Diplomat ADEPT DA 270 User manual

DIPLOMAT DENTAL s.r.o.

Vrbovská cesta 17

921 01 Piešťany

SLOVAKIA

PRODUCT INFORMATION

Dental unit

DIPLOMAT ADEPT DA 270

DIPLOMAT ADEPT DA 280

gb_da270,da280_2014_06 2/42

CONTENTS

1. PURPOSE AND USE.............................................................................................................3

2. PRODUCT DESCRIPTION ....................................................................................................4

3. TECHNICAL DATA................................................................................................................4

4. DESCRIPTION OF THE DENTAL UNIT ...............................................................................5

4.1 DATA PLATE ..........................................................................................................................6

5. PRE-INSTALLATION REQUIREMENTS ...............................................................................8

5.1 ENVIRONMENTAL CONDITIONS.................................................................................................8

5.2 REQUIREMENTS FOR THE INSTALLATION OF MEDIA....................................................................8

5.3 FLOOR...................................................................................................................................9

5.4 ENVIRONMENT .......................................................................................................................9

6. ASSEMBLY AND INSTALLATION........................................................................................9

7. PUTTING THE UNIT INTO OPERATION.............................................................................10

8. PRODUCT OPERATION .....................................................................................................11

8.1 CONTROL PANEL WITH INSTRUMENTS ...................................................................................11

8.1.1 Description of buttons ..................................................................................................12

8.1.2 Setting of water amount................................................................................................21

8.1.3 Button of the brake of the control panel (according the model)................................21

8.1.4 Fitting of the tray of the tray table................................................................................22

8.1.5 Operation of individual instruments ............................................................................22

8.2 FOOT CONTROLLER..............................................................................................................27

8.3 SPITTOON BLOCK................................................................................................................31

8.3.1 Assistant table...............................................................................................................32

8.3.2 Double holder................................................................................................................32

8.3.3 Equipment of the spittoon block..................................................................................33

8.4 LIGHT..................................................................................................................................33

8.5 HYGIENE..............................................................................................................................34

8.6 MANUAL CONTROL OF THE HEAD REST ..................................................................................34

8.7 MANUAL CONTROL OF THE RIGHT ARM REST .........................................................................35

8.8 COMPLETION OF WORK.........................................................................................................36

9. PRODUCT MAINTENANCE ................................................................................................36

10. CLEANING, DISINFECTION AND DECONTAMINATION.................................................37

10.1 DISINFECTION OF THE INTERNAL DISTRIBUTIONS OF THE INSTRUMENTS .................................37

10.2 DECONTAMINATION OF THE SPITTOON BOWL........................................................................37

10.3 CLEANING AND DECONTAMINATION OF THE SALIVA EJECTOR................................................37

10.4 CLEANING AND DECONTAMINATION OF THE BOG AND SMALL ASPIRATOR...............................38

11. DISPOSAL OF THE EQIPMENT........................................................................................40

12. REPAIR SERVICE.............................................................................................................40

13. CONTENT OF THE PACKAGING .....................................................................................41

14. GUARANTEE.....................................................................................................................41

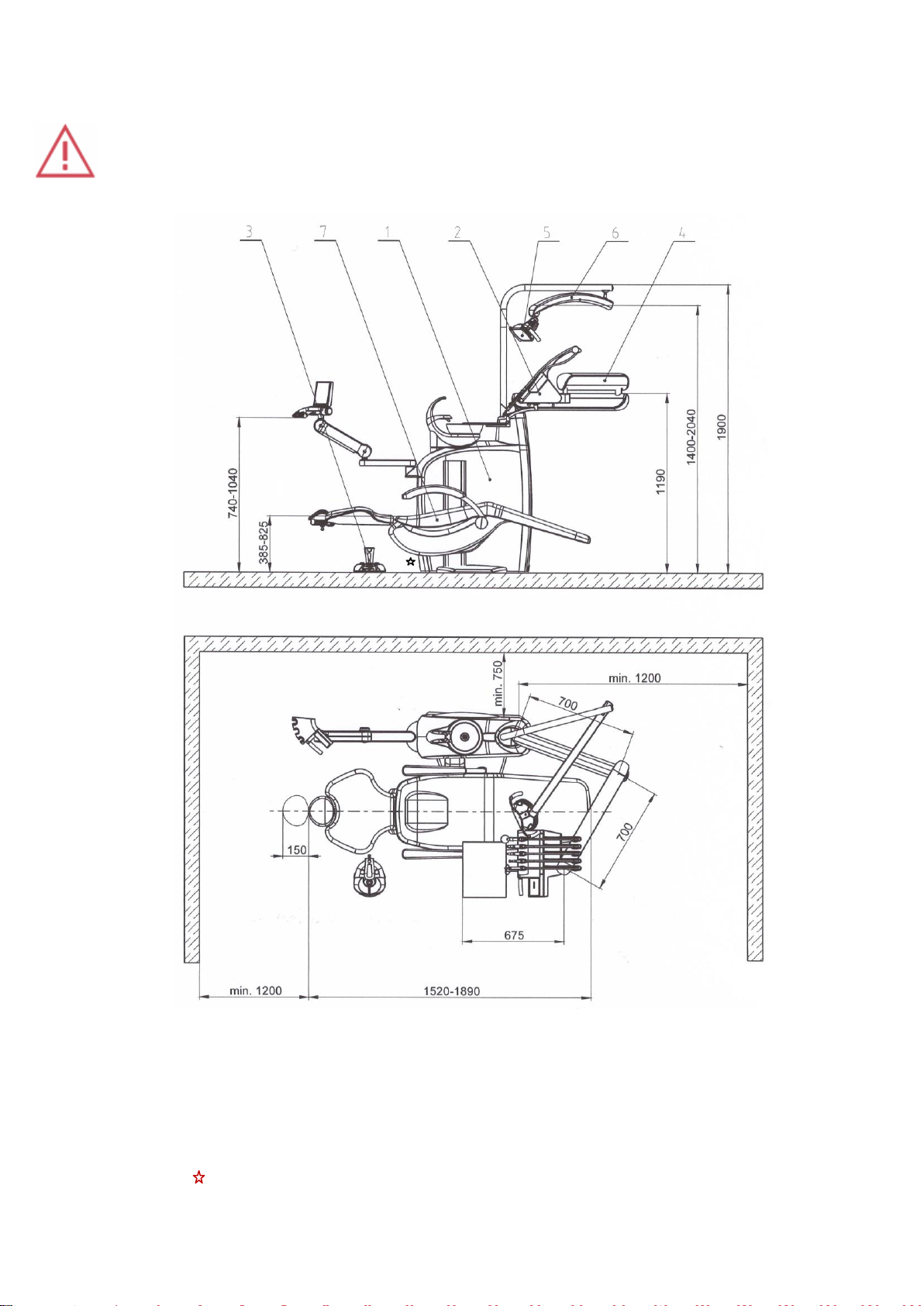

INSTALLATION PLAN ............................................................................................................42

gb_da270,da280_2014_06 3/42

1. PURPOSE AND USE

These Instructions for Use describes how to use the dental units of DIPLOMAT ADEPT DA

270 and DA 280. Please read these Instructions for Use thoroughly before attempting to use

the unit. The dental unit is allowed to be operated only by the dentist who has been made

familiar with the present Instructions for Use and the dental apllications that can be done by

means of the dental unit in question. In order for you to be satisfied with the dental unit, the

following must be observed: Installation, setting and/or modifications must be made by the

qualified authorized service personnel of an organization that has licence for such activity.

Conditions for the use of media and installation given in the Instructions for use of

DIPLOMAT ADEPT DA 270 and DA 280 must be met, too.

