Dings DS-OLS7-FRS4 User manual

page│1

Technical Manual

DS-OLS7-FRS4

DS-OLS7-FRS4 Technical Manual

VER 1.0

page│2

Table of Contents

1.

Features…………………………………………………………………………...………………3

2. Technical Parameters…………………………………………………………...........……………...3

3. Schematic and Interface Definition...........................................................................................4

4. Power Supply…………………………..……………………………………………………………....8

4.1

Voltage…………………………………………………………………………….……………….8

4.2

Current…………………………………………………………………………………………….. 8

4.3

Regeneration of Discharge……………………………………………………………………...8

5. Motor Connection……………………………………………………………………………..……….9

6. Signal Input………………………………………………………………………………………...…10

6.1

Pulse Signal :STEP…………………………….…………………………..……………………10

6.2

Direction Signal : DIR……………………………………………………………………………10

6.3

Pulse / Direction Input Timing diagram…………………………………………..…………….11

7. Typical Signal Connection……………………………………………………………...…………....12

7.1

Common Positive Connection…………………………………………………………………12

8. Typical Connection of Signal Output………………………………………………………………...13

8.1

Relay Connection…………………………………………………………..…………………....13

8.2

Optocoupler Connection……………………………………………………..………………….13

9. Wiring Requirements………………………………………………………………………………....14

10. Installation Dimensions……………………………………………….…………………………….15

11. Control Parameter………………………………………………………………………………….16

11.1

Control Basic Status (Class 01)………………………………………...……………………..16

11.2

Basic Parameter Setting (Class 02)…………………………………………………………..16

11.3

Control Parameters (Class 05)………………………………………………………………...17

11.4

Input Block Designation (Class 06)……………………………………..……………………..19

11.5

Output Block Specification (Class 07)………………………………………………………..21

12. Modbus-RTUProtocol Example...…………………………………………...……………………..22

12.1

Running Motor……………………………………………………………………………..…....22

12.2

Read Motor Status..........................…………………………………………………………...26

12.3

Read Alarm Status......................……………………………………………………………....28

13. Part……………………………………………………………………………...……………………..29

Click to return to table of contents

Contents

page│3

1. Features

Input power: DC 24V-48V

PWM constant current bipolar subdivision drive

Single / double pulse selection

Optically isolated input function

Motor short circuit protection

Compact design, low noise and low vibration

Adjustable driving current peak below 3.2 A

Support RS 485 communication

2. Technical Parameters

STEP Drive model DS-OLS7-FRS4

Adapter motor Adapted to two-phase hybrid stepping motor, DS-OLS7 FRS4

Maximum fit 3.2A

Power supply 24 - 48V DC

Output current DS-OLS7-FRS4:0.1A-3.2A/ phase

Drive mode Full-bridge bipolar PWM driver

Input signal IN1(DIR)signal Optocoupler input voltage H = 3.5 - 26.0V , L = 0 - 0.8V

On current 6-15mA

IN2(STEP)signal

Output signal OUT Output Optically isolated output, highest withstand voltage30VDC,

Maximum saturation current 50mA

Size 94 × 77 × 27mm(Including terminal block)

