Dive System Kirby Morgan 300-145 User manual

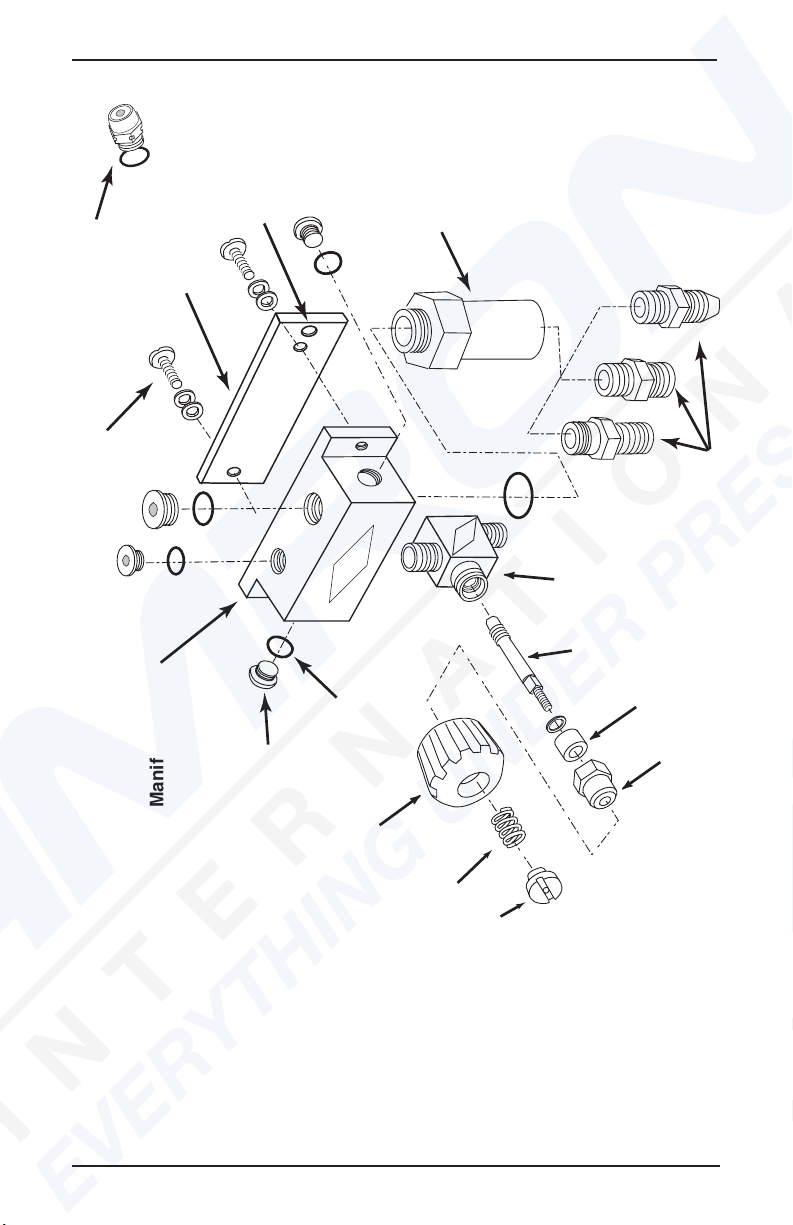

Diver’s Manifold Block

Product Part #s 300-145, 300-150, 300-155

User Guide

Document Part #: 100-134

Kirby Morgan Dive Systems, Inc.

1430 Jason Way

Santa Maria, CA 93455, USA

Telephone (805) 928-7772, FAX (805) 928-0342

E-Mail: KMDSI@KirbyMorgan.com, Web Site: www.KirbyMorgan.com

Guide prepared by: KMDSI

© ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. Document # 130329001

Kirby Morgan Manifold Block

2 © Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001

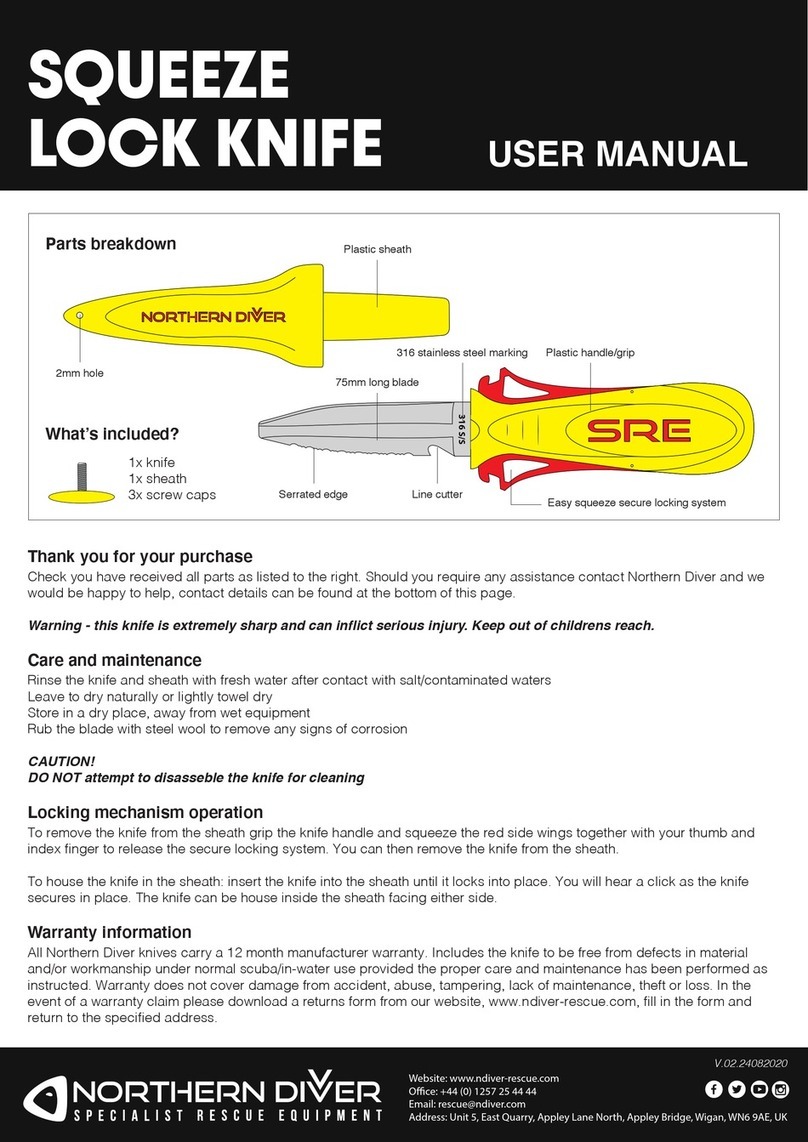

If you use an EXO-26 or other full

face mask for surface-supplied div-

ing, a manifold block which has a

one way valve (also referred to as a

“non-return” valve) and provides for

correct attachment of the umbili-

cal is essential. The emergency gas

supply valve on the manifold block

controls the ow of the bailout sup-

ply. There are three different ttings

available on the one way valve:

Part #

300-145 9/16” SCUBA tting

300-150 9/16” oxygen tting

300-155 #6 JIC tting

Diving in the Surface-supplied Mode

If you have not been trained in the proper use of surface-supplied diving

equipment we strongly recommend that you complete a training course in

the use of this equipment prior to diving surface-supplied.

Many full-face masks are not equipped with a one way

valve (non-return valve) as supplied from the factory. For

surface-supplied diving, the diver must use a manifold

block equipped with a one way valve. This will help to

prevent a “squeeze” in the event of a loss of the top-

side air supply. Without this valve, if a squeeze like this

occurs, the diver will suffer serious personal injury or

death.

WARNING

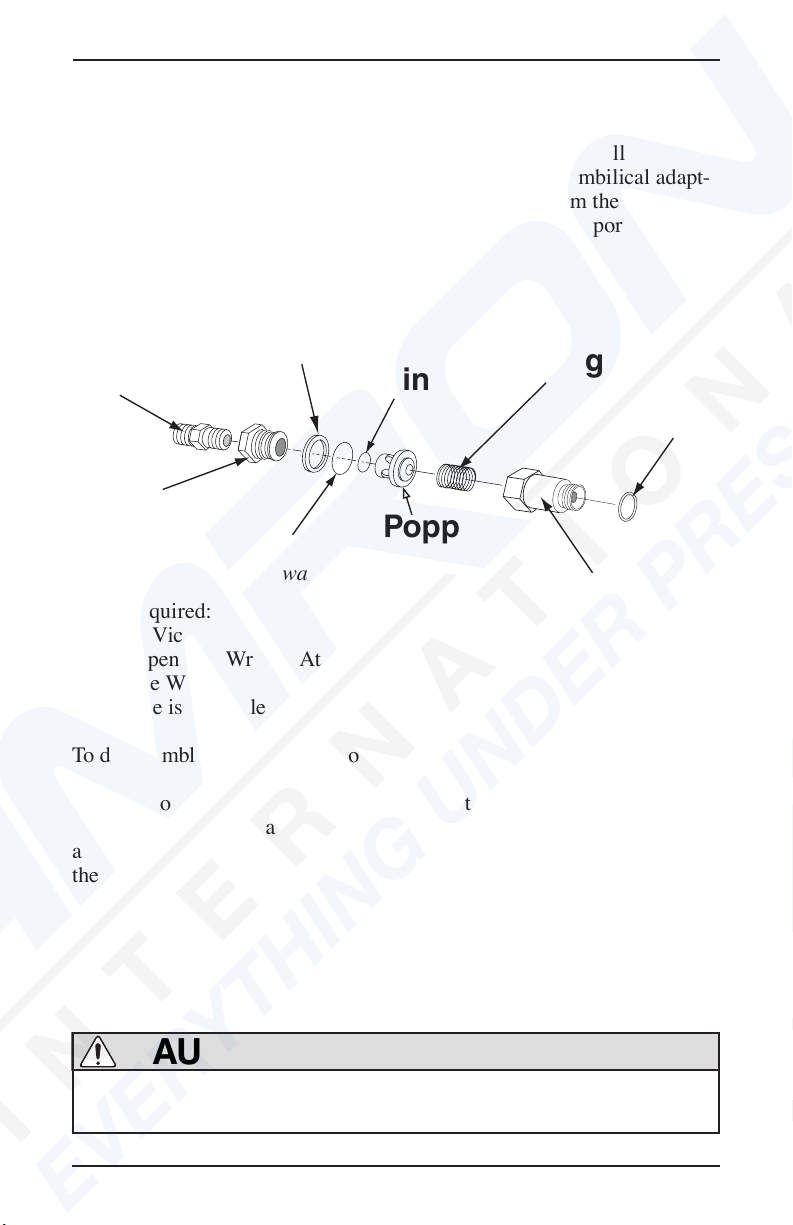

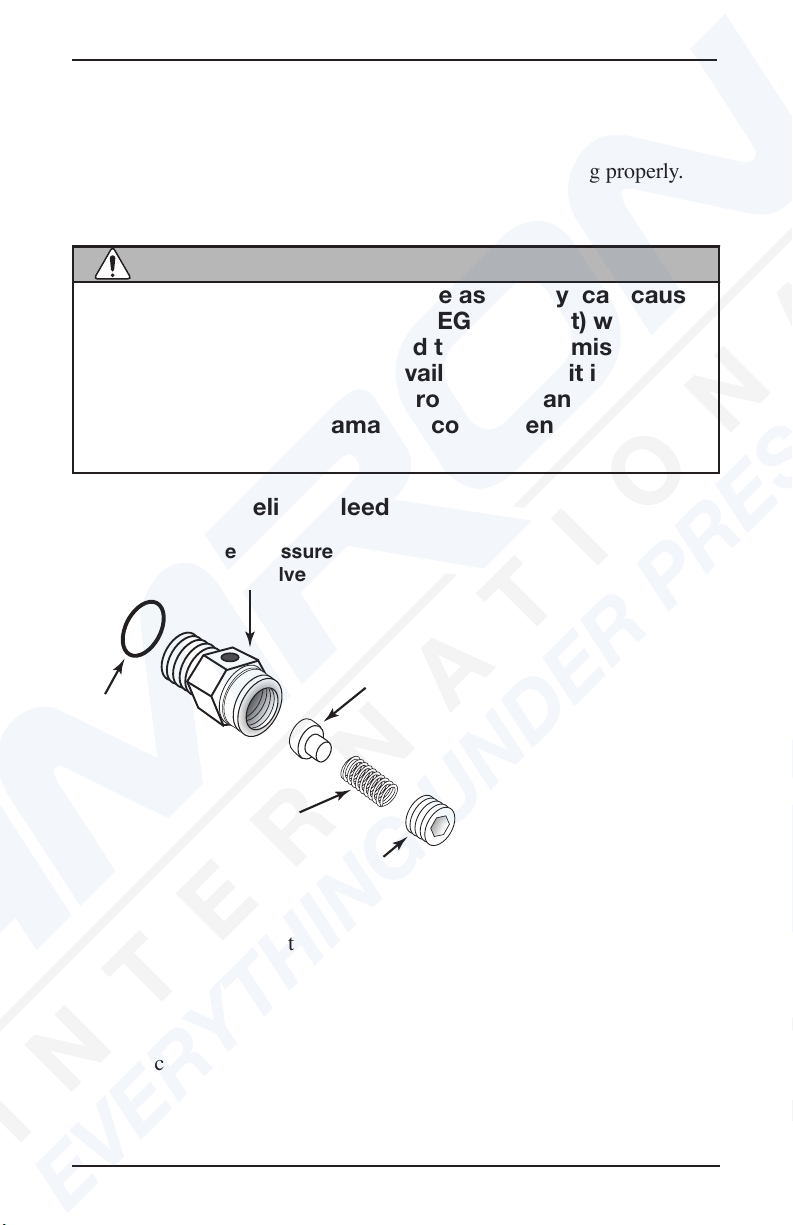

Adapter

Seat

Wiper

O-ring

O-ring

Poppet

Spring

Body

O-ring

Components of the one way valve

Kirby Morgan Manifold Block

© Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001 3

The one way valve is a very important component. It prevents the ow of

air out of the mask in the event of a sudden lowering of pressure in the

umbilical supply hose due to an accidental break in the hose or tting.

Not only would the emergency air be lost if the one way valve failed (con-

current with a hose or tting break) but the diver could be “squeezed,” a

very serious accident. Do not dive in the surface-supplied mode with-

out a one-way valve in the breathing system mounted on the diver’s

harness.

At a minimum, if you are doing surface-supplied diving, the following

systems and components must be in place and in proper working condi-

tion.

1) Air Supply: Either a low pressure compressor or high pressure air

bottles with a pressure reducing regulator capable of being manually

adjusted to 140 p.s.i over bottom pressure.

2) Dive Control System: An air management box to control the ow of

air to the diver or divers (such as the KMACS offered by KMDSI).

3) Divers Umbilical: Hose bundle consisting of air supply hose, pneu-

mofathometer hose (depth sensing), communications wire and rope as a

strength member.

4) Diver’s Manifold Block: A metal block that has a one way valve that

the umbilical attaches to, an emergency valve that the bail out system at-

taches to, and L.P. ports for attaching the mask hose, dry suit inators and

other accessories.

5) Bailout System: Consisting of a harness, bail out bottle, rst stage

regulator with over-pressure relief valve. This system connects to the

emergency valve on the divers manifold block assembly by a hose. Also

known as an Emergency Gas System.

6) Communications System: Provides hard wire communication be-

tween diver and top side.

Do not dive without a diver worn Emergency Gas System.

If the main gas supply is lost, you will have nothing to

breathe and may drown.

WARNING

Kirby Morgan Manifold Block

4 © Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001

Testing the Manifold Block

Prior to assembling a bailout system, the one way valve and emergency

valve should be tested for proper function.

Equipment Needed:

-Manifold Block

-Bailout bottle

-1st Stage regulator w/octopus and scuba reg

hose attached

-DCS system with an umbilical supply hose

-Bucket of water

Testing The One-Way Valve

1) With all the accessory holes plugged on the manifold block, attach the

SCUBA type regulator hose from a rst stage regulator that also has an

octopus attached, to the emergency valve on the manifold block assembly.

The octopus will be used for depressurization once the test is concluded.

2) Connect the rst stage to the bailout bottle, open the emergency valve

all the way, and pressurize the system.

3) Place the pressurized manifold block in a bucket of water and check

the one way valve for leaks. No air should leak through the one way valve

or from anywhere else on the manifold block assembly. If there is a leak,

the one way valve MUST be rebuilt or replaced.

4) As a secondary test, close the emergency valve trapping pressure inside

the manifold block assembly and relieve the pressure on the rst stage

using the octopus.

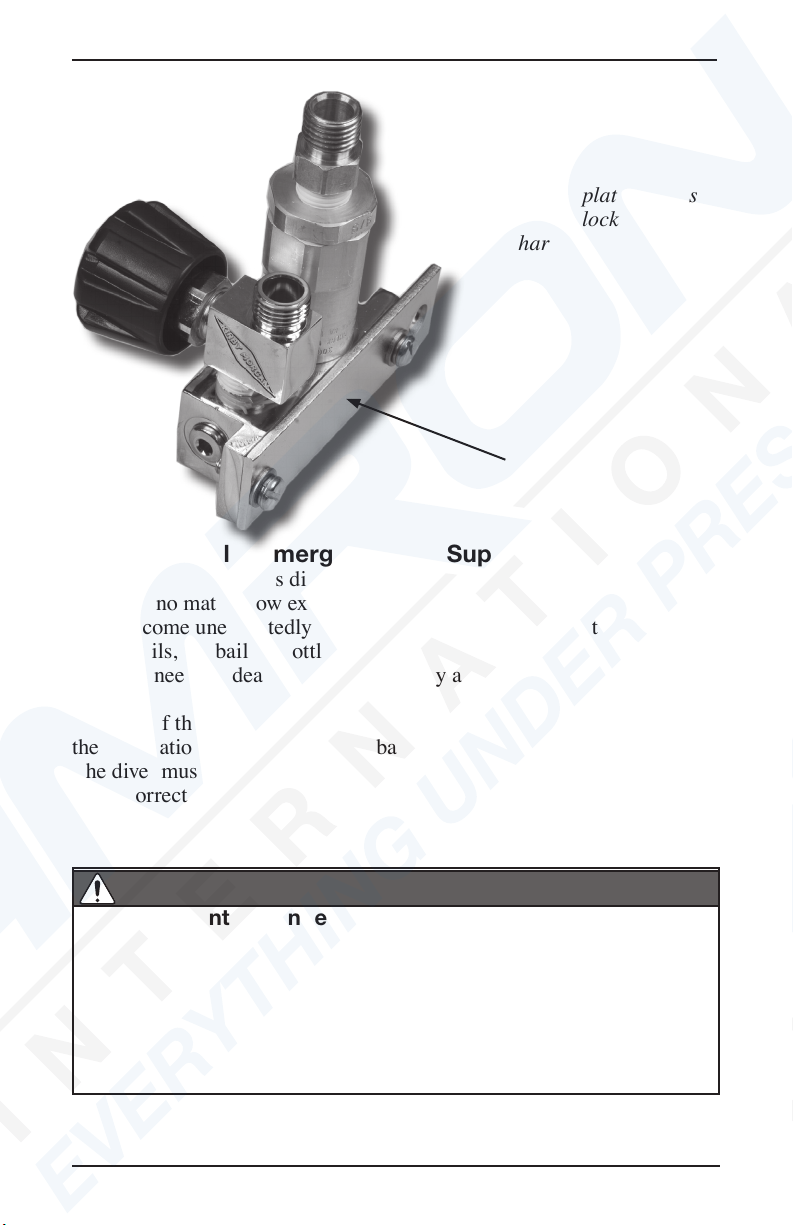

Emergency Gas

Supply Valve

On/Off Knob

Air supply

connects here

One-way valve

Low-pressure

port

Attachment plate

Low-pressure

ports (not in view)

Emergency gas

supply

connects here

Kirby Morgan Manifold Block

© Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001 5

Disconnect the hose from the emergency valve.

5) Quickly open the emergency valve by turning the knob. You should

hear the trapped air escaping through the emergency valve.

Testing The Emergency Valve

1) With all the accessory holes plugged on the manifold block, attach the

umbilical hose to the one way valve.

2) Make sure that the emergency valve is closed all the way and pressur-

ize the umbilical.

3) Place the pressurized manifold block in a bucket of water and check

the emergency valve for leaks. No air should leak through the emergency

valve or from anywhere else on the emergency valve assembly or mani-

fold block assembly. If there is a leak, the emergency valve MUST be

rebuilt or replaced.

4) Turn umbilical off and open the emergency valve to depressurize the

system and disconnect the hose.

Diver’s Harness

The harness provides an attachment point for the manifold block, tools

the diver may use while in the water, and the ”D” ring where the umbili-

cal shackle connects. The umbilical shackle must connect to the strength

member of the umbilical. The manifold block attaches to the harness

and the harness is the primary attachment point for the diver’s umbilical

using a shackle. Arrange the umbilical so it attaches to the harness, then

to the manifold block on the harness. This helps eliminate the possibility

of a direct pull on the diver’s mask by topside. The harness may also be

used to lift an unconscious diver from the water and should be of sturdy

construction.

The diver must always wear a

bail-out bottle attached to a diver’s

harness for surface-supplied div-

ing.

Kirby Morgan Manifold Block

6 © Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001

Never dive without attaching the umbilical to some type of

harness or clip on the diver’s body. Never allow the umbili-

cal to pull on the mask directly or the diver could suffer

a neck injury, or the mask could be pulled off the diver’s

head.

WARNING

The diver’s umbilical must

always be connected by a snap

hook to the harness. Note the

submersible pressure gauge used

to monitor the bail-out supply.

Installing the Manifold Block on the Harness

The manifold block assembly is designed to be worn on the diver’s har-

ness. Most divers prefer to attach the manifold block to the right side

of the diver’s harness. The shackle which attaches the umbilical to the

harness “D” ring, is usually located on the left side. After attaching the

umbilical to the “D” ring on the left side of the harness, the umbilical is

normally routed behind the diver’s back to the manifold block.

To attach the manifold to the diver’s harness:

1) Remove one of the screws which holds the mounting plate on the

manifold block body and loosen the other screw to provide enough clear-

ance for a harness strap.

2) Swing the plate to one side and position the manifold block on the har-

ness.

3) Swing the plate back into the correct mounting position and thread the

screw through the plate and into the manifold body.

4) Tighten both screws until the harness is compressed between the mani-

fold and mounting plate holding the manifold block assembly in place.

Kirby Morgan Manifold Block

© Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001 7

Bail-Out Bottle (Emergency Gas Supply)

The diver should always dive with a bailout bottle when diving surface-

supplied, no matter how experienced or what the water depth. Should the

diver become unexpectedly entangled underwater, or if the top side air

supply fails, the bailout bottle must provide the few extra minutes of air

the diver needs to deal with the emergency and return to the surface.

The size of the bailout bottle should be determined by the water depth,

the penetration distance, or the probability of entanglement of the diver.

The diver must have sufcient air in the bail-out bottle to make an ascent

at the correct ascent rate and complete a precautionary decompression

stop or any required decompression.

The mounting plate secures

the manifold block to the

diver’s harness.

Rapid ascent is dangerous. It can lead to air embolism or

decompression sickness. Air/gas embolism can cause im-

mediate loss of consciousness and/or death. Even on a

no decompression dive, a rapid ascent may cause decom-

pression sickness. A diver must only make a rapid ascent

when he is in immediate danger of death by drowning or

asphyxiation.

