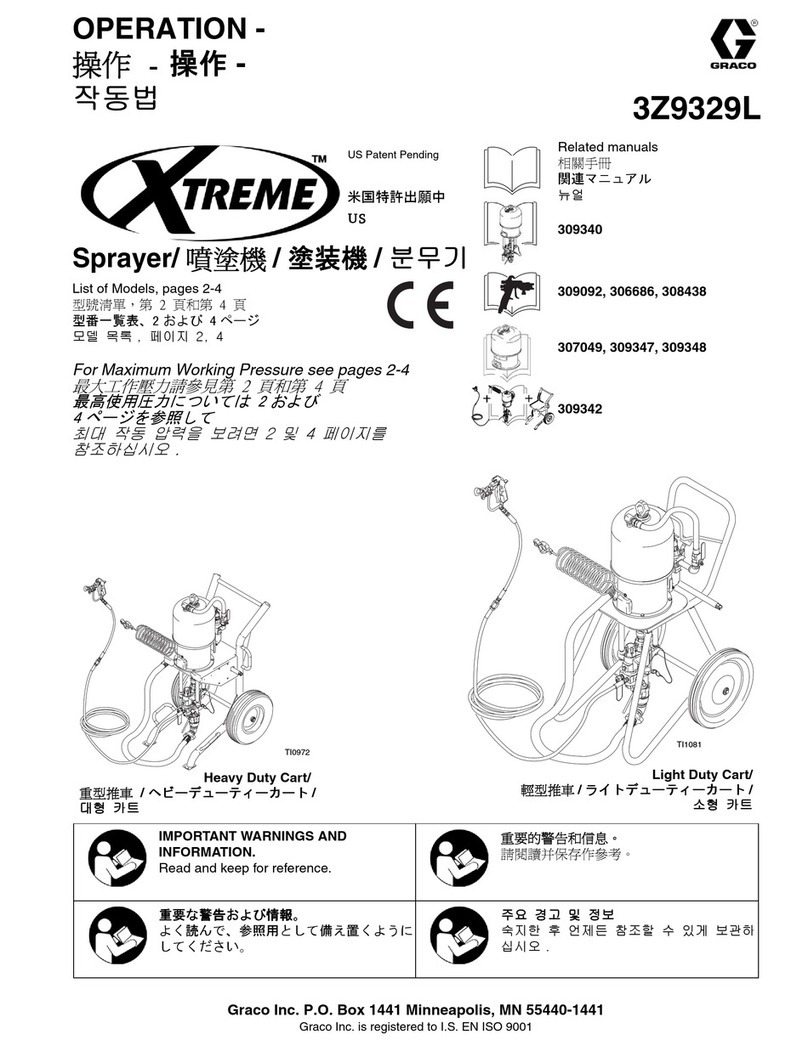

Graco T Series Operation manual

Other Graco Paint Sprayer manuals

Graco

Graco True Airless ProLTS 190 User manual

Graco

Graco Ultra-lite 235627 Datasheet

Graco

Graco 231-351 Operation manual

Graco

Graco 246220 User manual

Graco

Graco Finishpro 390 User manual

Graco

Graco Magnum X5 User manual

Graco

Graco Reactor H-25 Series Use and care manual

Graco

Graco Magnum 261825 User manual

Graco

Graco MAGNUM PROJECT PAINTER PLUS Instruction Manual

Graco

Graco 241284 User manual

Graco

Graco XM Series User manual

Graco

Graco DURON Performance 390 User manual

Graco

Graco 289353 Parts list manual

Graco

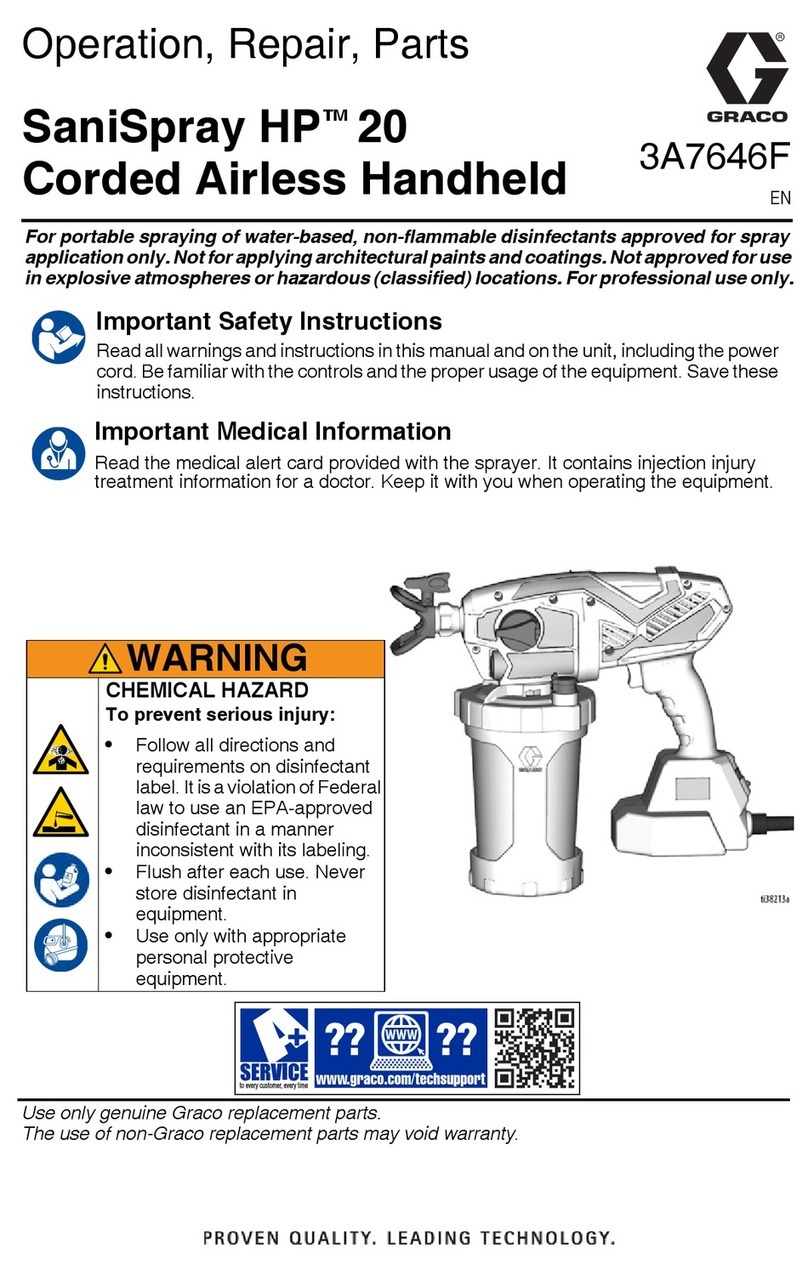

Graco SaniSpray HP 20 Use and care manual

Graco

Graco XTR A Series User manual

Graco

Graco T-Max Applicator 256383 Use and care manual

Graco

Graco 310624E User manual

Graco

Graco Reactor E Series User manual

Graco

Graco GH 200 Instruction Manual

Graco

Graco 2K device EcoMix 2000 Operation manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual