear and

overheatingoftherotatingfrictiondisc.Themagnetgap

canvaryfrom“originalsetting”±.005betweencorners.

After setting gap, readjust torque spring length per

dimension “H”.

CAUTION:MAGNETGAPMUSTNOTEXCEED

“D”MAXIMUM.

FRICTIONDISCREPLACEMENT

RefertoFigures3,4&5.Tables1or2

Whenrotating frictiondisc(4)wearsdowntoa

thicknessof7/32”,replacedisc.

1. Removecoverscrews(24)andcover(23),plus“O”

ring(28)andgasket(32)onenclosedmodels.

2. Standardreleasemodel:Unhookloopoftorsion

springs(11)frompinsatrearofmagnetplate(16).

Removereleasestopscrews(14)washers(12)and

shims(13).SeeFigure5.MarkIIreleasemodel:

Removecotterpin(13)andreleaselever(12).See

Figure4.

3. Removeadjustinglocknuts(22)magnetassembly

(16),adjustingnuts(21),torque nuts(9),washers

(8),torquespring(7)andpressureplate(6).

4. Removefrictiondisc(4)andstationarydisc(5).

Replacewornfrictiondiscs.

5. Reassembleallpartsinreverseorder.Setspring

length “H”andmagnetgap“D”.Assemblemanual

release.Seefollowingparagraph.

MANUALRLEASEASSEMBLY

RefertoFigures3,4&5

Whenassemblingastandardmanualreleasemechanism

(Figure5),add onlyenoughshim washers(13)toobtain

properreleaseaction.Toomanyshim washerswill

preventautomaticresetwhenelectricalpowerisapplied.

Toofewwasherswillpreventthemotorshaftfrom

turningfreely.Replacesopscrews(14).Windeach

torsionspring(11)approximately ¼ turnandhook

springloopoverpin.

WhenassemblingaMarkIImanualreleasemechanism

(Figure4),attachlever(12)toreleaserod(1)withpin

(11)andcotterpins(13).Withlever(12)inraised

position,rotateleveruntilpressureplate(6)makes

contactwithmagnetassembly(16)closinggap“D”.

Lowertheleverandturn counterclockwise ¼ turn.The

levershouldnowhangdown,andifnot,removelever

andrelocateitascloseaspossibletodownpositionas

holesinrod(10)allow. The levermusthangdown

because resetisbygravity(verticalmountedbrakeshave

returnsprings).

Tocheckreleaseaction,raiselever.Motorshaftshould

turnfreely.Applypower.Levershouldreturntodown

position automatically. Ifshaftdoesnotturnfreely,turn

leverclockwise ¼ turn.Relocatelevertodownposition.

Ifleverdoesnotreturnautomatically,turnlever

counterclockwise ¼ turn.Relocatelevertodown

position.

