DMF RW-1019 Quick start guide

DIVERSIFIED METAL FABRICATORS, INC.

DMF 665 Pylant Street Atlanta, Georgia 30306

Parts (404) 607-1684 Parts Fax (404) 879-7888 parts@dmfatlanta.com

Service Department (404) 879-7882 service@dmfatlanta.com

Phone (404) 875-1512 Fax (404) 875-4835 info@dmfatlanta.com

http://www.dmfatlanta.com

Parts & Service Manual

RW-1019/1212

Chipper Railgear

May 2020

SERIAL NUMBER (FRONT) ________________________

SERIAL NUMBER (REAR) ________________________

NOTE:

Please refer to the serial numbers when ordering parts or

inquiring about warranty items.

DIVERSIFIED METAL FABRICATORS, INC. CHIPPER RAILGEAR

© 2020 DMF, Inc. All Rights Reserved.

Message from DMF

No matter what your job function is, Operation, Installation, Maintenance, or Repair, it is your

responsibility to familiarize yourself with the entire manual. Once you have read the entire

manual, there are some specific sections that you will want to pay special attention to,

depending on your role.

If you find anything missing, incorrect or unclear in this manual, please contact us. We are

always trying to improve our manuals.

Manuals, service bulletins and general information are available on our website listed below.

We reserve the right to update our manuals without notice. You can download a current manual

at our website (http://www.dmfatlanta.com).

Thank you for choosing DMF Railgear. We make every effort to provide quality, safe and rugged

products for the railroad. We hope you'll find our gear to be satisfactory in every way. We take

product support very seriously, so if you have any questions, please contact us.

Contact:

Diversified Metal Fabricators

665 Pylant St. NE

Atlanta, GA 30306

(404) 875-1512

(404) 875-4835 Fax

(404) 607-1684 Parts

http://www.dmfatlanta.com

info@dmfatlanta.com

Ship to:

668 Drewry St. NE

Atlanta, GA 30306

DIVERSIFIED METAL FABRICATORS, INC. CHIPPER

RAILGEAR

© 2020 DMF, Inc. All Rights Reserved.

TABLE OF CONTENTS

SECTION 1.0 GENERAL INFORMATION

1.1 General Description, Weights & Capacities ...............1-2

1.2 Chipper Railgear ...................................................1-3

SECTION 2.0 OPERATIONS

2.1 Before You Operate the Railgear .............................2-2

2.2 Highway Operation ...............................................2-3

2.3 Getting On the Rail ...............................................2-4

2.4 Getting Off the Rail ...............................................2-6

SECTION 3.0 ROUTINE MAINTENANCE

3.1 Inspection and Maintenance ...................................3-2

3.2 Fluids and Lubrication ...........................................3-4

3.3 Wheel Wear Gauge ...............................................3-5

3.4 Derailment ...........................................................3-7

SECTION 4.0 RAILGEAR INSTALLATION

4.1 Pre-Install ............................................................4-2

4.2 Initial Instructions ................................................4-6

4.3 General Information ..............................................4-7

4.4 Installation of Chipper Railgear ...............................4-8

4.5 Alignment and Rail Test Procedures ........................4-14

SECTION 5.0 RAILGEAR OPTIONS

5.1 Rail Sweeps .........................................................5-2

5.2 Rail Brakes ..........................................................5-6

SECTION 6.0 HYDRAULIC SYSTEM

6.1 General Information ..............................................6-2

6.2 Hydraulic & Electrical Schematics ............................6-6

6.3 Hydraulic and Electrical Component Drawings ..........6-12

SECTION 7.0 REAR RAILGEAR PARTS

7.1 Before Ordering Parts ............................................7-2

7.2 Assembly Drawings ...............................................7-3

7.3 Axle Drawings ......................................................7-6

DIVERSIFIED METAL FABRICATORS, INC. CHIPPER

RAILGEAR

© 2020 DMF, Inc. All Rights Reserved.

