Dini Argeo 3590 Series Use and care manual

MANUALE D’USO ITALIANO

www.diniargeo.com

AF03GT

Program for weighbridges

For 3590 series touch screen indicators

CALIBRATION METHOD - v7 ENGLISH

3

AF03GT

Calibration of a channel connected analogue weighbridge 4

Analogue calibration with equalisation 8

Setting and calibration of digital cell weighbridges 12

Calibration of a WWS wireless weighing system 16

Calibration of a dual digital weighbridge system 20

Calibration of a dual scale system consisting of wireless WWS platforms 26

TECH_MAN_CAL_ENG_AF03GT_v7

Index

4

AF03GT

1 2 3 4 5 6 7 8 9 10 11 12 13 14

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Vin

GND

GND

+Vaux

OUT

COM

OUT1

OUT2

OUT3

OUT4

IN

COM

IN1

IN2

TX1

RX1

GND

CTS2

TX2

RX

GND

+Vdc

A(+)

B(-)

EARTH

SIG+

SIG-

SEN +

/

REF +

SEN +

/

REF -

EXC+

EXC-

+BAT

J1

CAL

J3

J2

EXC+

EXC-

SIG+

SIG-

GND

+5V

RX

-

-

TX

CH4 CH3 CH2 CH1

DISPLAY

POWER

DISPLAY ON

ON

RS232

OUTPUT OUTPUT

INPUT

COM1

RS232

485

COM2

RS232

COM3

BOOT

SENSOR

A.

J2 J3

SEN + / REF + SEN + / REF -EXC + EXC -

TECH_MAN_CAL_ENG_AF03GT_v7

Calibration of a channel connected analogue weighbridge

With switched-off indicator and power supply unplugged, connect the weighbridge to the indicator.

Load cells

Junction box

Weighbridge

Procedure:

CASE 1: An indicator connected to a weighbridge.

PREMISE

CASE 2: An indicator connected to a scale composed of several weighbridges in series (up to 48 1000 Ohm cells).

5

AF03GT

Scale configuraon

Esc

Calibrazione

Technical set-up

Esc

Diagnoscs

Esc Esc ADC-mV

1

Channel

344673

kg

A

f=7

d=74

15000

ADC

SCALE 1

308333

min

308333

W1

MAX

1. 2. 3.

B.

Calibraon

Esc

Calibraon

Esc

Scale selecon

Esc

Scale configuraon

Esc

Insert the number of calibraon

points other than the zero.

Cancel OK

Calibraon

1.

1.

2.

2. 3.

...

...

...

... ...

...

...

...

...

...

... ...

...

...

...

...

... ...

...

...

...

...

...

... ...

...

...

...

... ...

...

... ...

C.

D.

E.

Calibraon

Esc

Scale configuraon

Esc

Parameters

Esc

1. 2. 3.

...

...

...

...

...

TECH_MAN_CAL_ENG_AF03GT_v7

Turn on the indicator, enter the setup menu and check that the signal coming from the weighbridge is stable and increases with

weight increase.

Select the number of weighbridges and each weighbridge load cell type.

Set scale metric parameters (capacity / division, etc.)

Perform calibration.

Example of dual scale weighbridge configuration: Number of decimals = 0; Unit of measure = kg; Range number = 2;

Range 1 division = 10; Capacity / Range 1 = 30000; Range 2 division = 20; Capacity / Range 2 =60000.

Scale selecon

Diagnosc Weight test

Scale 1

Number of scales

Calibraon

= 1

Type of load cell = Analogue

Number of channels (Scale 1) = 1

Scale 1

Number of decimals

Range 1 division

Unit of measure

Capacity / Range 1

Parameters Range number

Range 2 division

6

AF03GT

Scale configuraon

Esc

Scale configuraon

Esc

Calibrazione

Calibrazione

Calibraon

Esc

Calibraon

Esc

Calibraon

Esc

Scale configuraon

Esc

Scale configuraon

Esc

Scale configuraon

Esc

Zero acquision underway

Please wait...

