55 kg

MAX 215 KG

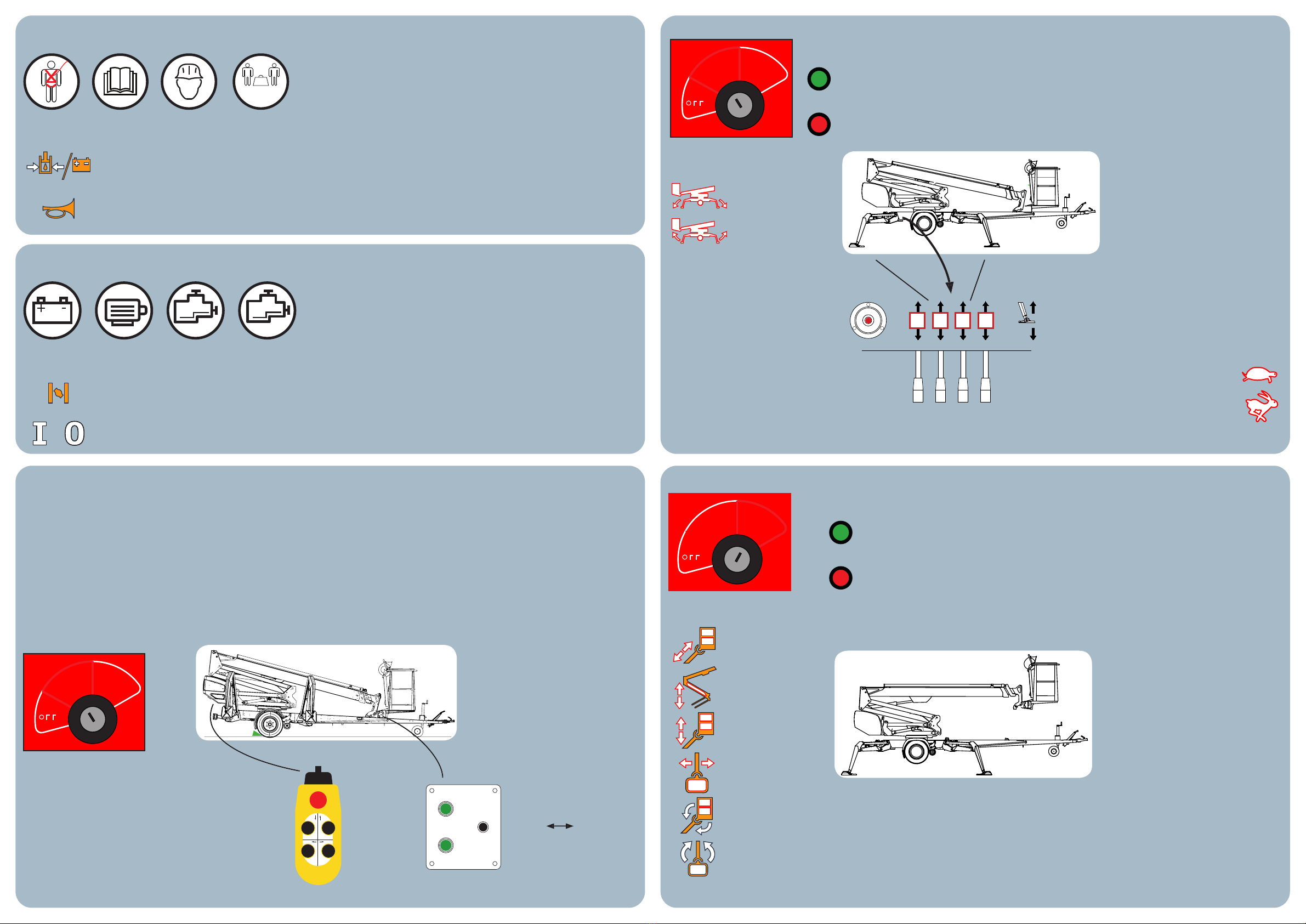

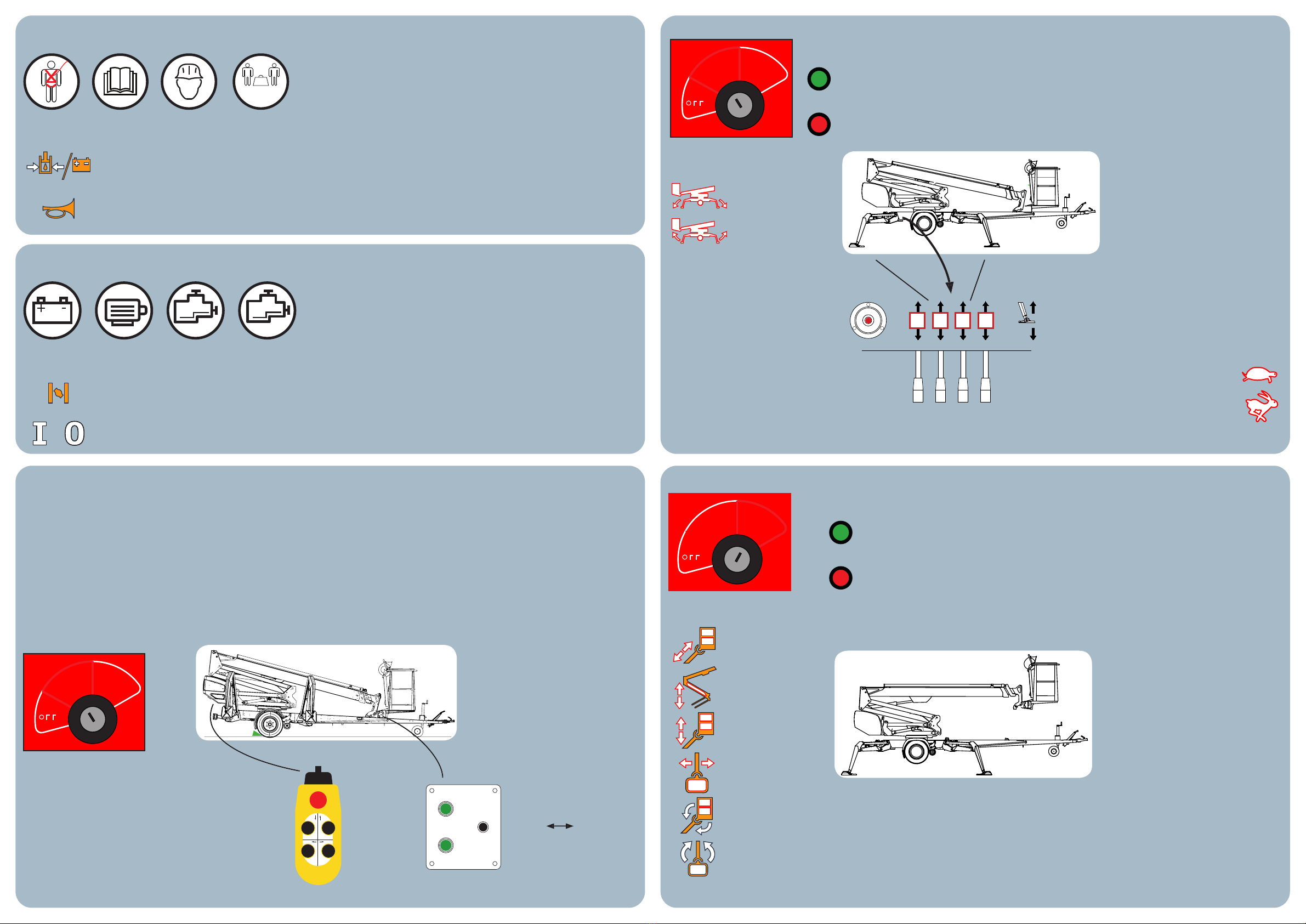

TOWING AND USING THE DRIVING DEVICE WITH THE LIFT IN THE TRANSPORT POSITION

PD

ALTERNATIVE POWER SOURCES

Towing the lift

• Connect the ball-coupling and cable

• Connect the power line and check the

lights

• Release the parking brake

• Lift up the jockey wheel

• Make sure that the driving device is not

connected

Driving with the driving device

• The selector switch must be set to

"chassis control center"

• Switch the driving device to the

driving position

• Release the hand brake

• Drive the lift with the drive controls

• Beware of obstacles and power lines

Choke

Engine

start / stop

XT II emergency descent system

start-up. (XTB II emergency

descent with a hand pump)

Sound signal

WORK SAFELY

Battery Mains power Petrol

engine

Diesel

engine

Controls for safety devices:

Forward

Right

Left

Please note information related to power sources:

• The aggregate does not start if the lift is connected

to the mains

• Maximum cable length in mains network 25 meters

(2,5mm2cable), fuse 10 A.

• Make sure that the batteries have time to charge

sufciently with aggregate or mains power.

• If the engine does not start, make sure that none

of the emergency stop buttons has been pressed

down.

The lift may only be moved in the transport position

• The boom lowered on the boom support

• The cover of the platform control centre closed

• Outriggers fully up

• No objects on the platform or the chassis

• Make sure that the electrical cable is disconnected or

the cable is long enough

• This quick guide does not replace the operating

instructions. Read the operating instructions before

using the lift

• The lift operator must be over 18 years old

• The use of a faulty lift is strictly forbidden

• The use of the lift is forbidden if the temperature is

below -20oCand/or the wind speed over 12,5 m/s

• The lift must not be used as a crane

• Make sure the work area is free

• The maximum permissible load must not be

exceeded