LIST OF FIGURES/TABLES

Figure 1.2.1 RW-1019 Chipper Railgear Components ........................1-3

Figure 1.2.2 RW-1212 Chipper Railgear Components ........................1-4

Figure 4.3 RW-1019 Chipper Railgear Major Components ...............4-7

Figure 4.4.1.A Tower Assembly Alignment w/ Axle ..............................4-8

Figure 4.4.1.B Selecting a Common Alignment Reference Point .............4-9

Figure 4.4.1.C Stowed & Deployed Measurements RW-1019 .................4-10

Figure 4.4.1.D Stowed & Deployed Measurements RW-1212 .................4-10

Figure 4.4.1.E Tower Assembly Alignment ..........................................4-11

Figure 4.4.1.F Axle Rod Pin, Axle Lugs & Cylinder Interface ..................4-12

Figure 4.4.1.G Axle Lug Weldment ....................................................4-12

Figure 4.4.1.H Alignment of Second Axle ............................................4-13

Figure 4.5.1 Railgear Alignment Single Axle .....................................4-15

Figure 4.5.2 Railgear Alignment Dual Axles .....................................4-16

Figure 5.2.1 Rail Brake Adjustment ................................................5-6

Table 4.1.6 Manufacturer Equivalent Welding Rod ...........................4-5

DIVERSIFIED METAL FABRICATORS, INC. CHIPPER RAILGEAR

`

© 2020 DMF, Inc. All Rights Reserved. 1-1

SECTION 1.0 GENERAL INFORMATION

1.1 GENERAL DESCRIPTION, WEIGHTS & CAPACITIES ......................................... 1-2

1.1.1 Weights and Capacities .................................................................................... 1-2

1.1.2 Installation ..................................................................................................... 1-2

1.1.3 Options.......................................................................................................... 1-2

1.1.4 Brakes ........................................................................................................... 1-2

1.2 CHIPPER RAILGEAR ....................................................................................... 1-3

1.2.1 RW-1019 Chipper Railgear Components ............................................................. 1-3

1.2.2 RW-1212 Chipper Railgear Components ............................................................. 1-3

DIVERSIFIED METAL FABRICATORS, INC. CHIPPER RAILGEAR

1-2 © 2020 DMF, Inc. All Rights Reserved.

1.1 GENERAL DESCRIPTION, WEIGHTS & CAPACITIES

DMF’s Chipper Railgear is designed for tow behind chippers. The Railgear completely lifts the

chipper tires above rail when deployed. This allows for various tracked chippers to be used on

the same gauge rail.

Two version of the Chipper Railgear are offered. The first version, RW-1019 Chipper Railgear

uses a RW-1019 standard 10” wheel and axle assembly. The gear is actuated by two hydraulic

cylinders per axle. RW-1019 Chipper Railgear is standard for most applications and tailored for

lighter chippers. The second version, RW-1212 Chipper Railgear uses a RW-1212 standard 12”

wheel and axle assembly. This gear uses four hydraulic cylinders per axle. The RW-1212

Chipper Railgear is used only in applications where the chipper is too heavy for standard RW-

1019 Chipper Railgear.

1.1.1 Weights and Capacities

Chipper Railgear Capacity per Railgear Axle @ 20 MPH:

RW-1019 Chipper Railgear: ~8,200 lbs.

RW-1212 Chipper Railgear: ~12,300 lbs.

Chipper Railgear installed weights per axle, no brakes:

RW-1019 Chipper Railgear: ~300 lbs.

RW-1212 Chipper Railgear: ~540 lbs.

1.1.2 Installation

The DMF Chipper Railgear assemblies were designed to minimize the mounting space needed

with minimal modifications to the trailer. The Chipper Railgear is mounted just behind the rear

axle where space is available. The Railgear can be ordered with a second axle, for mounting to

the front of the frame. Spacing should be considered to balance the chipper when the Railgear

is deployed. It should be noted that chippers requiring a second axle must be towed with a

drawbar.

1.1.3 Options

There are multiple options available when ordering a set of Chipper Railgear. The most

commonly ordered options include rail wheel brakes for aided stopping on rail, insulated wheels

to prevent crossing signal actuation and rail sweeps to clear the rail of potentially damaging

materials.

