www.diverite.com

October 2020 © Lamartek, Inc. dba Dive Rite 16

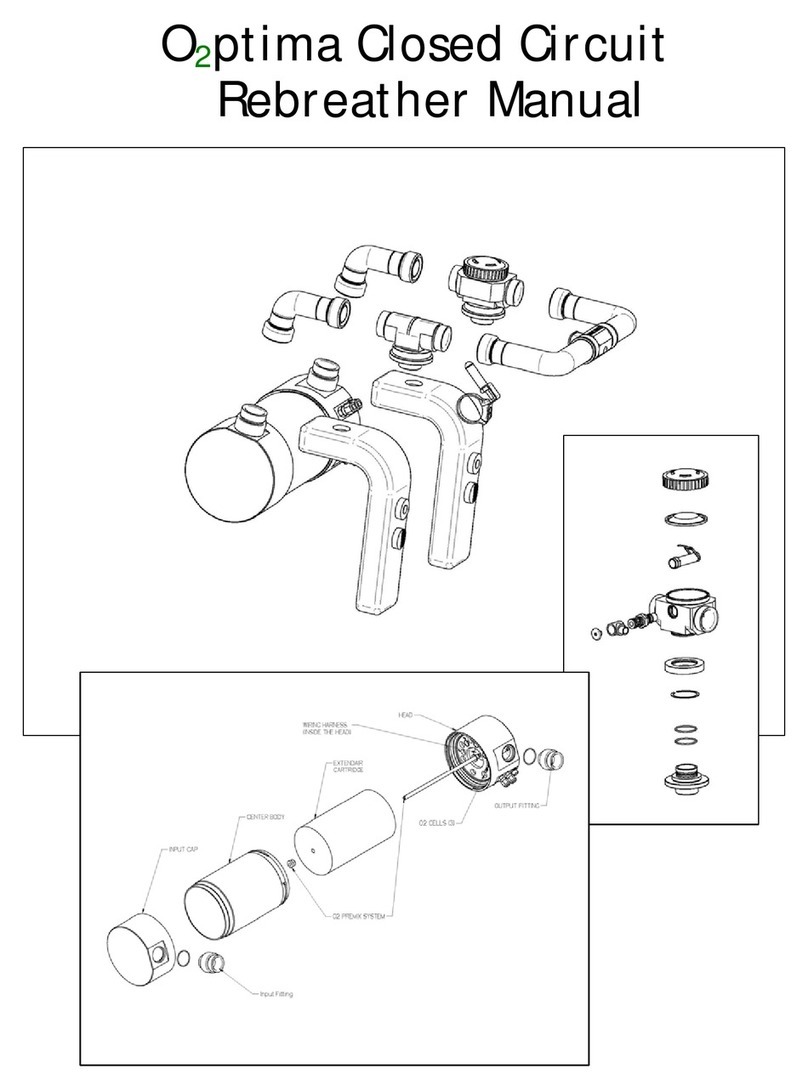

Micropore ExtendAir Cartridge Overview

(Information from www.microporeinc.com)

ExtendAir® adsorbent technology is a combination of a microporous gas

adsorbent sheet and the geometry in which it is utilized. The adsorbent

material is manufactured with a proprietary process into a microporous

sheet that can be made into different thicknesses and widths, using the same

chemistry as in granular adsorbents.

Sheets of adsorbent material are wrapped around a core to form an

ExtendAir® cartridge. The molded ribs in the

material create channels through which the breathing gases flow. One of

the unique features of an ExtendAir® cartridge is that the breathing

resistance of the adsorbent can be precisely controlled by varying rib

height and spacing. This controlled channeling of the breathing gases

results in a very uniform reaction zone within the adsorbent.

In a granular canister, gases seek the path of least resistance through the bed. The flow pattern can be

very random and will certainly vary from person to person. Learning to load a granular canister requires

instruction to learn the proper technique. Optimal loading of the canister

requires tapping to achieve a uniform bed of granules. This takes time and

can cause dusting of the adsorbent. All of this leads to variations in duration,

wasted adsorbent and the potential for "caustic cocktail".

In contrast to a granular system, ExtendAir® cartridges use channels, molded

in at the factory, that remain constant and controlled by the manufacturing

process. The user simply places the

cartridge into the canister, without any

need for tapping or shaking as the canister

is being loaded. As such, the duration

variability due to irregular granule settling

patterns, as well as variability due to individual loading technique are

completely eliminated. Eliminating this variability will directly

translate into longer minimum duration, and a +/-5% variation in

duration at any test condition (granules can vary up to +/-30%).

An important concept to understand with ExtendAir® cartridge technology is that the gas flow

distribution through the cartridge must be uniform in order for the system to perform optimally. For

example, one way to visualize flow through an ExtendAir® cartridge system is to take a bunch of soda

straws in your hand (50 or so). What would happen if you blew air down through just a group of 5

straws? All of the air would flow down those five straws, and none of the air would flow through the

other 45. The same thing would happen if you blew air into just one side of an ExtendAir® cartridge

canister: all of the air would flow through that side only.