DANGER

Mounting plate

Kirby Morgan Manifold Block

8 © Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001

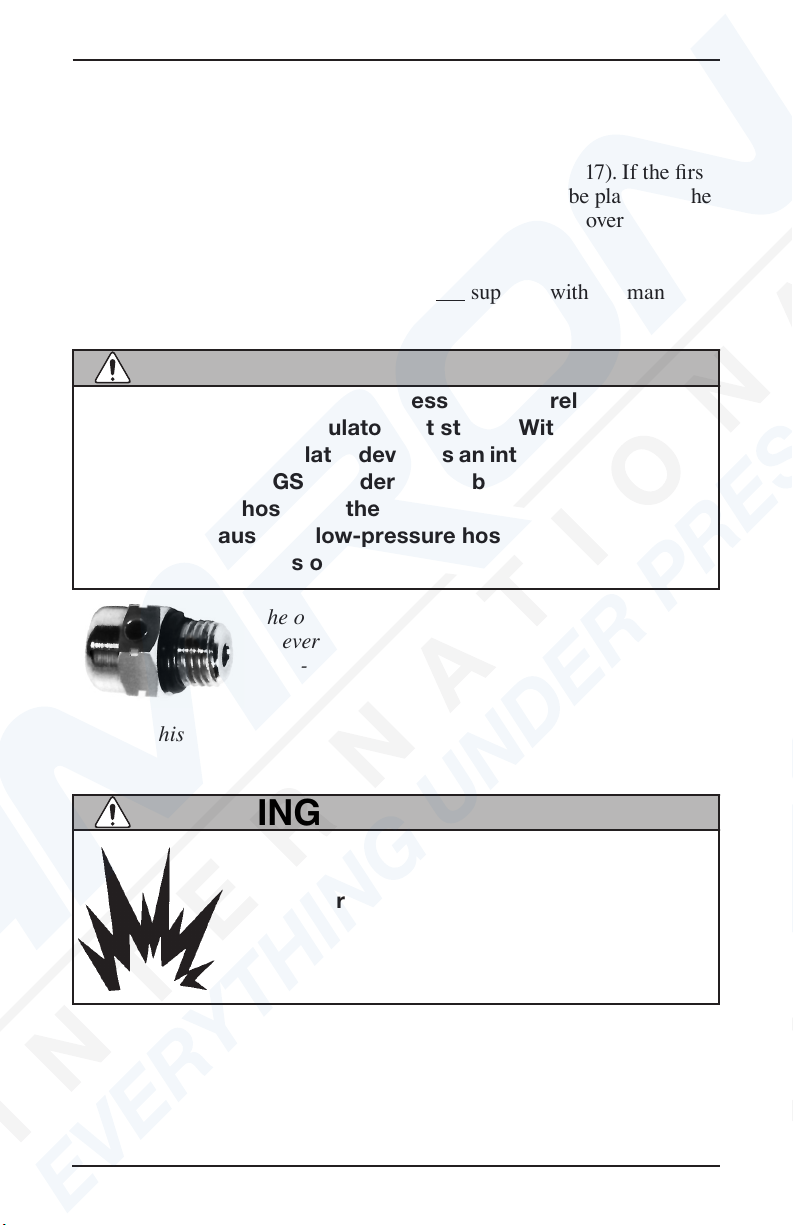

The over-pressure relief valve should be installed

on every rst stage used for bailout. KMDSI Part

#200- 017

NOTE: This valve can be adjusted for various relief pressures.

Over-Pressure Relief Valve

The rst stage regulator must have at least two low pressure ports. One

port is used for the connector hose to the emergency valve and the second

is used to install an over-pressure relief valve (Part #200-017). If the rst

stage develops a leak, the full pressure of the tank could be placed on the

low pressure hose. This could cause the hose to burst. The over-pressure

relief valve will bleed off any leak.

Note that the over-pressure relief valve is not supplied with the manifold

block, but must be purchased separately.

Never dive without an over-pressurization relief valve in-

stalled on the EGS regulator (1st stage). Without the relief

valve if the EGS regulator develops an internal leak, the full

pressure of the EGS cylinder would be placed on the low-

pressure EGS hose and the Emergency Gas Supply Valve.

This could cause the low-pressure hose to burst resulting

in the complete loss of the EGS system.

WARNING

Ensure the relief/bleed valve is only in-

stalled in a low-pressure port of the rst

stage regulator. Installation in a high-

pressure port will lead to loss of EGS sup-

ply and possible serious personal injury

if the valve fails.

WARNING

Kirby Morgan Manifold Block

© Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001 9

Manifold Block Maintenance

Daily- A daily pre-dive inspection should be done prior to using the

Manifold Block. Carefully inspect the assembly for any sign of damage or

worn components.

Tools: open end wrenches, 1”, 11/16”, 9/16”, 5/8” and a 5/16 Allen wrench.

1) Check to ensure all the port plugs are installed and are tight.

2) Check to ensure the emergency gas supply whip is installed and tight,

on the emergency valve

3) Using a 5/8” open-end wrench, check to ensure the packing nut on

the emergency valve is snug. Note: do not over tighten. The valve handle

should turn freely. Check to ensure the packing nut does not turn -when a

light force is applied with the wrench.

4) Ensure the non-return valve and umbilical adapter are securely in

place.

5) Test the one way valve by sucking on the inlet tting with your lips. If

any air is drawn through the valves the valve must be rebuilt or replaced.

Post Dive Procedures

Daily post dive maintenance of the manifold block requires a brushing

with a solution of mild soapy water and a thorough rinsing with fresh

water. If hoses have been removed, ensure port plugs have been installed

and the umbilical connection has been capped or bagged.

Kirby Morgan Manifold Block

10 © Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001

Annual Overhaul of the Manifold Block Assembly.

The KMDSI manifold block should be rebuilt on an annual basis, or

when damage or corrosion is suspected or found.

Tools required: Table vise, 1” open end wrench (2ea), l l/16”, 5/8”, and

9/16” open end wrenches, a large at blade screwdriver, 5/16 Allen

wrench, 0-300 in Ibs. Torque wrench, soft nylon tooth brush, brass O-ring

pick and a solution of 50/5O white vinegar and water.

Parts required:

Manifold Repair Kit #325-095

Tools and Materials Needed:

1. Vise and clean rags

2. 9/16”, 5/8”, 11/16” and 1” (2) open end wrenches

3. 5/32” hex wrench

4. Large at blade screwdriver

5. Torque wrench, 0 - 300 inch pounds

6. Soft Nylon tooth brush

7. O-ring pick

8. White vinegar

Disassembly of Manifold Block

1) Remove the two at head screws from the manifold backing plate, and

remove the plate.

2) Remove all hoses and port plugs. Remove the O-ring from each plug

and place the plugs in a solution of 50/50 white vinegar and water.

3) Using a soft jaw vise or a rag wrapped around the manifold block to

keep from marring the nish, remove the one way valve from the mani-

fold block using the 1” wrench.

NOTE: The one way valve must be removed from the manifold block

before the emergency valve.

4) Using the 9/16 open-end wrench, loosen and remove the emergency

valve from the manifold block.

5) Place the manifold block body in a solution of vinegar and water, and

allow to soak while the other components are being disassembled. Using

the 1” wrench and the 9/16” wrench, loosen and remove the umbilical

adapter tting. Place it in the vinegar solution.