• Never add load while in the upper position

• Maximum permitted lateral force load of 400 N

XT II

XTB II

Back

Forward

Back

Left Right

LIFT SUPPORT AND USE FROM THE CHASSIS CONTROL CENTRE

OPERATING THE LIFT FROM PLATFORM CONTROL CENTRE

1234

0o

NOTICE! Support outriggers movements do not operate if the boom is not on the boom support.

NOTICE! The boom movements do not operate if the support outriggers are not rmly on the ground

Positioning and levelling:

• Make sure the ground is

even and sturdy enough. If

necessary, use additional

support plates.

• Lower the front support

outriggers

• Lower the rear support

outriggers

• Level the lift. The air

bubble in the level gauge

must be located inside the

inner ring.

• Make sure that the tyres

are properly off the ground

Before use

• Perform daily maintenance

procedures

• Check that the lift is

properly supported in a

level position

• Check the emergency stop

and the emergency descent

system

• Check the work area

Telescope in /

out

Articulated

arms down / up

Boom

up / down

Boom

rotation

Basket

rotation

Basket

levelling

Indicator lights:

The outrigger legs are supported and use

of the boom is permitted.

Overload or the load at the outreach range

limit

Indicator lights:

The load is within outreach range.

Overload or the load at the outreach

range limit

Automatic leveling (optional):

Support

outriggers down

Support

outriggers up

The control panel symbols:

While in operation

• Monitor the danger area

• Beware of high-voltage

power lines

• Do not climb onto the

platform railing

• Do not drop objects from

the platform

• If the overload indicator

lights up, retract the

telescope until the platform

is back in working range.

Max support force on the

outriggers:

160XT II/XTB II: 16800 N

(1700 kg)

180XT II/XTB II: 16800 N

(1700 kg)

210XT II/XTB II: 22800 N

(2300 kg)

Boom movements can also be used

from chassis contor center after the

outriggers are on the ground.

The battery operated

models have two operating

speeds for boom functions.