Dino lift 135TB II User manual

OPER ATING

INSTRUCTIONS

Manufacturer:

Dinolift Oy

Raikkolantie 145 | FI-32210 LOIMAA

DINO TB II

135 • 150 • 180

3

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

Valid from serial number

135TB II 130172,

150TB II 150024,

180TB II 180011,

4

Operating instructions • DINO 135TB II • 150TB II • 180TB II

CONTENTS

1. TO THE OPERATOR................................................................................................... 7

1.1. OVERVIEW OF THE UNIT.................................................................................. 8

1.2. INTENDED USE OF THE WORK PLATFORM ................................................... 8

2. TECHNICAL SPECIFICATIONS ................................................................................. 9

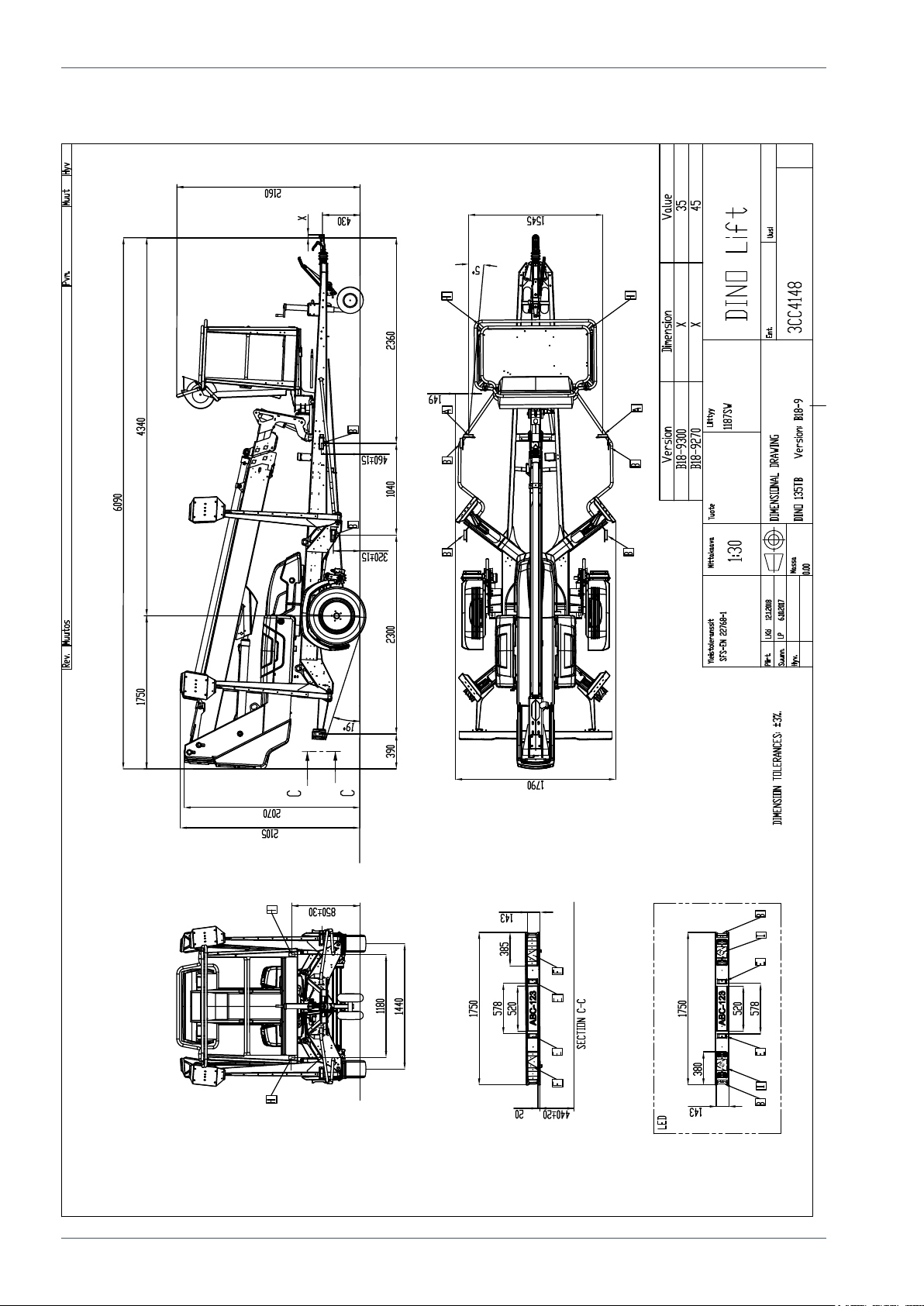

2.1. DIMENSION DRAWINGS ................................................................................. 10

2.1.1. 135TB II ....................................................................................................................... 10

