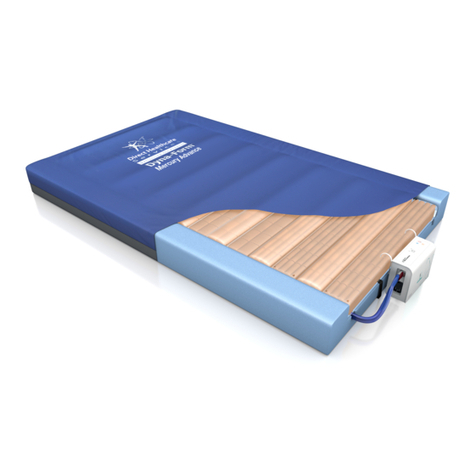

Direct Healthcare Group Dyna-Form Mercury Advance User manual

DIRECTHEALTHCAREGROUP.COM

User Manual

Trolley

Mercur

y Advance

2

DYNA-FORM MERCURY ADVANCE TROLLEY

DIRECTHEALTHCAREGROUP.COM

USER MANUAL

3

DIRECTHEALTHCAREGROUP.COM

The Dyna-Form Mercury Advance Trolley Mattress has been designed especially for users considered to be that of Very High

Risk of pressure ulcer development in potentially lengthy A&E waiting environments. This product can be made to measure in

order to fit most trolley designs and is ideal for use in busy A&E departments that have an extensive patient turnover. Offering high

levels of patient comfort, this system has the facility to “step up” to that of a dynamic mattress when clinically required. Similarly,

the mattress function can be downgraded as the patient’s condition improves. These features make it particularly beneficial for use

in an acute environment and help reduce moving and handling, logistical and decontamination impact costs. A higher maximum

weight capacity, up to 40 stone / 254kg, allows the product to meet the modern challenges of those heavier clients. All component

parts are interchangeable and replaceable, maximising product life and reducing environmental impact. The outer cover

comprising a high frequency welded, multi stretch and vapour permeable fabric satisfies the strictest infection control policies.

1. Introduction .....................................................................................................................................................................4

2. Quick Reference Guide & Frequently Used Functions............................................................................................................4

3. Troubleshooting ...............................................................................................................................................................6

4. Installation .......................................................................................................................................................................7

5. Operation .........................................................................................................................................................................7

6. Transportation ..................................................................................................................................................................8

7. Warnings .........................................................................................................................................................................8

8. Maintenance Procedures...................................................................................................................................................9

9. Technical Specification ...................................................................................................................................................10

10. Technical Data..............................................................................................................................................................14

11. Optimum Conditions for Use ...........................................................................................................................................14

12. Symbols Guide & Contraindications for Use .....................................................................................................................14

13. Detachable / Removable Parts .......................................................................................................................................15

14. Disposal ......................................................................................................................................................................15

Contents

Trolley

Mercur

y Advance

4

DYNA-FORM MERCURY ADVANCE TROLLEY

DIRECTHEALTHCAREGROUP.COM

1. Introduction

The Mattress consists of a foam head cell and series of 14 transverse air cells, each containing a unique

foam profiled insert, which are in turn held within a foam U Core, all protected by a vapour permeable

waterproof cover. The single head end cell and the formers consist of foam only. The transverse cells are

arranged into alternate pairs of A and B cells which are filled and emptied in sequence.

In Static Mode, the mattress attains the pressure reducing properties of the Dyna-Form Mercury

static foam mattress (details available on request), whilst in Alternating Mode the mattress is able to

offer similar properties to a pressure relieving dynamic system.

The digitally controlled Power Unit controls a pump that allows air to flow into, or out of the air cells

as required according to the operating mode selected. It also maintains the air pressure within the

mattress at the required level and controls the action of the audible/visual Audible Warning System in

the event of mains supply failure or over or under inflation pressure. A CPR Valve located at the pump

end of the umbilical hose permits the rapid deflation of the Mattress in an emergency.

Power Switch Audible Warning Reset

The power switch simply switches the mains power to the pump on and off.

When the pump detects an Audible Warning condition, this can be silenced (see page 5)

and re-set by switching the pump off and then back on again.

CPR Valve

Please ensure that the CPR connector is always placed fully home, prior to inflating the mattress.

NB: The mattress will NOT inflate properly should this not be the case.

The CPR connector is only to be used in the event of a clinical emergency for priority use.

However, disconnecting this function will cleverly deflate air rapidly from the mattress in

readiness for transport / static mode.