BULLETINNO.BK4603

DATE8/94

4740WESTELECTRICAVENUEŸMILWAUKEE,WI53219Ÿ(414)6727830 ŸFAX(414)6725354

4

BULLETINNO.BK4603

DATE8/94

4740WESTELECTRICAVENUEŸMILWAUKEE,WI53219Ÿ(414)6727830 ŸFAX(414)6725354

5

BULLETINNO.BK4603

DATE8/94

4740WESTELECTRICAVENUEŸMILWAUKEE,WI53219Ÿ(414)6727830 ŸFAX(414)6725354

6

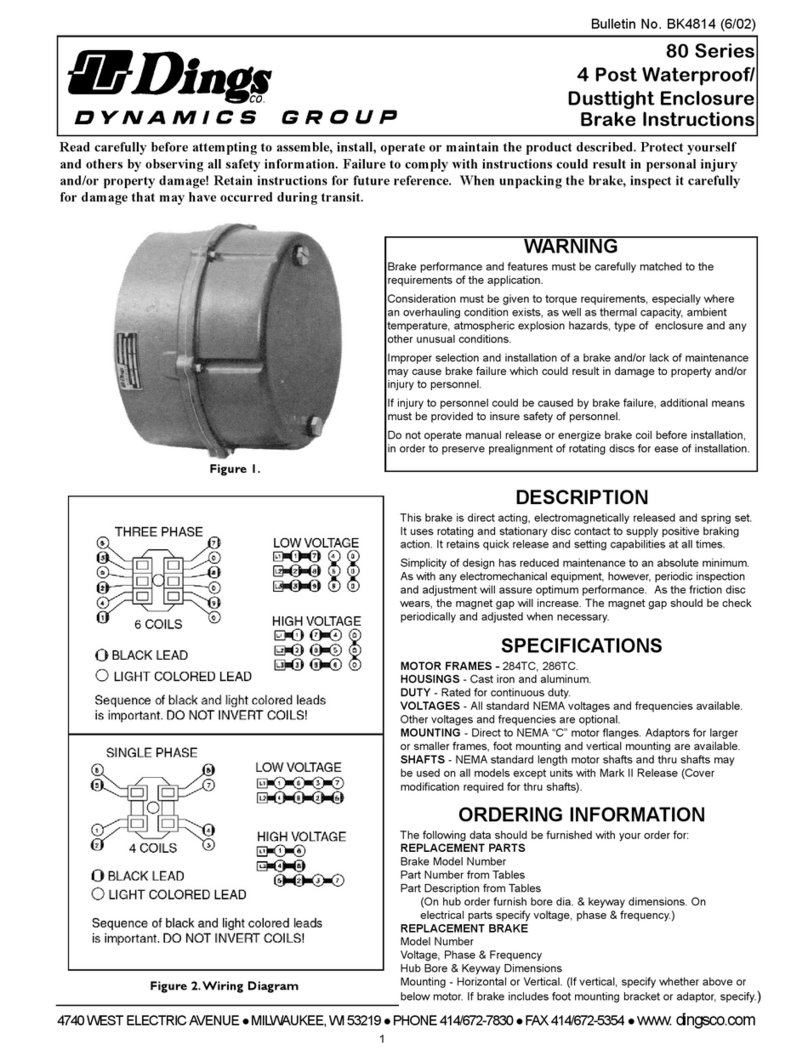

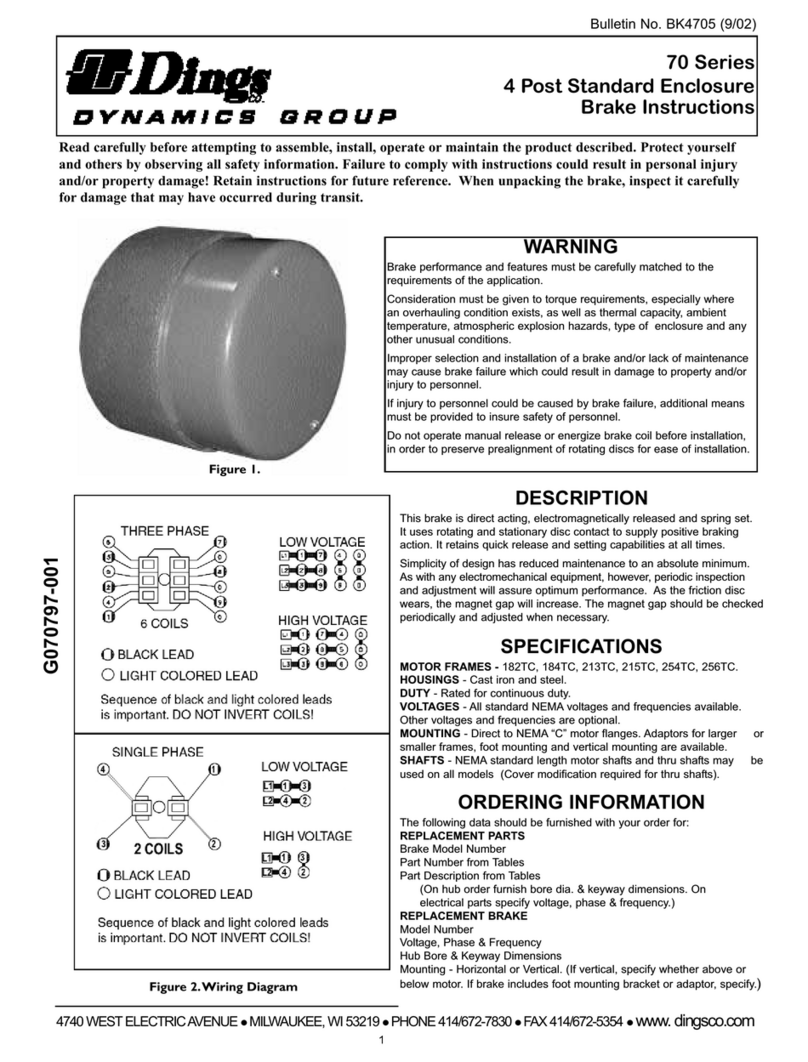

MAGNETCOILREPLACEMENT

Refertofigures5&6.

RemovemagnetassemblyasoutlinedunderFRICTIONDISC

REPLACEMENT.

Coils(18)areheldinplacewithepoxycement. Force coil offmagnet

mountingplateandremoveexcessepoxyfromallsurfaces.

Replacementcoilsshouldbeheldinplacewithnewepoxycement. The

epoxycementshouldbeheatresistantandshockresistant.Placean

insulatingwasher(19or19a)belowthecoils.Orderinsulatingwashers

whenorderingcoils.Aninsulation washercanbecuttosuitwhen

replacingonlyonecoilon amultiplecoilassembly.

Wheninstallingcoils,itisveryimportanttofollowEXACTLYthe

sequenceofblackandlightcoloredleadsasshowninwiringdiagram

(Figure2).Thebrakewillnotoperateproperlyunlesscoilsareallinthe

correctposition.

BULLETINNO.BK4603

DATE8/94

4740WESTELECTRICAVENUEŸMILWAUKEE,WI53219Ÿ(414)6727830 ŸFAX(414)6725354

7

TROUBLESHOOTING

A. IFBRAKEDOESNOTRELEASE:

1. Checkbrakevisuallyforbrokenordamaged

parts.

2. Checkforbroken leadwireorbadelectrical

connection.

3. Checkforcorrectvoltage.Linevoltagemust

correspondtothevoltageforwhichthebrake

coilsareconnected.Ifthelinevoltageismore

than10%belowthevoltageforwhichthebrake

