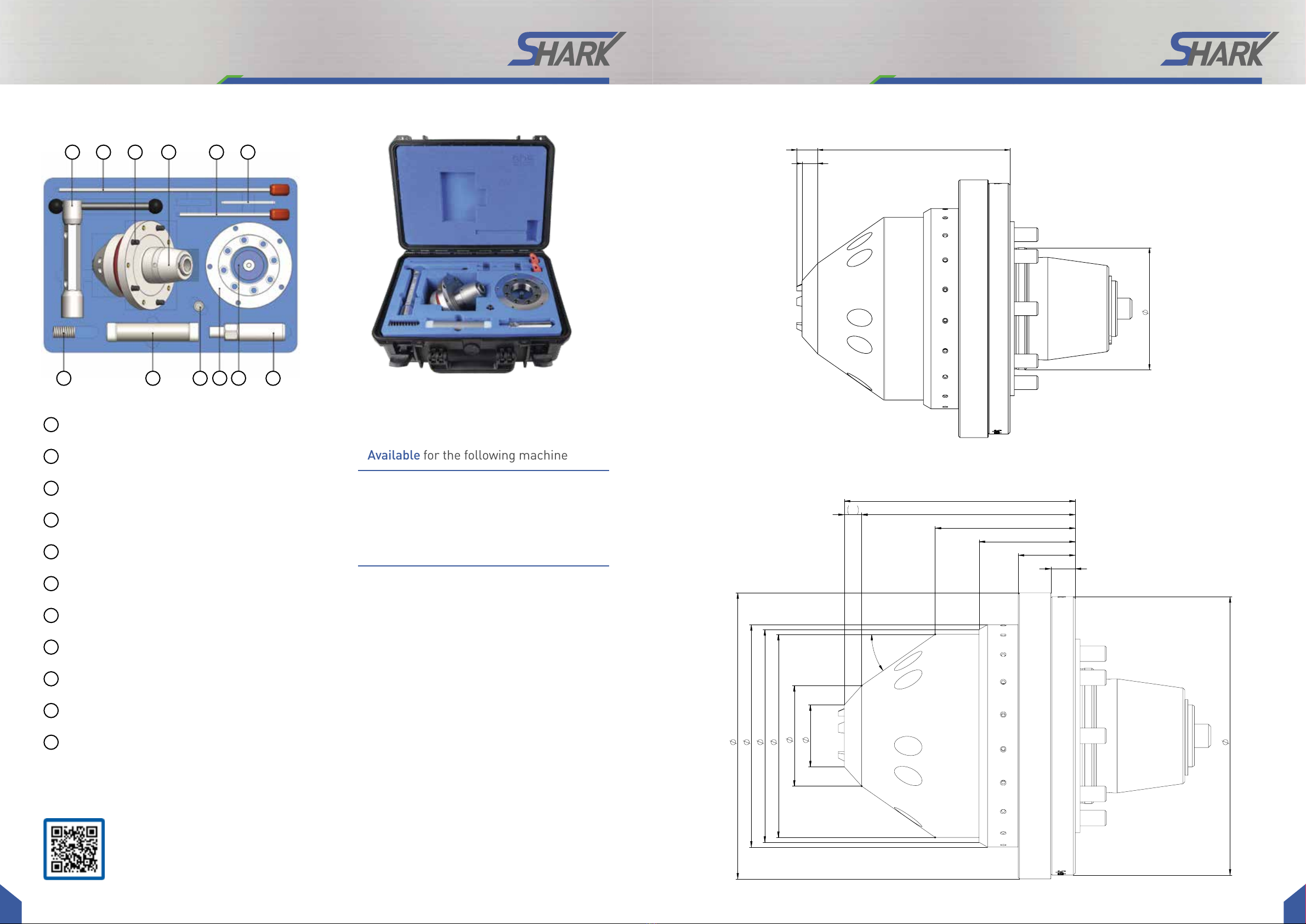

8 9

As a result of continuous improvement and further development of our designs, the information and illustrations in this brochure are not binding.

The specifications and installation lengths of the machine manufacturer must be observed. All specifications are in mm. Errors and omissions excepted.

GDS SHARK ANCA basic safety instructions

Basic safety instructions

Danger to persons and property may arise from this product due to incorrect handling, assembly

and maintenance if these operating instructions are not observed. Damage and defects must be

reported to the manufacturer immediately and repaired without delay in order to keep the extent of

damage to a minimum and to ensure that the safety of the product is not impaired.

Only original GDS spare parts may be used.

Notes on special hazards

Danger to persons (risk of injury) and damage to property can arise from the SHARK 5-Jaw Chuck

system if:

• it is not used as intended;

• it is improperly installed or maintained;

• the safety and assembly instructions, the safety and accident prevention regulations applicable

at the place of use and the EC Machinery Directive are not observed.

Use not in accordance with the intended purpose

The multi-range chuck must not be used for turning or milling. The precision grinding chuck is not

being used for the intended purpose, for example:

• if tools are not properly clamped.

• if, in disregard of the safety regulations, persons are working on the 5-jaw chuck without additi-

onal protective devices, e.g. in order to machine clamped tools.

• the technical data are exceeded when using the 5-jaw chuck.

• the 5-jaw chuck is used for machines not intended for this purpose.

Intended use

The SHARK 5-Jaw Chuck is used for clamping tools with cylindrical shanks for tool grinding on

grinding machines.

• The product may only be used within the scope of its technical data.

• The product is intended for installation in a machine. The applicable directives must be observed

and complied with.

• The product is intended for industrial use.

• Intended use also includes compliance with all the information in these instructions.

CAUTION:

Risk of injury to the operating personnel in case of jaw breakage or loss of work-

piece due to flying parts!

• When using the 5-jaw chuck, protective equipment must be used in accordance

with the EC Machinery Directive so that in the event of failure of the 5-jaw chuck or a

component of the chuck, parts flying away are caught by the protective equipment.

• The machine manufacturer must ensure sufficient wall thicknesses for his enclo-

sure/protective equipment (in compliance with the currently applicable regulati-

ons and standards).

GDS SHARK ANCA basic safety instructions

CAUTION:

Risk of injury to the operating personnel in case of improper use and exceeding the

technical data due to failure of the 5-jaw chuck! Improper use and exceeding the

technical data may cause failure of the 5-jaw chuck, resulting in danger to life and

limb of the operator and considerable damage to the equipment.

• Observe the values of the technical data

• Only use the 5-jaw chuck for its intended purpose.

• Comply with the applicable safety standards and safety regulations.

CAUTION:

Risk of injury due to falling down of the multigange clamping system during trans-

port, mounting and dismounting. Protect the 5-jaw chuck from falling down during

transport and installation or dismantling.

CAUTION:

During manual loading and unloading, there is a risk of crushing limbs due to ope-

ning and closing of the clamping jaws. Do not reach between the clamping jaws. For

hand-loaded machines, the tool feed must be carried out via a setting aid.

CAUTION:

Risk of injury during manual loading and unloading of the tools due to sharp cutting

edges. Remove the tools only when the machine is at a standstill. Prefer an automa-

tic loading and unloading of the tools.