2. Quick Reference Guide (Frequently used functions)

This is a quick reference guide for the Dyna-Form Mercury Advance Trolley System

Product Code MAT/ADV/TROL/SIZE

USER MANUAL

5

DIRECTHEALTHCAREGROUP.COM

This symbol when illuminated (The green indicator light) is not used to indicate that the

equipment is on or ready for use.

When a patient requires a true dynamic function or indeed more pressure in the cells, as they

may be uncomfortable or feel as though the support surface is too soft or unstable, then please

select a “High” setting (pressure 26mmHg). This must only be used by a trained clinician as often

too high pressures can further agitate certain patient conditions.

When a patient requires less pressure in the cells, as they may be uncomfortable or indeed hyper

sensitive to cell movement or indeed if the patient is still reddening further, then please select a

“Low” setting (pressure 18mmHg). This must only be used by a trained clinician.

This function is used to silence the Audible Warning. The LED will remain lit if the Audible

Warning has been silenced previously, however a fault is still detected. Refer to the power switch

in order to re-set fully. If the Audible Warning continues to sound repeatedly, along with an

illuminated light, then an engineer must be called.

This symbol indicates an “Audible Warning Failure”.

Please see troubleshooting guide below for how to re-set.

This symbol when illuminated indicates a Service is required.

DHG recommends a service every 8760 hours of operation (one continuous year running).

LED Mode Settings

Note: Please ensure (when available) that all securing straps on the base of the mattress are secured onto

the MOVING PARTS of the bed frame.

For shut down procedure, see 4.2 Power Unit (Pump) section.

Power On / Off

True Dynamic /Firmer Setting

Silence Audible Warning

Audible Warning Failure

Service Indicator

Low / Comfort Pressure Setting

6

DYNA-FORM MERCURY ADVANCE TROLLEY

DIRECTHEALTHCAREGROUP.COM

Warning / Fault Cause

Control Unit does

not operate;

no display lights

illuminate

The Control

Unit may not be

attached to a

power source or

a fuse may need

replacing.

1. Check the Control Unit is connected to mains power outlet with the correct voltage.

2. Check the Control Unit is switched on. Switch off and unplug the unit before restarting.

3. Check the mains plug fuse (5 AMP) then check both Control Unit fuses (1 AMP) –

fuses can be released using a screwdriver to push and turn.

Do not try to open the Control Unit. Opening the unit could cause personal injury

or equipment damage.

Ensure the replacement of fuses is carried out accordance with local legislation.

Warning LED C

+ audible warning

Mains failure /

Other

See above,

plus:

1. Reset the audible warning – turn off power and press the audible warning mute button.

2. Check the handle is intact, ensuring all four sealing connectors are firmly fitted to the control unit

and the air hoses. Check the CPR tag is attached and all sealing connectors are firmly secure.

3. Check all air hoses along the inside of the mattress – each should be firmly connected.

Check each air cell is securely attached to its connecting air pipe.

4. Check all cells, pipes and hoses for any air leakage.

5. Switch on power.

Warning LED B

+ audible warning

Pressure too low 1. Reset the warning – turn off power and press the audible warning mute button.

2. Check the handle is intact, ensuring all four sealing connectors are firmly fitted to the control unit

and the air hoses. Check the CPR tag is attached and all sealing connectors are firmly secure.

3. Check all air hoses along the inside of the mattress – each should be firmly connected.

Check each air cell is securely attached to its connecting air pipe.

4. Check all cells, pipes and hoses for any air leakage.

5. Check that the air filter cover is correctly secured and the air filter is clean.

6. Switch on power.

Warning LED B+C

+ audible warning

Pressure too low /

Air pipe kinked

1. Check all air hoses along the inside of the mattress – each should be firmly connected.

Check each air cell is securely attached to its connecting air pipe.

Warning LED A

+ audible warning

Pressure

too high

1. Reset the warning – turn off power and press the audible warning button.

2. Disconnect the air hoses to reduce pressure, reconnect when pressure

has decreased.

3. Check for twists in the air hoses between Mattress and Control Unit.

4. Switch on power.

Warning LED A+B

+ audible warning

Alternating

Mode Failure (no

alternation)

1. Reset the warning – turn off Power and press the audible warning mute button.

2. Disconnect the air hoses to reduce pressure – reconnect when pressure has decreased.

Warning LED A,B+C

+ audible warning

Initialising Failure 1. Press the audible warning mute button to silence the audible warning.