Weight About 175 g

Use

surroundings

Use occasion Avoid dust, oil mist and corrosive gases

Humidity < 85 % RH, No condensation

Temperature 0°C - +40°C

Heat dissipation Installed in a ventilated environment

Features / Technical Parameters

page│4

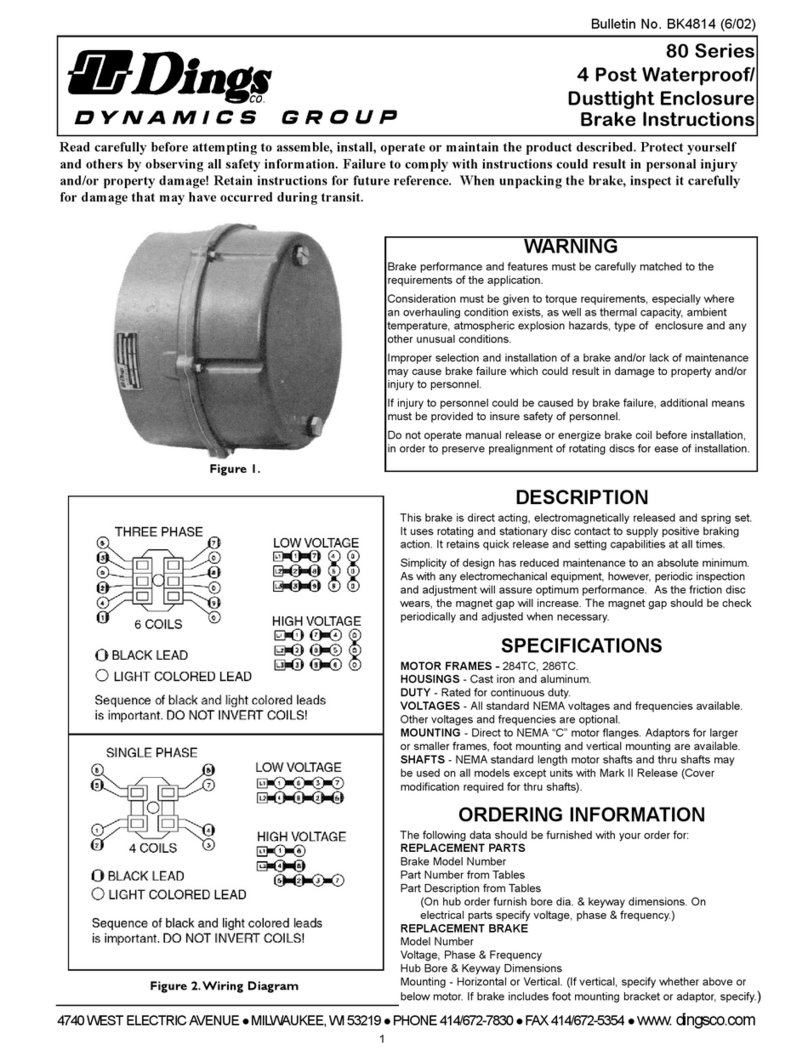

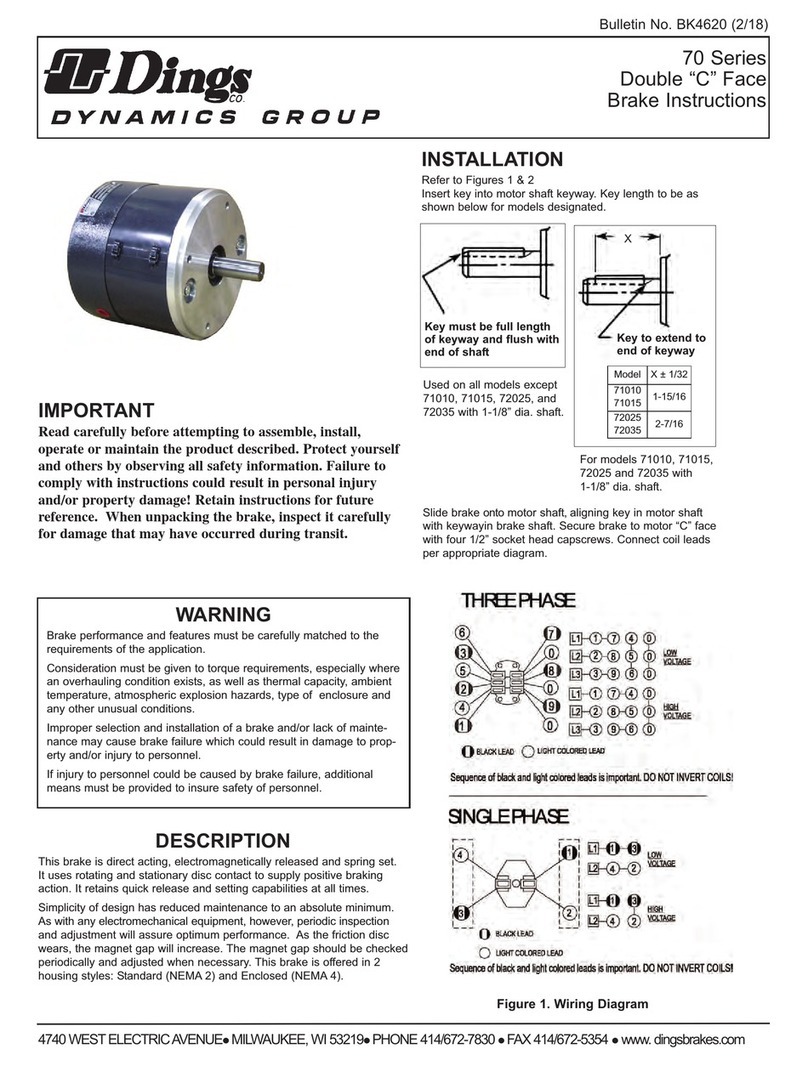

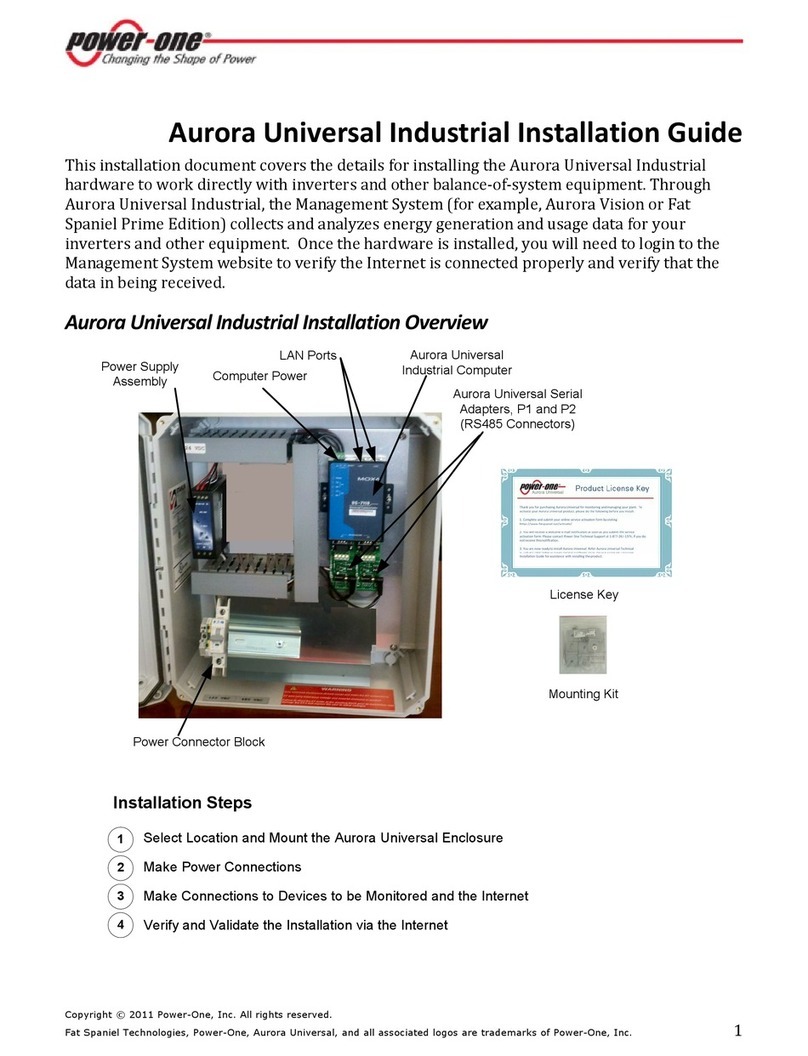

3. Schematic and Interface Definition

1) Signal input (as shown from left to right)

Operation mode selection 0: external pulse

1 pin --- pulse STEP +, 2 pin --- pulse STEP-, 3 pin --- direction DIR +, 4 pin --- direction DIR-

5 feet --- output OUT +, 6 feet --- output OUT-

Operation mode selection 1: internal pulse

Pin 1 --- Input port IN1 +, Pin 2 --- Input port IN1-, Pin 3 --- Input port IN2 +, Pin 4 --- Input port IN2-

Pin 5 --- Output OUT +, Pin 6 --- Output OUT-

2) Motor connection and power input (as shown from left to right)

1 pin --- A +, 2 pin --- A- 3 pin --- B +, 4 pin --- B-, 5 pin --- V-, 6 pin --- V +

3) RS485 IN / RS485 OUT(side)