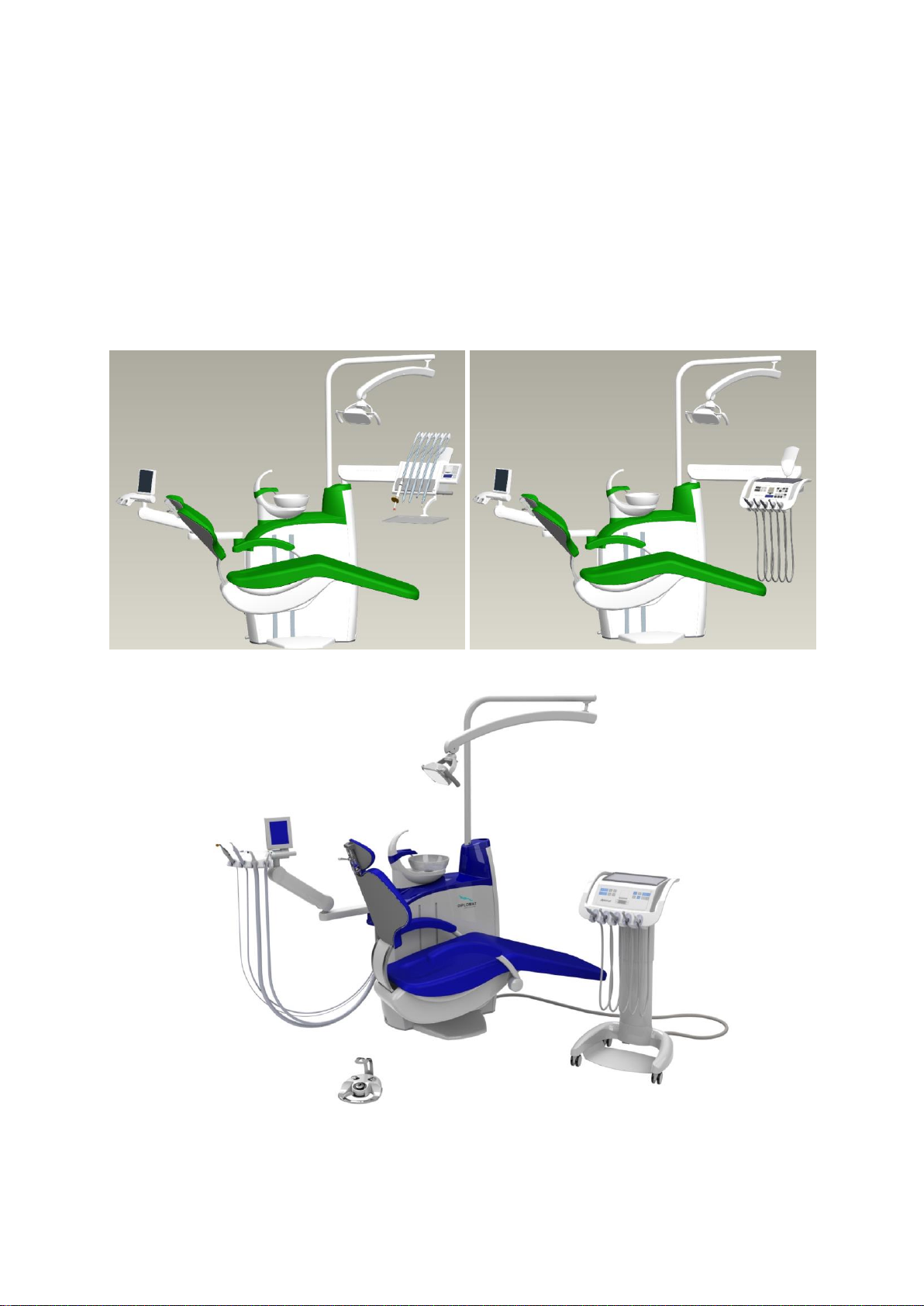

DIPLOMAT ADEPT DA 280

DIPLOMAT ADEPT DA 270

DIPLOMAT ADEPT DA 280 CART

gb_da270,da280_2014_06 4/42

2. PRODUCT DESCRIPTION

The dental unit of DIPLOMAT ADEPT DA 270 is designed as a stationary unit with a carried

chair and upper hose delivery and DIPLOMAT ADEPT DA 280 with lower hose delivery of

instruments. DIPLOMAT ADEPT DA 280 dental unit is also available in a Cart Version. Control

panel pantograph with the control panel and instruments, and light pantograph with the dental

operating light are fitted at the upper part of the bearing pillar of the spittoon block. In a special

mobile Cart Version DA280 features a cart-mounted rear delivery system. The

instruments are controlled by the foot controller, except for the syringe, big and small aspirator,

saliva ejector (and/or polymerization lamp and intraoral camera). On the face surface of the

control panel is a membrane keyboard or glass touch screen with a display and negatoscope.

The handle serves for re-positioning of the control panel. X-ray images are attached to the

negatoscope by means of a clip furnished. The spittoon block is delivered in various versions

with a saliva ejector or with an assistant arm with big and small aspirator. The spittoon bowl and

bowl flushing tube are detachable. The bowl drive is either manual or powered (according to

the requirements). Suction handpieces of the small and big aspirator are detachable, capable of

being disinfected and sterilized. Handpieces of the saliva ejector are for single use. Side table

with a side dish fixed to the arm of the light pantograph and monitor arm with LCD monitor are

installed as an option upon order. The dental unit of DIPLOMAT ADEPT DA 270, DA 280 is

always equipped on the control panel with a syringe.

The control panel can be fitted with the following instruments:

max. 4 rotary instruments

min. 1 syringe

max. 5 instruments with light

1 scaler

max. 4 turbines

1 polymerization lamp (led)

max. 4 micromotors (max. 3 DC motor,

max. 2xMX motor)

1 polisher

Note

Optional and supplementary equipment (see the valid price list).

3. TECHNICAL DATA

Supply voltage

230V ± 10%

Frequency

50 Hz ± 2 %

Max. power input at 230V/50 Hz

1550 VA + 10%

Input pressure of air

from 0,45 to 0,8 MPa

Input pressure of water

from 0,3 to 0,6 MPa

Dental unit weight

210 kg + max.35 kg acc.to version

Type of protection against electric shock

Class I equipment

Degree of protection against electric shock

applied parts of B type

Temperature of water for the cup

36±5 °C (with heater fitted)

Max. loading capacity of the tray table

1,5 kg

Max. loading capacity of the side table

3 kg

Operation mode

continuous with intermittent loading,

corresponding to the common dental practice.

Chair

Range of the height of the seat above the floor

397 ÷ 825 mm 15 mm

Range of the tilting of the back rest from vertical plane

20°÷ 90° 2°

Vertical movement time

max. 20 sec

Back rest movement time

max. 18 sec

Maximum loading capacity of the chair (EN ISO 6875)

max. 200 kg

Type of operation

1 : 16 (cycle, e.g.25s run, 400s rest)

Sound pressure level of the chair

max. 54 dB

gb_da270,da280_2014_06 5/42

Caution

To eliminate the risk of electric shock, the present equipment must be connected to the supply

mains with protective earthing.