Kirby Morgan Manifold Block

© Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001 11

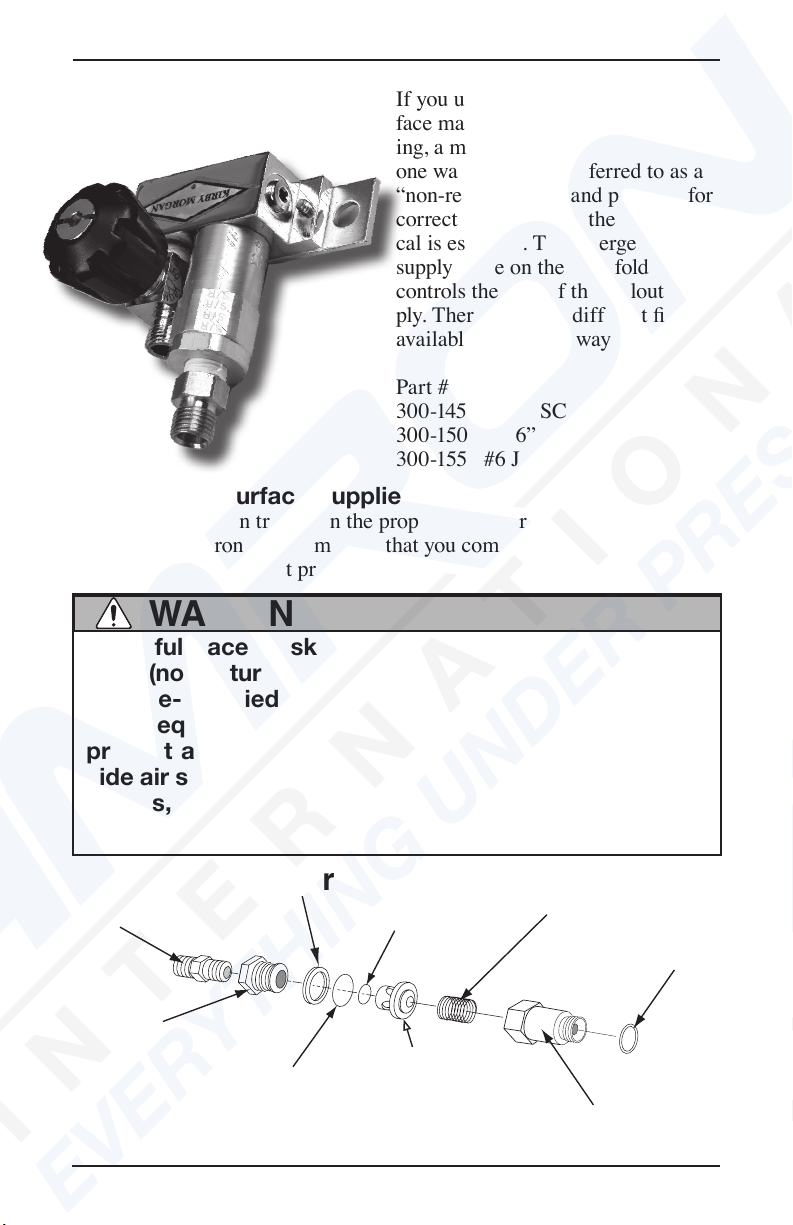

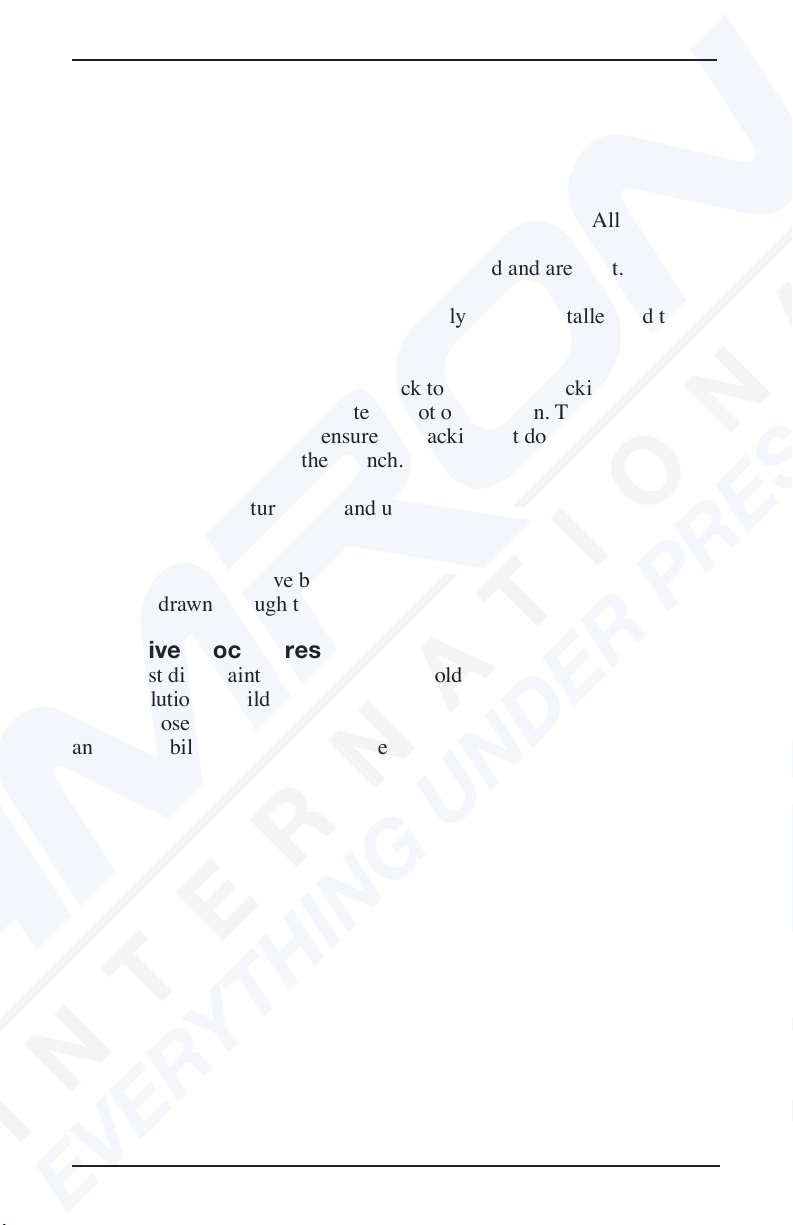

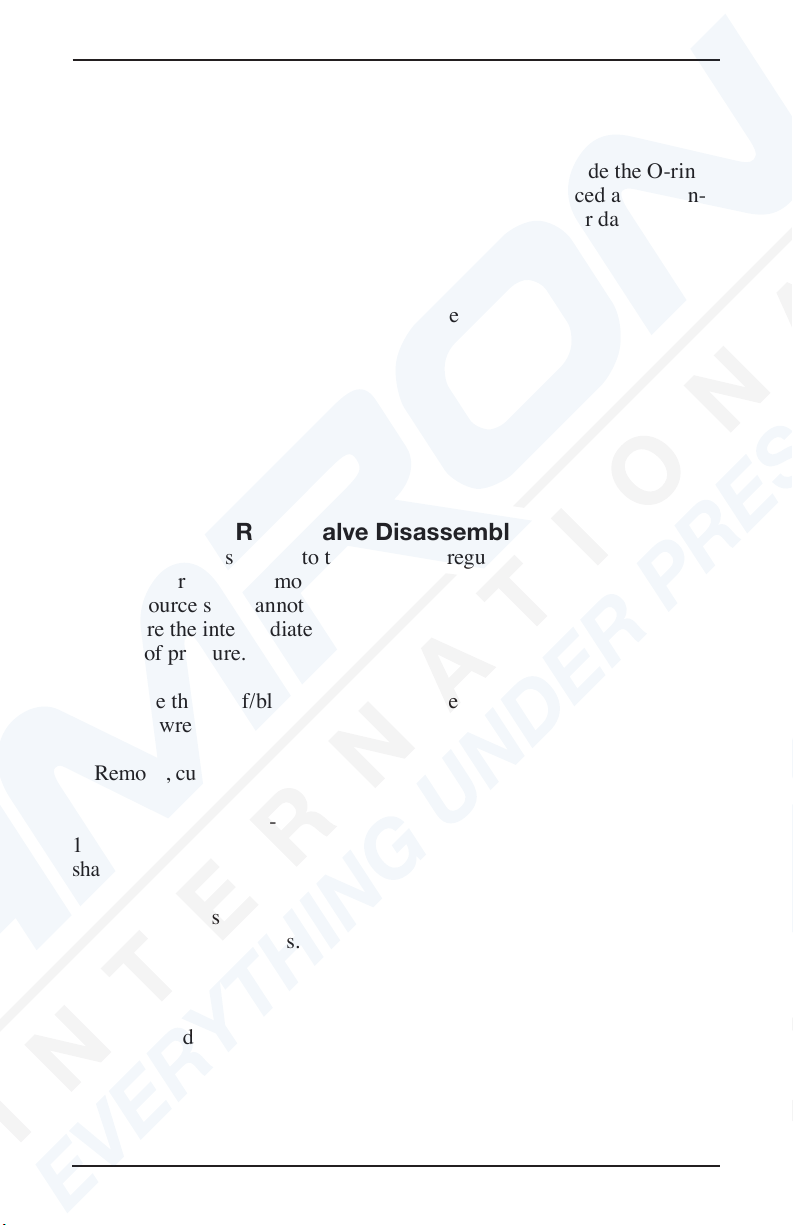

Lock

nut

Spring

Knob

Hose adapters

Valve

Stem

EGS Valve

Body

One-way

Valve

Low-pressure

plug

O-ring

Mounting

screw

Manifold Block Mounting

plate

Relief Valve for

EGS Regulator

Packing

Nut

Packing

Hole for

Shackle

Blow-apart drawing of

the manifold block

Kirby Morgan Manifold Block

12 © Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001

6) Carefully clean the manifold block body with a nylon toothbrush and

vinegar solution. Remove all traces of old lubricants, dirt and corrosion.

Rinse with fresh water and blow dry with compressed air or allow to air

dry. Using the nylon brush, clean the manifold plate and umbilical adapt-

er. Take special care to remove all the old Teon tape from the threads of

the umbilical adapter. Air or blow dry. Inspect all threaded ports for any

damage.

Adapter

Seat

Wiper

O-ring

O-ring

Poppet

Spring

Body

O-ring

Overhauling the One-Way Valve

Tools Required:

Soft Jaw Vice

1 inch Open End Wrench Attachment

on Torque Wrench

(If no vise is available use a backup 1 inch open end wrench)

To disassemble and inspect the one way valve assembly:

1) Use two wrenches or hold the hex part of the body in a soft jaw vise

while removing the seat with a wrench. As the seat is removed, the wiper

and the o-ring slide out in place in a groove on the seat. The poppet and

the poppet o-ring usually come out in the seat being followed by the

spring.

The only functional part remaining in the valve body is a non-moving,

pressed-in cage. The function of the cage is to contain the poppet during

high gas ows.

Do not use pliers on the main body of the one way valve.