1 pin --- A, 2 pin --- B 3 pin --- GND

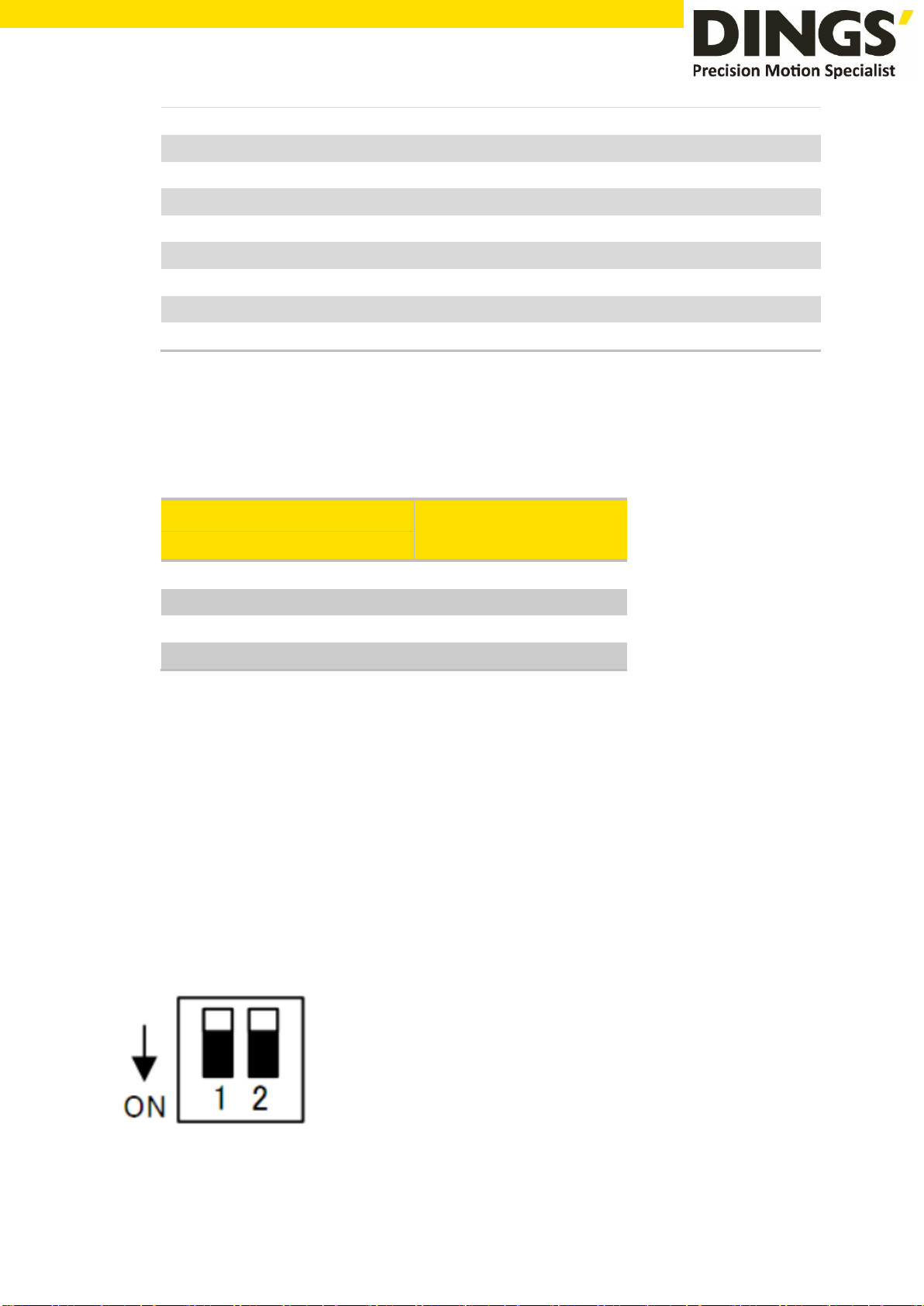

Setting Switch

Schematic and Interface Definition

page│5

4) mailing address

Users can control up to 30 DS-OLS7-FRS4 drives simultaneously using the RS-485 bus.

The drive communication address setting uses a 5-digit DIP switch.

The address setting range is 1-32, where address 32 is reserved for the system. When the

drive address setting is greater than 31, it needs to be set and saved using the upper

debugging software.

And the switch must be set to all OFF (default is 1).

Notes

1)

One controller can control up to 30 DS-OLS7-FRS4 drives simultaneously via

the RS-485 bus.

2) The communication address setting of each drive must be unique,

otherwise it will cause communication error.

DIP switch

address

SW1

SW2

SW3

SW4

SW5

ON ON ON ON ON 1

ON ON ON ON OFF 2

ON ON ON OFF ON 3

ON ON ON OFF OFF 4

ON ON OFF ON ON 5

ON ON OFF ON OFF 6

ON ON OFF OFF ON 7

ON ON OFF OFF OFF 8

ON OFF ON ON ON 9

ON OFF ON ON OFF 10

ON OFF ON OFF ON 11

ON OFF ON OFF OFF 12

ON OFF OFF ON ON 13

ON OFF OFF ON OFF 14

ON OFF OFF OFF ON 15

ON OFF OFF OFF OFF 16

OFF ON ON ON ON 17

OFF ON ON ON OFF 18

OFF ON ON OFF ON 19

OFF ON ON OFF OFF 20

OFF ON OFF ON ON 21

OFF ON OFF ON OFF 22

OFF ON OFF OFF ON 23

Schematic and Interface Definition

page│6

OFF ON OFF OFF OFF 24

OFF OFF ON ON ON 25

OFF OFF ON ON OFF 26

OFF OFF ON OFF ON 27

OFF OFF ON OFF OFF 28

OFF OFF OFF ON ON 29

OFF OFF OFF ON OFF 30

OFF OFF OFF OFF ON 31

OFF OFF OFF OFF OFF N/A

5)Communication baud rate

DIP switch

Baud rate (bps)

SW6

SW7

ON

ON

4800

ON

OFF

9600

OFF

ON

19200

OFF

OFF

38400

6)Test run

The commissioning function is used to verify the performance of the drive. Turn the SW8

switch to ON when the power is off. Then, after power-on, without pulse input, the SW8

gear dial switch is turned from the ON position to the OFF position. After 1 second, the

OFF position is set to the ON position, that is, the test run function is started (the motor is

at 1 rev/sec. The speed of the cycle is positive and negative movements in a circle).

7)DIP switch (SW9-10) setting

Set the terminal resistance to ON/OFF

Please set both switches of the final node to ON only.

Never set more than two device switches to ON.

Schematic and Interface Definition

page│7

8)Idle current

After 500 milliseconds of no pulse input, the current will automatically enter the idle current

to reduce motor heating. The current is restored to the set value during pulse input.

9)Indicator function

This product has 2 LEDs indicating that the light shows the working status:

1. Green light: (work instructions)

When the motor has no current, the lamp flashes 2 times (0.5 second low level, 0.5 second

high level) to complete the 2 second high level, and then recirculate.

It is always on when the motor is running.

The lamp flashes when the motor is running (0.5 second low level, 0.5 second high level).

2. Red light: (fault indication)

Mode: Blinking (0.5 sec low level, 0.5 sec high level) times to complete 2 seconds high level,

then recirculate.

Alarm function Flashing light Description

Motor overcurrent Constantly bright Motor phase current overcurrent or driver failure

Motor phase loss Flashing once The motor is not connected

Power overcurrent 2 flashes Power overcurrent or drive failure

Undervoltage 3 flashes Power input is less than 18V

Overpressure 4 flashes Power input is greater than 52V

overheat 5 flashes Drive heatsink temperature above 80 °C

overload 8 flashes Brake resistor failure

other other Other failure

Schematic and Interface Definition

page│8

4. Power Supply

4.1 Voltage

The chopper driver continuously changes the size and direction of the motor winding voltage

and detects the current to obtain accurate phase current. If both high efficiency and low noise

are to be ensured, the driver supply voltage shall be at least 5 times the motor rated phase

voltage (that is, the motor rated phase current × phase resistance).

If you need the motor to get better high speed performance, you need to increase the driver

supply voltage.

If power is supplied from a regulated power supply, the supply voltage shall not exceed 48V.

If non-stabilized power supply is used, the voltage shall not exceed 34V.

Because the rated current of non-stabilized power supply is full load current ; When the load is

light, such as when the motor is not running, the actual voltage is up to 1.4 times the rated

voltage of the power supply. For smooth and quiet operation of the motor, choose low voltage.

4.2 Current

The maximum supply current shall be the sum of the two phase currents. Usually, the amount

of current you need depends on the type of motor, voltage, speed, and load conditions. The

actual supply current value is much lower than this maximum value, because the driver USES

a switching amplifier that converts high voltage and low voltage current into low voltage and

high current. The more the supply voltage exceeds the motor voltage, the less supply current

is required. When the motor is connected to a 48V power supply, the output current of the

power supply is half of that of the 24V power supply.