ADC=308261

Calibraon

30%

Cancel OK

Calibraon

Acquision of point 1.

Load the plaorm with 30000kg

and press the OK buon.

4.

7.

11.10.

5.

8.

12.

6.

Bilancia 1

Bilancia 1

Bilancia 1

Calibrazione

Calibrazione

Calibrazione

Calibraon points

1 8 ~

1

4

7

C

2

5

8

0

3

6

9

.

/

*

-

+

Esc

BkSp

OK

Cancel OK

Calibraon

Acquision of point 1.

Insert the weight value.

Calibraon

Acquision of point 1 underway.

Please wait...

30%

ADC=308261

1Zero acquision.

Unload the plaorm and press

the OK buon.

Cancel OK

Calibraon

Point 1 weight

0 ~999999

30000

1

4

7

C

2

5

8

0

3

6

9

.

/

*

-

+

Esc

BkSp

OK

OK

Calibraon

Calibraon terminated

successfully.

Pun / div = 84

kg kg kg kg kg

TECH_MAN_CAL_ENG_AF03GT_v7

9. Load the weighbridge and distribute

the mass evenly.

7

AF03GT

G.

H.

I.

Backup & Restore

Esc

Calibrazione

Technical set-up

Esc

Technical set-up

Esc

Technical set-up

Esc

Backup & Restore

Esc

Backup all sengs?

No Yes

Configuraon backup

1.

1.

2.

2.

3.

... ...

i

Cancel No

Technical set-up

Yes

Setup changed.

Save changes before restart the

indicator?

F.

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

i

TECH_MAN_CAL_ENG_AF03GT_v7

Perform backup

Receive calibration with Dinitools.

Exit setup and save.

Backup & Restore Backup of the conguraon

It is possible to enter a protection password to restore the stored parameters.

Repeat the procedure from step Cfor calibration of the second weighbridge (if present).

Saving has completed correctly only if the asterisk is present: Backup of the conguraon (*)

8

AF03GT

Technical set-up

Esc

Diagnoscs

Esc Esc ADC-mV

1

Channel

344673

kg

A

f=7

d=74

15000

ADC

SCALE 1

308333

min

308333

W1

MAX

1. 2. 3.

ch1 ch2 ch3 ch4

... ...

... ...

... ...

... ...

... ...

A.

B.

ch1

ch2 ch3

ch4

i

TECH_MAN_CAL_ENG_AF03GT_v7

PREMISE

Analogue calibration with equalisation

With switched-off indicator and power supply unplugged, connect the scale to the indicator.

CASE 2: Scale composed of various weighbridges in sequence, each connected to a channel of the indicator.

Up to 48

1000 Ohm cells.

Turn on the terminal, enter the setup menu and check that the signal coming from the scale is stable and increases with weight

increase.

Diagnosc Weight test

Procedure:

CASE 1: The weighbridge load cells are connected to the 4 indicator channels.

Load cells

Weighbridge

Each weighbridge shall be individually equalised via junction box.

9

AF03GT

Scale configuraon

Esc

D.

E.

Calibraon

Esc

Scale selecon

Esc

1. 2.

...

... ...

... ...

...

... ...

C.

Calibraon

Esc

Scale configuraon

Esc

Parameters

Esc

1. 2. 3.

...

...

...

...

...

...

...

...

...

...

...

...

...

...

kg

kg

kg

kg

kgkgkgkg

kg

kgkg

kg

TECH_MAN_CAL_ENG_AF03GT_v7

For CASE 1: equalisation aims to optimise the angles of the scale.

For CASE 2: equalisation aims to make each weighbridge the same, in order for the weight measured on each individual one

to be the same.

Set scale metric parameters (capacity/division) etc.

Perform the guided equalisation procedure.

Equalisaon

= 1

= Analogue

= 2 ... 4

Select the number of scales and load cell type.