You may damage the valve if pliers are used.

CAUTION

Components of the one-way valve.

Kirby Morgan Manifold Block

© Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001 13

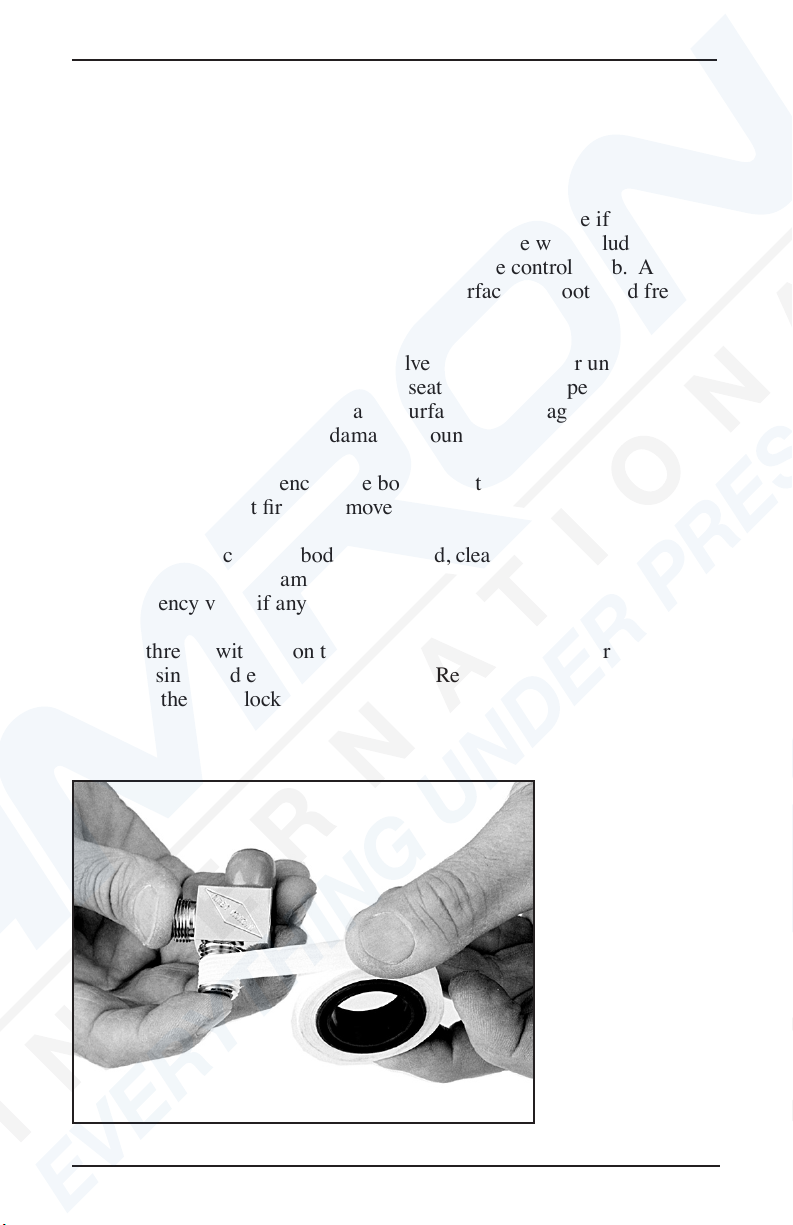

2) Inspect the body interior for foreign matter of any type and clean, if

necessary. Clean in accordance with the KMDSI cleaning instructions.

If corrosion is present, clean using the acidic solution as outlined in the

KMDSI cleaning procedures.

3) Inspect the seat, wiper, o-ring, poppet o-ring and poppet for wear,

replace if necessary. Be sure each part is clean and all components are

lightly lubricated with the appropriate lubricant. A repair kit is available

for replacement parts, (Part #525-330). All o-rings should be replaced

during normal/annual overhauls.

4) Be careful to wipe the poppet and poppet o-ring thoroughly, remov-

ing nearly all silicone to prevent foreign materials from sticking to these

components.

5) Inspect the spring and clean or replace as needed.

Reassembly of the One Way Valve

1) Slide the new o-ring over the poppet.

2) Insert the new spring into the valve body, followed by the poppet.

3) Next, install the new o-ring and new wiper on the seat. Thread the seat

into the valve body.

4) Tighten the seat to 150 inch lbs. (17 newton meters) with a torque

wrench while holding the body in a soft jaw vice or wrench.

5) If the adapter has been removed, it must be cleaned and wrapped with

Teon tape.

NOTE: The one way valve must be installed in the manifold block after

the emergency valve.

Do not allow any Teon tape to cover the end of the adapt-

er, or to enter the one-way valve. Loose pieces of Teon

tape can interfere with the performance of the one-way

valve or the regulator and may block the diver’s air supply.

This could lead to death through suffocation.