4.3 Regeneration of Discharge

When the motor slows down, it ACTS like a generator, converting the kinetic energy of the load into

electricity. Some energy is consumed by the driver and motor. If your application has a large load

running at high speed, a considerable amount of kinetic energy can be converted into electricity.

Easy to cause the drive alarm (overvoltage) may even cause damage to the drive.

Since this driver has the function of anti-power connection, it can prevent the driver

damage caused by power connection, so the use of external regenerative discharge

device does not work.

When your application has a large load running at high speed, please contact the

company in advance, shield anti - reverse connection function, and external

Power Supply

page│9

regenerative discharge device. Please note that the positive and negative terminals of

the power supply should not be inversely connected when there is no anti-inversely

connected function.

The driver damage caused by inversely connected power supply cannot be guaranteed.

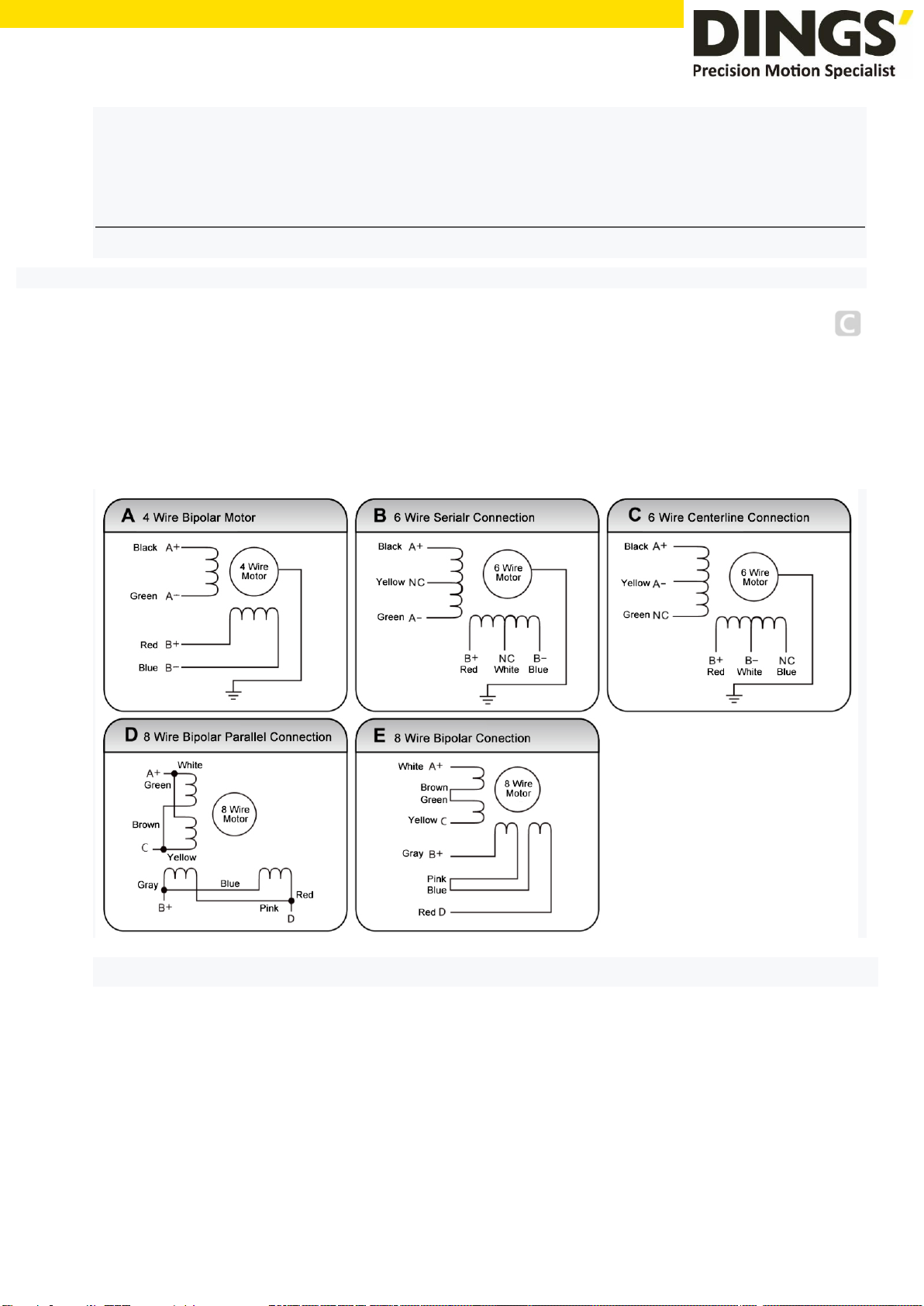

5. Motor Connection

Warning: When connecting the motor to the drive, first make sure that the power of the drive is

turned off. Make sure that the unused motor leads are not short-circuited with other objects.

The motor cannot be disconnected while the drive is energized. Do not connect motor leads to

ground or power.

1) Four-wire motors can only be connected in one way.

2) Six-wire motors can be connected in two ways: full group and half group. In the full group mode, the

motor has greater torque at low speeds, but it cannot run as fast as in the half group. When the whole

group is running, the motor needs to run at less than 30% of the half-group current to avoid overheating.

3) Eight-wire motors can be connected in two ways: series and parallel. The series mode has greater

torque at low speeds and less torque at high speeds. When running in series, the motor needs to run

at 50% of the current in parallel to avoid overheating.

Power Supply / Motor Connection

page│10

Notes

1) The corresponding colors of different motors are different. When using the

motors, the specifications of the motors shall prevail. For example, the colors of

57 and 86 motor wires are different.

2) The phases

are relative, but the windings of different phases cannot be

connected to the terminals of the same phase of the driver (A +, A- is one phase,

B +, B- is the other phase). If the motor direction is different from the expected

direction, only A + , A-.

3) This driver can only drive two-phase hybrid stepping motors, not three-phase

and five-phase stepping motors.

4) The method of judging whether the stepper motor is connected in series or in

parallel: Rotate the shaft of the motor directly by hand without connecting the

driver. If it can rotate easily and evenly, it means that the wiring is correct. If it

encounters large resistance and unevenness Accompanied by a certain sound

indicating that the wiring is incorrect.

6. Signal Input

6.1 Pulse Signal : STEP

The driver port has a built-in optocoupler, which can accept 5-24VDC single-ended or

differential signals, and the highest voltage can reach 26V. Its change from off to on is

understood as accepting a valid pulse edge command. For the common anode, the low level

is valid (the common negative is valid for the high level). At this time, the driver will drive the

motor to run one step according to the corresponding timing. For the normal operation of the

driver, the duty cycle of the effective level signal should be below 50%. In order to ensure the

reliable response of the pulse signal, the duration of the pulse effective level of the subdivided

driver should not be less than 1us. The signal response frequency of the subdivision driver is

500KHz, and an excessively high input frequency may get an incorrect response.

6.2 Direction Signal : DIR

Can accept 5-24VDC single-ended or differential signals, the highest voltage can reach 26V.

The on / off of the internal photocoupler at this end is interpreted as two directions of motor

operation. The change of the direction signal will change the direction of motor operation. The

floating of this end is equivalent to the input high level. It should be noted that the subdivision

driver should ensure that the direction signal is established at least 10us ahead of the pulse

signal input to avoid the driver s incorrect response to the pulse signal. When the motor is

commutated, it must be switched after the motor decelerates and stops to the starting

Motor Connection / Signal Input

page│11

frequency. The commutation signal must be changed after the last STEP pulse of the previous

direction signal and before the first STEP pulse of the next direction. When no commutation is

required, the direction signal terminal can be left floating.

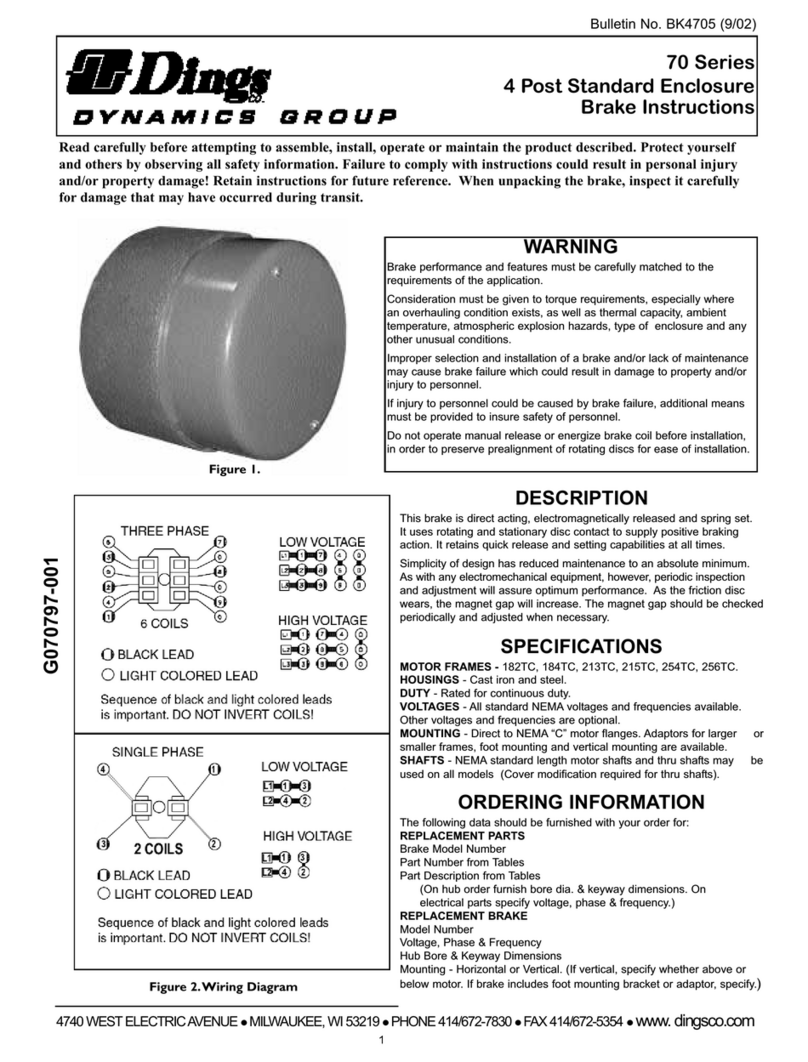

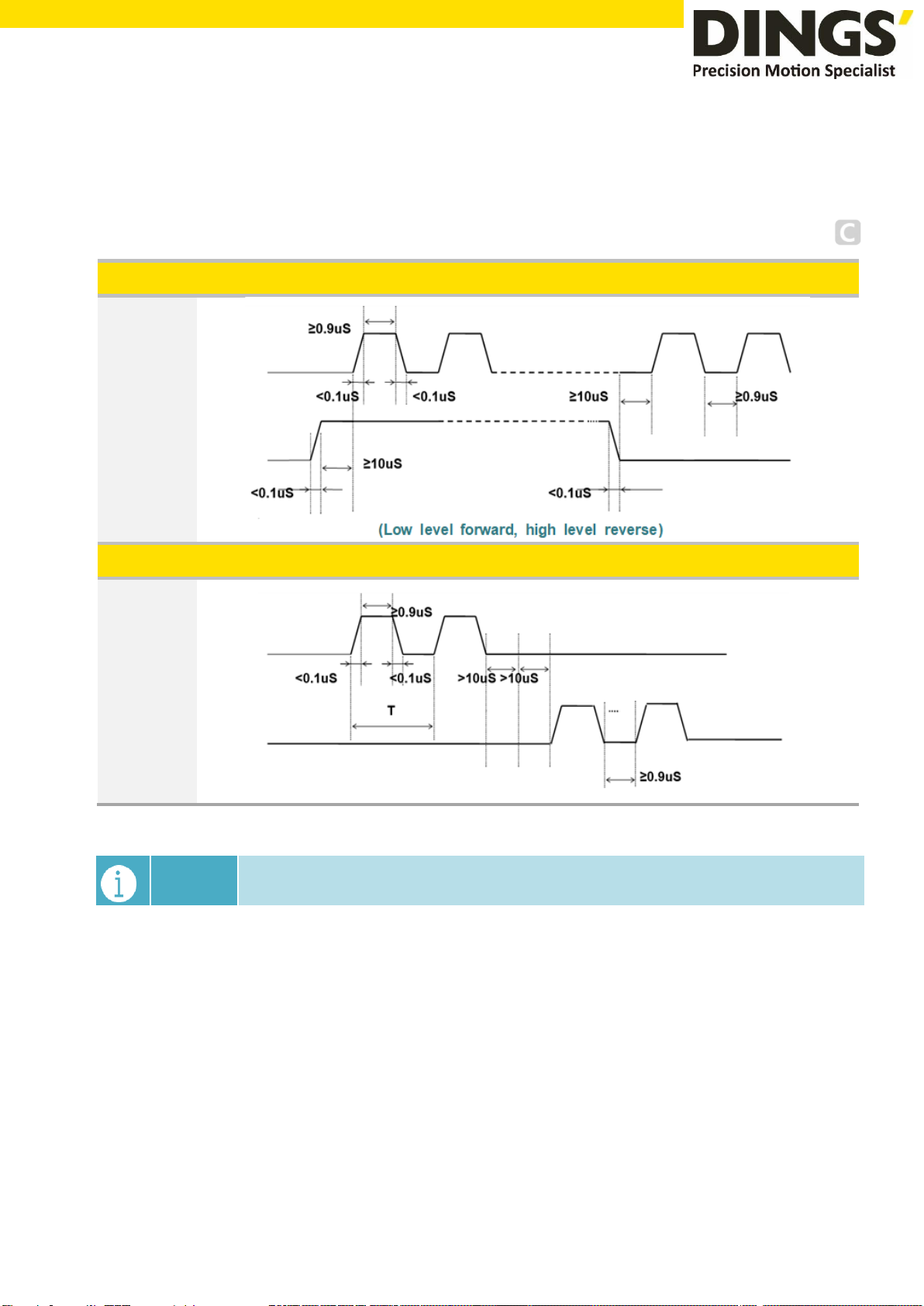

6.3 Pulse / Direction Input Timing Diagram

Input signal waveform and timing (single pulse method)

STEP Input

DIR Input

Input signal waveform and timing (double pulse method)

STEP Input

(Forward)

DIR Input

(Reverse)

Notes When the driver is set to e

xternal pulse control, IN1 is the STEP pulse input port

and IN2 is the DIR direction input port.