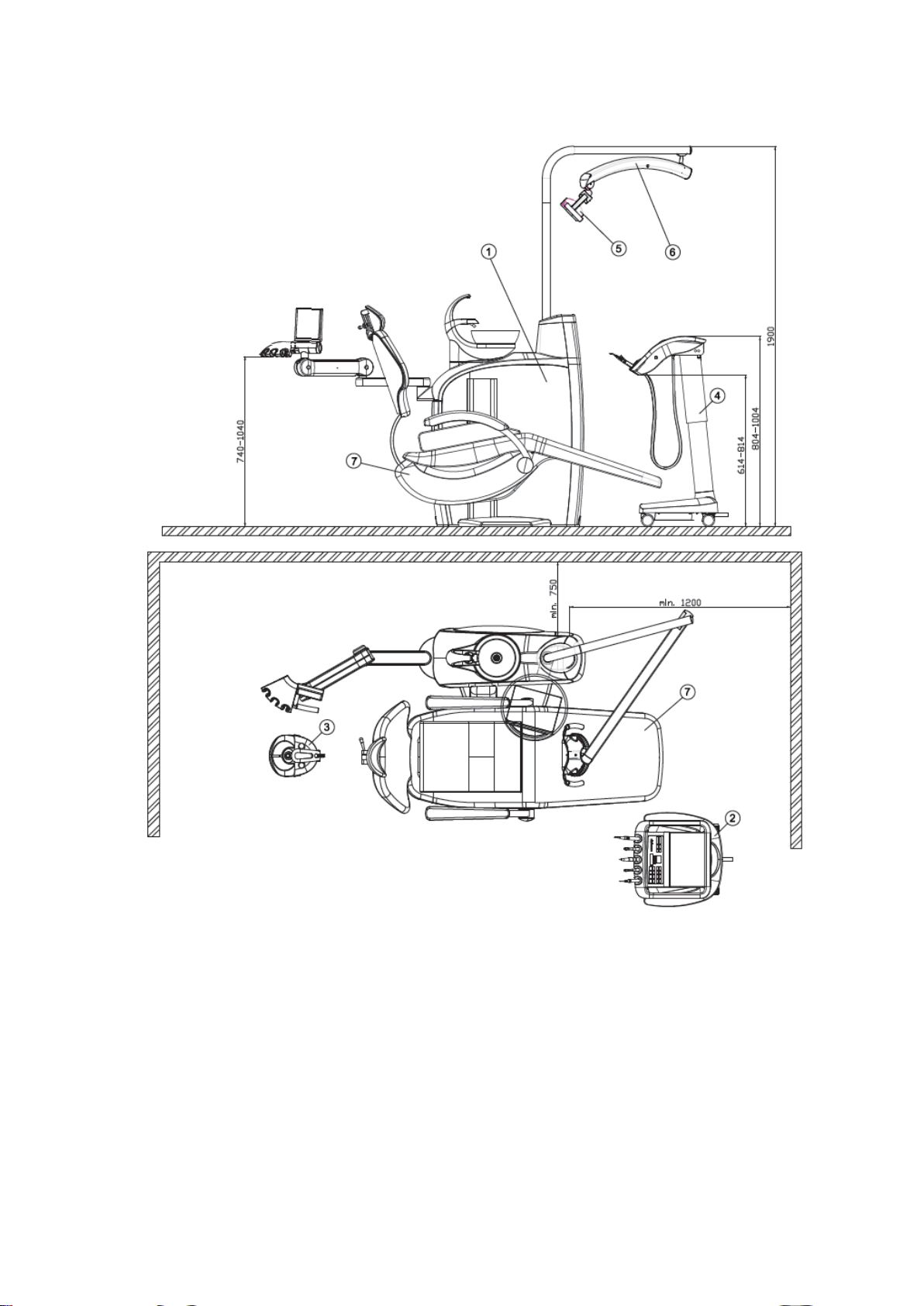

4. DESCRIPTION OF THE DENTAL UNIT

1.Spittoon block with assistant arm

2.Control panel

3.Foot controller

4.Pantograph of the control panel

5.Dental operating light

6.Pantograph of the light

7.Dental chair

main switch, located onthe outer side of the spittoon block

gb_da270,da280_2014_06 6/42

DESCRIPTION OF THE DENTAL UNIT DA 280 CART

1.Spittoon block with assistant arm

2.Control panel

3.Foot controller

4.Cart

5.Dental operating light

6.Pantograph of the light

7.Dental chair

gb_da270,da280_2014_06 7/42

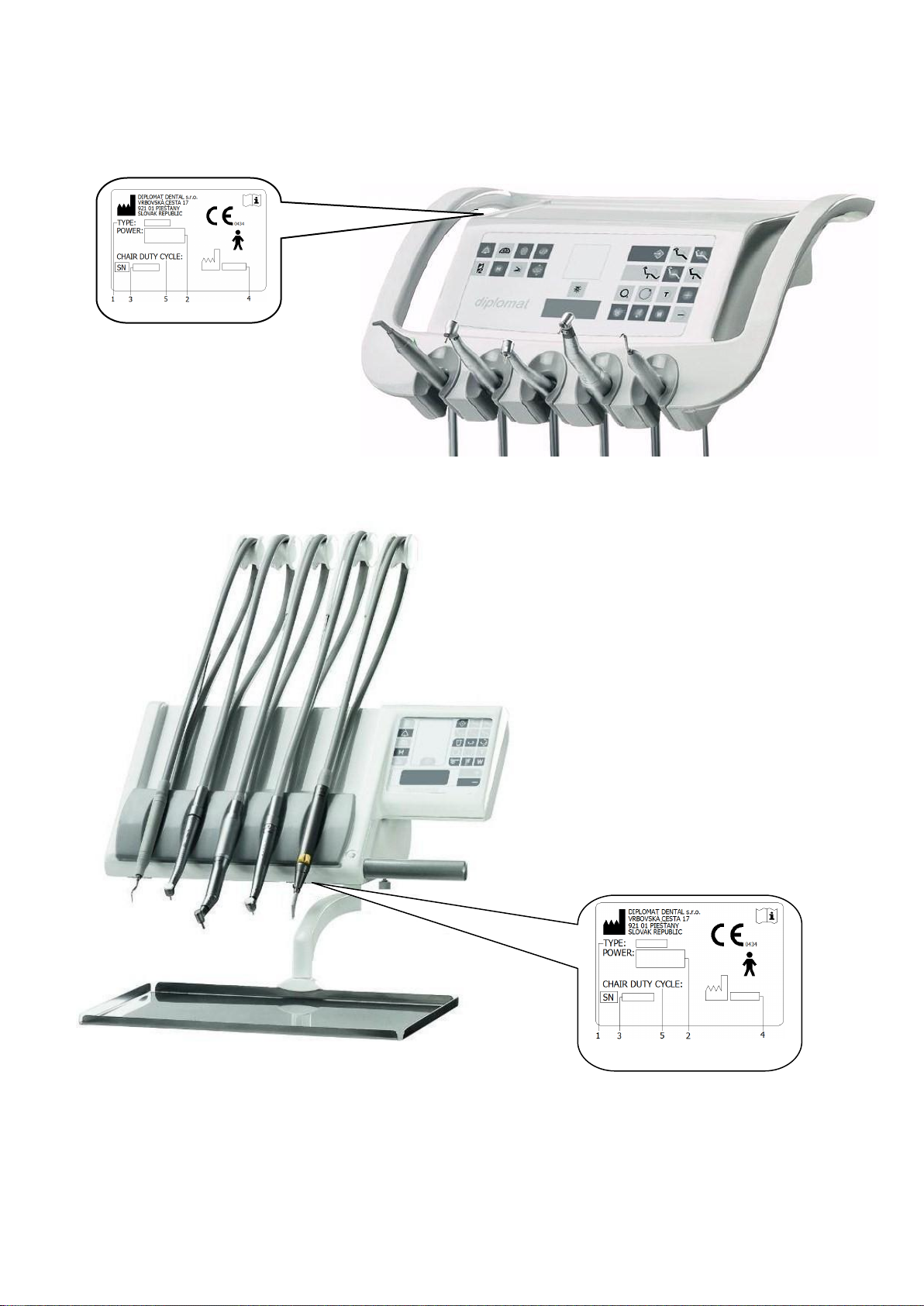

4.1 Data plate

1 –designation of the unit type

2 –basic electrical parameters

3 –serial number

4 –production date

5 –chair operation type

gb_da270,da280_2014_06 8/42

5. PRE-INSTALLATION REQUIREMENTS

5.1 Environmental conditions

Not to be installed in the premises with explosion hazard!

5.2 Requirements for the installation of media

Water

Drinkable water with input pressure of 0,3 MPa to 0,6 MPa with the flowrate of min.4 l/min.,

without particles bigger than 50 µm, which might clog the small cross sections of the pipes of

the dental unit, must be used. If the water contains particles bigger than 50 µm, there must be

introduced 50 µm advance filter /strainer.

Cooling of the instruments with water from the central distribution

There must be introduced advance 5 µm filter.If the water contains more than 50 mg CaO/l,

or 36 mg MgO/l, there must be introduced water treatment device connected to the input of the

water distribution. Hard water may even cause the unit not to function. Water treatment device

is introduced if distilled water is not used. The distribution after the filter must be made of Cu,

and/or PE tube. A suitable certified closing valve must be introduced into the central distribution

of water for the unit! In installation it is necessary to install a device to prevent the backflow at

the point of the connection to the supply of municipal tap water. The said device is not part of

the dental unit.

Air

Supply of at least 55 l/min. of air at the pressure of 0,45 to 0,8 MPa, oilless, clean and dry,

must be ensured. Tubes made of Cu and/or PE are recommended.

Suction ( in the event of the version of the spittoon block with big and small

aspirator)

Static vacuum must be within the range of min. 0,005 MPa (50 mbar) to max. 0,02 MPa (200

mbar), measured at the installed position. When the static vacuum is higher than 0,02 MPa,

a suction calibration (regulating) valve should be introduced in the suction branch to restrict the

max. vacuum to 0,02 MPa. The said regulating valve is not part of the dental unit. The suction

unit must produce the flowrate of at least 450l/min., measured at the installed position.

Waste

The waste /drain/ branch must have continuous slope of min. 1% with minimum flowrate of

10l/min. and must be free of sharp bends and conditions that might cause backflow. Do not

use the same waste branch with another dental unit or a basin! It is allowed to use tubes

made of polypropylene or cured polyethylene.

Caution

Pre-installation and installation must be performed according to the applicable standards of the

particular country and in accordance with the valid documentation of the manufacturer, which is

owned by each authorized representative of Diplomat Dental s.r.o.

Note

If the regulations of the country in which the installation is carried out require an amalgam

catcher, the dental unit with the spittoon block without the amalgam catcher must be connected

gb_da270,da280_2014_06 9/42

to an external amalgam catcher. Installation of the external amalgam catcher must be carried

out according to the instruction of its manufacturer!

Recommended mains fuse rating

Recommended rating of the fuse of the supply main is 16A (in the event of circuit breaker –

circuit breaker with switching-off characteristic of C type). No other equipment should be

connected to the supply main in question! Max. power input of the dental unit is 1550 VA. The

supply main must comply with the respective national standard.

Recommendation

Unless national standard stipulates otherwise, the manufacturer recommends to use current

protective switch with the sensitivity of 30mA and instantaneous time of switching-off.

Pre-installation requirements having been met, assembly and installation of the dental unit is

carried out and it is connected to the media.

5.3 Floor

The floor must have a concrete foundation of at least 100mm thickness. The slope of the floor

shall not exceed 1%. The use of antistatic floor is recommended.