Scale 1

Scale 2

Number of decimals

Range 1 division

Unit of measure

Capacity / Range 1

Parameters Range number

Range 2 division

= 1/8 Max (kg)

= 1/8 Max (kg)

Scale selecon

Number of scales

Type of load cell

Number of channels (Scale 1)

10

AF03GT

Scale configuraon

Esc

Scale configuraon

Esc

Scale configuraon

Esc

Calibrazione

Calibrazione

Calibrazione

Calibraon

Esc

Calibraon

Esc

Calibraon

Esc

Calibraon

Esc

Scale configuraon

Esc

Scale configuraon

Esc

Scale configuraon

Esc

Scale configuraon

Esc

Insert the number of calibraon

points other than the zero.

Cancel OK

Calibraon

Zero acquision underway

Please wait...

ADC=308261

Calibraon

30%

Cancel OK

Calibraon

Acquision of point 1.

Load the plaorm with 30000kg

and press the OK buon.

1.

4.

7.

10.

10.

2.

5.

8.

11.

3.

6.

Bilancia 1

Bilancia 1

Bilancia 1

Calibrazione

Calibrazione

Calibrazione

F.

Calibraon points

1 8 ~

1

4

7

C

2

5

8

0

3

6

9

.

/

*

-

+

Esc

BkSp

OK

Cancel OK

Calibraon

Acquision of point 1.

Insert the weight value.

Calibraon

Acquision of point 1 underway.

Please wait...

30%

ADC=308261

1Zero acquision.

Unload the plaorm and press

the OK buon.

Cancel OK

Calibraon

Point 1 weight

0 ~999999

30000

1

4

7

C

2

5

8

0

3

6

9

.

/

*

-

+

Esc

BkSp

OK

OK

Calibraon

Calibraon terminated

successfully.

Pun / div = 84

i

kg kg kg kg kg

TECH_MAN_CAL_ENG_AF03GT_v7

Scale 1 Calibraon

Perform the procedure for each channel.

9. Load the weighbridge and distribute

the mass evenly.

11

AF03GT

G.

H.

I.

Backup & Restore

Esc

Calibrazione

Technical set-up

Esc

Technical set-up

Esc

Technical set-up

Esc

Backup & Restore

Esc

Backup all sengs?

No Yes

Configuraon backup

1. 2. 3.

... ...

i

Cancel No

Technical set-up

Yes

Setup changed.

Save changes before restart the

indicator?

i

TECH_MAN_CAL_ENG_AF03GT_v7

Perform backup

Receive calibration with Dinitools.

Exit setup and save.

Backup & Restore Backup of the conguraon

It is possible to enter a protection password to restore the stored parameters.

Saving has completed correctly only if the asterisk is present: Backup of the conguraon (*)

12

AF03GT

A(+) B(-)

1 2 10

5 1 9

2 4 12

6 3 11

3 6 14

7 5 13

4 8 16

8 7 15

A.

B.

C.

Calibraon

Esc

Scale selecon

Esc

1. 2.

i

1 2 3 4 5 6 7 8 9 10 11 12 13 14

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Vin

GND

GND

+Vaux

OUT

COM

OUT1

OUT2

OUT3

OUT4

IN

COM

IN1

IN2

TX1

RX1

GND

CTS2

TX2

RX

GND

+Vdc

A(+)

B(-)