2. Check the power cable is firmly plugged into the mains outlet and the Control Unit;

and check the mains power is switched on.

3. Check the Control Unit fuse (1 AMP) – fuses can be released using a screwdriver

to push and turn.

Solution

3. Troubleshooting

USER MANUAL

7

DIRECTHEALTHCAREGROUP.COM

4. Installation

4.1 Mattress (This is the applied part type BF)

Place the Dyna-Form® Mercury Advance Trolley Mattress directly on to the bed platform ensuring

that the Blue multi-stretch waterproof cover is on top and that the umbilical hose is located at

the left hand corner at the foot end of the bed. Note: The umbilical hose can be located inside the

cover under the “Open Here for Air Inlet” printed in the bottom left hand corner of the mattress.

Cover the Mattress with a loose fitting sheet.

Static Mattress Use

The Dyna-Form® Mercury Advance Trolley Mattress can be used as a pressure reducing mattress

for patients at High Risk of pressure ulcer damage without the need to attach the pump.

Alternating Mattress Use

If / When required, the Dyna-Form® Mercury Advance Trolley Mattress can be used as an

alternating mattress system by attaching the Dyna-Form® Mercury Advance Trolley Power Unit

(Pump) system.

No other system should be attached to the mattress as the design settings and internal

air pressure properties of the Dyna-Form® Mercury Advance Trolley Power Unit (Pump) are

specific to this mattress only.

The Dyna-Form® Mercury Advance Trolley is a replacement mattress system and should NOT be

placed on top of any existing mattress.

The startup time from static to dynamic mode is immediate.

4.2 Power Unit (Pump)

Hang the Power Unit (Pump) onto the footboard. The mounting hooks swivel to suit the thickness

of the footboard or rail. Connecting the Umbilical Hose to the Power Unit (Pump), place the 3-pin

electrical plug into the wall outlet and switch on:

(a) Open the zip located at the bottom left hand side of the mattress and pull out the Blue Umbilical hose.

(b) Attach the Blue Umbilical Hose to the Power Unit (Pump) by connecting the air connector

at the end of the Umbilical Hose to the air inlet connector at the bottom left hand side of the

pump. Ensure that the Red CPR Release button is located on top of the Air Inlet connector after

connection is complete.

(c) Re-close the zip as far as possible without clamping the Blue Umbilical Hose to ensure the

mattress and air cells are sealed within the cover.

(d) Shut down is the reverse of items a, b & c above.

5. Operation

Attach the mains cable to the pump by inserting the “kettle” type connector into the recess

located on the left hand side of the pump. The mains cable has been designed specifically as a

removable part to aid in easy replacement should it become damaged in use.

The mains plug should be turned off and removed from wall socket as a means of isolation.

Plug the mains cable into a suitable 230v mains socket and switch on the Power Unit using the

on/off switch.

After the pump has been turned on both the “High “and the “Low” lights will flash together

intermittently until the pump has attained its initial operating pressure. Once the pump has

attained its initial operating pressure the “Low” light will stay on constantly and the mattress is

ready for use.

8

DYNA-FORM MERCURY ADVANCE TROLLEY

DIRECTHEALTHCAREGROUP.COM

5.1 Low / High Settings

The Dyna-Form® Mercury Advance Trolley Mattress, in Alternating Mode, has two pressure settings.

The initial setting that the pump will revert to upon set up is “Low”. The “Low” comfort setting is

ideal for the lighter patient or those who feel discomfort when on a normal alternating air type

mattresses system. However, for patients with existing pressure damage or those at Very High

Risk, it is recommended that dependant on the clinical judgement of the clinician,

the “High” setting is activated by pressing the +/- button once, which is located on top of the

pump.

In “High” Mode the pump attains more of the characteristics of an alternating air mattress system

whilst still utilising the advantages of the static foam inserts. Repeatedly pressing the ‘mode’

button enables the Low & High modes to be selected in turn.

5.2 CPR Deflation

The CPR system consists of a manually operated button located on the Air Inlet connector

attached to the pump. By pressing the Red Button, which will release the connector locking

system, the user can remove the connector unit which will deflate the mattress air system back

to that of a static foam mattress.

Note: After a short period as the Mattress deflates the ‘Low Pressure’ Audible Warning is

activated and can be cancelled by switching the Power Unit off.