WARNING

Kirby Morgan Manifold Block

14 © Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001

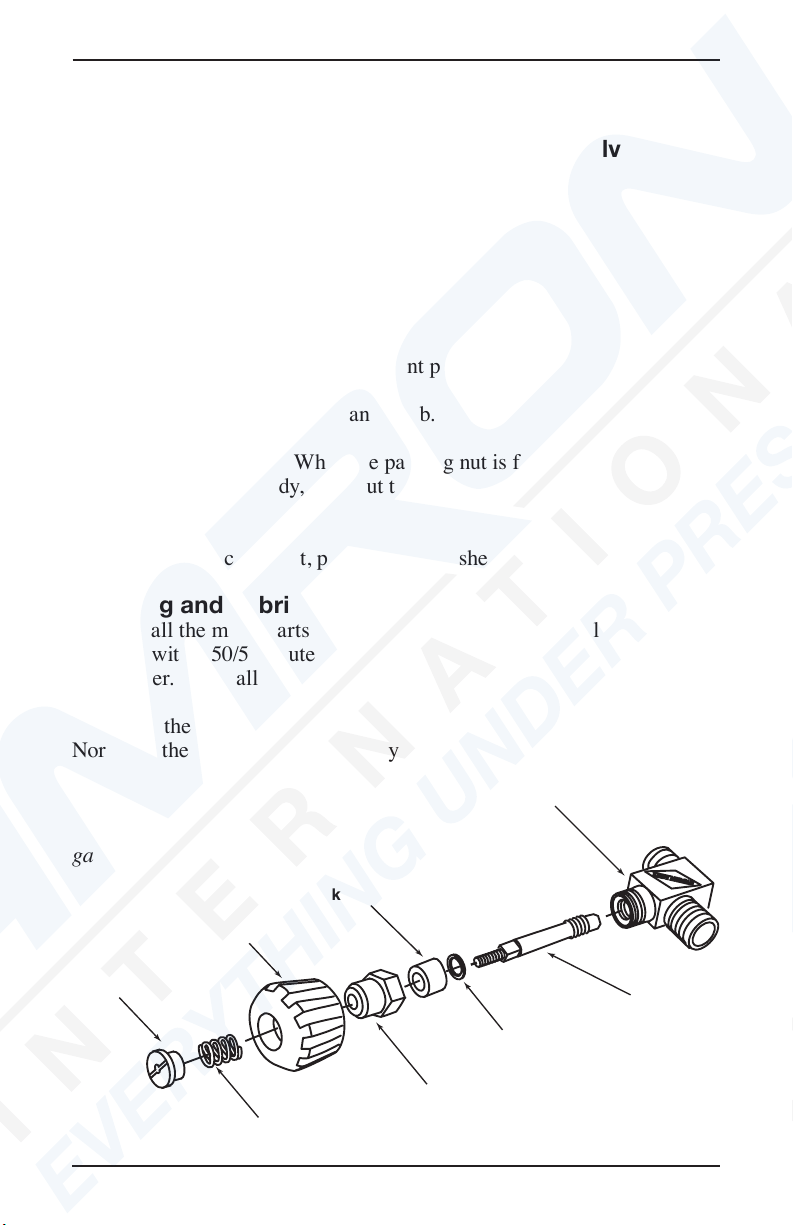

Valve Body

Valve Stem

Packing nut

Knob

Spring

Lock nut

Packing

Washer

6) Test the operation of the valve.

Disassembly of the Emergency Gas Supply Valve

Tools Required:

11/16 inch Open End Wrench

1 inch Open-end Wrench

Torque Wrench Attachments & Torque Wrench

3/8 inch Slotted Flat Blade Screwdriver

Soft Jaw Vice

Lubricant

Teon Tape

Normal minimum overhaul replacement parts: None

1) Remove the lock nut, spring, and knob.

2) Undo the packing nut. When the packing nut is free of the threads of

the emergency valve body, back out the stem until it is free of the emer-

gency valve body.

3) Remove the packing nut, packing, and washer from the stem.

Cleaning and Lubricating

1) Clean all the metal parts in a soap and water solution, followed by

cleaning with a 50/50 dilute solution of white vinegar/water. Rinse with

fresh water. Clean all parts.

2) Inspect the packing and washer for wear and replace if necessary.

Normally the packing will last a very long time and does not require

Components of the emergency

gas supply valve

Kirby Morgan Manifold Block

© Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001 15

replacement as long as the valve operates smoothly and does not leak. To

replace the packing place the packing nut in a vise and carefully work

the packing out with a small screw driver, taking care not to damage the

threads of the packing nut. Replace the washer.

3) Inspect the stem seat for unevenness or wear and replace if necessary.

It must also be replaced if the stem is bent. Damage will include dam-

aged threads, and/or rounded ats that engage the control knob. Also

inspect the shaft to ensure the conical seat surface is smooth and free of

corrosion or damage.

4) Check the seat in the emergency valve body for wear or unevenness,

galling and corrosion. To clean up the seat surface use a pencil eraser to

buff the surface. Inspect all threaded surfaces for damage. Replace the

emergency valve body if any damage is found.

5) To remove the emergency valve body from the side block the one way

valve assembly must rst be removed.

6) If the emergency valve body is removed, clean and inspect the pipe

thread and inspect for damaged threads, cracking, or distortion. Replace

the emergency valve if any damage is present.

Re-tape threads with Teon tape, 1 1/2 wraps starting two threads back.

Tighten using good engineering practice. Reinstall the emergency valve

body into the side block before installing the one way valve assembly.

Use only Teon

taped to seal the

emergency valve

in the manifold

block.

Kirby Morgan Manifold Block

16 © Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001

Reassembly of Emergency Valve

1) Lightly lubricate the stem threads in the body as well as the bonnet

threads.

2) Replace the washer and packing on the stem, then lightly lubricate the

stem shaft and threads.

3) Holding these components in place on the stem, screw the stem into

the emergency gas valve body.

4) Rotate the stem until it is seated all the way in then, back it out -1/2

turn.

5) T

hread the packing nut onto the emergency valve body. Run the nut in

and tighten slightly with a wrench.

6) Inspect the emergency gas valve knob for wear and damage. Ensure the

ats that engage the valve stem shaft are not rounded, cracked or damaged.

The valve knob should not have rotational play greater than 1/16th of a turn.

7) Place the emergency gas valve knob onto the stem and rotate the stem

all the way out, then back again. The rotation must be smooth. If “hard

spots” or unevenness are felt during the rotation, the stem may be bent

and could need replacement.

8) Tighten the packing nut with a torque wrench until moderate resis-

tance is felt when turning the knob. Torque to 50 inch pounds after seat-

ing.

9) Place the spring, and locknut onto the stem securing the knob.

10) Tighten the locknut until its top is ush with the top of the knob. The

assembly is now complete and ready for testing.

Do not use any sealant on pipe threads

on Kirby Morgan products other than

Teon tape or other approved sealants.

Other sealants may not be oxygen com-

patible and may lead to re or explosions

which may cause severe personal injury

or death.

WARNING

Kirby Morgan Manifold Block

© Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001 17

A leaking Emergency Gas Valve assembly can cause

the diver to exhaust his entire EGS (bailout) without

his knowledge. This may lead the diver to mistakenly

assume his EGS supply is available when it is not.

This could lead to panic or drowning in an emer-

gency. Any worn or damaged components must be

replaced.

WARNING

11) Test the valve by attaching it to an emergency air supply source. There

must be no leakage of gas past the stem or through the packing nut. Turn

on the bailout bottle and leave the supply on for several hours. There must

be no drop in pressure in the system if the valve is operating properly.

Overpressure Relief / Bleed Valve Overhaul Procedures

The relief/bleed valve should always be used on all Emergency Gas Sup-

ply (EGS/bail-out) rst stage regulators to prevent the hose from ruptur-

ing in the event the rst stage pressure creeps. The Kirby Morgan relief

body is made of stainless steel.