EARTH

SIG+

SIG-

SEN +

/

REF +

SEN +

/

REF -

EXC+

EXC-

+BAT

J1

CAL

J3

J2

EXC+

EXC-

SIG+

SIG-

GND

+5V

RX

-

-

TX

CH4 CH3 CH2 CH1

DISPLAY

POWER

DISPLAY ON

ON

RS232

OUTPUT OUTPUT

INPUT

COM1

RS232

485

COM2

RS232

COM3

BOOT

SENSOR

TECH_MAN_CAL_ENG_AF03GT_v7

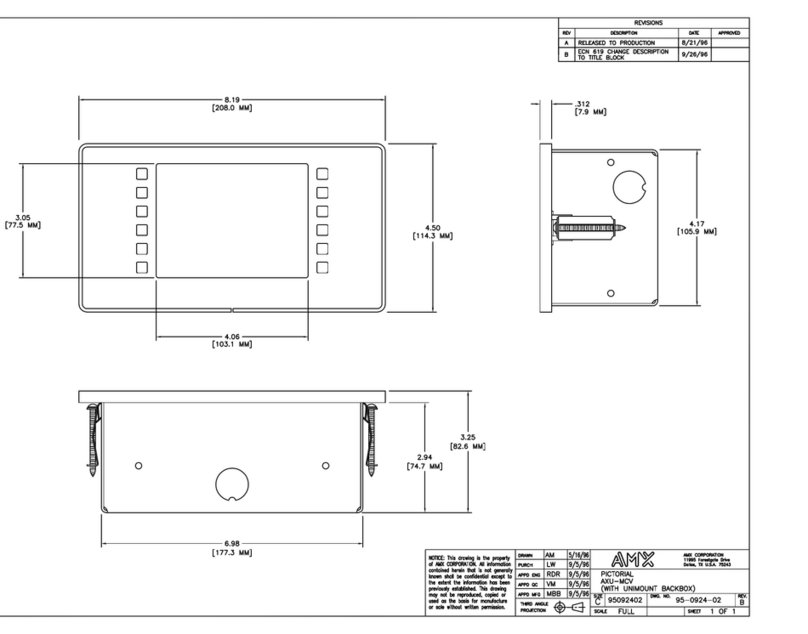

PREMISE

RS485 RS485

With switched-off indicator and power supply unplugged, connect the scale to the weighing terminal 3590.

Select the number of scales and load cell type.

Set digital cell serial number.

Premise

Number the load cells for easier identification during maintenance, for example:

Procedure:

Setting and calibration of digital cell weighbridges

CASE 2:

Scale selecon

Number of scales = 1

Type of load cell

Number of cells

Chip 485

For digital cells operation installation of

chip 485 is required.

Load cells

Junction box

Weighbridge

Dip switch to enable termination resistor

= RCPTD, RCD, SP/CS, CB50X-DL, RC3D

RL5426/RL5416, C16i, ZSFD, DGX, WWS

= 1 - 16

13

AF03GT

D.

E.

F.

Serial number configuraon

Esc

1.

...

...

...

...

Scale configuraon

Esc

Scale configuraon

Esc

1.

Excute load cells equalizaon?

No Yes

Equalisaon

Scale selecon

Esc

Serial number configuraon

Esc

1. 2.

... ...

... ...

... ...

... ...

...

Calibraon

Esc

Scale configuraon

Esc

Parameters

Esc

1. 2. 3.

...

...

...

...

...

i

TECH_MAN_CAL_ENG_AF03GT_v7

Perform the load cell automatic numbering procedure:

Set scale metric parameters (capacity/division) etc.

Perform equalisation following the indicator’s guided procedure.

= The indicator assigns to each load cell its number, which will identify it in each

programming or diagnostics menu.

If the operation does not succeed, check connection between cells and

indicator.

Equalisaon

= Enter for each load cell its serial number,

displayed on the casing of the cell.

Scale 1

Number of decimals

Range 1 division

Unit of measure

Capacity / Range 1

Parameters Range number

Range 2 division

If the operation succeeds, set the dip switch to “ON” to enable termination resistor.

Cell n

Address assignment

Serial number conguraon Cell n

Address assignment

14

AF03GT

Scale configuraon

Esc

Scale configuraon

Esc

Calibraon

Esc

Calibraon

Esc

Calibraon

Esc

Scale configuraon

Esc

Scale configuraon

Esc

Scale configuraon

Esc

Insert the number of calibraon

points other than the zero.

Cancel OK

Calibraon

Zero acquision underway

Please wait...

ADC=308261

Calibraon

30%

1.

4.

7.

2.

5.

8.

3.

6.

G.

Calibraon points

1 8 ~

1

4

7

C

2

5

8

0

3

6

9

.

/

*

-

+

Esc

BkSp

OK

Cancel OK

Calibraon

Acquision of point 1.

Insert the weight value.

1Zero acquision.

Unload the plaorm and press

the OK buon.

Cancel OK

Calibraon

Point 1 weight

0 ~999999

30000

1

4

7

C

2

5

8

0

3

6

9

.

/

*

-

+

Esc

BkSp

OK

kg

kg

kgkg

kg

kg kg

kg

kg kg

kg kgkg kg

kg kg

kg kg kg kg kg

TECH_MAN_CAL_ENG_AF03GT_v7

Perform calibration.

Scale 1 Calibraon

Example of a 4 cell weighbridge: equalisation aims to

optimise each cell of the scale.

Example of an 8 cell weighbridge: equalisation aims to

optimise each cell of the scale

= 1/8 Max (kg) = 1/8 Max (kg)

9. Load the weighbridge and distribute

the mass evenly.

15

AF03GT

H.

J.

K.

Backup & Restore

Esc

Calibrazione

Technical set-up

Esc

Technical set-up

Esc

Technical set-up

Esc

Backup & Restore

Esc

Backup all sengs?

No Yes

Configuraon backup

1. 2. 3.

... ...

i

Cancel No

Technical set-up

Yes

Setup changed.

Save changes before restart the

indicator?

Calibraon

Esc

Scale configuraon

Esc

11.10. 12.

Bilancia 1 Calibrazione

Calibraon

Acquision of point 1 underway.

Please wait...

30%

ADC=308261

OK

Calibraon

Calibraon terminated

successfully.

Pun / div = 84

i

Scale configuraon

Esc

Calibrazione

Cancel OK

Calibraon

Acquision of point 1.

Load the plaorm with 30000kg

and press the OK buon.

i

TECH_MAN_CAL_ENG_AF03GT_v7

Perform backup

Receive calibration with Dinitools.

Exit setup and save.

Backup & Restore Backup of the conguraon

It is possible to enter a protection password to restore the stored parameters.

Perform the procedure for each scale.

Saving has completed correctly only if the asterisk is present: Backup of the conguraon (*)

16

AF03GT

A.

B.

i

11

22

33

44

55

66

MODULO

RADIO

TX

GND

5÷12V

RX

GND

5÷12V

TX

RX

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Vin

GND

GND

+Vaux

OUT

COM

OUT1

OUT2

OUT3

OUT4

IN

COM

IN1

IN2

TX1

RX1

GND

CTS2

TX2

RX

GND

+Vdc

A(+)

B(-)

EARTH

SIG+

SIG-

SEN +

/

REF +

SEN +

/

REF -

EXC+

EXC-

+BAT

J1

CAL

J3

J2

EXC+

EXC-

SIG+

SIG-

GND

+5V

RX

-

-

TX

CH4 CH3 CH2 CH1

DISPLAY

POWER

DISPLAY ON

ON

RS232

OUTPUT OUTPUT

INPUT

COM1

RS232

485

COM2

RS232

COM3

BOOT

SENSOR

TECH_MAN_CAL_ENG_AF03GT_v7

PREMISE

Calibrate and set metric parameters of each WWS platform. Check that each platform is configured on the same

radio channel (channel “0”)

With indicator switched-off and disconnected from the electrical grid, connect the radio module to the AUX port.

Procedure :

Calibration of a WWS wireless weighing system

This configuration lets

you manage up to 16

platforms.

System diagram:

CPU Board Radio module

17

AF03GT

C.

Technical setup

Esc

Input texts

Serial ports

Printout

Ext. keyboard - Barcode reader

Remote scale

Digital outputs

Cancel OK

Communicaon port

PC port

Disabled

Auxiliary port

Printer port

Serial ports

Esc

Serial ports funcon mode

Printer port configuraon

Pc port configuraon

Auxiliary port configuraon

Radio Frequency interface

Radio Frequency interface

Esc

Communicaon port

Channel

Radio Frequency interface

Esc

Communicaon port

Radio Frequency interface

Esc

Communicaon port

Channel

1.