5.3 Troubleshooting

For assistance (if needed) in setting up, using or maintaining the Mercury Advance System, or to

report unexpected operation or events, please contact Direct Healthcare Group on the contact

details on the reverse of this manual.

6. Transportation

To change the location of the mattress, remove the Umbilical Cord and allow the mattress to

return to its Static Mattress form. Switch off the Power Unit (Pump) using the on/off switch and

disconnect the electrical supply cable from the mains socket. The mattress can now be moved to

a new location where it must immediately be reconnected to the mains electrical supply and the

Power Unit (Pump) switched back on. Once the Mattress has been refilled, the ‘Alternating’ mode

will automatically revert back to the Low setting and should be reselected to High should this be

desired by the clinician.

Warning: The Mattress will not ‘alternate’ when disconnected from the Power Unit (Pump)

and /or the mains electrical. Also refer to environmental conditions section at rear of this manual.

7. Warnings

Warning conditions are indicated by a flashing red display accompanied by an audible warning.

In each case the user should respond by turning the Power Unit’s switch off and investigating the cause.

7.1 High Pressure Warning

This condition could be caused, for example by a kinked Umbilical Hose or visitors,

and others, sitting suddenly on the Mattress.

7.2 Low Pressure Warning

This condition could be caused, for example, by incorrect fitting of the air inlet connector,

opening of the CPR Valve or a leak in the Mattress due to a cut or puncture.

7.3 Mains Failure Warning

This condition may be caused, for example if Mains power is lost.

USER MANUAL

9

DIRECTHEALTHCAREGROUP.COM

8. Maintenance Procedures

8.1 Safety Warning

Only qualified technicians trained or formally approved by Direct

Healthcare Group Ltd. in the operation and maintenance of

Direct Healthcare Group products may carry out maintenance,

modification or repair work on the equipment. Unqualified

personnel attempting to work on Direct Healthcare Group Power

Units risk serious injury to themselves and others and possibly

death by electrocution. Inlet fuse NOT to be replaced by operator

or patient, to be replaced by service personnel only.

Warning – Do not modify this equipment without

authorisation of Direct Healthcare Group.

8.1.1 Servicing

A service light will illuminate when a service is due.

Direct Healthcare Group (DHG) recommend that the Power

Unit (Pump) should be serviced every 8760 hours of operation (one

continuous year running). The unit contains no user serviceable

parts and should only be carried out by persons as described in

section 8.1. DHG will make available on request service manuals,

component parts lists and other information necessary for any

suitably qualified person (As in 8.1) to carry out repair or service

the system. For Service, maintenance and any questions regarding

this please contact DHG.

8.2 Cleaning Procedures

Warning: Before cleaning the System make sure that the Power

Unit (Pump) is disconnected from the mains electricity supply.

Do not immerse the Power Unit (Pump) in water or other fluids.

Do not autoclave, nor use phenol for cleaning.

Do wash hands before commencing the cleaning process.

Wear appropriate protective clothing such as gloves, apron

and a mask.

Ensure all work surfaces are cleaned before and after contact

with the Mattress.

8.3 Warning – Cleaning the Mattress

1. Cleaning should take place after use or between patients.

2. With cover left on the Mattress disconnect the Mattress from

the Power Unit (Pump).

3. Clean the surface of the wash down table with Hypochlorite

solution or equivalent disinfectant.

4. Wash Mattress top using hot water (60 degrees C) containing

detergent – dry with a paper towel.

5. Use a Hypochlorite solution 1,000 parts per million available

chlorine. For heavy contamination use a Hypochlorite solution

10,000 parts per million available chlorine.

Please ensure

thorough rinsing after cleaning.

6. Using suitable brush, hot water, detergent or Hypochlorite

solution, clean Umbilical Hose and CPR Valve. Dry with

paper towel.

7. If required, the Mattress Cover may be removed and

machine-washed at a temperature of 80 degrees C, for not

less than 10 minutes. The individual Air Cells can be wiped

down with established disinfectants.

8. To avoid shrinkage of the cover line dry in an indoor clean

environment or tumble dry on a low heat setting not

exceeding 40 degrees C and not for longer than 10 minutes.

Covers must be thoroughly dried before re-fitting to the

mattress.

8.4 Warning – Cleaning the Power Unit (Pump)

The Power Unit can be cleaned by wiping with a cloth dampened

with a detergent solution or Hypochlorite solution.

Also refer to symbol chart.

