Dino lift DINO 260XTD Technical specifications

MAINTENANCE

INSTRUCTIONS

DINO 260XTD

Dealer:Manufacturer:

Dinolift Oy

Raikkolantie 145

FI-32210 LOIMAA

Tel. +358 20 1772 400

www.dinolift.com

3

ORIGINAL INSTRUCTIONS

Valid from serial number

260XTD 26419 -

4

Maintenance instructions •DINO 260XTD

CONTENTS

1. TO THE MAINTENANCE PERSONNEL..................................................................... 6

1.1. GENERAL WARRANTY TERMS......................................................................... 7

1.2. SAFETY AND THE ENVIRONMENT................................................................... 8

1.2.1. General safety instructions for maintenance .................................................................8

1.2.2. Filling quantities of chemical substances.......................................................................9

1.2.3. Materials and recyclability..............................................................................................9

1.3. SAFETY-RELATED NOTIFICATIONS............................................................... 10

1.4. SAFETY DEVICES............................................................................................ 11

2. MAINTENANCE SCHEDULE.................................................................................... 15

2.1. SCHEDULE FOR INSPECTIONS REQUIRED BY THE AUTHORITIES .......... 17

2.2. LUBRICATION PLAN ........................................................................................ 18

3. ROUTINE MAINTENANCE DURING OPERATION .................................................. 19

3.1. INSTRUCTIONS FOR DAILY MAINTENANCE AND INSPECTIONS .............. 20

3.1.1. Check the condition of chassis, the boom and the work platform................................ 20

3.1.2. Check the tyres and tyre pressure...............................................................................20

3.1.3. Check the lights ...........................................................................................................20

3.1.4. Check the hydraulic oil level ........................................................................................20

3.1.5. Check the hydraulic hoses, pipes and connectors ......................................................20

3.1.6. Check the operation of the safety limit switches..........................................................21

3.1.7. Check the operating controls.......................................................................................21

3.1.8. Check the operation of the emergency descent, the emergency stop and the sound

signal 21

3.1.9. Decals, stickers and signs ...........................................................................................21

3.1.10. Instruction manuals......................................................................................................21

4. PERIODIC SERVICE.................................................................................................22

4.1. INSTRUCTIONS FOR MONTHLY SERVICE AND INSPECTION .................... 22

4.1.1. Lubricate the greasing points ......................................................................................22

4.1.2. Check and adjust the play between the slide pads and the slide surface ...................22

4.1.3. Check the adjustment of the tow hitch and the overrun brake..................................... 23

4.1.4. Check the driving device..............................................................................................24

4.1.5. Check the condition and attachment of the battery and the wiring..............................24

4.1.6. Check the operation and condition of the platform's levelling system .........................24

4.2. INSTRUCTIONS FOR INSPECTIONS EVERY 6 MONTHS............................. 25

4.2.1. Check and lubricate the turning device bearings and the gear ring............................. 25

4.2.2. Lubricate the telescope cylinder bearings ...................................................................25

4.2.3. Lubricate the Flyer-chain .............................................................................................25

4.2.4. Check the attachment of the wheels and the tyre pressures.......................................25

4.2.5. Lubricate the tow hitch and the overrun.......................................................................26

4.2.6. Check the condition of the brakes ...............................................................................26

4.2.7. Checking the adjustment of the overload protection device ........................................27

4.2.8. Check the operation of the load regulation valves.......................................................27

5

4.3. INSTRUCTIONS FOR ANNUAL MAINTENANCE OF THE LIFT...................... 29

4.3.1. Inspect thoroughly the support outriggers and the outrigger cylinder joints ................ 30

4.3.2. Check the frame structures, the boom system, the work platform and the platform carrier

30

4.3.3. Check thoroughly the tow hitch and the overrun ......................................................... 31

4.3.4. Inspect thoroughly the hydraulic hoses, pipes and connections..................................32

4.3.5. Inspect the axle and the suspension ........................................................................... 32

4.3.6. Check thoroughly the condition of the brakes..............................................................32

4.3.7. Check electro-hydraulic rotary adaptor........................................................................32

4.3.8. Inspect thoroughly the turning device..........................................................................33

4.3.9. Inspect thoroughly the Flyer-chains.............................................................................34

4.3.10. Inspect the cylinders, and lubricate the joint bearings.................................................35

4.3.11. Check the battery, the electrical appliances and the wiring .........................................35

4.3.12. Measure hydraulic pressures.......................................................................................36

4.3.13. Inspecting the condition and functionality of the operating controls ............................ 36

4.3.14. Decals, stickers and signs ...........................................................................................37

4.3.15. Instruction manuals......................................................................................................37

4.3.16. Check the attachment and condition of the safety devices..........................................37

4.3.17. Checking the operation of the safety limit switches.....................................................37

4.3.18. Checking the operation of the overload limit switches RK4 and RK5..........................38

4.3.19. Test loading..................................................................................................................40

4.3.20. Check the lights ...........................................................................................................41

4.3.21. Inspect thoroughly the driving device ..........................................................................41

4.3.22. Lubricate the slide and threads of the jockey wheel....................................................41

4.3.23. Changethehydraulicoilandthelter .........................................................................41

4.3.24. Inspect the anti-corrosion treatment ............................................................................41

4.4. ADJUSTING THE OVERLOAD LIMIT SWITCHES........................................... 42

4.5. SPECIAL INSPECTION .................................................................................... 42

5. INSTRUCTIONS FOR FAULT-FINDING ................................................................... 43

5.1. PROBLEMS RELATED TO POWER SUPPLY AND START-UP ....................... 43

5.2. OPERATIONAL PROBLEMS RELATED TO MOVEMENTS............................. 45

5.3. DRIFTING OF BOOM OR OUTRIGGERS........................................................ 47

5.4. PROBLEMS RELATED TO TOWING................................................................ 49

6. HYDRAULIC SYSTEM .............................................................................................. 51

6.1. HYDRAULIC COMPONENTS 26209 ja 26229 ->............................................. 51

5.5. HYDRAULIC DIAGRAMS ................................................................................. 51

7. ELECTRIC SYSTEM ................................................................................................. 53

7.1. ELECTRIC COMPONENTS.............................................................................. 53

7.2. ELECTRIC DIAGRAM....................................................................................... 59

6

Maintenance instructions •DINO 260XTD

1. TO THE MAINTENANCE PERSONNEL

Thismaintenanceinstructionmanualisintendedtogivethequaliedserviceperson,who

is familiar with the basic structure of the lift, the required instructions for maintenance,

adjustments and repairs of the lift.