coilsareconnected,themagnetwillnotpullin,

causingthecoilstoburnoutwithinminutes.If

thelinevoltageismorethan10%above the

voltageforwhichthebrakecoilsareconnected,

thecoilswilloverheatandburnout.

4. Checkforburnedoutcoils(coilsmaybecharred

orburned).

5. Checkforexcessivemagnetgap.(SeeWEAR

ADJUSTMENT.)

6. Checkforfailureofpowersupplytobrake.

B. IFBRAKEDOESNOTSTOP:

1. Checkbrakevisuallyforbrokenordamaged

parts.

2. Makecertainhubhasnotshiftedpositiononthe

motorshaftandthatallrotatingdiscsarefully

engagedonthehub.

3. Check thatthemanual release isinthenormal

position.

4. Check discwear.(SeeWEAR

ADJUSTMENT).

C. IFBRAKECHATTERSORHUMS:

1. Seethatmagnetfacesareclean.Toremovedirt,

insertacleansheetofpaperbetweenmagnet

facesandenergizebrake.Movepaperaround

betweenfacestodislodgedirt,thenremove

paper.

2. Checkforlowvoltage.Magnetwillnotpullin,

andcoilswillburnoutiflinevoltageisbeyond

10%below thevoltagethebrakecoilsare

connectedfor.

3. Seethatmagnetfacesareparallelwithin

tolerance.Readjustmagnetgapto “D”min.

(SeeWEARADJUSTMENT).

4. Checkifshadingcoil(2)iscracked,brokenor

outofposition (singlephaseonly).

D. IFMANUALRELEASEDOESNOTWORK:

1. Checkforbroken ordamagedparts.

2. Check returnspring(11).Brakewillnotreset

automaticallyifthisspringisbroken.

3. Checkmagnetgapwithbrakeinreleased

position.(SeeMANUALRELEASE

ASSEMBLY).

4. Checkquantityofshimwashers(13)under

releasestopscrews.(SeeMANUALRELEASE

ASSEMBLY.)

This manual suits for next models

29

Table of contents

Other Dings Industrial Equipment manuals