Signal Input

page│12

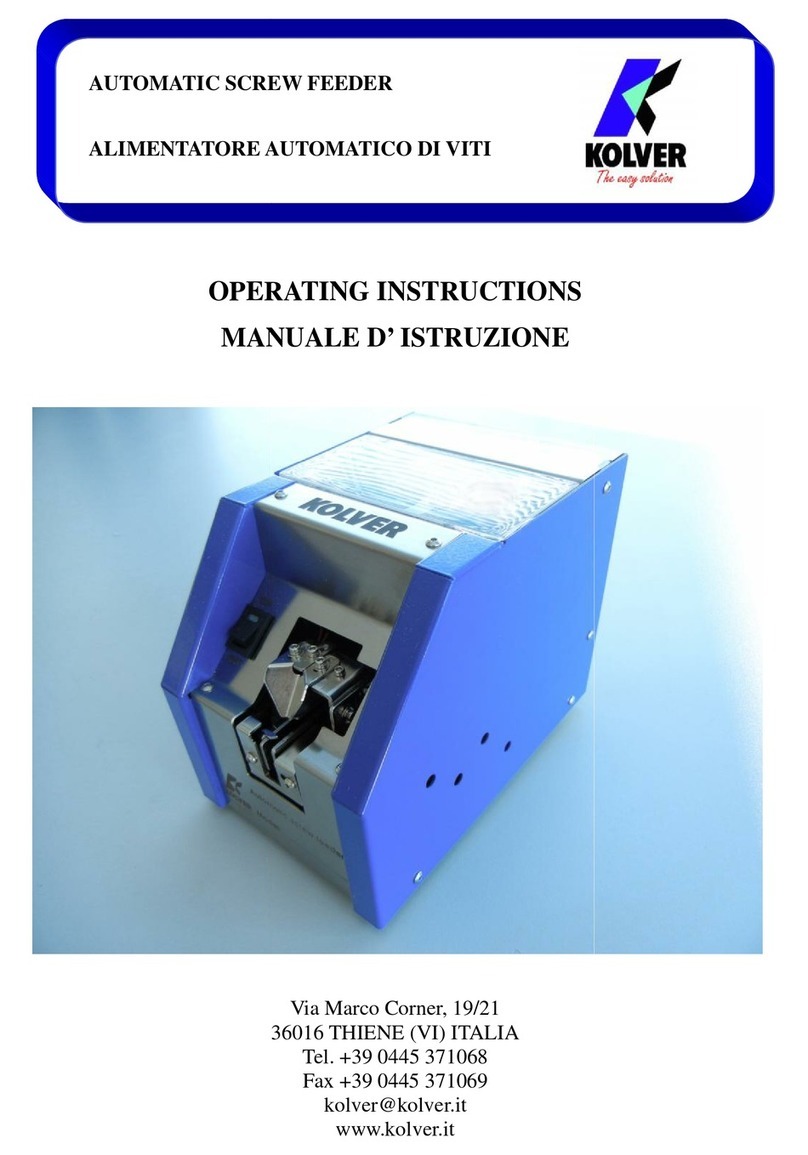

7. Typical Signal Connection

7.1 Common Positive Connection

Notes The pulse and direction terminals have a constant current input function, which

can be directly connected to the input signal without external series resistor step-

down current limiting protection. The VCC value is 3.5-26V.

Typical Signal Connection

page│13

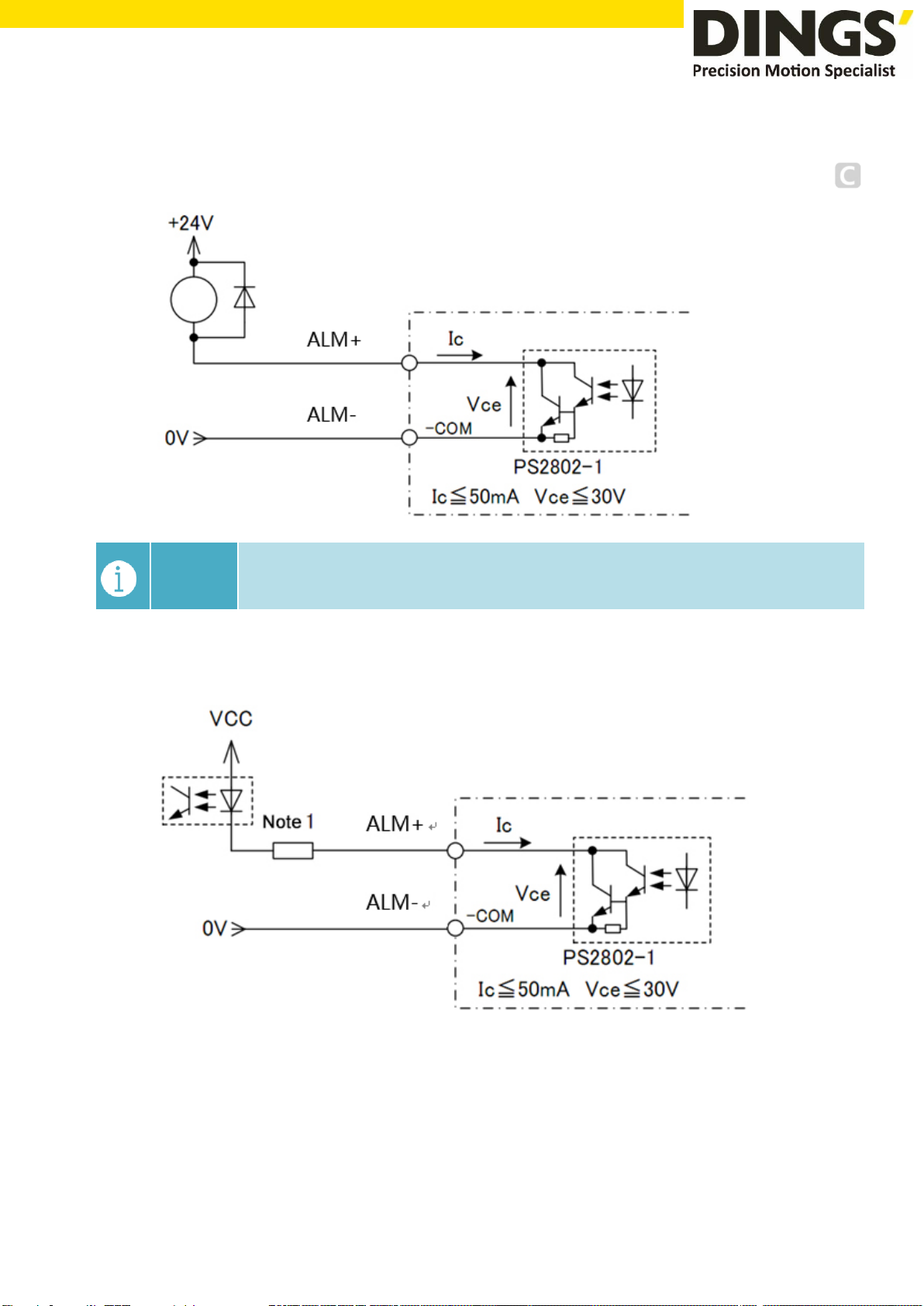

8. Typical Connection of Signal Output

8.1 Relay Connection

Notes When the relay is connected, it is required to connect diodes at both ends of the

relay (such as IN4000 series)

8.2 Optocoupler Connection

The alarm output is optically isolated, with a maximum voltage of 30VDC and a maximum

saturation current of 50mA.