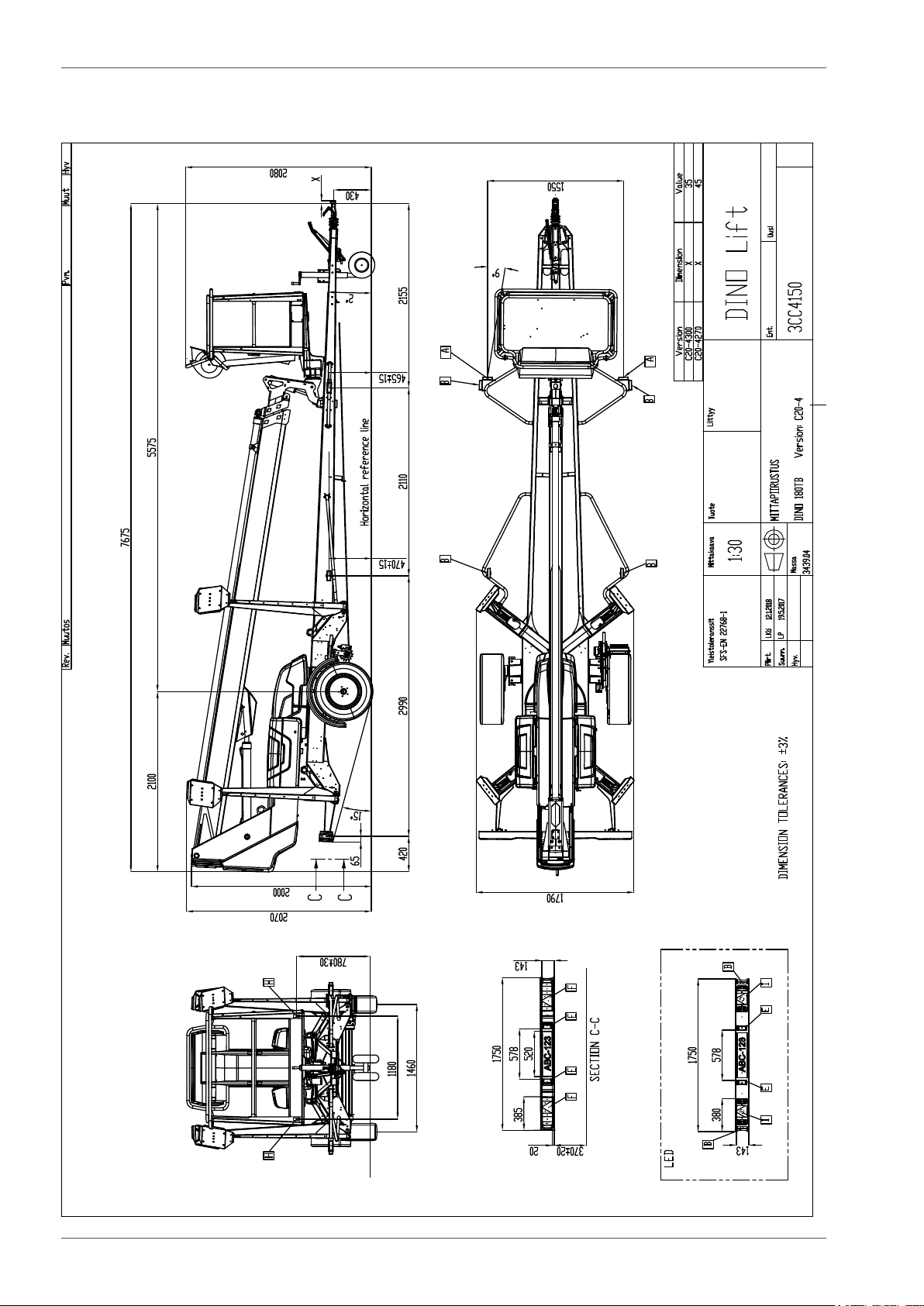

2.1.2. 150TB II ....................................................................................................................... 11

2.1.3. 180TB II ....................................................................................................................... 12

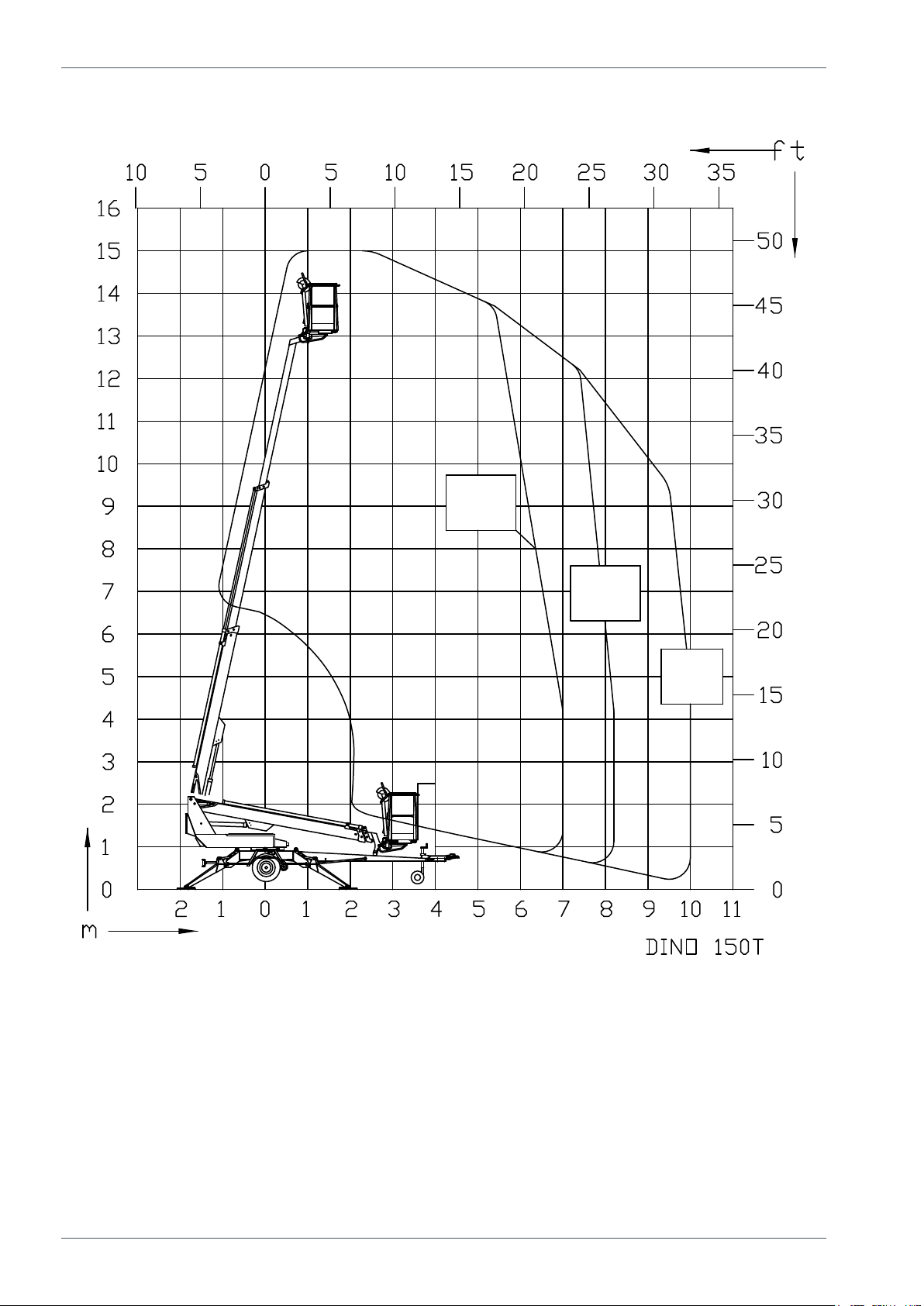

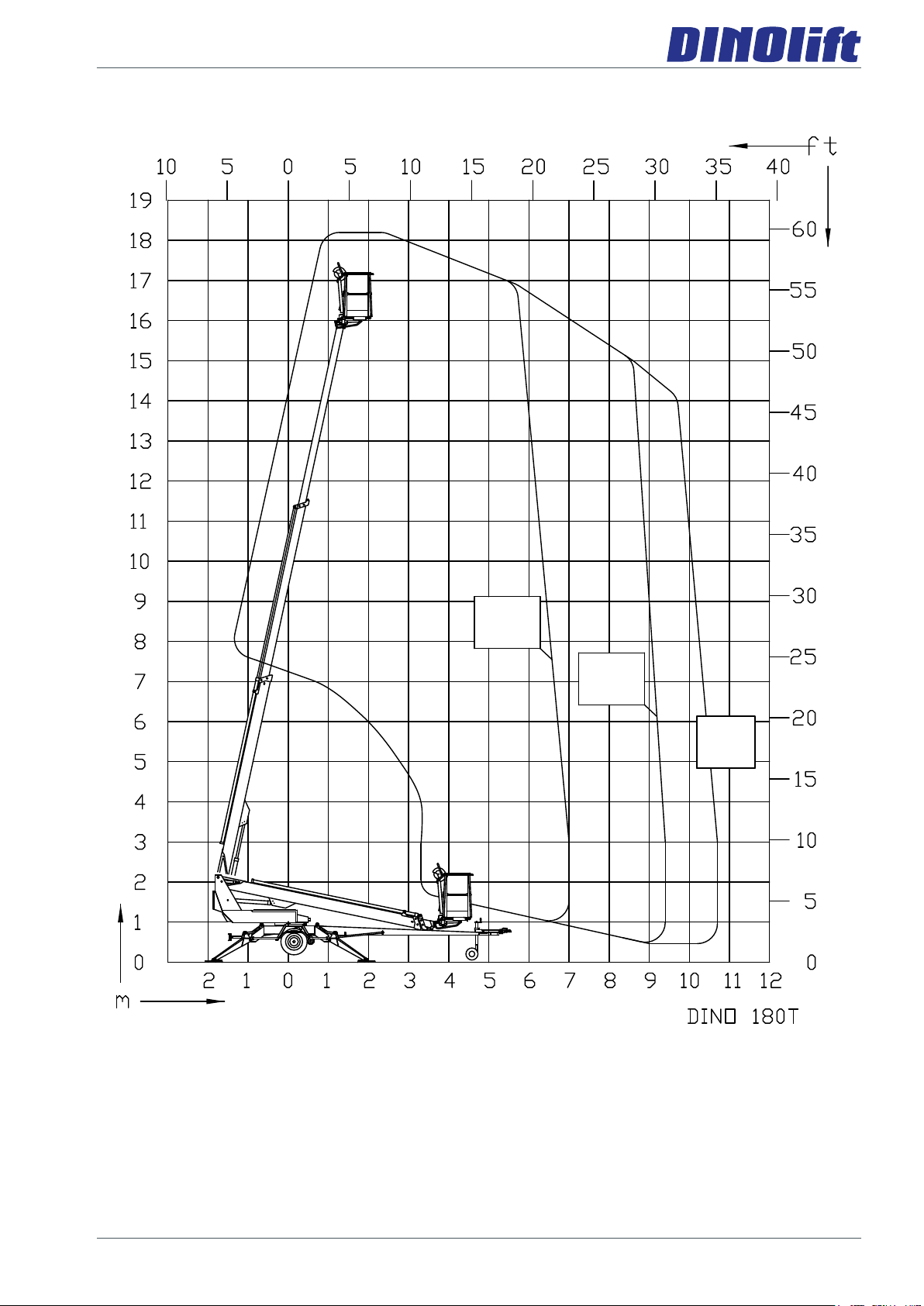

2.2. REACH DIAGRAM ............................................................................................ 13

2.2.1. 135TB II ....................................................................................................................... 13