5.4 Environment

ambient temperature range from +10°C +40°C

relative humidity range from 30% 75 %

atmospheric pressure range from 700 hPa 1060 hPa

6. ASSEMBLY AND INSTALLATION

Unpacking of the unit and inspection of the delivery

Inspect the transport packages for damage. If a defect of the transport package is found, do not

open the consignment, and report the defect to the forwarding agent or seller immediately. If the

consignment is intact, carefully open the package and unpack individual parts of the dental unit.

Check the completness of the delivery according to the Packing List. If the unit is equipped

with a glass keyboard, take care of its glass surface in handling.

The installation must be carried out by a service technician with valid certificate, otherwise

potential guarantee shall not be accepted. The guarantee form must be completed and sent to

the manufacturer or the seller.

Note:

Sieves (packed with small parts) are to be inserted in the tips of the aspirators according to

Fig.10.1. (chapter 10.4)

to

to

to

gb_da270,da280_2014_06 10/42

7. PUTTING THE UNIT INTO OPERATION

1. switch on the compressor and let it get pressurized

2. open the central water supply

3. turn on the suction unit (if the spittoon block is fitted with the big and small aspirator)

4. turn on the main switch located on the cover of the spittoon block –position I, the indicator

light of the main switch goes on. The following message is displayed:

Thus indicating the readiness of the unit for operation. The unit is connected to the distribution

of water and air. After approx. 5s the unit is ready to work. If the dental unit is equipped with

electrical water heater, it is necessary to wait for approx. 10 min. for the water to be warmed up

to the desired temperature. In turning the unit on, no instruments should be taken, the foot

controller should be in the rest position and the buttons of the keyboards should not be

depressed.

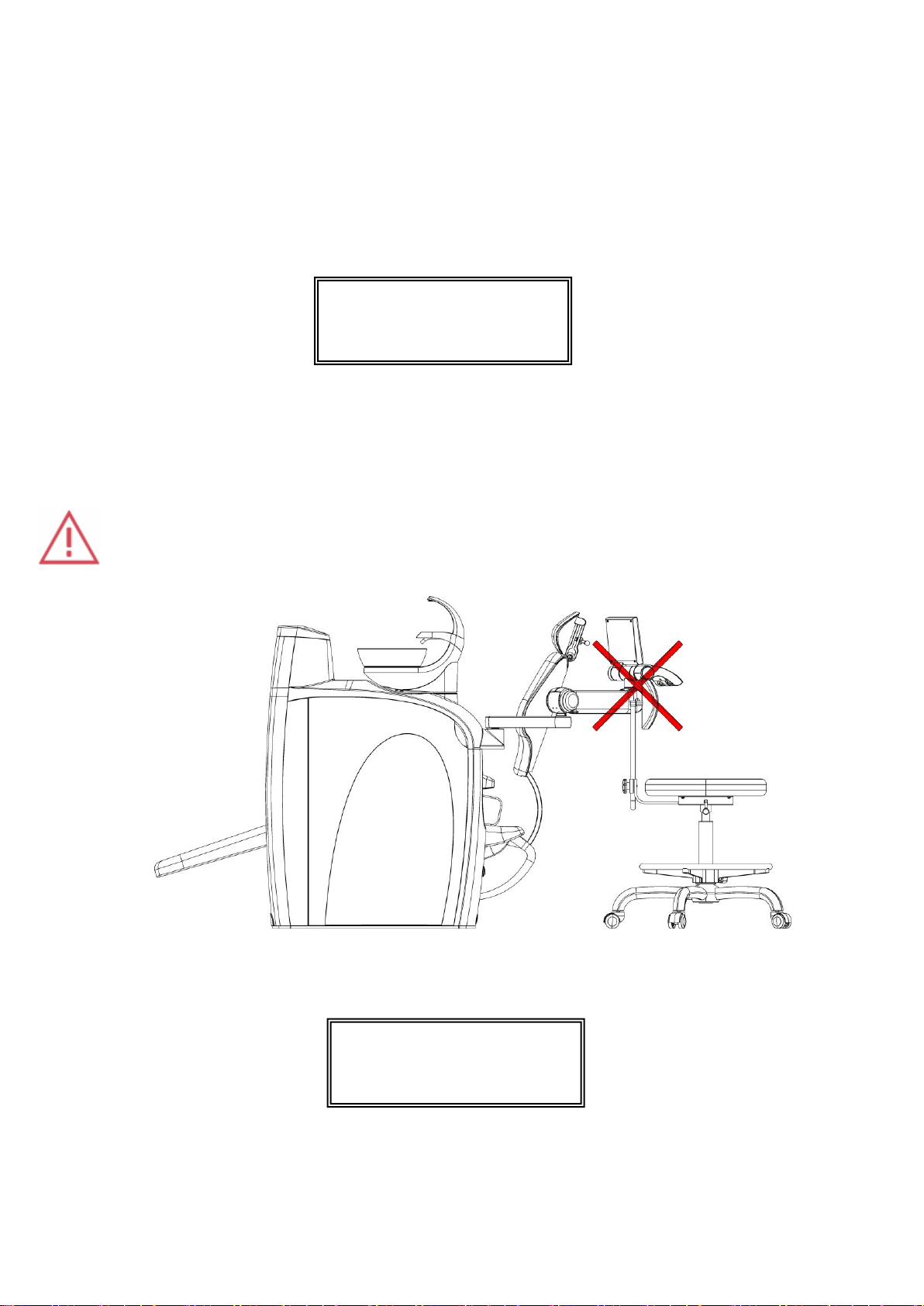

Caution

When moving the chair, the arm and the assistant table must not be in the trajectory of the

chair. (see the illustration).

Besides the saliva ejector, small and big aspirator –according to the version –polymerization

lamp and the syringe (on the control panel) only one instrument can be used (taken)

simultaneously! Not observing of the condition above is indicated on the display by the following

message:

DENTAL UNIT V1

READY FOR WORK

DENTAL UNIT V1

INSTRUMENT ERROR

gb_da270,da280_2014_06 11/42

8. PRODUCT OPERATION

8.1 Control panel with instruments

Note

The display is legible in each working position of the dentist (both sitting and standing).

In the event of the glass keyboard, after pressing the button it is active for ca 10 seconds –

indicated by means of the indicator of the pressing of the button on the display.

Programming of the time of the cup filling and bowl flushing in the event of the glass keyboard

for more than 10 s is possible only by means of the foot controller or by means of the buttons

on the assistant table.