These maintenance instructions are an addition to the operating instructions. It is essential,

that the person, responsible for the maintenance, has familiarised himself

with the operating and safety instructions of the lift before

starting the service operations.

DANGER

WARNING

CAUTION

NOTICE

Perform all the service and repair operations in accordance with the local regulations for

occupational safety.

Exercise particular caution while performing service- and maintenance operations. A faulty

machine may cause severe, unforeseen risks.

If you are not sure which parts, tools or measures are necessary, consult your dealer or the

manufacturer's service organisation.

Dinolift Oy is constantly developing its products. For this reason, the contents of this manual

might not always be in full compliance with the most recent version of the product. Dinolift Oy

reserves the right to modify the product without prior notice. Dinolift Oy assumes no liability

for any problems caused by changed or missing data or mistakes in this manual.

Please consult your dealer or the manufacturer for more information and detailed

instructions.

DANGER

WARNING

CAUTION

NOTICE

The operator must receive instructions and consent from the manufacturer for

all such specic work methods or conditions, as well as for service, repair or

modication operations, that the manufacturer has not explicitly dened in the unit's

operation and maintenance instructions.

7

1.1. GENERAL WARRANTY TERMS

Dinolift Oy warrants newly delivered DINO aerial work platforms to be free from defects in

materials, constructional parts, components and workmanship, with terms and limitations set

out in the warranty terms. Full warranty terms are provided by the distributor.

The warranty period starts from the date of delivery from factory. Warranty cases related to

engines and generators or other accessories manufactured by external suppliers are to be

handled by and with the local authorized distributor of each respective manufacturer.

The warranty covers only the cost of constructional parts and components used in the

equipment. The warranty does not cover:

• damage or loss caused by transportation.

• damage or loss caused by misconduct, misapplication or accident damage, failure or

losscausedbynegligenceofinstructions,manufacturerspeciedserviceprogram,

maintenance or storage.

• normal wear of the equipment and damage resulting therefrom, nor wearing parts and

materials,suchasrubbertyres,seals,hoses,ttings,batteries,lters,etc.

• damage, failure or loss caused by maintenance or repair work performed by unauthorised

service personnel.

• damage, failure or loss caused by the purchaser’s acts or omissions causing alterations

ormodicationstothestructure,congurationorqualityoftheproduct.

• anyindirectdamageorlosssuchaslossofprotanddowntimecosts,etc.

• any claims by a third party.

• any damage caused to other property.

Warranty claims and damaged parts shall be processed according to Dinolift instructions of

warranty procedure. Contact the distributor for further instructions. No claim will be accepted

ifDinoliftnoticationandwarrantyproceduresarenotfollowedornon-originalpartsorparts

not approved by the Supplier have been used.

For more information on warranty procedures, contact the distributor or

Dinolift Oy

After Sales Services

Raikkolantie 145

FI-32210 Loimaa

Finland

8

Maintenance instructions •DINO 260XTD

1.2. SAFETY AND THE ENVIRONMENT

1.2.1. General safety instructions for maintenance

Exercise particular caution always when carrying out service- and maintenance operations.

A faulty lift, or a lift from which covers, safety devices or other parts have been removed,

may operate in an unexpected way.

If you must disable any of the safety devices for maintenance, make sure to resume its

operation after the maintenance, and check that it works correctly.

Beware of sudden and unexpected movements.

Support the platform, the boom system, the articulated arms and the support outriggers in

a position where the load does not rest on the structure under repair or cause any other

danger (e.g. in transport position or use of supporting structures)

When removing hydraulic cylinders, also note that

• the cylinders may be oily and slippery

• the cylinders are heavy. Use a lift and suitable lifting gear for lifting

Do not spill oil on the ground.

Dispose of used oils and oily waste appropriately. Observe the local regulations and the

regionalorsite-specicrecyclinginstructions.

Remember when handling batteries:

Electrolytic liquid is highly corrosive – always wear protective clothing and eye guards.

Thebatteriesgeneratehydrogengasduringcharging–nakedameprohibited,dangerof

explosion

Use genuine spare parts for maintenance. This way, you will ensure correct operation and

structural safety of the lift even after the maintenance.

9

1.2.2. Filling quantities of chemical substances

Liquid type Volume

Hydraulic oil

Fuchs Hydraway Bio SE 22

Fuchs Hydraway Bio SE 32-68

Mobil EAL 32

30-35 l

Hydraulic oil (winter option) Neste Hydrauli 28 Arctic 30-35 l

Lubricant Mobilux EP2 NLGI 2

Mobil Grease XHP 222

Chain lubricant Würth HHS Grease

Engine oil SAE 10W-30 1.1 l

Consulttheseparateenginemanualformoreinformationandspecicrecommendationsfor

engine oil.

Thehydraulicoiltype,usedinthelift,ismarkedonthelabel,afxedtothesideofthe

reservoir.

1.2.3. Materials and recyclability

Tyres

Type Radial M+S Size 225/75R17,5

The tyres meet the requirements of the REACH regulation.