The basic components last a long time but the valve should be disas-

sembled, cleaned, and inspected at least once a year or whenever it fails

testing. The valve should be tested monthly. Cleaning and overhaul is

easily performed using a nylon toothbrush and a 50/50 solution of vinegar

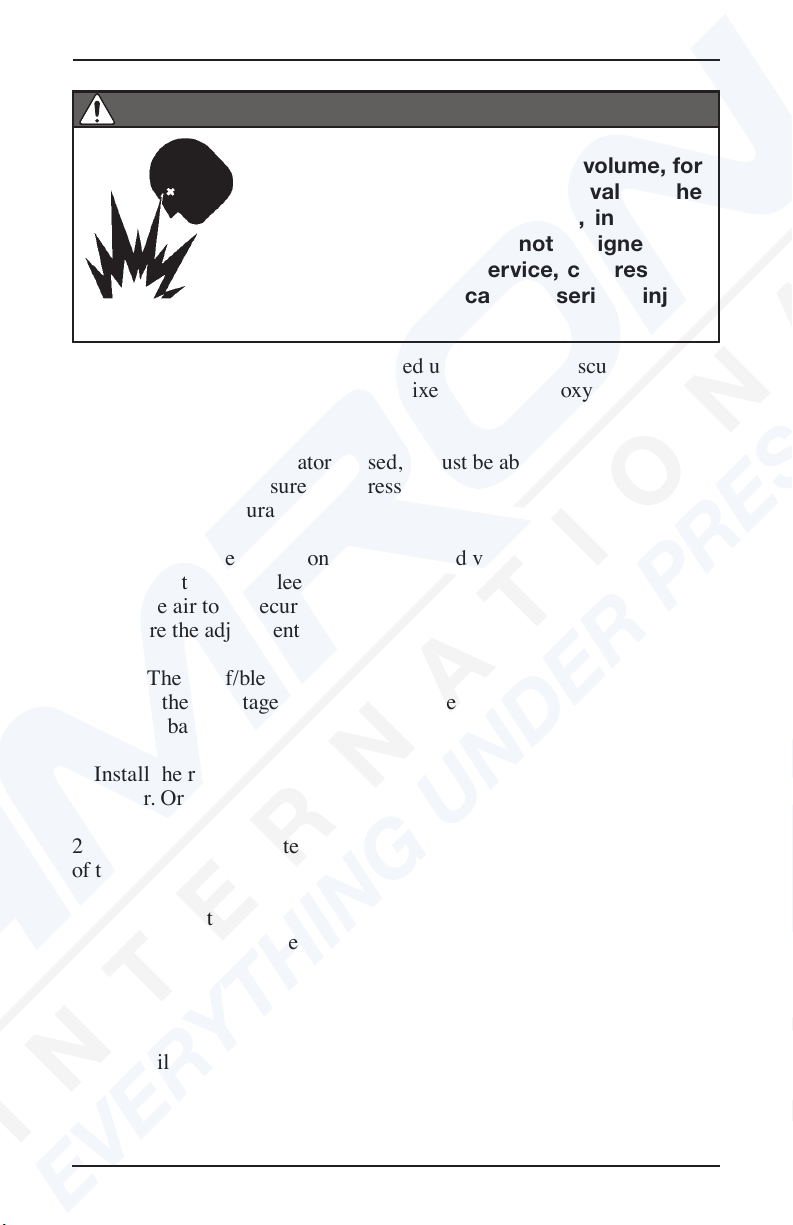

O-ring

Over-Pressure

Relief Valve Body

Seat

Spring

Adjustment

Screw

Kirby Morgan Manifold Block

18 © Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001

and fresh water. Cleaning for 15 minutes in an ultrasonic sink, if avail-

able, with the 50/50 vinegar solution is highly recommended.

Repair parts are available. Normal replacement parts include the O-ring,

soft seat, spring, and hex nut. The O-ring should be replaced at least an-

nually. The other parts require replacement only if worn or damaged.

Tools Required.

Torque wrench

1/2” open-end wrench attachment for torque wrench

1/8” Allen wrench

Nylon toothbrush

Vinegar, Fresh water

Mild dish soap

Ultrasonic sink, if available

Magnifying glass

New valve body o-ring

Overpressure Relief Valve Disassembly and Cleaning

1) Turn off the gas supply to the rst stage regulator, then bleed off any

remaining pressure. Remove the rst stage regulator from the air/breath-

ing gas source so it cannot be accidentally turned on, i.e., pressurized.

Make sure the intermediate pressure in the regulator hose is also fully

drained of pressure.

2) Remove the relief/bleed valve from the regulator body using the 1/2”

open-end wrench.

3) Remove, cut, and discard the relief/bleed valve body O-ring.

4) Using the 1/2” open-end wrench to hold the bleed/ relief body, use the

1/8” Allen wrench to remove the Allen head adjustment screw. Then,

shake out the spring and soft seat.

5) Place all parts in the 50/50 solution of vinegar and water and allow to

soak for 15 to 30 minutes. If using an ultrasonic sink, reduce time to 15

minutes.

6) Using the nylon toothbrush, brush all components to remove corrosion

and mineral deposits. Then, rinse with fresh water and blow or air dry.

7) Using the magnifying glass, carefully inspect all components for

excessive corrosion and/or damage. Replace the spring and/or adjustment

Kirby Morgan Manifold Block

© Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001 19

nut, if either part is excessively corroded or shows signs of wear and/or

damage.

Inspect the soft seat for nicks, cuts, and wear and replace if any damage

is found. Replace the entire assembly if any damage to the valve body is

present.

NOTE: A deep groove in the soft seat is normal. Replacement is only

necessary if the rubber seat is deteriorated, cut, and/or chipped.

Overpressure Relief Valve Reassembly

1) After cleaning, inspection and/or parts replacement, reassemble the

valve by installing the soft seat, spring, and adjustment nut. Screw the

adjustment nut down until it is approximately 1/2 thread from being ush

with the top of the valve body.

2) Lightly lubricate a new body O-ring, then install on the valve body.

3) Test the relief/bleed valve according to the test procedure below.

Overpressure Relief Valve Lift Check/Setting

Tools required:

Adjustable rst stage scuba regulator or controlled adjustable pressure

source

Intermediate pressure test gauge

Torque wrench

1/2” open-end wrench adapter for torque wrench

1/8” Allen wrench

HP air source {SCUBA tank) with at least 500 p.s.i.g. (34.4 bar).

Mild dish soap

The purpose of lift checking the relief/bleed valve is to ensure it oper-

ates properly, allowing excess pressure to escape in the event the rst stage

develops a slight leak. Without the relief/bleed valve, high-pressure gas will

continue to increase until the emergency supply hose ruptures, possibly caus-

ing injury and a complete loss of the Emergency Gas System (EGS).

This procedure explains the steps necessary for readjusting the relief/bleed

valve after it is cleaned, overhauled or any time the valve is tested.

NOTE: The relief/bleed valve is lift checked and/or adjusted using an

adjustable rst stage regulator, equipped with a low-pressure test gauge,

which is used for adjusting the intermediate pressure of scuba regulators.

Kirby Morgan Manifold Block

20 © Copyright ⅯⅯⅩⅢ Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 130329001

Do not use oxygen, or mixed gas contain-

ing more than 23% oxygen by volume, for

lift checking the relief/bleed valve. The

use of oxygen, or mixed gas, in a high-

pressure supply system not designed and

cleaned for oxygen service, can result in

a re or explosion causing serious injury

or death.

DANGER

The check/adjustment can be performed using a standard scuba test stand,

or a gas control console, using air or mixed gas with an oxygen content

below 23% by volume.

If a rst stage scuba regulator is used, it must be able to be adjusted to

the desired lifting pressure. The pressure gauge should be compared to a

gauge of known accuracy.

NOTE: If the Allen screw on the relief/bleed valve hex nut is rotated too

far, too fast, the relief/bleed valve will pop open. This could possibly

require the air to be secured at the cylinder or supply source to reset the

seat before the adjustment can be accomplished.

NOTE: The relief/bleed valve can be installed in any rst stage regulator,

providing the rst stage has an intermediate setting of 135 - 165 p.s.i.g.

(9.3 – 11.4 bar).

1) Install the relief valve in a low-pressure port on an adjustable 1st stage

regulator. Or install on the scuba test stand.

2) Install the intermediate pressure gauge in one of the low-pressure ports

of the rst stage regulator.

3) Install the 1st stage regulator on the cylinder. Ensure the relief valve

and intermediate pressure gauge are attached to low-pressure ports.

4) Wet the relief valve with soapy water to help indicate gas ow.

5) Slowly bring up air pressure while watching the intermediate pressure

gauge until the pressure gauge indicates 180- 200 p.s.i.g. (12.40-13.78

bar). If the relief valve starts venting at a pressure below 180- 200 p.s.i.g.

(12.40-13.78 bar), secure the air supply and adjust the adjustment screw

This manual suits for next models

2

Table of contents

Other Dive System Diving Instrument manuals