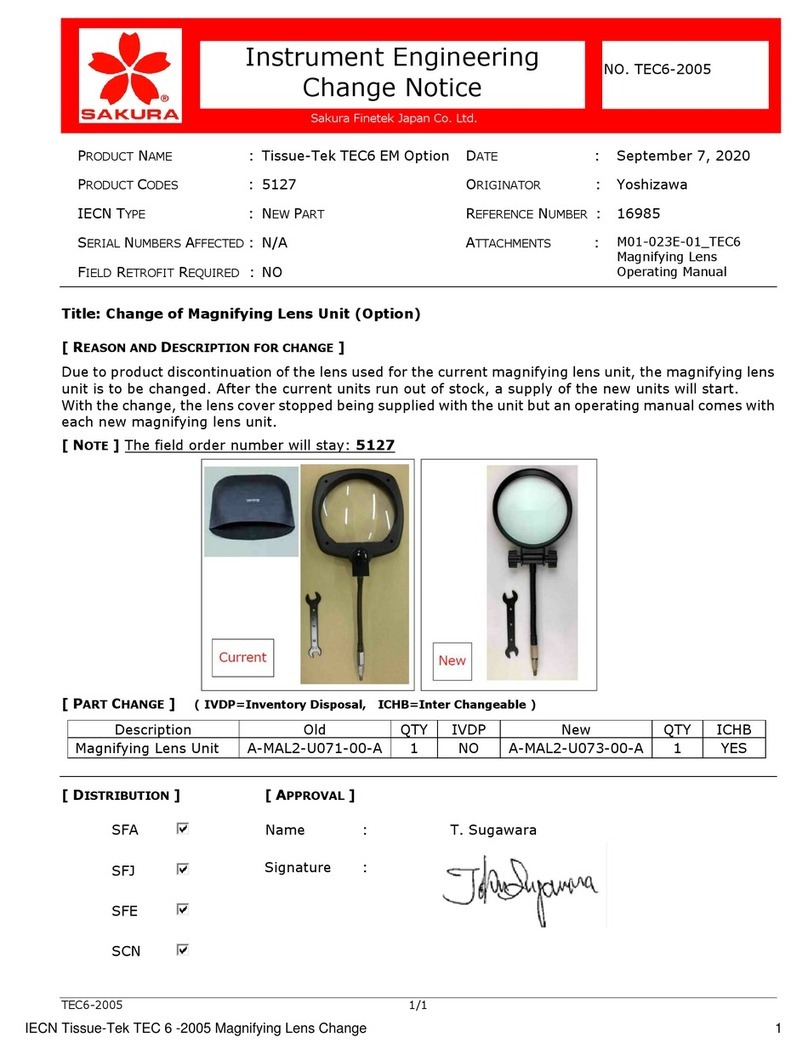

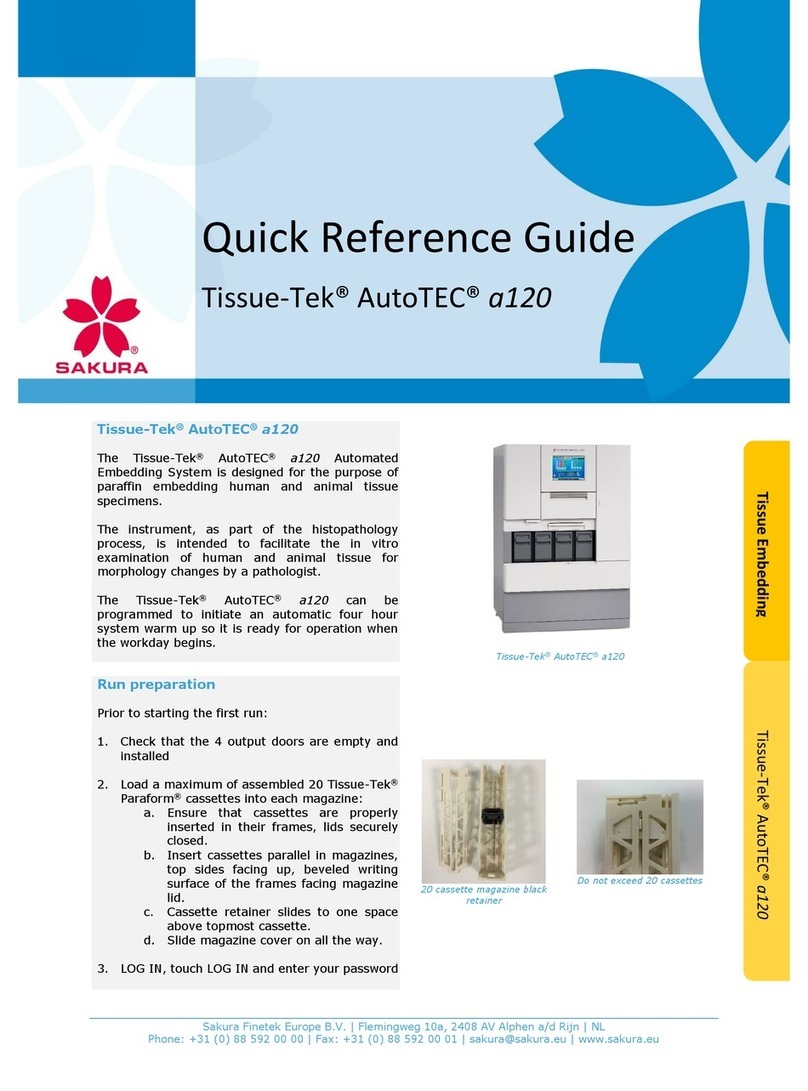

Sakura Tissue-Tek TEC 6 Instruction Manual

Other Sakura Laboratory Equipment manuals

Sakura

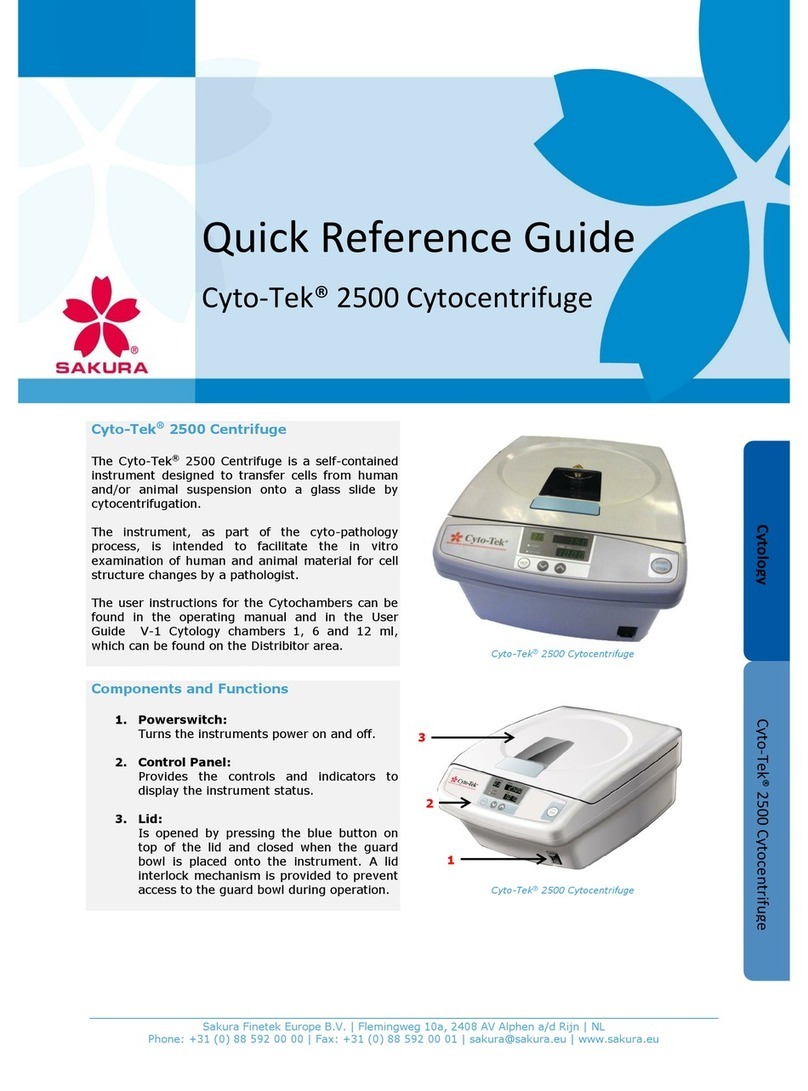

Sakura Cyto-Tek 2500 User manual

Sakura

Sakura Tissue-Tek Prisma Plus Prisma-P-AD User manual

Sakura

Sakura Tissue-Tek Prisma Plus User manual

Sakura