The tyres can be recycled. A recycling fee has been paid for the tyres, so the used tyres may be left

for recycling if they are replaced.

Note the national and local regulations and policies.

Other materials

Metals

Steel, aluminium, cast iron

RecyclableHydraulic pipes and components

Power pack, axles

Plastics

Covers,mudaps(ABS,PE) Recyclable

Plastic parts are marked with material

ID.

Tyres

Battery Lead battery Recyclable

Electric components Wires, components Partly recyclable

Hydraulic hoses Not recyclable Hazardous waste.

Oils and lubricants Usedoils,oilyltersetc. Not recyclable Hazardous waste.

10

Maintenance instructions •DINO 260XTD

1.3. SAFETY-RELATED NOTIFICATIONS

The following safety alert symbols and safety signal words are used in this manual.

Observe all the safety instructions that follow these symbols, in order to avoid dangerous

situations and personal injuries.

This is a general safety alert symbol and it is used to alert you about a potential

hazard. Observe the additional instructions given in form of text or symbols that

follow this symbol.

DANGER

WARNING

CAUTION

NOTICE

Red DANGER-message warns for an imminent or potential hazardous situation which, if not

avoided, may result in death or serious injury.

DANGER

WARNING

CAUTION

NOTICE

Orange WARNING -message is used in connection with potential risk factors, which if not

avoided, under certain conditions, may result in death or serious injury.

DANGER

WARNING

CAUTION

NOTICE

Yellow CAUTION -message is used to warn about a hazardous situation which, if not

avoided, could result in minor or moderate injury.

DANGER

WARNING

CAUTION

NOTICE

Bluenotice-messageisusedtodrawyourattentiontospecialnoticationsorinstructions

that are related to the operation or maintenance. Such messages include, for example,

instructions that are related to reliability of the machine or aim to avoid material losses.

11

1.4. SAFETY DEVICES

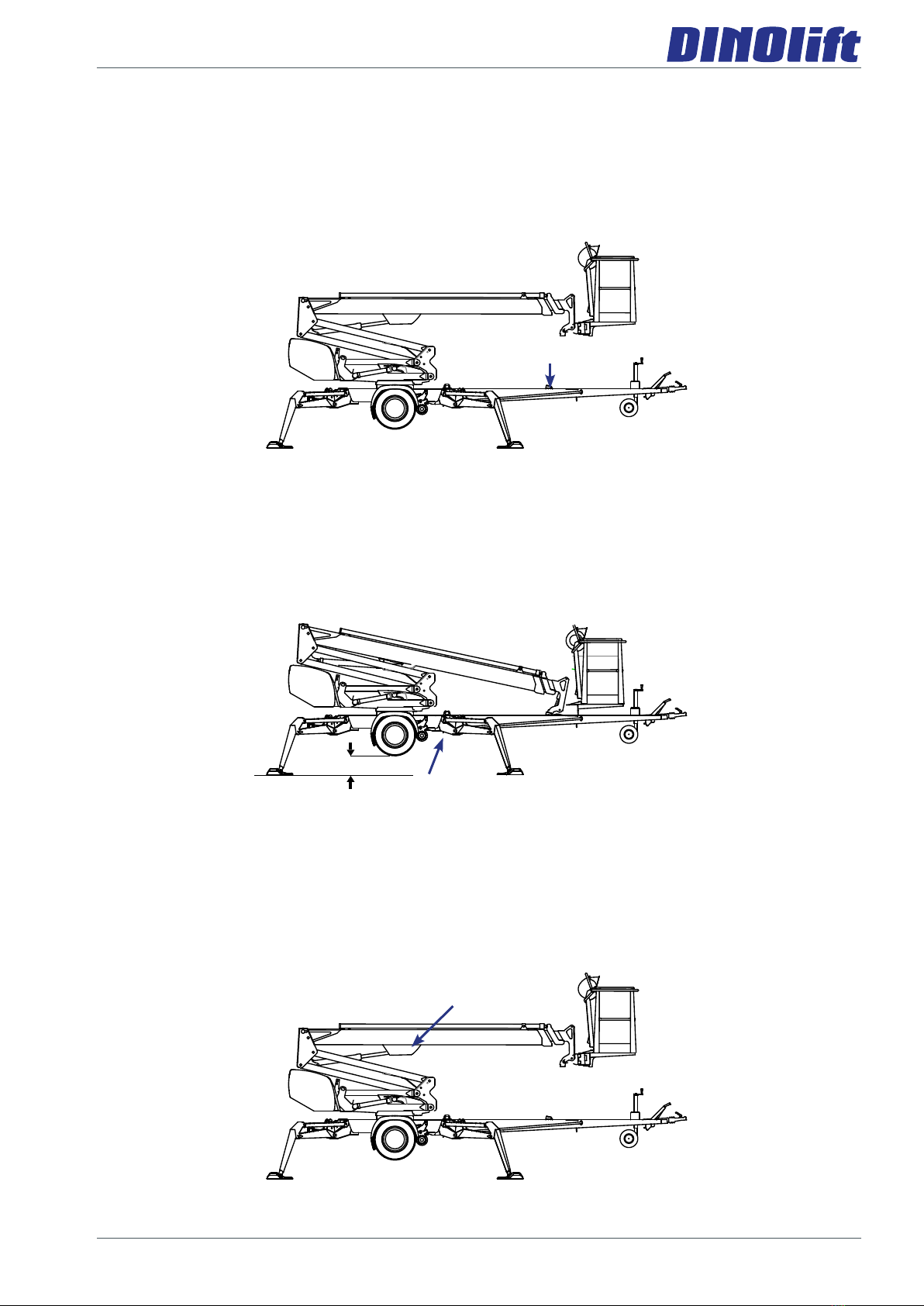

1. Supervision of transport position of the boom

The safety limit switch RK3 prevents the operation of the outriggers and the driving device

when the boom is not resting on the transport support. The switch is located on the tow-bar

at the transport support.