2.2.2. 150TB II ....................................................................................................................... 14

2.2.3. 180TB II ....................................................................................................................... 15

2.3. EXAMPLE OF THE MACHINE’S NAMEPLATE ................................................ 16

2.4. EXAMPLE OF EU DECLARATION OF CONFORMITY .................................... 17

2.5. SAMPLE OF INSPECTION PROTOCOL FOR THE ACCESS PLATFORM ..... 18

3. SAFETY..................................................................................................................... 20

3.1. SAFETY INSTRUCTIONS................................................................................. 20

3.2. SAFETY-RELATED NOTIFICATIONS............................................................... 24

3.3. SAFETY DEVICES............................................................................................ 25

4. STRUCTURE AND FUNCTIONS OF THE LIFT ....................................................... 29

4.1. STRUCTURE OF THE WORK PLATFORM...................................................... 29

4.2. FUNCTIONS OF THE WORK PLATFORM....................................................... 30

4.3. OPERATING CONTROLS FOR THE FUNCTIONS.......................................... 31

4.3.1. Operating controls in the chassis control centre..........................................................31

4.3.2. Operating controls for the outriggers ...........................................................................33

4.3.3. Operating controls in the platform control centre.........................................................34

4.3.4. Setup with two control levers (option)..........................................................................36

5. OPERATING INSTRUCTIONS .................................................................................. 37

5.1. START-UP ......................................................................................................... 37

5.1.1. Worksite inspection...................................................................................................... 37

5.1.2. Positioning the lift......................................................................................................... 38

5.1.3. Starting up ................................................................................................................... 39

5.1.4. Supporting the lift......................................................................................................... 39

5.2. OPERATION...................................................................................................... 40

5.2.1. Operating the lift from the chassis control centre ........................................................40

5.2.2. Operating the lift from the platform control centre ....................................................... 42

5.2.3. Special instructions for winter use ...............................................................................44

5.2.4. Ending the work ........................................................................................................... 44

5

5.3. TRANSFERRING THE LIFT.............................................................................. 45

5.3.1. Preparing the lift for transport ......................................................................................45

5.3.2. Using the driving device............................................................................................... 46

5.3.3. Towing the lift ............................................................................................................... 48

5.3.4. Lifting the device.......................................................................................................... 49

5.4. LONG-TERM STORAGE .................................................................................. 50

5.5. IN CASE OF EMERGENCY.............................................................................. 52

5.5.1. When at risk of losing the stability ...............................................................................52

5.5.2. In case of overloading.................................................................................................. 52

5.5.3. In case the power supply is interrupted .......................................................................53

5.5.4. In case of malfunction, when even the emergency descent system is not operational53

6. INSTRUCTIONS FOR FAULT-FINDING ................................................................... 54

7. MAINTENANCE SCHEDULE.................................................................................... 58

7.1. SCHEDULE FOR INSPECTIONS REQUIRED BY THE AUTHORITIES .......... 60

7.2. LUBRICATION PLAN ........................................................................................ 61

8. ROUTINE MAINTENANCE DURING OPERATION .................................................. 62

8.1. INSTRUCTIONS FOR DAILY MAINTENANCE AND INSPECTIONS .............. 63

8.1.1. Check the condition of chassis, the boom and the work platform................................ 63

8.1.2. Check the tyres and tyre pressure...............................................................................63

8.1.3. Check the lights ........................................................................................................... 63

8.1.4. Check the hydraulic oil level ........................................................................................63

8.1.5. Check the hydraulic hoses, pipes and connectors ...................................................... 63

8.1.6. Check the operation of the safety limit switches..........................................................64

8.1.7. Check the operation of the emergency descent, the emergency stop and the sound

signal 64

8.1.8. Decals, stickers and signs ...........................................................................................64

8.1.9. Instruction manuals...................................................................................................... 64

8.2. MAINTENANCE OF THE BATTERIES ............................................................. 66

9. CHANGE OF OWNER............................................................................................... 69

6

Operating instructions • DINO 135TB II • 150TB II • 180TB II

BLANK

7

1. TO THE OPERATOR

Keep this manual on the work platform of the lift in the box reserved for it. If the instruction

manual gets lost, damaged, or for some other reason becomes unreadable, order a new

manual from the manufacturer.

