Page 5 of 11

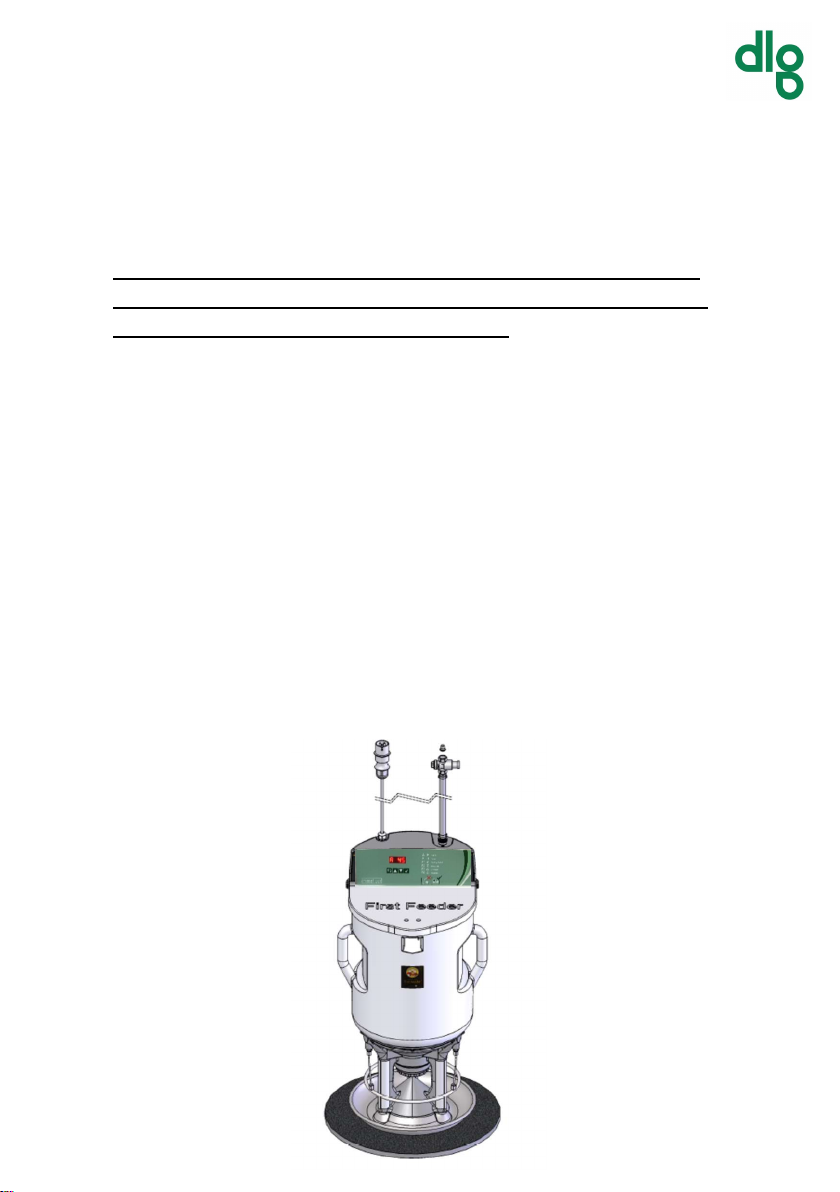

3 Principle of operation:

First Feeder settings are divided into feeding periods of one hour

each. For each hour it is possible to indicate the number of minutes

in which the feed is to be available for the piglets.

At the beginning of each feeding period the device makes a buzzing

sound and at the same time a portion of feed is dispensed.

When the piglets activate the feeding ring, the automatic device

releases 10 gram of feed and then adds water in accordance with

the desired dry matter content. The sensor ensures that

the trough does not become overfilled and the feed is always fresh

and hygienic.

4 Placement and connection:

The First Feeder device is designed for indoor operation in a frost-

free space.

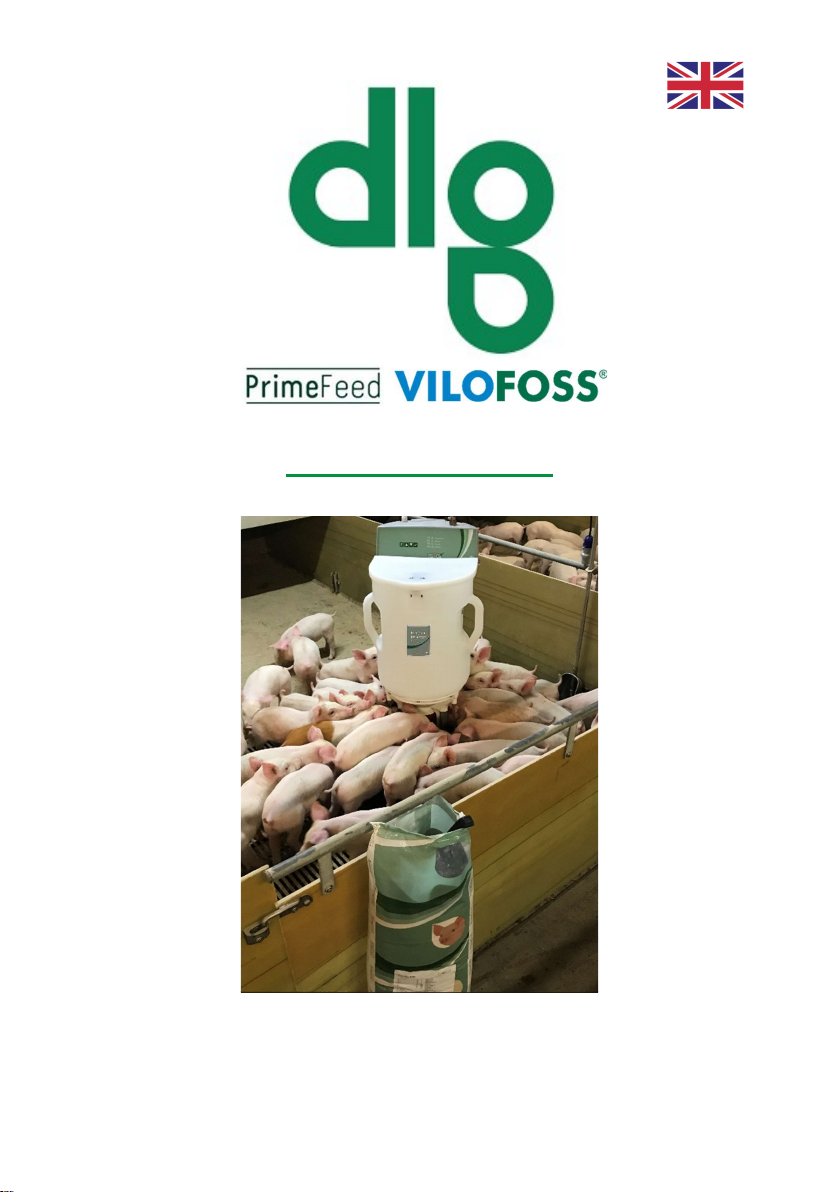

After thorough cleaning, First Feeder® should be placed in the

middle of a piglet box (max. 50 piglets pr. device).

Connect First Feeder to 230 V power supply socket with earth wire.

The installation must be protected with a ground fault circuit

interrupter.

Use square cable with a thickness of at least 1.5 /translator’s

remark: no unit is mentioned in the source text/. Make sure that the

cable is laid in a safe way, so that there is no risk of it getting

damaged, either by the piglets or by the wheels of carts, etc.