RK3

2. Supervision of supporting

The lift’s all support outriggers must be in the support position before the boom is lifted.

Make sure that the wheels are off the ground.

The safety limit switches RK11, RK12, RK13 and RK14 are located on the support

outriggers.

RK11, RK12, RK13, RK14

3. Overload control of the boom

The outreach limit switch RK4 and overload limit switch RK5 prevent the lift from being

overloaded by limiting the outreach of the lift to the side.

The limit switches are located under the cover at the top end of the lifting cylinder. During

operation, the cover must be intact and in place.

RK4, RK5

12

Maintenance instructions •DINO 260XTD

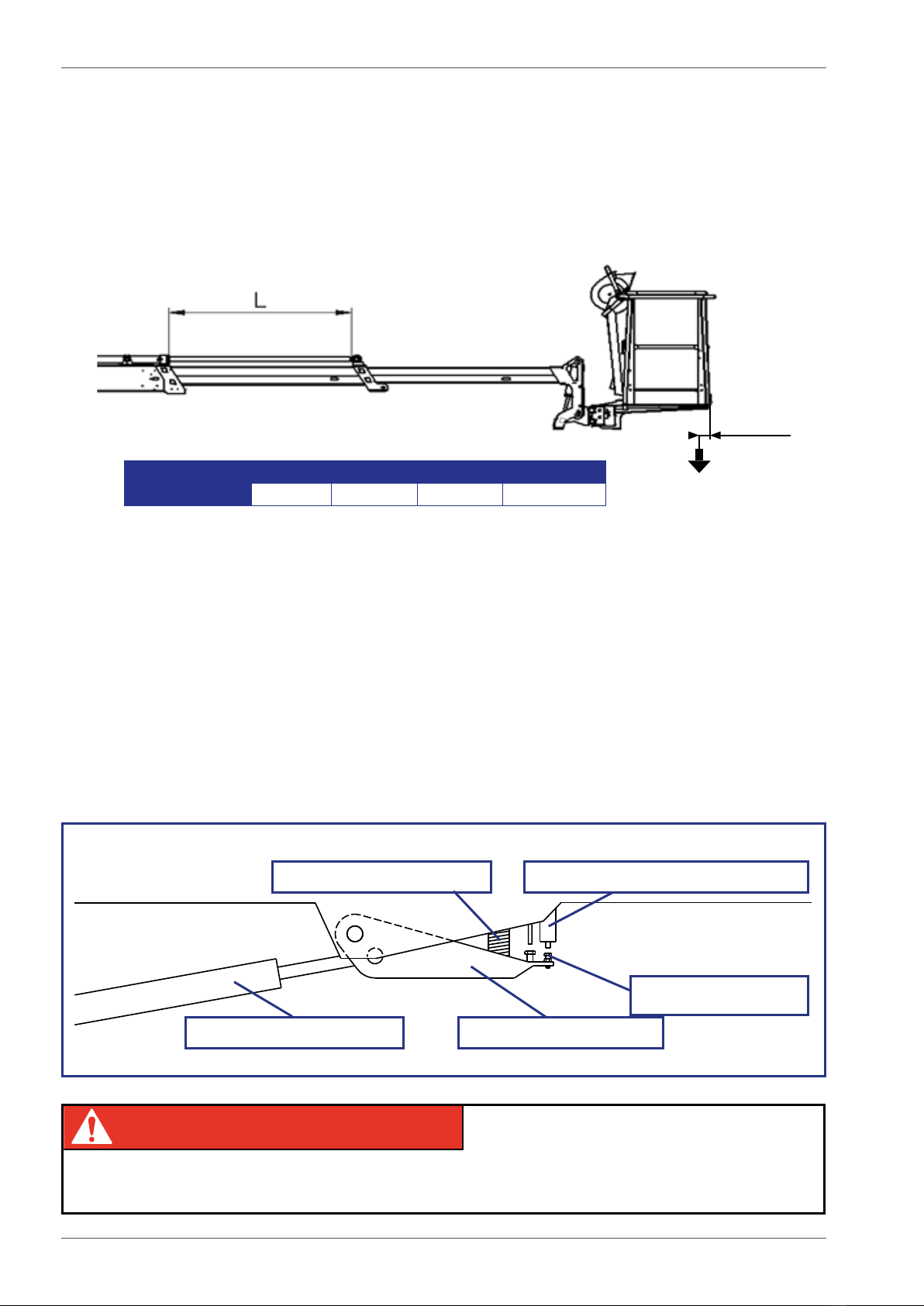

The green light in the control centre on the platform is lit, when the platform is within the

allowed operating range.

The reach limit switch RK4 will stop the movements, which impair the stability of the lift

(extending the telescope and lowering the boom), at a predetermined position.

Adjusted values of the limits:

100 mm

w

W RK4 - L RK5 - L

260XTD 80 kg 2050 mm 2350 mm +0 / -50 mm

The red warning light for overloading will illuminate as soon as the RK4 has stopped the

movement. While at the outreach limit, the red warning light and the green signal light will

ashinturns.Inthissituation,theliftcanbeoperatedinthedirection,inwhichitremains

inside the permitted outreach area.

The overload limit switch RK5 backs up, if the RK4, for some reason, does not work.

Once the RK5 is activated, the red warning light for overloading in both control centres will

be continually illuminated, and a warning buzzer will sound on the platform.

The operation of the overload limit switches is based on monitoring of the boom's lifting

torque.