This manual is intended to familiarise the user with the structure and functions of the work

platform, as well as with its appropriate use. The manual provides guidance on the service

measures that are the responsibility of the user of the work platform.

Other maintenance procedures on the work platform require special skills, special tools or

accurate knowledge about measurements or adjusted values. Guidance for these measures

is provided in a separate service manual. For situations that require service or repair

measures, contact the authorised service provider, importer or manufacturer.

Read all the instructions in this manual before using the aerial work platform. Make sure that

you have understood all the instructions. The instructions must absolutely be followed during

operation and maintenance of the aerial work platform.

When handling the unit, in addition to the instructions in this manual, the user must also

observe the local legislation, the guidelines stipulated by the employer, and regulations valid

at the work site.

Dinolift Oy is constantly developing its products. For this reason, the contents of this manual

might not always be in full compliance with the most recent version of the product. Dinolift Oy

reserves the right to modify the product without prior notice. Dinolift Oy assumes no liability

for any problems caused by changed or missing data or mistakes in this manual.

Please consult your dealer or the manufacturer for more information and detailed

instructions.

8

Operating instructions • DINO 135TB II • 150TB II • 180TB II

1.1. OVERVIEW OF THE UNIT

This unit is a trailer mounted, towable aerial work platform.

This aerial work platform complies with the standard EN280 type 1. Moving the lift by means

of the driving device or by towing is possible only when the lift is in the transport position.

For the operation, the tyres of the lift shall be raised off the ground by means of the hydraulic

outriggers.

1.2. INTENDED USE OF THE WORK PLATFORM

The aerial work platform is exclusively intended for transferring people and tools to the work

position and acting as a work platform within its permissible load-bearing capacity and reach

(refer to the “Technical Specications” table and the “Reach Diagram”).

The intended use also covers:

• Following all the instructions in the Operating Instructions

• Performance of the inspections and maintenance operations.

• Observation of the occupational safety regulations and road trafc regulations.

This aerial work platform is NOT insulated, and does not offer protection against contact with

electric current. The aerial work platform must not be used for work on electric systems.

Observe the safety instructions concerning the operating environment, and the restrictions

given in them,

The operator must receive instructions and consent from the manufacturer for all

such specic work methods or conditions that the manufacturer has not explicitly

dened in the unit's operation and maintenance instructions.

The primary power source of the lift is the electric motor. The outriggers and the boom

system are hydraulically powered.

As an option, the lifts can be equipped with a hydraulic driving device.

Consult the chapters “Technical data" and “Structure and functions of the work platform" in

this manual for more detailed information about the lift.

9

2. TECHNICAL SPECIFICATIONS

135TB II 150TB II 180TB II

Max. working height 13,5 m 15,0 m 18,0 m

Max. platform height 11,5 m 13,0 m 16,0 m

Max. outreach 9,1 m 10,0 m 10,7 m

Boom rotation continuous

Platform rotation 90°

Turn area refer to the reach diagram

Support width 3,8 / 4,2 m 3,8 / 4,2 m 3,8 / 4,2 m

Transport width 1,79 m 1,79 m 1,79 m

Transport length 6,09 m 6,66 m 7,68 m

Transport height 2,16 m 2,12 m 2,08 m

Weight 1765 kg 1835 kg 1945 kg

Max. allowed load on platform 215 kg

Max. number of persons + additional load 2 persons + 55 kg

Max. allowed sideways load (caused by persons) 400 N

Max. lateral inclination (chassis) ±0,3°

Max. wind speed during operation 12,5 m/s

Min. ambient temperature when working - 20 °C

Max. support force on the outriggers 11300 N 12800 N 16800 N

Platform size 0,7 x 1,3 m

Gradeability 25%

Power supply

- battery powered 24V/2kW, 4x6V 235Ah

Sound pressure level 73 dB

Whole-body vibration Not detectable

- mains current, battery charging 230V/50Hz/10A

Socket outlets on the platform 2 x 230V/50Hz/10A

Battery voltage:

29.6V Charging voltage

25.46V Voltage of batteries that are 100 % charged. Charger disconnected, the voltage has

been stabilizing for a few hours

20.88V Voltage of 0 % charged batteries. Movements "Boom up" and "Telescope out"

impeded.

about 17 V All movements impeded

10

Operating instructions • DINO 135TB II • 150TB II • 180TB II

2.1. DIMENSION DRAWINGS

2.1.1. 135TB II

11

2.1.2. 150TB II

12

Operating instructions • DINO 135TB II • 150TB II • 180TB II

2.1.3. 180TB II

13

2.2. REACH DIAGRAM

2.2.1. 135TB II

215KG

475LB

120KG

265LB

14

Operating instructions • DINO 135TB II • 150TB II • 180TB II

215KG

475LB

120KG

265LB

80KG

175LB

2.2.2. 150TB II

15

2.2.3. 180TB II

215KG

475LB

120KG

265LB

80KG

175LB

16

Operating instructions • DINO 135TB II • 150TB II • 180TB II

2.3. EXAMPLE OF THE MACHINE’S NAMEPLATE

The name of the manufacturer, and the production number and serial number of the machine

have been marked on the nameplate as shown in the picture below.

The nameplate of the lift is located on the

right-hand side of the tow-bar, as shown in

the picture.

The serial number is also engraved in the

lift's chassis, on the upper surface of the

right-hand tow-bar.

The nameplate of the trailer is located on

the tow-bar, on the right-hand side of the

nameplate of the lift, as shown in the picture.

Following data is written on the plate:

EU Type Approval Number (if available)

Serial number

Total weight kg

0Maximum allowed weight on the towing

hitch kg

1 Maximum allowed axle weight kg

2 kg

Raikkolantie 145

32210 Loimaa

FINLAND

400 N

230 V

-20 C

o

12,5 m/s

50 Hz

o

kg

kg

DINO

54.516

Serial number

Type Manufacturer

Year of manufacture Manufacturer's address

Voltage Frequency

Min. ambient temperature

when working Maximum allowed wind speed

Weight kg Max. allowed load on platform 215

Maximum allowed sideways

load Max. lateral inclination (chassis) 0.3

Maximum allowed number of

persons

Maximum allowed additional

load

2 55

17

2.4. EXAMPLE OF EU DECLARATION OF CONFORMITY

EU declaration of conformity for machine

Manufacturer

Dinolift Oy

Raikkolantie 145

FI-32210 Loimaa, FINLAND

declares that

DINO 150TB Aerial Work Platform no YGCD150TB F0150015

conforms to the provisions of the Machine Directive 2006/42/EC

as well as the national decree (VNA 400/2008), through which they have been brought

into effect

The inspection in accordance with Annex IX to the directive 2006/42/EC has been

carried out by the notied body no. 0537,

VTT

P.O.Box 1300

FI-33101 Tampere, FINLAND

has granted the certicate no. VTT 174/524/14

In addition, the aerial work platform also complies with the provisions of the following

European Directives:

EMC: 2014/30/EU

In designing the machine, the following harmonised standards have been applied:

SFS-EN 280+A1:2015, SFS-EN ISO 13849-1:2015, SFS-EN 60204-1/A1:2009,

SFS-EN-ISO 12100:2010

The person, who has compiled the technical construction le: Santtu Siivola

Chief Engineer

Dinolift Oy, Raikkolantie 145,

FI-32210 Loimaa, FINLAND

Loimaa 07.01.2015

-----------------------------------------

Santtu Siivola

Chief Engineer

18

Operating instructions • DINO 135TB II • 150TB II • 180TB II

2.5. SAMPLE OF INSPECTION PROTOCOL FOR THE ACCESS PLATFORM

TEST CERTIFICATE

DATE: I

START-UP TESTS:

Inspection place: Dinolift Oy Inspector's signature: I

I

BASIC INFORMATION

Manufacturer: Dinolift OY Place of manufacture: Finland

Address: Raikkolantie 145

32210 LOIMA

A

Importer:

Type of lift:

Chassis:

Boom:

Outriggers:

TECHNICAL SPECIFICATIONS

Machine and type: DINO 150TB Max. platform height 13 m

Number of manufacture IMax. outreach: Depend on load

Year of manufacture I

Max. lifting capacity: 215 kg Boom rotation: Continuous

Max. person number: 2Support width: 3,80 m

Max. additional load: 55 kg Transport width: 1,79 m

Power supply: 24 VDC Transport length: 6,66 m

Lowest temperature: -20 °C Transport height: 2,13 m

Weight: 1835 kg Basket size: 0,7 x 1,3 m

INSPECTION POINTS: (Y = meet standards N = do not meet standards)

Y

N

Y

N

A. GENERAL REQUIREMENTS C. STRUCTURES

1. Suitability for use 1. Transport position / transp. equipment

2. Certificate of conformity 2. Driving/towing equipment

3. User manual and storage 3. Chassis

4. Machine plate - inspection plate 4. Turning device

5. Instructional and safety plates 5. Boom system

6. Safety colours 6. Structure and position of work platform

7. Hydraulic system

B. STABILITY D. ELECTRIC SYSTEM

1. Load plate and reach diagram 1. Electric system

2. Supports / outriggers 2. Electric appliances

3. Indicator for horizontal position 3. Lights

Boom platform Scissor platform Mast platform

Car Self propelled Trailer mounted

Articulated boom Telescopic boom Articulated telescopic boom

Fixed mast Telescopic mast Scissor

Hydraulic turning Hydraulic pushing Mechanical

19

The initial inspection and test loading of the Dino aerial work platforms is performed by the

manufacturer. A protocol, drawn up during the inspection, will accompany the lift.

The protocols of the start-up and periodic inspections must be kept with the lift or its

immediate proximity for at least ve years.

E. SAFETY AND CONTROL DEVICES F. SAFETY FEATURES

1. Safety limit switches 1. Prevention of unauthorized use

2. Sound signal 2. Locking device, covers and guards

3. Emergency descent system 3. Prevention of lifting

4. Protection of controls 4. Prevention of opening of support

5. Symbols / control directions 5. Safety distances

6. Placement of controls 8. Control of loading

7. Emergency stop 9. Limiting devices

G. TEST LOADING

1. Overload test (150%) 323 kg

2. Functional test (110%) 237 kg

FAILINGS AND NOTES

Failings have been repaired. Date: Signature:

20

Operating instructions • DINO 135TB II • 150TB II • 180TB II

1. SAFETY

All the essential safety instructions and warnings, relevant to transport, use and maintenance

of the lift, are described in this chapter.

DANGER

Failure to observe these instructions and safety regulations may cause a severe injury or

even death. Familiarise yourself with all the safety regulations, operating instructions and

signs afxed to the machine, and follow them.

Make sure that you understand all the safety instructions and regulations. Also make sure

that others operating the machine or working on the work platform are familiar with these

instructions.

1.1. SAFETY INSTRUCTIONS

Only specially trained personnel with authorisation in writing, who are well familiarised with

the device, and at least 18-years old, are allowed to operate the unit.

Keep the lift free of any dirt, which may impair safe operation, and impede the inspection of

the structures.

The device must be serviced and inspected regularly.

Only skilled persons, familiar with the service and repair instructions for the lift, are allowed

to carry out servicing and repair work.

It is strictly prohibited to use a lift which is out of order.

Never remove or disable any safety devices of the machine.

WARNING

The device must neither be altered without the manufacturer’s consent nor be used under

conditions, which do not meet the manufacturer's requirements.

The operator must be given instructions and consent from the manufacturer for all such

specic work methods or conditions that the manufacturer has not explicitly dened.

This manual suits for next models

5

Table of contents

Other Dino lift Boom Lift manuals

Dino lift

Dino lift DINO 260XTD Technical specifications

Dino lift

Dino lift DINO 160XT II User manual

Dino lift

Dino lift DINO 185XTC II Instructions for use

Dino lift

Dino lift DINO 280RXT User manual

Dino lift

Dino lift DINO 185XTC II User manual

Dino lift

Dino lift 240RXT Technical specifications

Dino lift

Dino lift 240RXT User manual