When the driver is working normally, the output is closed.

When the drive fails, the output is left floating.

Typical Connection of Signal Output

page│14

example

Connecting with Keyence products

Typical Connection of Signal Output / Wiring Requirements

9. Wiring Requirements

1) In order to prevent the driver from being disturbed, it is recommended to use shielded cable

for the control signal, and the shield layer should be shorted to the ground. Except for special

requirements, the shielded wire of the control signal cable is grounded at one end: the upper

end of the shielded cable is grounded The driver end of the wire is left floating. Grounding

can only be performed at the same point in the same machine. If it is not a real ground wire,

the interference may be serious, and the shielding layer is not connected at this time.

2) Pulse and direction signal lines and motor lines are not allowed to be bundled side by side,

preferably at least 10cm apart, otherwise motor noise may easily interfere with pulse direction

signals, causing inaccurate positioning of the motor, system instability and other faults.

3) If one power supply is used for multiple drives, a parallel connection should be adopted at the

power supply. It is not allowed to connect one to the other in a chain.

4) It is strictly forbidden to plug and unplug the drivers strong current (motor and power)

terminals. When the charged motor is stopped, a large current still flows through the coil.

Plugging and unplugging the strong current (motor and power) terminals will cause a huge

momentary induced electromotive force to burn out. driver

5) It is strictly forbidden to add lead to the terminal after adding tin, otherwise the terminal may

be damaged due to overheating due to the increased contact resistance.

6) The wiring head must not be exposed outside the terminal to prevent the driver from being

accidentally shorted.

page│15

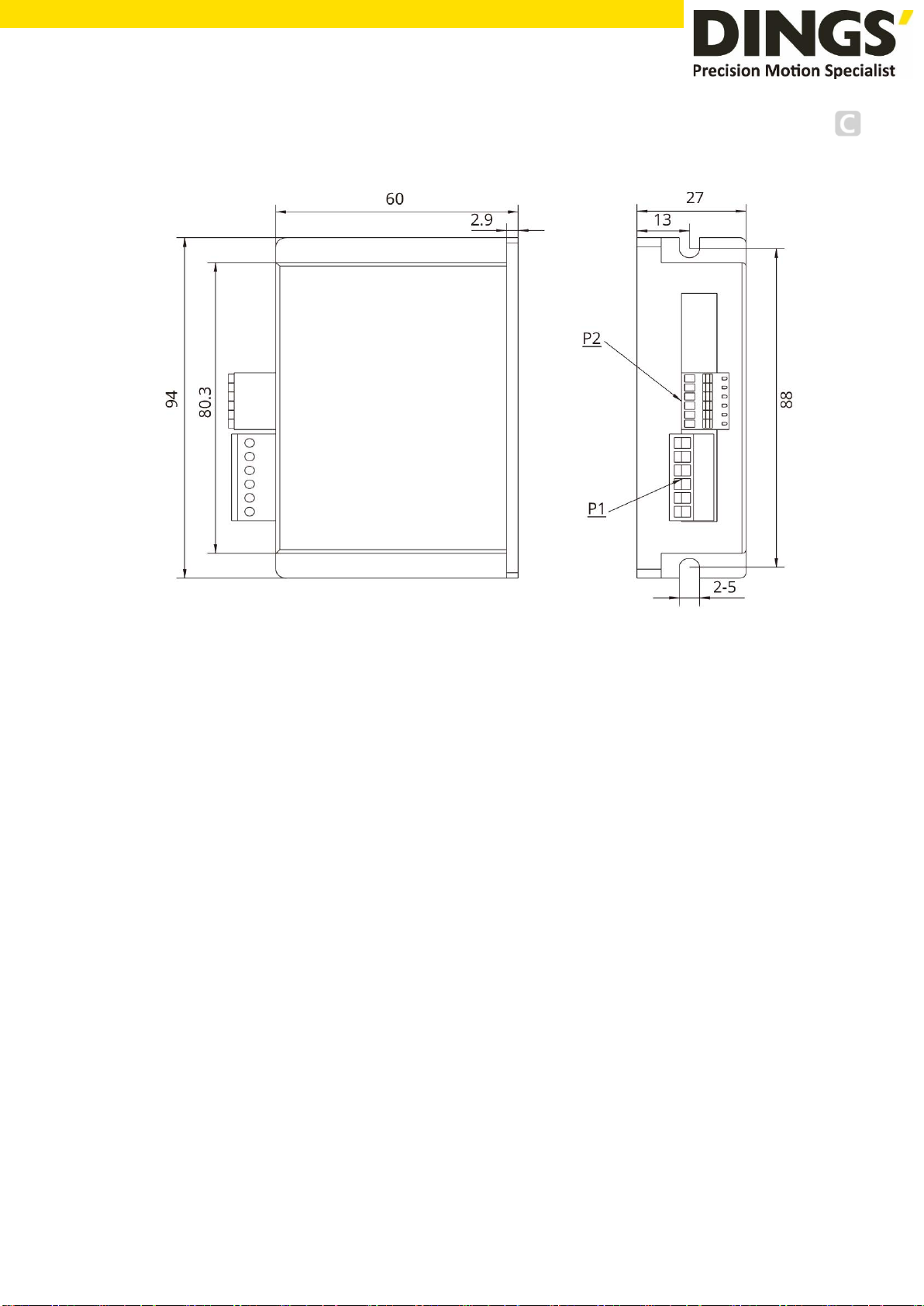

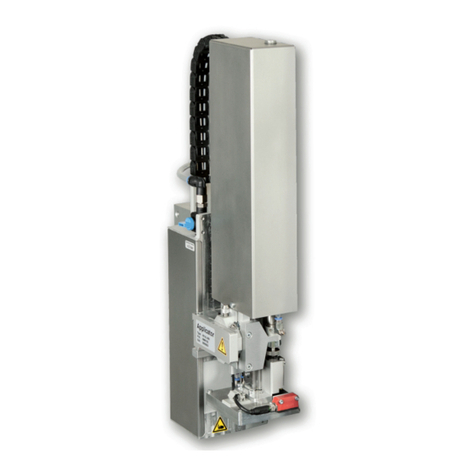

10.Installation Dimensions (unit : mm)

[ Drive installation ]

Install with narrow sides, and install with M3 / M4 screws through the holes on both sides.

The power device of the driver will generate heat. If it works continuously under high input

voltage and high power conditions, it should expand the effective heat dissipation area or

force cooling.

Do not use in places where air circulation is not allowed or where the ambient temperature

exceeds 40 ° C; do not install the drive in humid or metal shavings.

Installation Dimensions

page│16

11. Control Parameter

Notes

Informal version of communication parameters, some parameters are fixed

and not open.

