3

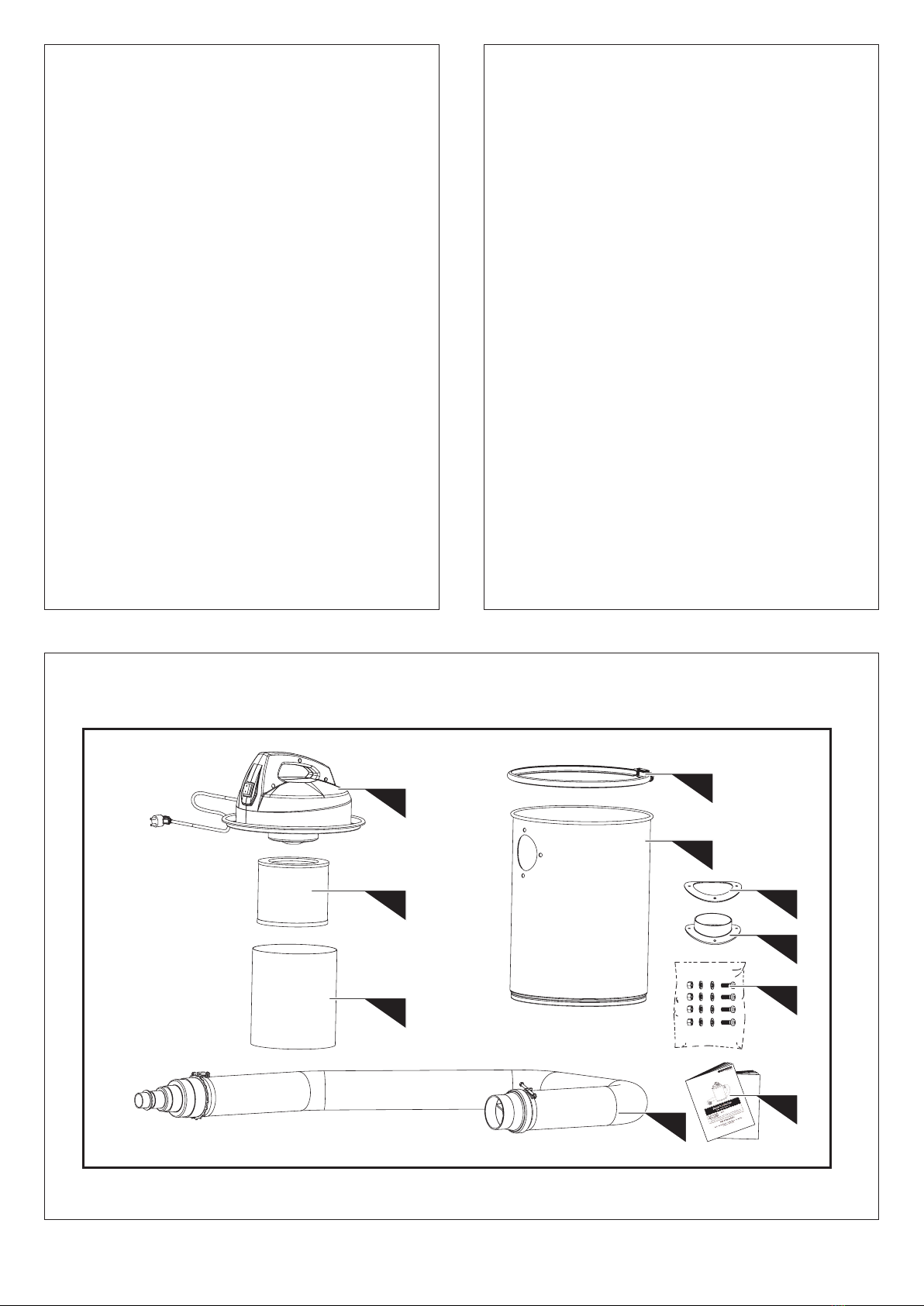

3. Unpacking

●Open the packaging and remove the device carefully.

●Remove the packaging material as well as the

packaging and transport bracing (if available).

●Check if the delivery is complete.

●Check the device and accessory parts for transport

damage.

●If possible, store the packaging until the warranty

period has expired.

ATTENTION

The device and packaging materials are not toys!

Children must not be allowed to play with plastic

bags, film and small parts! There is a risk of

swallowing and suffocation!

4. Safety

a) General Safety Rules

Understand your Machine

Read this manual and labels affixed to the machine to

understand its limitations and potential hazards.

Be thoroughly familiar with the controls and their

proper operation. Know how to stop the machine and

disengage the controls quickly.

Do not attempt to operate the machine until you fully

understand how to properly operate and maintain

the engine and how to avoid accidental injuries and/or

property damage.

If the unit is to be used by someone other than original

purchaser or loaned, rented, or sold, always provide

this manual and any needed safety training before

operation. The user can prevent and is responsible for

accidents or injuries that may occur to themselves,

other people, and property.

Do not force the machine. Use the correct machine for

your application. The correct machine will do the job

more efficiently and safer at the rate it was designed.

Personal Safety

Do not permit children to operate this machine at any

time.

Keep children, pets, and other people not using the

unit away from the work area. Be alert and shut off

unit if anyone enters work area. Keep children under

the watchful care of a responsible adult.

Do not operate the machine while under the influence

of drugs, alcohol, or any medication that could affect

your ability to use it properly.

Dress properly. Wear heavy long pants, boots, and

gloves. Do not wear loose clothing, short pants, or

jewelry of any kind. Secure long hair so it is above

shoulder level. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts.

safety glasses with side shields when operating.

Protect eyes, face, and head from objects that may be

thrown from the unit. Always wear safety goggles or

safety glasses with side shields when operating.

Wear appropriate hearing protection. Wear respiratory

protection to avoid the risk of inhaling harmful dust.

Always keep hands and feet away from all moving

parts during operation. Moving parts can cut or crush

body parts.

Always keep hands and feet away from all pinch

points.

Do not touch parts that might be hot from operation.

Allow parts to cool before attempting to maintain,

adjust, or service.

Stay alert, watch what you are doing, and use common

sense when operating the machine.

Do not overreach. Do not operate the machine

while barefoot or when wearing sandals or similar

lightweight footwear. Wear protective footwear that

will protect your feet and improve your footing on

slippery surfaces. Keep proper footing and balance at

all times. This enables better control of the machine in

unexpected situations.

Inspect your Machine

Check your machine before starting it. Keep guards in

place and in working order. Make sure all nuts, bolts,

etc., are securely tightened.

Never operate the machine when it is in need of

repair or is in poor mechanical condition. Replace

damaged, missing, or failed parts before using it.

Keep the machine in safe working condition. Regularly

check to see that keys and adjusting wrenches are

removed from the machine area before starting it. A

wrench or a key that is left attached to a rotating part

of the machine may result in personal injury. Avoid

accidental starting. Be sure the motor switch is off

before transporting the machine or performing any

maintenance or service on the unit.

Transporting or performing maintenance or service on

a machine with its switch on invites accidents. If the

machine should start to vibrate abnormally, stop the

motor and check immediately for the cause. Vibration

is generally a warning sign of trouble.

Electric Safety

Protect yourself from electric shock. Do not plug or

unplug the motor while standing in or around damp

or wet ground. Do not use the unit in wet or damp

areas or expose it to rain. Prevent body contact with

grounded surfaces: pipes, radiators, ranges, and

refrigerator enclosures. Make sure your fingers do

not touch the plug’s metal prongs when plugging or

unplugging the unit.

Avoid inadvertent starting. Make sure that the switch

is switched off when plugging the plug into an outlet.

Only use approved and appropriately identified

extension cables for use outdoors. Only use cable reels

in the unrolled state.