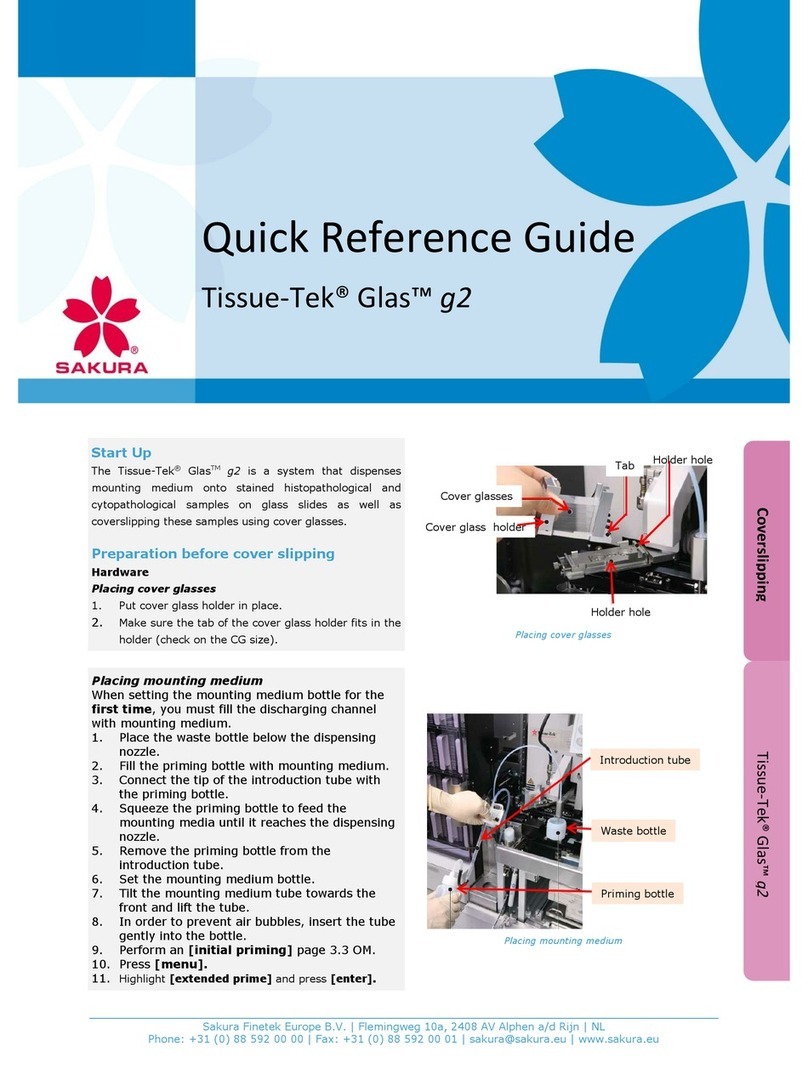

Sakura Tissue-Tek Glas g2 User manual

Sakura

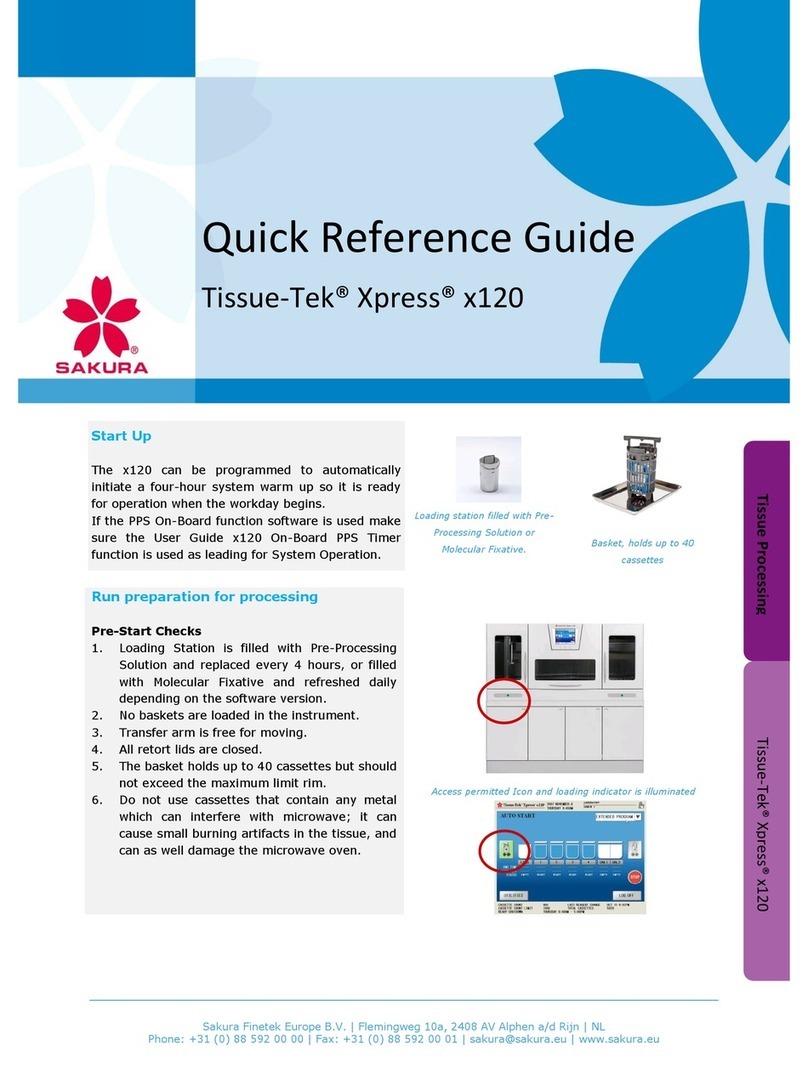

Sakura Tissue-Tek Xpress x120 User manual

Sakura

Sakura Tissue-Tek Glas User manual

Sakura

Sakura Cyto-Tek 2500 User manual

Sakura

Sakura Tissue-Tek DRS 2000 User manual

Sakura

Sakura Tissue-Tek Glas g2 User manual

Sakura

Sakura Histo-Tek VP1 User manual

Popular Laboratory Equipment manuals by other brands

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual

BD

BD 644787 user guide

DENTAURUM

DENTAURUM Compact Megaplus Instructions for use

Biuged Laboratory Instruments

Biuged Laboratory Instruments BGD 626 instruction manual

VWR

VWR SAS Super IAQ instruction manual

illumina

illumina MiSeqDx reference guide