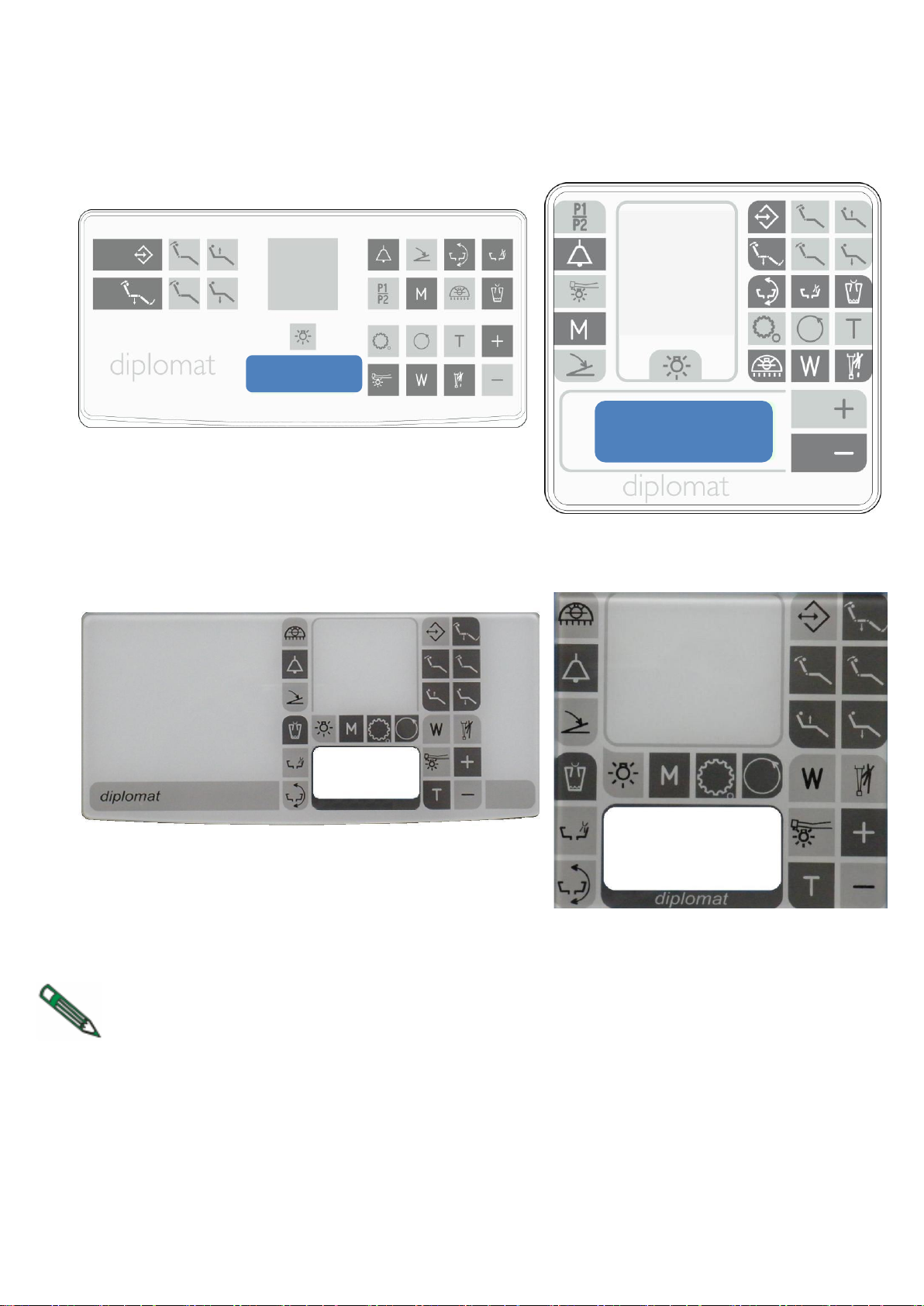

Membrane keyboard

Membrane keyboard

Glass keyboard

Glass keyboard

gb_da270,da280_2014_06 12/42

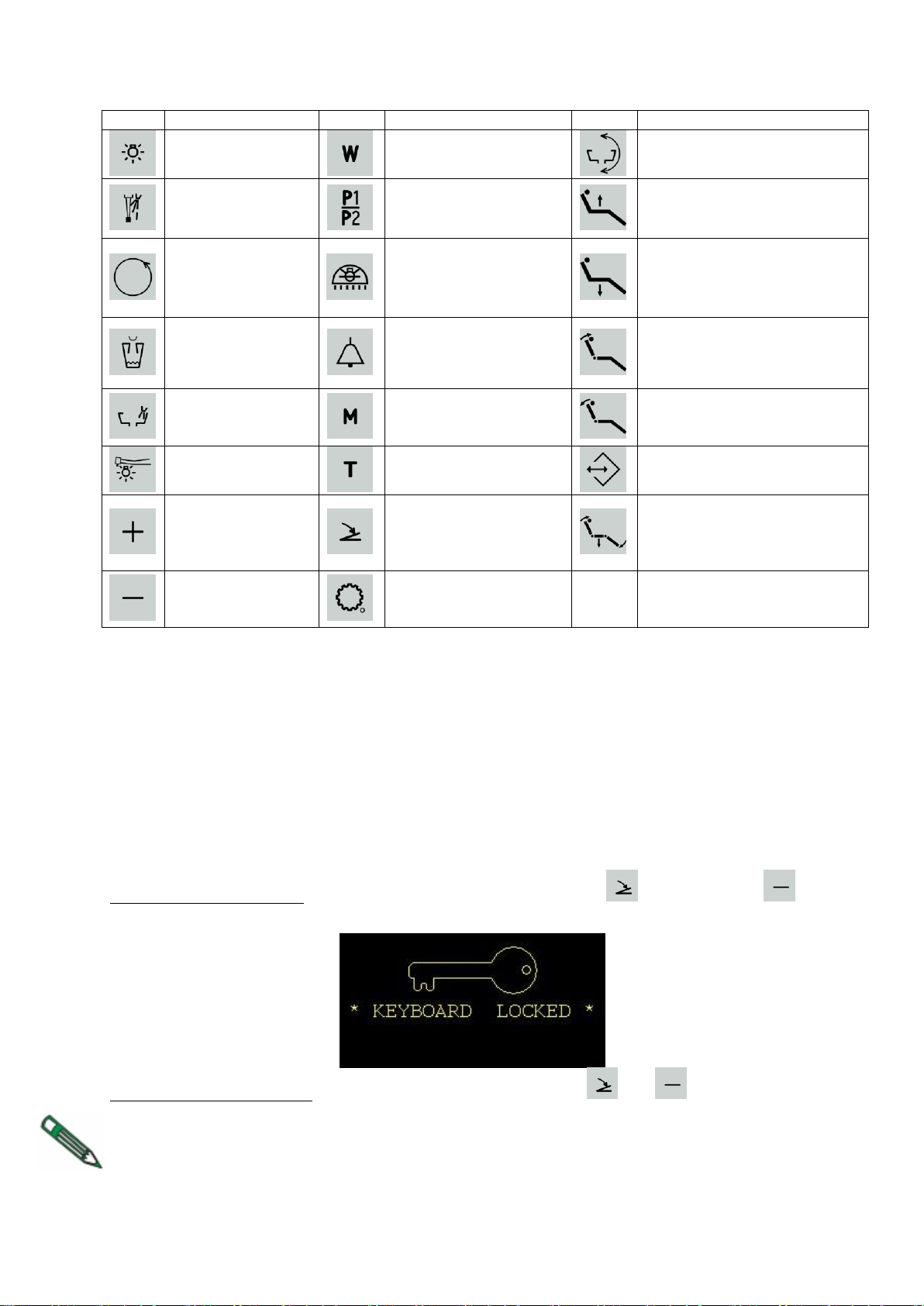

Button

Description

Button

Description

Button

Description

negatoscope

illumination

setting of the amount

of cooling water

rotation of the spittoon bowl

(only for el. control)

instrument cooling

changing-over of the

program sets

switch to move the chair up

reversing of the

rotations of the

micromotor,ENDO,

AFT

main light control

(valid for particular

type)

switch to move the chair

down

cup filling

supplementary button

(e.g.door opening)

(valid for particular type)

switch to move the rest

forward

spittoon bowl

flushing

selection of activity

mode for MX motor

and torque for motor

switch to move the rest

backward

illumination of

instruments

setting of torque for

micromotor

writing-in and recalling of

program positions

button to increase

parameters

changing-over of the

function of the foot

controller (analogue -

ON/OFF)

automatic setting of the

starting (getting-on) position

button to decrease

parameters

change of the

transmission ratio of

the instrument head

8.1.1 Description of the buttons

To activate a function, it is enough just to press (with the membrane keyboard) and/or touch

(with the glass keyboard) at the point of selected button. With the glass keyboard, the selection

of chosen function is indicated in addition to the display also by a short beep and a dot on the

display. For all controllable parameters, their informative values is represented by means of

a bar indicator in the lower part of the display (valid only for the glass keyboard). Maximum of

the bar corresponds to 100% of the set value. Maximum time of the selection of any symbol is

ca 10 sec. After the said time has elapsed, a condition is achieved as if the function was not

selected.

Locking and unlocking of the keyboard (valid only for the glass keyboard)

Locking of the keyboard –simultaneous selection of the button and the button . Key

symbol is displayed and the keyboard keys do not respond to the selection of buttons.

Unlocking of the keyboard –simultaneously select the buttons and again.

Note

Always lock the keyboard before cleaning the keyboard while the dental unit is turned on. After

the keyboard has been cleaned, it is necessary to unlock the keyboard, because the

instruments are locked too.