4.

2.

5.

3.

6.

Channel

0 ~7

0

1

4

7

C

2

5

8

0

3

6

9

.

/

*

-

+

Esc

BkSp

OK

D.

E.

Calibraon

Esc

Scale selecon

Esc

1. 2.

WWS configuraon

Esc

WWS configuraon

Esc

Gravity value

9.75001 ~9.84999

9.80390

1

4

7

C

2

5

8

0

3

6

9

.

/

*

-

+

Esc

BkSp

OK

TECH_MAN_CAL_ENG_AF03GT_v7

Select the number of WWS which make up the system.

Set the instrument’s radio channel

Scale selecon

Number of scales = 1

Type of load cell = WWS

Number of cells (Scale 1) = Corresponds to the number of WWS platforms

which make up the system, set from 1 - 16.

1.

Establish communication between indicator and WWS platform.

= Acquires metric parameters from

the WWS and modifies them on

the indicator.

If the operation does not suc-

ceed, check connection with the

platforms.

2. Set the gravity value of the area of use.

WWS conguraon acquision

Remote WWS conguraon

18

AF03GT

F.

G.

Backup & Restore

Esc

Calibrazione

Technical set-up

Esc

Backup & Restore

Esc

Backup all sengs?

No Yes

Configuraon backup

1. 2. 3.

Calibraon

Esc

Scale configuraon

Esc

Parameters

Esc

1. 2. 3.

...

...

...

...

...

i

i

TECH_MAN_CAL_ENG_AF03GT_v7

Set indicator metric parameters (if required).

Perform backup

Backup & Restore Backup of the conguraon

Scale 1

Number of decimals

Range 1 division

Unit of measure

Capacity / Range 1

Parameters Range number

Range 2 division

If WWS platforms are approved for use in relation with third parties:

• total system capacity must be equal to the sum of each individual WWS platform’s capacity.

• system division must be equal to the sum of each individual WWS platform’s division rounded up to the highest one.

• set these parameters to be able to approve the system.

E.g.: in a system consisting of 8 WWS platforms with “Max.=15,000kg” and “e=5kg”, maximum capacity will be

“Max.=120,000kg” and the division “e=50kg”.

If the platforms are not approved:

• total system capacity must be equal to the sum of each individual WWS platform’s capacity.

• system division equals division of the single WWS platform.

E.g.: in a system consisting of 8 WWS platforms with “Max.=15,000kg” and “e=5kg”, maximum capacity will be

“Max.=120,000kg” and the division “e=5kg”.

The system’s total capacity and division can be modified to create specific internal use systems (see step F).

This operation overwrites the data in the memory.

19

AF03GT

i

H.

I.

Technical set-up

Esc

Technical set-up

Esc

... ...

Cancel No

Technical set-up

Yes

Setup changed.

Save changes before restart the

indicator?

i

TECH_MAN_CAL_ENG_AF03GT_v7

It is possible to enter a protection password to restore the stored parameters.

Receive calibration with Dinitools.

Exit setup and save.

Saving has completed correctly only if the asterisk is present Backup of the conguraon (*)

20

AF03GT

GROSS

AB

PRESET

CUSTOMER

MATERIAL

VEHICLE

1. WEIGH 2. WEIGH PRINT >>

FREE PLATE

0 0

kg

kg kg

SUPPLIER

NOTES

i

TECH_MAN_CAL_ENG_AF03GT_v7

PREMISE

System diagram:

RS485

With this configuration the weight of each platform is displayed separately.

Weight “A”, Weight “B”

or Sum “A” + “B”

(enabling “A+B” function).

See page 23

Calibration of a dual digital weighbridge system

It is possible to install weighing systems with more than one weighbridge based on the number of cells of each

(Max. 16 digital cells, max. 8 CCI AD cells).

Load

cells

Junction

box

Weighbridge

Other manuals for 3590 Series

1

Table of contents

Other Dini Argeo Touch Panel manuals