8.4.1 Warning

Ensure the Mercury Advance System is not exposed to:

1. Excessive heat sources e.g. fires, radiators etc.

2. Water, particularly immersion of the pump.

7.4 Alternating Mode Failure (no alternation)

This will be indicated by a warning LED on A and B and an audible warning.

1. R eset the warning – turn off Power and press the audible warning mute button.

2. Disconnect the air hoses to reduce pressure – reconnect when pressure has decreased.

7.5 Initialising Failure

This will be indicated by a warning LED on A, B and C and an audible warning.

1. Press the audible warning mute button to silence the audible warning.

2. Check the power cable is firmly plugged into the mains outlet and the Control Unit;

and check the mains power is switched on.

3. Check the Control Unit fuse (1 AMP) – fuses can be released using a screwdriver

to push and turn.

10

DYNA-FORM MERCURY ADVANCE TROLLEY

DIRECTHEALTHCAREGROUP.COM

9. Technical Specification

Guidance and manufacturer’s declaration – electromagnetic emission

The MAT1260001 is intended for use in the electromagnetic environment specified below.

The customer or the user of the system should ensure that it is used in such an environment.

Emission test Compliance Electromagnetic environment – guidance

RF emissions

CISPR 11

Group 1 The system uses RF energy only for its internal function.

Therefore, its RF emissions are very low and are not likely

to cause any interference in nearby electronic equipment.

RF emission

CISPR 11

Class B The system is suitable for use in all establishments, including

domestic establishments and those directly connected to

the public low-voltage power supply network that supplies

buildings used for domestic purposes.

Harmonic emissions

IEC 61000-3-2

Class A

Voltage fluctuations/flicker

emissions

IEC 61000-3-3

Complies

Declaration – electromagnetic emissions - for all ME EQUIPMENT and ME SYSTEMS

USER MANUAL

11

DIRECTHEALTHCAREGROUP.COM

9. Technical Specification

Declaration – electromagnetic immunity

Guidance and manufacturer’s declaration – electromagnetic immunity

The MAT1260001 is intended for use in the electromagnetic environment specified below.

The customer or the user of the system should ensure that it is used in such an environment.

Immunity test IEC 60601

test level

Compliance level Electromagnetic

environment – guidance

Electrostatic discharge (ESD)

IEC 61000-4-2

±6 kV contact

±8 kV air

±6 kV contact

±8 kV air

Floors should be wood,

concrete or ceramic tile.

If floor are covered with

synthetic material, the relative

humidity should be at least

30%.

Electrical fast transient/burst

IEC 61000-4-4

±2 kV for power

supply lines

±1 kV for input/output line(s)

±2 kV for power

supply lines

±1 kV for input/output line(s)

Mains power quality

should be that of a typical

commercial or hospital

environment.

Surge Immunity Test

IEC 61000-4-5

± 1 kV line(s) to line(s) ±1 kV differential mode Mains power quality

should be that of a typical

commercial or hospital

environment.

Voltage dips, short

interruptions and voltage

variations on power supply

input lines

IEC 61000-4-11

Voltage Dips

%U T

Period

(Cycles)

Voltage Dips

%U T

Period

(Cycles)

Mains power quality

should be that of a typical

commercial or hospital

environment. If the user of

the Span system requires

continued operation during

power mains interruptions,

it is recommended that the

system be powered from an

uninterruptible power supply

or a battery.

30 25 30 25

60 5 60 5

>95 0.5 >95 0.5

Voltage

Interruption

% U T

Seconds Voltage

Interruption

% U T

Seconds

>95 5 >95 5

Power frequency (50Hz)

magnetic field

IEC 61000-4-8

3 A/m 3 A/m Power frequency magnetic

fields should be at levels

characteristic of a typical

location in a typical

commercial or hospital

environment.

NOTE U T is the a.c. mains voltage prior to application of the test level.

12

DYNA-FORM MERCURY ADVANCE TROLLEY

DIRECTHEALTHCAREGROUP.COM

Guidance and manufacturer’s declaration – electromagnetic immunity

The MAT1260001 is intended for use in the electromagnetic environment specified below.

The customer or the user of the system should ensure that it is used in such an environment.