gb_da270,da280_2014_06 13/42

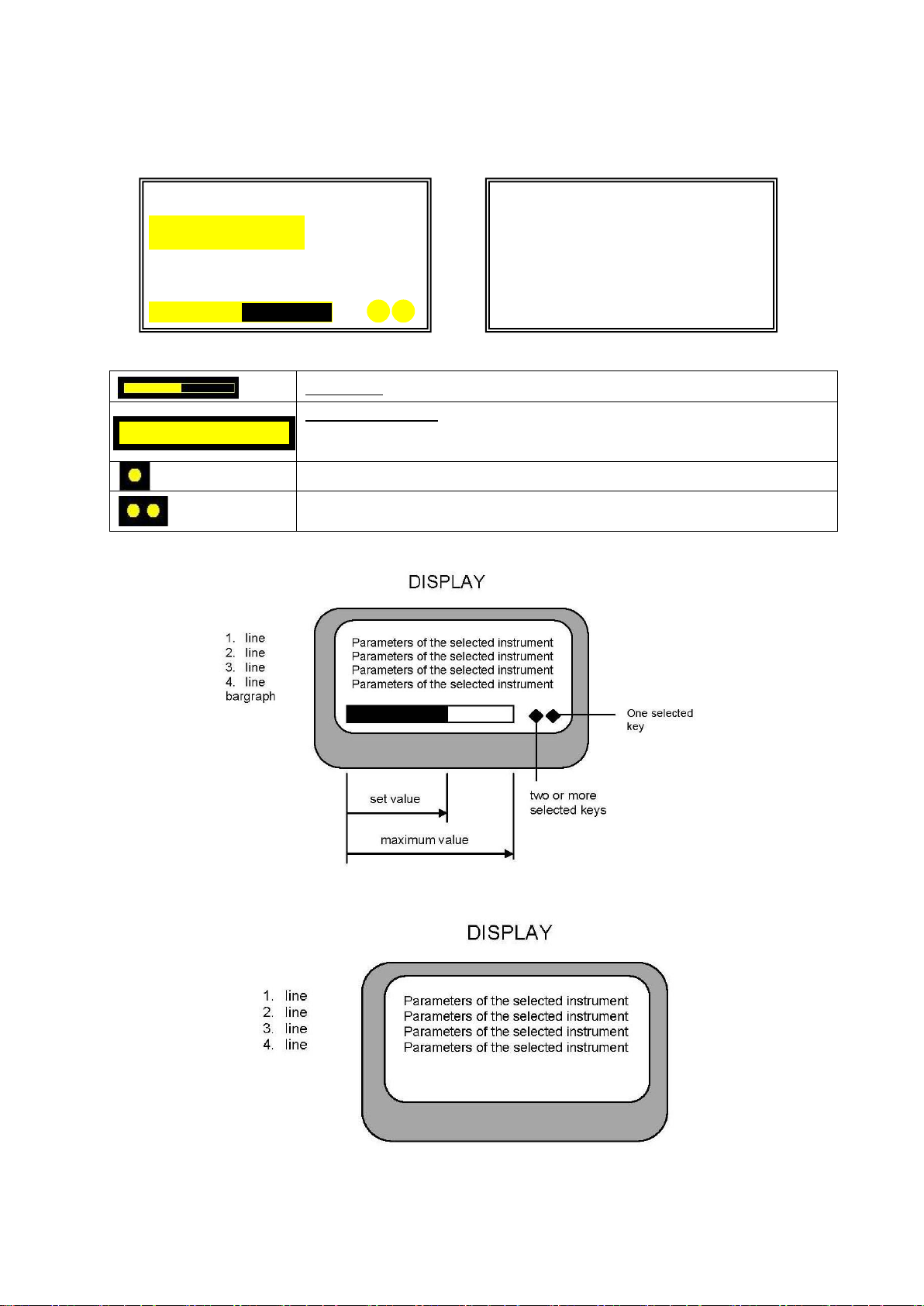

Representations on the display

Glass keyboard Membrane keyboard

Description of the data of the display–glass keyboard

Status bar –graphical representation of highlighted value

Highlighted value –active value that is currently set and which can

be changed by means of the buttons PLUS (increase) or MINUS

(decrease)

Indicator of the selection of a button („pressing“ of one key)

Indicator of the selection of arbitrary buttons („pressing“ of two and

more keys)

Membrane keyboard

Glass keyboard

N = 100000RPM

M3X N W A

T= 0 , 300Ncm R = 1 : 5

N = 100000RPM

50 , 00%

M3X N W A

T= 0 , 300Ncm R = 1 : 5

N = 100000RPM

50 , 00%

gb_da270,da280_2014_06 14/42

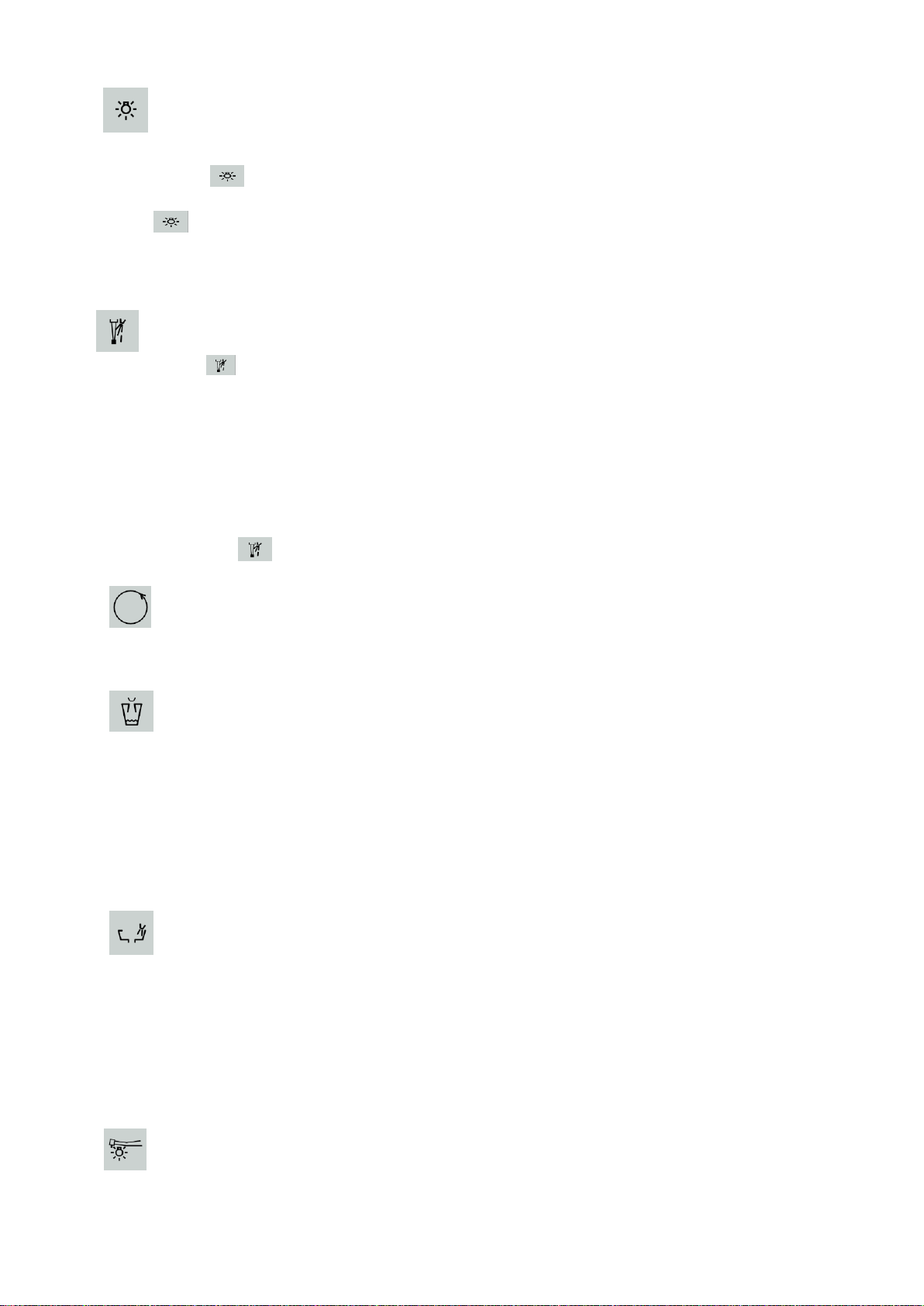

Press (touch) the button to turn the negatoscope illumination on. To turn the illumination

off, press (touch) it again. To control the intensity of the negatoscope, press (touch) the

button and the buttons PLUS and MINUS simultaneously with the negatoscope

turned on. After the negatoscope has been turned on, by keeping the finger on the button

for more than 4s the brightness of the negatoscope is increased up to maximum.

After the maximum brightness has been achieved, the brightness decreases to minimum

and then increases gradually. The set values of brightness are stored in the memory and

set automatically when the negatoscope illumination has been turned on again.

It is possible to switch the instrument cooling on by means of pressing (touching) the

button for micromotor and turbine, while the switched-on condition is indicated on the

display by going the symbol "S" or "W" on. When the instrument has been returned to the

basic position, the current setting of the instrument cooling is saved automatically.

Changing-over of the cooling mode in the event of the glass keyboard, see Cl. 8.2 –

SPRAY button.

The following 2 conditions of cooling are available:

"S" - spray cooling

"W" - water cooling

To change-over between the mode of cooling with water (W) and spray (S), press (touch)

the button for more than 10s and less than 16s. If the glass keyboard is used, the

cooling modes are changed-over by means of the spray button on the foot controller.

It serves to change the direction of the revolutions of the micromotor, to set the ENDO

function for the ultrasonic scaler and to set AFT (auto-forward time) for MX micromotor.

To let the patient cup fill for the set time, press (touch) the button and keep the finger on it

for more than 0,6s. To set the filling time up to the moment the button has been released,

press (touch) and keep the finger on the button for more than 4s. To interrupt the cup

filling during the cup filling time, press (touch) the button for min. 0,2s. Maximum

programmed cup filling time is 25s. The set cup filling time is saved automatically and with

repeated pressing (touching) shorter than 4 s the cup filling is started for the set time.