PRESSURE SPRING

LIFTING CYLINDER ARTICULATED ARM

LIMIT SWITCHES RK4 and RK5

ADJUSTMENT

SCREWS

DANGER

WARNING

CAUTION

NOTICE

The limit switches must never be readjusted, nor the operation of the mechanism be

impeded. Risk of turning over the lift!

13

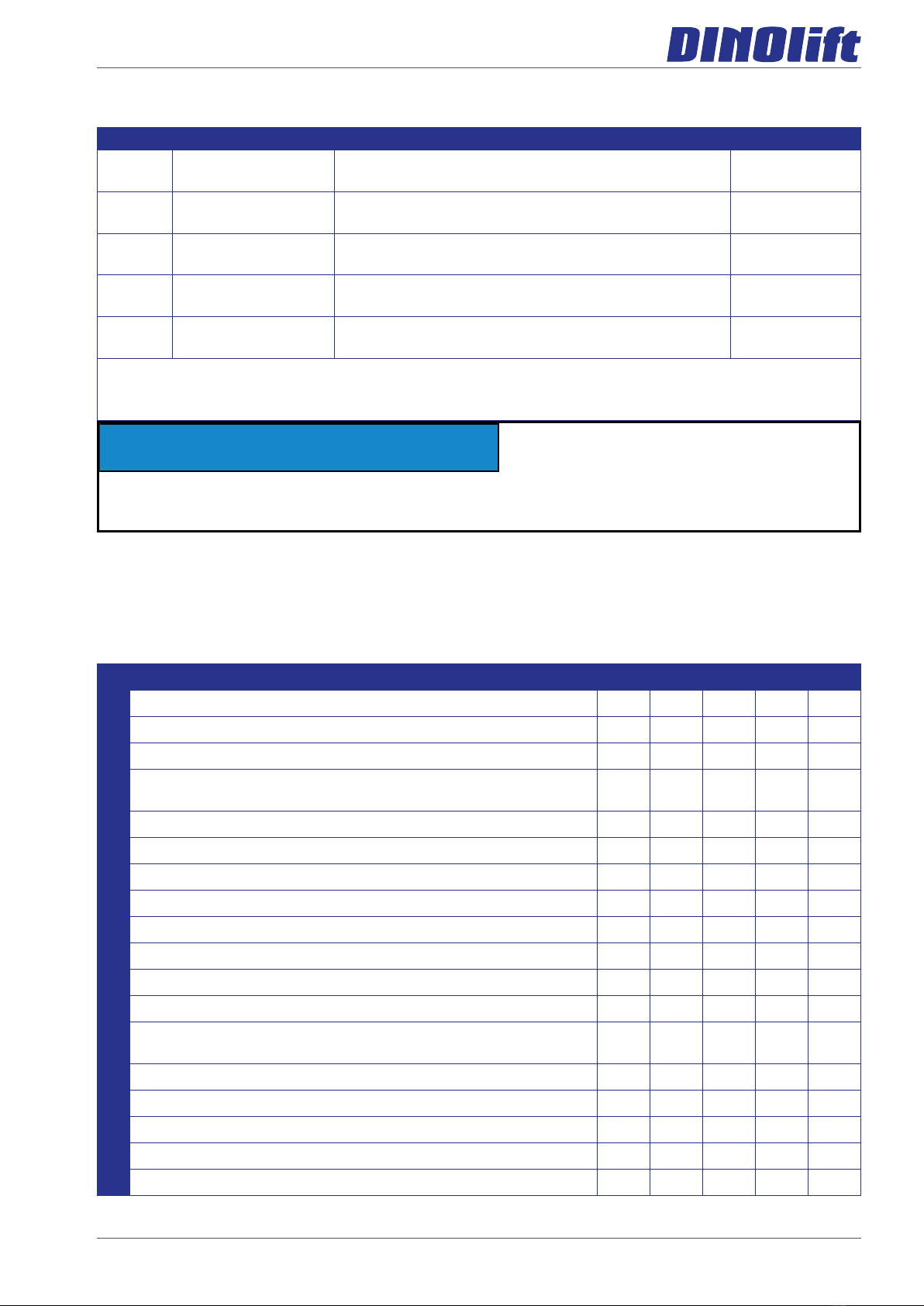

5. Supervision of the telescope chain

The extension chains for the telescope are doubled.

If the load-bearing chain slackens or breaks, the

doubling chain prevents the movements of the

telescope, and the safety switch RK7/RK15 breaks

the emergency stop circuit.

RK15

RK7

~

3

mm

~32

mm

~

40

mm

AA

A - A

A

B

A

B

C

C

LIMIT SWITCH RK7/RK15

EXTENSION CHAIN

DOUBLING CHAIN

RETRACTION CHAIN

6. Preventing the inclination of the platform

The platform is levelled hydraulically by means of a so-called slave cylinder system, where

the master cylinder controls the slave cylinder that inclines the work platform.

The platform keeps its level position only if the

valves in the system are tight.

The levelling system comprises the following

parts:

• Master cylinder

• Slave cylinder

• Load regulation valve

• Double load regulation valve

14

Maintenance instructions •DINO 260XTD

7. Safety devices for hose rupture

All the load-bearing cylinders are equipped with valves for rupture or leak in the hydraulic

system, which prevent the load from falling.

Outrigger cylinders Lock valves Prevent the inching of the

outriggers in either direction.

Lifting cylinder of the boom Load regulation valve Prevents the load from falling

Lifting cylinder of the

articulated arms Load regulation valve Prevents the load from falling

Telescope cylinder Load regulation valve Prevents the inching of the

telescope in either direction.

Levelling system Load regulation valves Prevents the inclination of the

platform

7. Emergency stop buttons

Depressing the emergency stop button, stops all the movements immediately and turns off

the power unit. The button can be found at each control station. Once the button has been

depressed, only the emergency descent functions remain operational.

The emergency stop button locks in the lower position, and it must be released before

starting the power unit.