Immunity test IEC 60601 test level Compliance level Electromagnetic environment – guidance

Conducted RF

IEC 61000- 4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to 80 MHz

3 V/m (Professional

Healthcare Environment)

10 V/m (Home

Healthcare Environment)

80 MHz at 2.7 GHz

3 Vrms

10 V/m

Portable and mobile RF communications equipment

should be used no closer to any part of the CT515,

including cables, than the recommended separation

distance calculated from the equation applicable to the

frequency of the transmitter

Recommended separation distance

d = 1.167√P

d = 1.167√P 80 MHz to 800 MHz

d = 2.333√P 800 MHz to 2.5 GHz

Where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF transmitters, as

determined by an electromagnetic site survey,

a

should

be less than the compliance level in each frequency

range.

b

Interference may occur in the vicinity of equipment

marked with the following symbol:

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection

from structures, objects and people.

a. Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios,

amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the

electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should be considered. If the measured

field strength in the location in which the Span system is used exceeds the applicable RF compliance level above, the system should

be observed to verify normal operation. If abnormal performance is observed, additional measures may be necessary, such as

reorienting or relocating the system.

b. Over the frequency range 150kHz to 80MHz, field strengths should be less than 3V/m.

9. Technical Specification

Declaration – electromagnetic immunity – for ME EQUIPMENT and ME SYSTEMS that are not LIFE-SUPPORTING

USER MANUAL

13

DIRECTHEALTHCAREGROUP.COM

9. Technical Specification

Recommended separation distances between portable and mobile RF communications equipment and the MAT1260001

Alternating Control Unit

The MAT1260001 is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled.

The customer or the user of the system can help prevent electromagnetic interference by maintaining a minimum distance between

portable and mobile RF communications equipment (transmitters) and the system as recommended below, according to the maximum

output power of the communications equipment.

Rated maximum output

power of transmitter (W)

Separation distance according to frequency of transmitter (m)

150 KHz to 80 MHz

d = 1.167√P

80 MHz to 800 MHz

d = 1.167√P

800 MHz to 2.5 GHz

d = 2.333

√

P

0.01 0.117 0.117 0.233

0 .1 0.369 0.369 0.738

11.16 7 1.16 7 2.333

10 3.689 3.689 7.379

100 11.667 11.667 23.333

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in meters (m) can be

estimated using the equation applicable to the frequency of the transmitter, where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1 At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection

from structures, objects and people.

Recommended separation distances between portable and mobile RF communications equipment and the EQUIPMENT

or SYSTEM – for ME EQUIPMENT or ME SYSTEM that are not LIFE – SUPPORTING

14

DYNA-FORM MERCURY ADVANCE TROLLEY

DIRECTHEALTHCAREGROUP.COM

10. Technical Data

9.1 Power Unit (Pump)

Serial Number ............................As per label on rear of pump

Electrical Supply. ................................220 – 240 volt, 50 Hz

Power Consumption ...............................................10 watts

Fuses ................................................................TA1H 250V

Protection against shock ...........................................Class 2

Noise Level ...............................................Approx. 30 dB (A)

Dimensions ...........................................245 x 160 x 95 mm

Weight...................................................................... 1.7 kg

Service Interval ............................... 12 months / 8760 hours

Expected life ............................................................5 years

Shelf life of parts ......................................................5 years

9.2 Mattress

Serial Number .....................Label on inside of mattress cover

Number of Air Cells ................ 14 Air Cells / 1 Static Foam Cell

Dimensions ..............................................Made to Measure

Weight........................................................................10kg

Expected life of Mattress ...........................................5 years

Shelf life of Mattress parts .........................................5 years

11. Optimum Conditions

(Applies to Mattress and Pump)

10.1 Environment Conditions for Use

Transport .................................................... -25˚C – +70˚C

Storage ...................................................... -25˚C – +70˚C

Usage ......................................................... +5˚C – +40˚C

Humidity .......................................................... 10% – 93%

Atmospheric Pressure ........................... 700hPa – 1060hPa

Operational Altitude .............................................. ≤ 2000m

10.2 Exposure

Exposure to direct sunlight, dust, lint and general debris is not

considered to be an issue with the Mercury Advance System.

REFER TO

USER MANUAL

SERVICE

REQUIRED

TUMBLE DRY ON LOW

0843

DO NOT IRON

DO NOT USE

SHARP INSTRUMENTS

WASH AT 80˚

REFER TO

USER MANUAL

DO NOT BLEACH

MAXIMUM USER

WEIGHT LIMIT

254 KG / 40 ST

ONES

DOUBLE INSULATED

CLASS II

NO SMOKING

DO NOT USE

PHENOL

DO NOT DRY CLEAN

TYPE BF

APPLIED PART

DO NOT DISPOSE OF

WITH HOUSEHOLD WASTE.