In the event of the glass keyboard, the programming of the cup filling time for more than

10s is possible only from the foot controller or by means of the button on the assistant

table.

To start the flushing of the spittoon bowl for the set time, press (touch) the button and

keep the finger on it for more than 0,6s. To set the spittoon bowl flushing time up to the

moment the button has been released, press (touch) and keep the finger on the button for

more than 4s. To interrupt the bowl flushing during the bowl flushing time, press (touch)

the button for min. 0,2s. Max. programmed bowl flushing time is 40s.

Programming of the time of the bowl flushing in the event of the glass keyboard for more

than 10 s is possible only by means of the foot controller or by means of the button on the

assistant table.

Instrument cooling

Reversing of the rotation of the micromotor

Cup filling

Bowl flushing

Illumination of instruments

Negatoscope illumination

gb_da270,da280_2014_06 15/42

Plus and minus

Press (touch) the button to turn the illumination of the rotary instruments (turbine,

micromotor) on and off. By pressing (touching) it is possible to modify the instrument that

has been taken. When the instrument illumination is turned on, "L" is displayed. The

instrument illumination goes on after putting the instrument into operation. The instrument

illumination goes off automatically after 10s has elapsed after the end of the use of the

instrument. After the instrument has been replaced to the basic position, the instrument

illumination goes off.

To increase (decrease) the parameter being set from min. up to max. value, press (touch)

the button for a short time. By pressing (touching) and holding the button for 1s, the

parameter in question is increased (decreased) up to the maximum (minimum) value.

The buttons serve to set the following:

the micromotor revolutions (speed)

the output when the scaler is used

negatoscope illuminance /illumination intensity/, with the negatoscope turned on

main light illuminance

flowrate of cooling water for instruments, except for the syringe

the torque for MX motor

changing-over of the program position P1...P8 in the combination with the button for

the glass keyboard

Depending on the version of the dental unit, it is possible to adjust the flowrate of cooling

water, see Cl. 8.1.2. If the unit is not equipped with the proportional valve, then (W) is not

displayed.

The button serves to select the programs. Each instrument has the option of 8 programs

P1–P8.

The selection of P1 –P8 programs is made by pressing the button P1/P2 on the dentist

control panel when the instrument is taken, while the current program is displayed in the

left lower corner.

In each program it is possible to make any changes and these changes are saved

automatically.

+

The button (combination of buttons) serves to select the programs. Each instrument has

the option of 8 programs P1–P8.

The selection of the P1 –P8 programs is made by touching and holding the button

and subsequent repeated touching in case of the glass keyboard –it is necessary to

observe the sequence of pressing the buttons on the dentist control panel with the

instrument taken, while the current program is displayed in the left lower corner.

Water

P1/P8 –programming of the instruments (membrane keyboard)

Programming of the instruments (glass keyboard)

gb_da270,da280_2014_06 16/42

The button serves to control the main dental light. Press (touch) the button to change-over

between the three conditions –lower illuminance, higher illuminance, light turned off. At

the higher illuminance it is possible to control the illuminance by simultaneous pressing

(touching) the button and the buttons PLUS or MINUS, namely so that in changing-

over from the lower illuminance to the higher, keep the finger on and increase or

decrease the illuminance of the dental light by means of the buttons PLUS or MINUS. It is

also possible to control the illuminance by keeping the finger on for more than 4s

when changed-over to the higher illuminance.

Acoustic indication is heard while the button is kept pressed (touched).

The button serves for the selection of the mode of activity for the MX micromotor, while

the selected mode is displayed: "MX N" –normal mode of activity, "MX R" - auto-reverse

mode, "MX F" - auto-forward mode. To change-over the torque for the brush motor, press

the button T and then press the button M (description, see the button T).

Setting of the limit torque for the MX motor. Press (touch) the button and then set the limit

torque by means of PLUS, MINUS. The mode of the setting of the limit torque is indicated

by means of the symbol "!" next to the symbol "T" ("T!xxx, xxxNcm"). With the glass

keyboard, the set value is highlighted. To finish the setting of the torque, press (touch) the

button again, the message "T=xxx,xxxNcm" is displayed.

New functions for brush micromotors

By means of the buttons and it is possible to change the torque of the brush

micromotors M1, M2 and M3.

In the left upper corner the following is displayed on the dentist control panel after the

micromotor M1, M2 and M3 has been taken:

M1 or M2 or M3

and then the following is displayed:

FL or FM or FH

FL ( Force Low) represents 80% value of the maximum torque

FM (Force Medium) represents 90% value of the maximum torque

FH ( Force High) represents 100% value of the maximum torque

Press the button on the dentist control panel and then change the value of the

maximum torque by pressing the button , while the message on the display changes

in the following sequence: FL, FM, FH and again FL.

The change can be made provided an instrument is taken and START function on the foot

controller is inactive. Changes are saved in the programs P1-P8 automatically.

Control of the main light (according to the version of the dental unit)

Button according to the version of the dental unit (e.g. door opening)

Selection of the mode of activity for brushless (MX) and brush (MC2, MC3)

motor motor

Setting of the torque for the motor

gb_da270,da280_2014_06 17/42

The button serves to change-over the mode of the foot controller. It is possible to change-

over between the mode of the proportional control and the "on /off" mode ( O/A on the

display).

By touching the button it is possible to choose one of the following transmission ratios:

1:5,1:2, 2:3, 1:1, 2:1, 3:1, 4:1, 5:1, 8:1, 10:1, 16:1, 20:1, 32:1, 64:1, 128:1. It does not

change the revolutions, only re-calculates the current value of the revolutions at the tip.

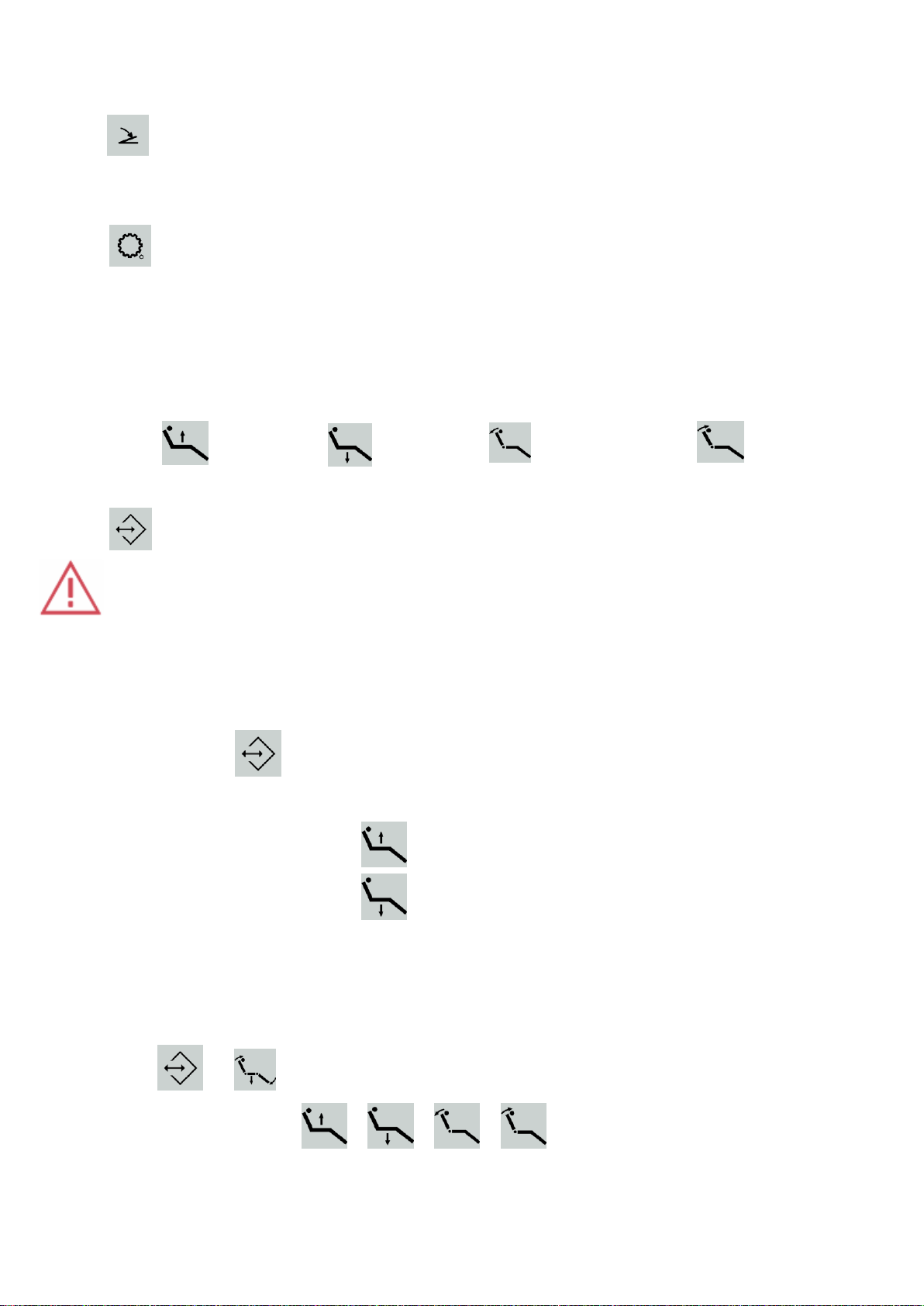

Chair movement

All the buttons below controls the chair directly with the instrument replaced or taken

when the foot controller pedal is in the zero position.

seat up seat down back rest backward back rest forward

Saving / recalling of a macro into / from the memory.