DANGER

WARNING

CAUTION

NOTICE

If the unit does not start, make sure that the emergency descent button is not in the lower

position at any of the control stations.

Theemergencystopbuttonintheplatformcontrolcentreisttedwithasignallight,which

remains illuminated while the lift is in the normal operating mode. The light will go out, if the

emergency stop function is activated by any of the emergency stop switches or by the safety

device.

15

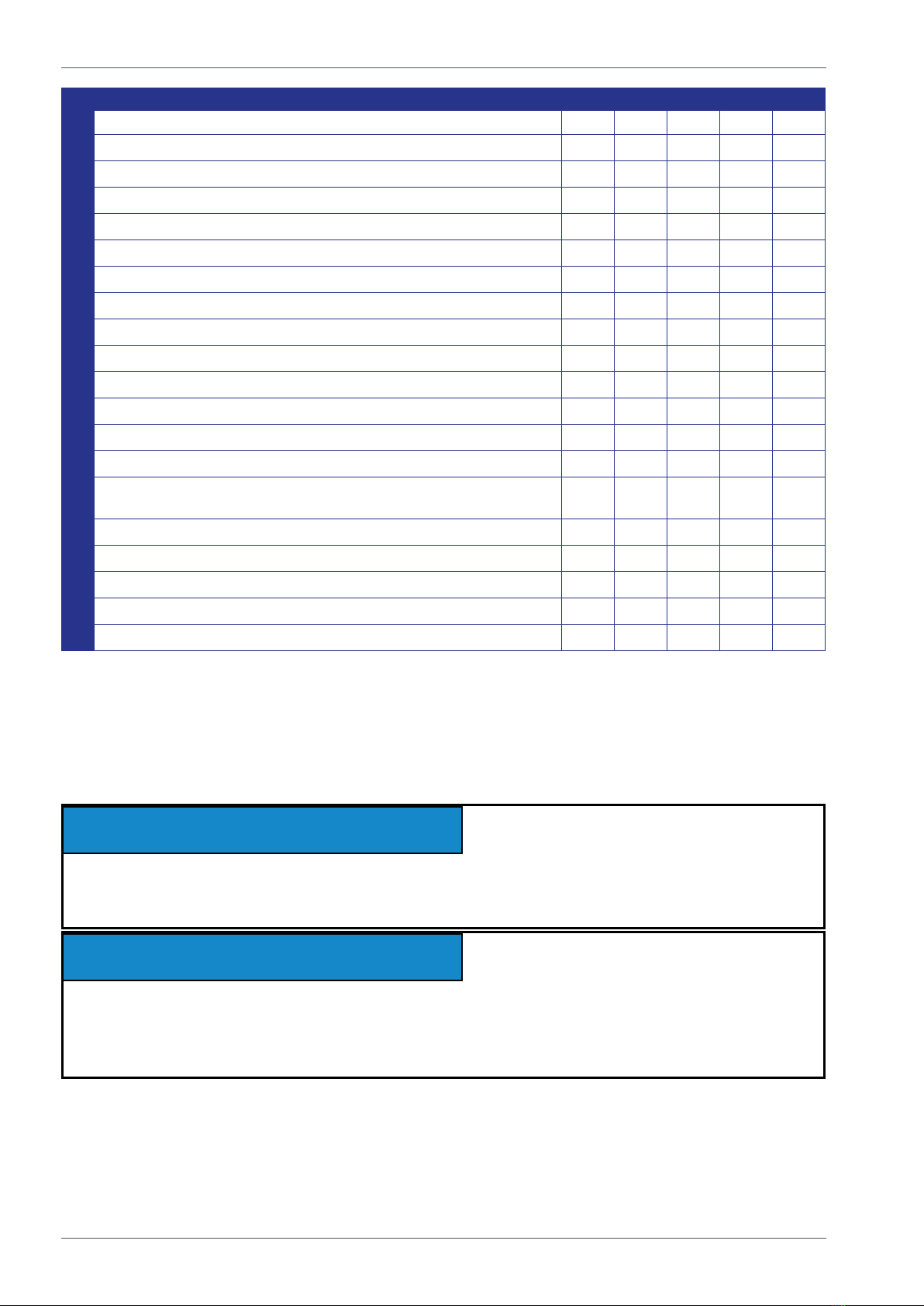

2. MAINTENANCE SCHEDULE

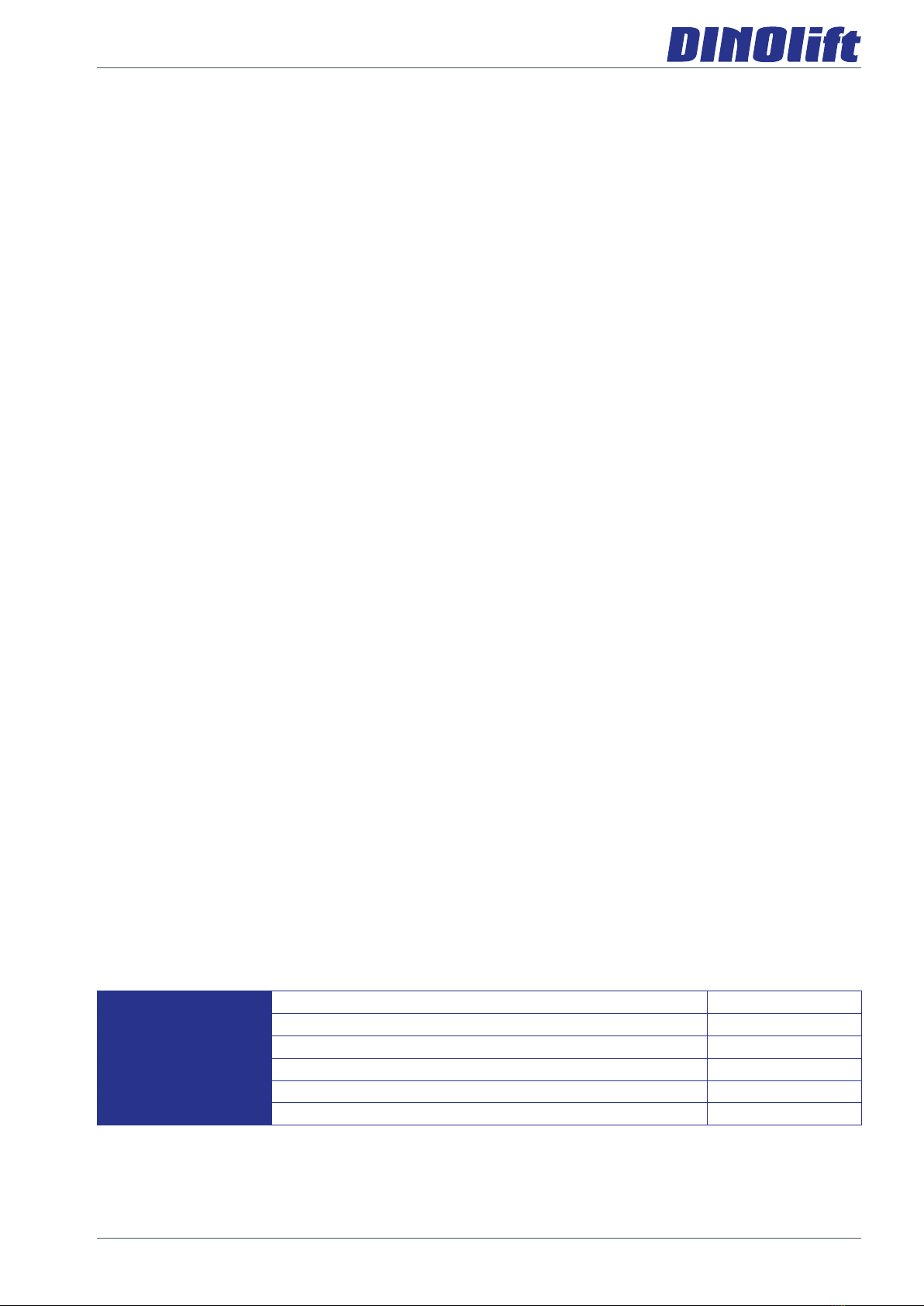

Maintenance measures A B C D E

1Frame structures, boom system and platform T T T P

2Bearings of the overload protection device V T/V T/V

3Joints of the outriggers and the outrigger cylinders V T/V P/V

4Joints of the outriggers' foot plates and the moving parts of

the outrigger limits V T/V P/V

5Bearings of the boom and the articulated arms V T/V T/V

6Bearings of the levelling system of the platform V T/V T/V

7Articulation bearings of the levelling cylinders V T/V T/V

8Articulation bearings of the lifting cylinders V T/V T/V

9Sliding surfaces and rollers of the telescope T/V T/V T/V

10 Bearing of telescope cylinder T/V T/V

11 Condition of cylinders P

12 Flyer-chain V P/V

13 Checking and adjusting the play between slide pads and

surfaces TTT

14 Turning device V P/V

15 Electro-hydraulic rotary adaptor T

16 Tyres and tyre pressures T T P P

17 Tow hitch/overrun T V P/V

18 Jockey wheel slide and threads P/V

DANGER

WARNING

CAUTION

NOTICE

In addition to the daily maintenance routines according to the maintenance schedule, every

operatorisobligedtoperformasite-specicworksiteinspection.

T = Check (general/visual checking of condition).

P = Thorough Inspection. To be performed follwing the separate procedure described in the