11.1 Controller Basic Status (Class 01)

adr word content Elaborate Range / unit

0100 1 Motor current Motor real-time current value 0.1%A

0101 1 Input voltage Current input voltage 1%V

0104 2 Set up segmentation Set segmentation value ppr

0106 1 Pulse mode 1 is pulse + direction mode, 2 is double

pulse mode

1-2

0108 1 error code Code at the time of alarm, see 1-2 for

content, and display "0" for no fault

-

0109 1 Operating status Drive running status, see 1-1 -

0110 1 hardware version Drive hardware version -

0111 1 Software version Drive software version -

0117 2 current position target location pulse

0119 1 Actual speed display - 0.01rps

0126 2 Actual location Run real-time location pulse

0174 1 IO select multiple run paragraphs - -

0176 1 Multi-segment writing error No - -

0178 1 Multi-stage operation - -

11.2 Basic Parameter Setting (Class 02)

adr word content Elaborate Range / unit

0201 1 Motor direction switching Select the motor running direction 0~1

0206 1 User instructions Set when the motor is stopped

1: user parameter reset

2: Clear the alarm (except for some

hardware failure alarms)

3: drive restart

0~5

0213 1 Half-flow ratio

Stop current ratio (effective in open

loop mode)

10%~120%

0224 1 Angular filtering The smaller the value, the smoother the

motor runs, but the higher the delay

1~700

0234 1 Digital filtering

Filter coefficient of input pulse. The

larger the value, the lower the input

1~15

Control Parameter

page│17

frequency response.

0241 1 Input Current Set current 100~3200

0.1A~-3.2A

0242 2 Set up segmentation Pulses per revolution 200~102400

ppr

0244 1 Pulse mode 1: Pulse + direction mode

2: double pulse mode

1~2

0245 1 Half-flow time

Delay time when the motor stops

running and enters half flow state

(open loop mode is valid)

1~32767

ms

0296 1 Selection of operating mode 0: external pulse

1: internal pulse

Default: 0

Note: After the function is modified,

you need to power off and restart

0~1

0298 1 mailing address Default: 1 1~255

0299 2 Communication baud rate Default: 19200 1600~115200

11.3 Control Parameters (Class 05)

adr word content Elaborate Range / unit

0301 1 Starting frequency Default:100 1~2000

0.01~20rps

0302 1 Stop frequency Default:100 1~2000

0.01~20rps

0303 1 Acceleration Default:100 5~10000

rps2

0304 1 deceleration Default:100 5~10000

rps2

0305 1 Return to origin mode Return to origin mode,

0: Return to origin clockwise

1: Return to the origin counterclockwise

0~1

0306 1 Fixed-length running speed Default: 1000 1~5000

0.01~50rps

0307 1 Speed mode running speed In speed mode, the running direction is

consistent with the speed direction

Default: 1000

-5000~5000

-50~50rps

0308 1 Jog running speed Default: 1000 1~5000

0.01~50rps

Control Parameter

page│18

0309 1 Home speed Default: 1000 1~5000

0.01~50rps

0310 1 Creeping speed Running speed after hitting the origin

Default: 1000

1~5000

0.01~50rps

0311 2 Home offset Default: 0 -2000000000~

2000000000

pulse

0313 2 Output pulse Running stroke

Absolute position mode: run to the

specified position

Relat

ive position mode: travel setting

offset stroke

Default: 0

-2000000000~

2000000000

pulse

0317 2 Positive soft limit Default: 2000000000

Note: It is invalid during return to origin

-2000000000~

2000000000

pulse

0319 2 Negative soft limit Default: -2000000000

Note: It is invalid during return to origin

-2000000000~

2000000000

pulse

0321 2 Set current position Default: 0 -2000000000~

2000000000

pulse

0323 1 control commands 0. empty

1. Absolute running, running to

the set

distance, running direction is determined

by distance plus or minus, speed plus or

minus value is invalid, it is effective to

modify target position during running

2. Relative running, running at a set

distance and running speed. The running

direct

ion is determined by the distance

plus or minus. The speed plus or minus

value is invalid. Modifying the movement

distance during running is invalid

3. Speed mode

4. Jog forward

5. Reverse jog

6.deceleration and stop

7. Emergency stop

8. Set the current position, which can only

0~29

Control Parameter

page│19

be set when the motor is stopped

12. Back to origin

13. Alarm clear

14.Multi-segment data verification

15.Multi-segment data storage

16.Multi-segment data starts

17.Multiple data pauses

18.End of multiple segments of data

Default: 0

0324 1 Internal control switch

Data bit Bit1 Bit0

Features Negative

soft limit

Positive

soft limit

1: open function, 0: close function

Default: 0

0-65535

0327 1 Number of paragraphs Default: 1 1~32

0328 1 Multiple selection Default: 0

Note: If IO port is configured with multi-

segm

ent selection function, IO

configuration multi-

segment selection is

preferred

0~31

11.4 Input Block Designation (Class 06)

adr word content Elaborate Range / unit

0400 1 IN1 function selection 0. empty

1. Absolute running, running to the set

distance, running direction is determined by

distance plus or minus, speed plus or minus

value is invalid, it is effective to modify target

position during running

2. Relative running, running at a set distance

and running speed. The running direction is

determine

d by the distance plus or minus.

The speed plus or minus value is invalid.

Modifying the movement distance during

running is invalid

3. Speed mode

0~30

Control Parameter

page│20

4. Jog forward

5. Reverse jog

6.deceleration and stop

7. Emergency stop

8. Set the current position, which

can only

be set when the motor is stopped

9.positive limit

10. Negative limit

11.Origin signal

12. Back to origin

13. Alarm clear

14.Multi-segment data verification

15.Multi-segment data storage

16.Multi-segment data starts

17.Multiple data pauses

18.End of multiple segments of data

20. Enable

25.IO port configuration multi-stage

selection Bit0

26.IO port configuration multi-stage

selection Bit1

27.IO port configuration multi-stage

selection Bit2

28.IO port configuration multi-stage

selection Bit3

29.IO port configuration multi-stage

selection Bit4

Default: 0

0401 1 IN2 function selection The setting content is the same as IN1

(default value: 0)

0~30

0402 1 IN3 function selection The setting content is the same as IN1

(default value: 0)

0~30

0429 1 Universal digital input logic

0410 1

Pseudo communication

settingIN1

0: OFF (initial value 0)

1: ON (trigger the action of IN1 configuration)

0~1

0411 1

Pseudo communication

settingIN2

0: OFF (initial value 0)

1: ON (trigger the action of IN2 configuration)

0~1

0412 1

Pseudo communication

settingIN3

0: OFF (initial value 0)

1: ON (trigger the action of IN3 configuration)

0~1

Control Parameter

Other Dings Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Enerpac

Enerpac AquaJack EAJ1 Series instruction sheet

Tractel

Tractel palturn Instructions for use

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS LVU-CD-10 Operating and maintenance instructions

CAB

CAB 4614-200L Service manual

Walinga

Walinga Agri-Vac 3510 OPERATOR'S MANUAL AND PARTS BOOK

Jetting

Jetting JetLogger V0 Safety, installation, and operation manual