It serves to save and recall pre-set positions of the chair.

With the glass keyboard, the button, as the only one, responds only after it has

been released and not immediately after touching it as others do! If the button needs to

be held in case of the glass keyboard, it is necessary to use the identical button on the

foot controller.

Selection of memory group.

Programable positions of the chair can be saved in two groups (2x5 positions).

Procedure how to select the desired set:

Hold the button (ca 3 seconds) until you hear an audio signal (short –long tone).

Only then the unit switches to the programming mode. Immediately after you have heard the

audio signal, press the button of the selection of the group in question.

For group 1 it is the button .

For group 2 it is the button .

The selection of the group is indicated by means of an audio signal –1 beep for group 1

and 2 beeps for group 2. The selection of the group remains saved in the memory even after

the unit has been turned off.

How to save the chair position into the memory:

Get the chair to the desired position and press the combination of the buttons one by one

+ + one of the buttons under which the position is to be saved:

, , , .

Changing-over of the function of the foot controller (analogue - ON/OFF)

Change of the transmission ratio of the instrument head

gb_da270,da280_2014_06 18/42

The button should be held (ca 3 seconds) until you hear an audio signal (short –

long tone). Only then the unit switches to the programming mode and it is possible to go on

programming. Otherwise the new data on the position will not be saved into the memory.

With the glass keyboard it is necessary to use the button from the foot controller.

Saving of the position is indicated by means of an audio signal –one long and two short

beeps.

If the writing-in fails, you will hear an audio signal –3 long beeps.

How to recall the chair position from the memory:

Press the combination below one by one

+ one of the buttons under which the position of the chair is saved.

Getting-on position

If all the instruments are replaced and the button is pressed (touched), the chair is set

automatically to the getting on/off position. At the same time, the main light goes off, the bowl is

returned to the basic position and flushed automatically (if powered bowl rotation and light

control is fitted). If an instrument is taken, only getting-on position is recalled.

Programming of the getting-on position:

The procedure is identical with that of programming any other position of the chair, i.e.

pressing the button combination below one by one

+ + .

The button should be held (ca 3 seconds) until you hear an audio signal (short –

long tone). Only then the unit switches to the programming mode and it is possible to go on

programming. Otherwise the new data on the position will not be saved into the memory.

With the glass keyboard it is necessary to use the button from the foot controller.

Saving of the position is indicated by means of an audio signal –one long and two short

beeps.

If the writing-in fails, you will hear an audio signal –3 long beeps.

To recall the getting-on position, simply press the button .

In the event that there might be a collision of the bowl and the chair, the chair is blocked

and an audio signal sounds–short repeated tone. To finish the movement of the chair it is

necessary to return the bowl to the basic position manually.

Rinsing position

By pressing the button for more than 1s and less than 4s the chair returns from the

rinsing position, while the bowl starts to rotate to the basic position, where it stops and at the

same time bowl flushing is carried out according to the programmed time. After pressing the

button, there is a short beep and after the time interval of more than 1s and less than 4s there is

a long beep.

By pressing the button for more than 4s the rinsing position of the chair is recalled and the bowl

starts to rotate towards the patient where it stops.

gb_da270,da280_2014_06 19/42

After the button has been pressed, there is a short beep and after a time interval of

more than 1s and less than 4s there is a long beep. After a time interval of more than 4s there is

a triple beep.

The chair should be pre-programmed so that the rinsing position is saved under the button for

seat down movement.

After the rinsing position of the chair has been recalled by means of the button for bowl rotation,

the chair should not be handled in any other way in order for the return from the rinsing position

of the chair recalled by means of the bowl rotation button to work properly.

For the rinsing position to function correctly it is necessary - while setting the said

position - to observe the safety height of the chair preventing the collision of the chair

and bowl while maintaining the patient safety. When the said condition is not observed,

the chair movement while the bowl is deflected is blocked to avoid injury to the patient

arm and/or the collision of the chair and bowl.

This occurs also at moving to the rinsing position from the position above the safety

height of the chair. If that is the case, the recalling of the rinsing position is unusable for

safety reasons.

How to set the rinsing position:

- lower the chair to the lower position

- put the bowl out

- by pressing and holding the button move the chair up until it stops automatically

- move the chair down by ca 2cm

- set the back rest position

- save the set position as the rinsing position under the respective button, i.e. the combination of

buttons

+ + .

Test of the setting of the rinsing position

Move the chair to the lower position.

Recall the rinsing position.

The bowl must be put out and the chair must move to the rinsing position.

Recall the return from the rinsing position.

The bowl must retract and the chair must move to the previous position.

Automatic bowl control applies only for powered bowl drive. In the event that the unit is not fitted

with powered bowl rotation and there might be a collision of the bowl and the chair, the chair is

blocked and an audible signal sounds - short repeated tone. To finish the movement of the

chair it is necessary to return the bowl to the basic position manually.

Caution

The button is active for approx. 4 seconds after pressing, i.e. within the said time the

second button from the required combination should be pressed, depending on the desired

function. After the said time has elapsed, the function is cancelled and the button must

be pressed again to recall it.

gb_da270,da280_2014_06 20/42

For the movement of the chair in the upper half of the trajectory it is necessary that the

bowl be in the basic position.

If that is not the case, then the chair movement is blocked and this is indicated by three long

beeps and an error message: „O“on the display of the chair control electronics in the spittoon

block. The movement of the chair to the programmed position is also blocked, if the said

position requires the movement of the chair in the upper half of the trajectory and the bowl is not

in the basic position. If that is the case, the blocking is indicated by an audio signal - short

repeated tone –until the bowl has been moved away to the basic position. Afterward the chair

continues in moving to the desired position.

If- during the movement of the chair in the upper half of the trajectory –the bowl is deflected,

then the chair stops! If that is the case, the blocking is indicated by an audio signal: long –long

–long tone. Return the bowl to the zero position and then repeat the command for the chair

movement.

When the chair hits an obstacle, the movement of the chair is stopped and changed-over to the

opposite direction (the reverse movement may not always occur when the back rest hits an

obstacle).

The said opposite movement lasts until the safety emergency switch has been released by

moving the chair away from the obstacle and/or until the chair has reached the end position in

the event that the safety switch has not been released. During such movement an alarm audio

signal sounds –long repeated tone. The following is monitored: movement of the chair

downwards, movement of the back rest backwards, bumping into the assistant table upwards. If

the chair hits the assitant table, the chair stops. If that is the case, the reverse movement does

not occur.

The manufacturer recommends to move the assistant table out of the chair trajectory

before moving the chair to avoid the collision of the chair with the assistant table and/or

damage to the assistant table.

When handling the chair, in case of a failure the information on the current failure is displayed

on the display of the chair control electronics in the spittoon block.

List and meaning of error messages on the display of the chair control electronics:

„O“ –blocking of the chair movement with the instrument running / the chair hits the instrument

holder on the assistant table

„o“ - blocking of the chair with safety switches in the chair –the chair hits an obstacle

„O.“–blocking of the chair when the bowl is moved and crosses the chair trajectory

„1.“ - error of the check of the content of EEPROM memory with the saved chair positions

„2.“ - faulty writing-in of a chair position into the EEPROM memory

„3.“ - motor1 is started but the potentiometer1 has not recorded any movement = defective

motor or potentiometer

„4.“ - motor2 je is started but the potentiometer2 has not recorded any movement = defective

motor or potentiometer

„5.“ - motor3 is started but the potentiometer3 has not recorde any movement = defective motor

or potentiometer

„6.“ - potentiometer1 is outside the working range –if the error reoccurs, perform

„AUTOSET“

„7.“ - potentiometer2 is outside the working range –if the error reoccurs, perform

„AUTOSET“

„8.“ - potentiometer3 is outside the working range –if the error reoccurs, perform

„AUTOSET“

„6“ - potentiometer1 –error of connection : short-circuited, disconnected or misconnected

wires –value outside the permissible limit

„7“ - potentiometer2 –error of connection : short-circuited, disconnected or misconnected

Other manuals for ADEPT DA 270

1

This manual suits for next models

1

Table of contents

Other Diplomat Dental Equipment manuals