maintenance instructions.

V = Grease

S = Carry out replacements, repairs or other maintenance tasks described in the instructions

Service Service interval Service person Instructed

A Daily Operator operating

instructions

Bevery month/100

hours* Competent person who is familiar with the lift maintenance

instructions

Cevery 6 months/400

hours* Competent person who is familiar with the lift maintenance

instructions

Devery 12

months/800 hours*

Technical specialist, who is well familiar with the

structure and operation of the lift

maintenance

instructions

E When necessary Technical specialist, who is well familiar with the

structure and operation of the lift

maintenance

instructions

* Service interval in months or operating hours, depending on whichever

comesrst.

16

Maintenance instructions •DINO 260XTD

Alwayslubricatetheliftandapplyaprotectivegreaselmimmediatelyafterthewashing.

The lift must always be subjected to a special inspection after an exceptional event. Special

inspection is required if the lift has been damaged in a manner,which may affect its load-

bearing capacity or safe operation. Consult the maintenance manual for more detailed

instructions.

DANGER

WARNING

CAUTION

NOTICE

If the lift is equipped with a petrol-driven or a diesel power pack, then in addition to the

normal maintenance routines must also be carried out the service measures in accordance

with the power pack's manual.

DANGER

WARNING

CAUTION

NOTICE

Under demanding conditions where moist, corrosive substances or corrosive climate may

speed up the deterioration of the structures and induce malfunctions, the maintenance

intervalsmustbeshortened,ortheinuenceofcorrosionandmalfunctionsmustbereduced

by using appropriate protective means.