PLEASE REFER TO DHS WEBSITE

THIS IS A STAT EMENT THAT

ALERTS THE USER TO THE

POSSIBILITY OF SERIOUS INJURY

OR OTHERWISE ADVERSE

REACTIONS WITH THE USE

OR MISUSE OF THE DEVICE

WARNING

THIS IS A STAT EMENT THAT

ALERTS THE USER TO THE

POSSIBILITY OF A PROBLEM

WITH THE SYSTEM ASSOCIATED

WITH ITS USE OR MISUSE

CAUTION

CAUTION

HUMIDITY

LIMITATION

ATMOSPHERIC PRESSURE

LIMITATION

PROTECT FROM HEAT

AND RADIOACTIVE SOURCES

TEMPERATURE

LIMITATION

0843

IP: INGRESS PROTECTION

2: PROTECTION AGAINST FINGERS OR

OTHER OBJECT NOT GREATER THAN

80MM IN LENGTH AND 12MM IN DIAMETER

1: PROTECTION FROM VERTICALLY

DRIPPING WATER

Mattress Symbols

12. Symbols Guide

General Symbols

REFER TO

USER MANUAL

SERVICE

REQUIRED

TUMBLE DRY ON LOW

0843

DO NOT IRON

DO NOT USE

SHARP INSTRUMENTS

WASH AT 80˚

REFER TO

USER MANUAL

DO NOT BLEACH

MAXIMUM USER

WEIGHT LIMIT

254 KG / 40 STONES

DOUBLE INSULATED

CLASS II

NO SMOKING

DO NOT USE

PHENOL

DO NOT DRY CLEAN

TYPE BF

APPLIED PART

DO NOT DISPOSE OF

WITH HOUSEHOLD WASTE.

PLEASE REFER TO DHS WEBSITE

THIS IS A STAT EMENT THAT

ALERTS THE USER TO THE

POSSIBILITY OF SERIOUS INJURY

OR OTHERWISE ADVERSE

REACTIONS WITH THE USE

OR MISUSE OF THE DEVICE

WARNING

THIS IS A STAT EMENT THAT

ALERTS THE USER TO THE

POSSIBILITY OF A PROBLEM

WITH THE SYSTEM ASSOCIATED

WITH ITS USE OR MISUSE

CAUTION

CAUTION

HUMIDITY

LIMITATION

ATMOSPHERIC PRESSURE

LIMITATION

PROTECT FROM HEAT

AND RADIOACTIVE SOURCES

TEMPERATURE

LIMITATION

0843

IP: INGRESS PROTECTION

2: PROTECTION AGAINST FINGERS OR

OTHER OBJECT NOT GREATER THAN

80MM IN LENGTH AND 12MM IN DIAMETER

1: PROTECTION FROM VERTICALLY

DRIPPING WATER

Pump (Unit) Symbols

REFER TO

USER MANUAL

SERVICE

REQUIRED

TUMBLE DRY ON LOW

0843

DO NOT IRON

DO NOT USE

SHARP INSTRUMENTS

WASH AT 80˚

REFER TO

USER MANUAL

DO NOT BLEACH

MAXIMUM USER

WEIGHT LIMIT

254 KG / 40 STONES

DOUBLE INSULATED

CLASS II

NO SMOKING

DO NOT USE

PHENOL

DO NOT DRY CLEAN

TYPE BF

APPLIED PART

DO NOT DISPOSE OF

WITH HOUSEHOLD WASTE.

PLEASE REFER TO

DHS WEBSITE

THIS IS A STAT EMENT THAT

ALERTS THE USER TO THE

POSSIBILITY OF SERIOUS INJURY

OR OTHERWISE ADVERSE

REACTIONS WITH THE USE

OR MISUSE OF THE DEVICE

WARNING

THIS IS A STAT EMENT THAT

ALERTS THE USER TO THE

POSSIBILITY OF A PROBLEM

WITH THE SYSTEM ASSOCIATED

WITH ITS USE OR MISUSE

CAUTION

CAUTION

HUMIDITY

LIMITATION

ATMOSPHERIC PRESSURE

LIMITATION

PROTECT FROM HEAT

AND RADIOACTIVE SOURCES

TEMPERATURE

LIMITATION

0843

IP: INGRESS PROTECTION

2: PROTECTION AGAINST FINGERS OR

OTHER OBJECT NOT GREATER THAN

80MM IN LENGTH AND 12MM IN DIAMETER

1: PROTECTION FROM VERTICALLY

DRIPPING WATER

USER MANUAL

15

DIRECTHEALTHCAREGROUP.COM

Contraindications For Use (Warning)

The Mercury Advance System should not be used for patients with

unstable fractures, gross oedema, burns, or intolerance

to motion.