19 Condition of brakes T T

20 Axle and suspension P

21 Driving device T V P

22 Lights T T T P

23 Hydraulic oils T T T S

24 Hydraulic hoses, pipe and conections T T T P

25 Condition and attachment of battery and wiring T T P

26 Hydraulic pressure P

27 Condition and attachment of safety devices T

28 Operation of safety devices (limit switches) T T T P

29 Operation of overload limit switches T P S

30 Operation of load regulation valves T T

31 Operation and condition of platform's levelling system T T T

32 Operation and condition of controls on platform T P

33 Operation of emergency descent, emergency stop and

sound signal TTTT

34 Stickers, plates and instructions T T T T

35 Test loading P

36 Anti-corrosion treatment T S

37 Adjusting the movement speeds S

38 Special inspection S

Maintenance measures A B C D E

17

2.1. SCHEDULE FOR INSPECTIONS REQUIRED BY THE AUTHORITIES

The inspections must be performed in accordance with local and national regulations,

in accordance with the legislation and standards.

The lift must be subjected to a start-up inspectionbeforeitisusedforthersttimeand

beforestartingitupthersttimeafteramajorrepairormodicationwork.

The lift must be subjected to a thorough periodic inspection with related test drive at

intervals of year.

Theinspectionmustbecarriedoutwithintwelve(12)monthsoftherstinspectionor

previous regular inspection.

In connection with the periodic inspection the lift must be subjected to a non-destructive

inspection/inspection disassembled in general at intervals of ten (10) years from the start-

up date.

In addition, the lift much be inspected to the extent applicable after any exceptional situation

The inspections of the lift must be carried out at regular intervals as long as it is in use.

If the lift is used under extreme conditions, intervals between the inspections shall be

reduced.

The overall operating condition of the lift as well as the condition of the safety-related control

devices shall be established in the regular inspections. Particular attention shall be paid to

changes, which affect the operational safety.

In connection with the regular inspection shall be established to what extent the lessons and

practical experience gained since the previous inspection could be utilized to improve the

safety even more.

For the inspection must be assigned an expert inspection body with documented

evidence of competence or an expert with documented evidence of competence.

A protocol must be drawn up of the executed inspections. The protocols of the start-up

andperiodicinspectionsmustbekeptwiththeliftoritsimmediateproximityforatleastve

years.

DANGER

WARNING

CAUTION

NOTICE

Check the regulations for the inspections and the competence of the inspector with

the local authorities.

18

Maintenance instructions •DINO 260XTD

6

9

7

11

7

8

1

5

5

3 2 12

3

4

10

13

2.2. LUBRICATION PLAN

14

19

3. ROUTINE MAINTENANCE DURING OPERATION

The maintenance operations, that are the responsibility of the operator, are described in this

chapter.

The more demanding maintenance operations that require special skills, special tools or

specicmeasurementsandadjustmentvaluesareinstructedintheseparateMaintenance

Instructions. In such maintenance and repair cases, the operator shall contact an authorized

service provider, the distributor or the manufacturer.

Make sure that all the service and maintenance procedures of the lift are performed in time

and according to the given instructions.

DANGER

WARNING

CAUTION

NOTICE

Any such faults, observed during operation or periodic service, which affect the operational

safety of the unit, must be repaired before the lift is used next time.

Keep the lift clean. Clean the lift especially carefully before services and inspections.

Impurities may cause serious problems, for example, in the hydraulic system.

Use original spare parts and consumables. Consult the spare parts list for more detailed

information about the parts.

The rst service after 20 hours of operation

• changethepressureandreturnlterelements

• adjust the brakes according to the instructions (see point “Wheel brakes and bearings”)

• check the wheel bolts for tightness after about 100 km of driving

If the lift is operated under demanding conditions (in exceptionally humid

or dusty environment, corrosive climate, etc.) the intervals between the

oil changes and the other inspections shall be shortened to meet the

prevailing conditions in order to maintain the operational safety and

reliability of the lift.

The timely performance of the periodic servicing and the inspections

is absolutely mandatory, because neglecting them may impair the

operational safety of the lift.

The guarantee will not remain valid, if the servicing and the periodic

inspections are not performed.

20

Maintenance instructions •DINO 260XTD

3.1. INSTRUCTIONS FOR DAILY MAINTENANCE AND INSPECTIONS

3.1.1. Check the condition of chassis, the boom and the work platform

Check visually the condition of the access routes, the work platform, the platform gate and

the handrails.

Check visually the condition of the boom and the frame structures.

3.1.2. Check the tyres and tyre pressure

Checkvisuallythatthetyresaredulyinated,anddonotshowanydamage.

3.1.3. Check the lights

Checktheconditionofallthewarningandsignallightsaswellastheroadtrafclightsofthe

trailer.

3.1.4. Check the hydraulic oil level

Check the hydraulic oil level with the platform in the transport position.

if necessary, top up hydraulic oil to the level with the upper edge of the level eye.

Kyltin numero 30002A

Kyltin koko (mm) 37 x 63 R5

Pohjan väri valkoinen

Tekstin (kuvion) väri musta

Tekstin korkeus 3,5 mm

Materiaali tarramuovi

Kiinnitystapa oma liima

Kiinnitysalusta maalattu teräslevy

Käyttöpaikka DINO 180XT, DINO 210XT, DINO 260XT

Lisätietoja

The hydraulic oil tank is located under a cover on the right-hand side of the lift.

At the same time, check in the level eye of the oil tank that the oil is looking clean and normal

(no excess foam etc.).

3.1.5. Check the hydraulic hoses, pipes and connectors

Check visually the hydraulic hoses, pipes and connections.

Make sure that there are no visible oil leaks.

Replaceanyexternallydamagedhosesandclashedpipesorttings.

Other manuals for DINO 260XTD

2

Table of contents

Other Dino lift Boom Lift manuals

Dino lift

Dino lift 240RXT Technical specifications

Dino lift

Dino lift DINO 280RXT User manual

Dino lift

Dino lift DINO 185XTC II User manual

Dino lift

Dino lift DINO 160XT II User manual

Dino lift

Dino lift 240RXT User manual

Dino lift

Dino lift DINO 185XTC II Instructions for use

Dino lift

Dino lift 135TB II User manual