General Information (Caution) (Warning)

• There are no special skills required to operate the system.

• The Medical Professional is responsible for applying his/her

best medical judgment when using the system.

• The electricity supply is of the type indicated on the Power

Unit (pump).

• Check the mains lead is free from damage and is positioned

so as not to cause an obstruction, or injury. E.g. Strangulation

of a child or trip hazard.

• Ensure the mains lead cannot become trapped or crushed,

e.g. by raising or lowering of the bed or bed rails or any other

moving object.

• The power unit (pump) must only be used with a suitably

approved power cord and plug set as supplied by DHG.

• The system is not to be used in the presence of flammable

anaesthetics.

• Suitable for continuous use.

• Not suitable for sterilisation.

• Do not position the power unit to make it difficult to disconnect

the power supply or plug.

• Do not place the System on or close to a source of heat.

• Do not use with hot water bottles or electric blankets.

• DHG strongly advise against smoking whilst the Power Unit

(pump) is in use. This is to prevent accidental secondary ignition

of items which may be flammable e.g. bed linen. The materials

used in the manufacture of the Mercury Advance System

comply with the required fire safety regulations.

• Do not use sharp objects on or near the mattress system

as this will cause damage.

• Do not store in damp conditions.

• Do not use in an oxygen enriched environment.

• Not suitable for use in an Outdoor Environment.

• Intended for both Home Healthcare and Professional Healthcare

environments.

• Do not connect to any other medical device or equipment.

• Correct fuse rating MUST be used. Failure to do so could result

in the risk of a fire.

• The System should be cleaned after use or between patients.

Refer to Cleaning section.

• All internal and external hoses must be free of twists, kinks.

The external hose should also be properly connected and

positioned so that the risk of obstruction or injury is eliminated.

• Do not use bleach, phenols. Chlorine based products which

exceed 1000ppm. Solvents or alcohol based cleaners.

• All the above warnings and cautions together with safety

considerations should be observed at ALL times during its use.

• Select correct setting ‘Hi’ or ‘Low’ as required. Care should be

taken not to accidentally change settings once set. This may

affect the desired requirement of the therapy. This could also be

caused by pets, pests or children.

• This device does not emit radiation.

13. Detachable/Removable Parts

1. Mattress (Detached from the pump by removing the CPR

connector). Part No. MAT/ADV/TROL/SIZE (or variants

of for the size)

2. Electric power cable. (Removed from the pump by pulling the

cable away from the mains inlet on the side of the pump).

Part No. DHG/ADV/MLEAD

N.B. The battery is an integral part of the PCB and is not

removable or changeable.

Caution

Use of detachable parts not listed is not recommended by

Direct Healthcare Group.

14. Disposal

Please refer to DHG website for recommendations and

responsibilities for disposal within the UK WEEE guidelines.

Direct Healthcare Group

Withey Court, Western Industrial Estate

Caerphilly, United Kingdom

CF83 1BF

T: +44 (0) 845 459 9831

F: +44 (0) 845 459 9832

C22773

DIRECTHEALTHCAREGROUP.COM

I

S

O

1

3

4

8

5

A

2

8

3

2

2

LIT-00008 Issue 4

Date: February 2018

Asia Pacific

Direct Healthcare Group PTY Ltd.

PO Box 562, Wembley

Western Australia 6913

T: +61 (0) 423 852 810

Intelligent Pressure Care

Specialist Seating

Rental & Service Solutions

Other manuals for Dyna-Form Mercury Advance

1

Table of contents

Other Direct Healthcare Group Medical Equipment manuals

Direct Healthcare Group

Direct Healthcare Group Dyna-Form Mercury Advance User manual

Direct Healthcare Group

Direct Healthcare Group Linido LI2613.000 Series User manual

Direct Healthcare Group

Direct Healthcare Group GATE Bure Double 2.0 User manual

Direct Healthcare Group

Direct Healthcare Group RoMedic Carina350EM User manual

Direct Healthcare Group

Direct Healthcare Group Bure Standard User manual

Direct Healthcare Group

Direct Healthcare Group Mover Aqua Troubleshooting guide