1.1.4 Brakes

NOTE:

Primary braking effort is provided from the towing vehicle when operating on rail. The rail

wheel brake system is intended to assist the vehicle. If the existing vehicle brakes are not

maintained in good working order, the rail wheel brakes are not capable of independently

stopping the vehicle in reasonably short distances.

The optional brakes are hydraulically actuated from the supplied Railgear power unit. When

enabled, the chipper brakes are applied when the brakes are applied in the tow vehicle. A

timer is used to limit the run time of the pump to prevent overuse.

DIVERSIFIED METAL FABRICATORS, INC. CHIPPER RAILGEAR

`

© 2020 DMF, Inc. All Rights Reserved. 1-3

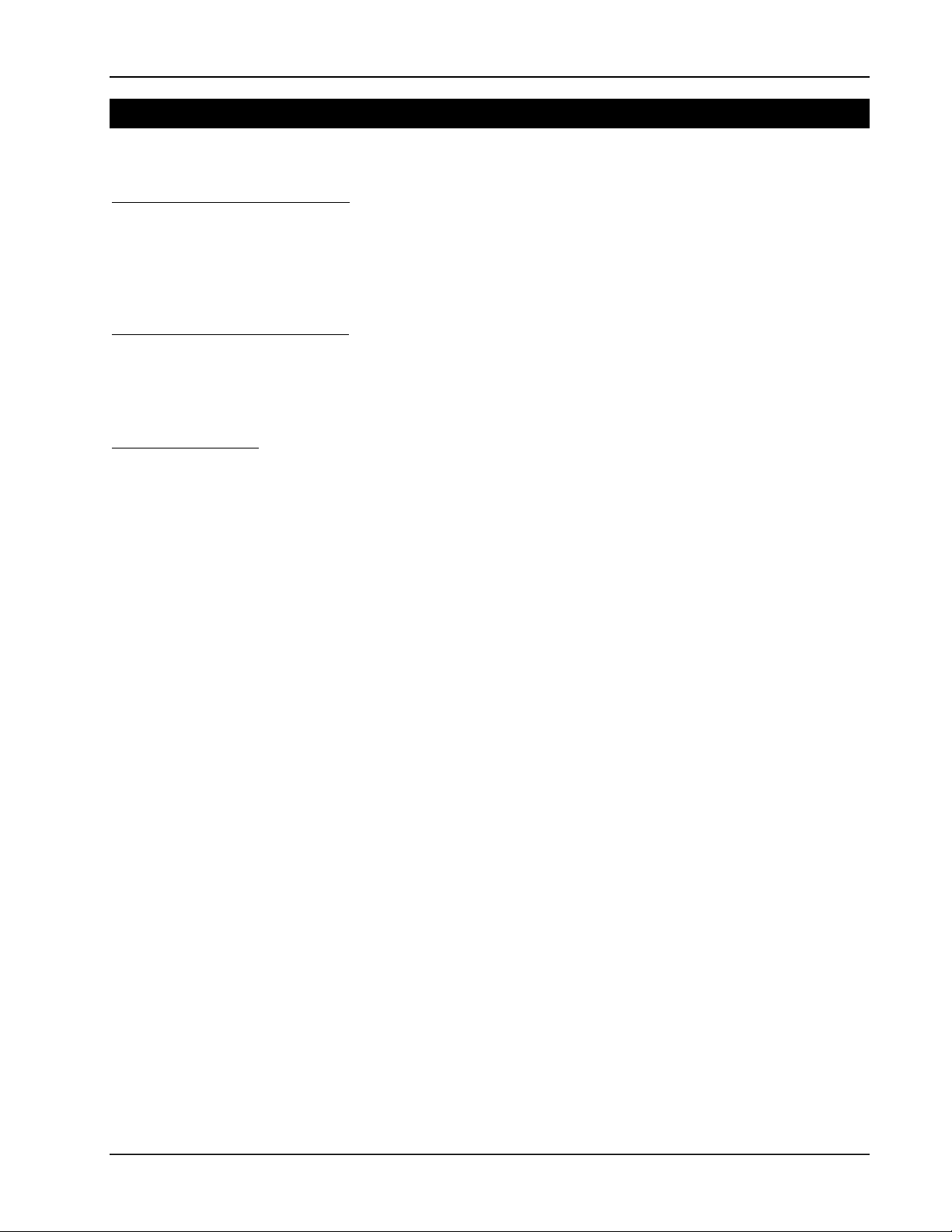

1.2 CHIPPER RAILGEAR

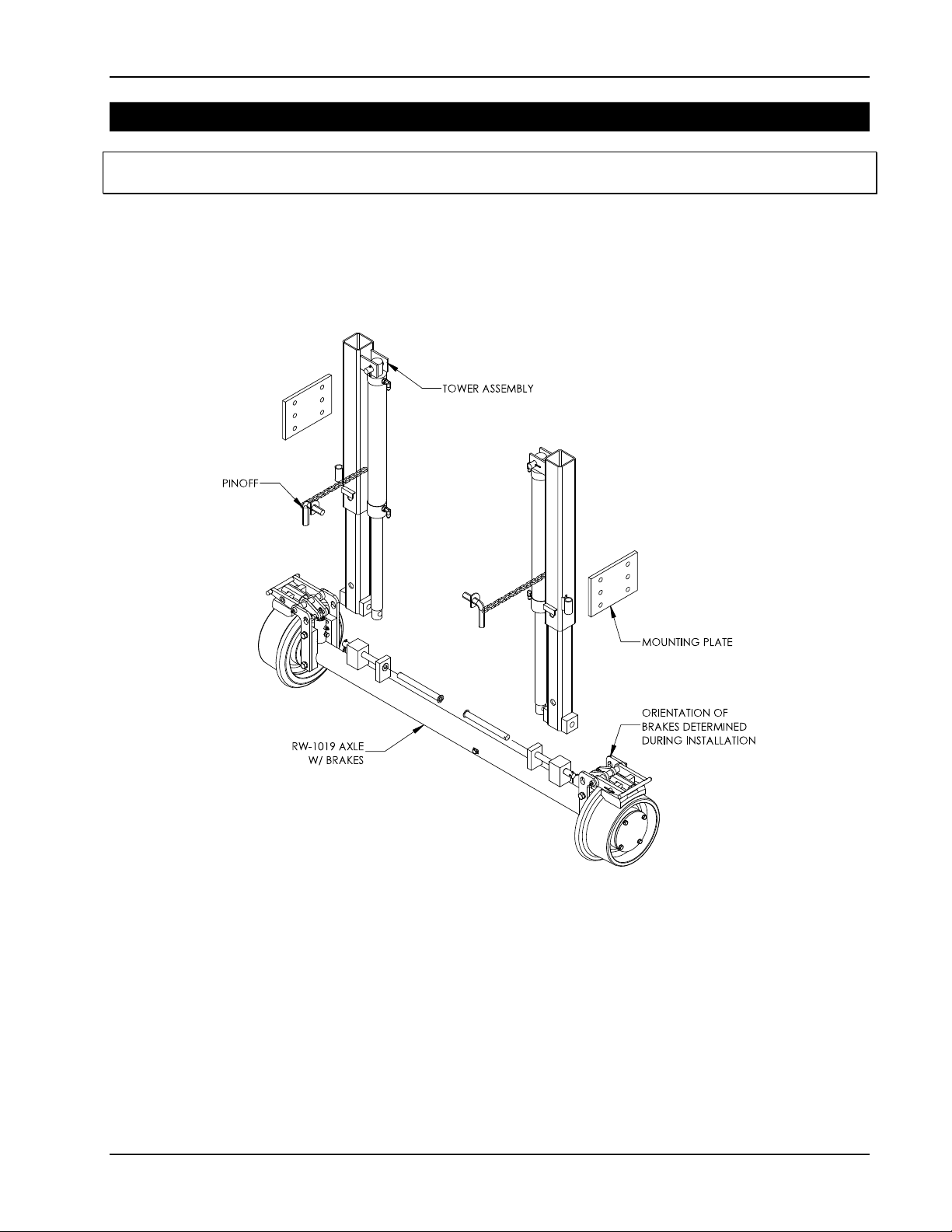

NOTE:

The orientation of brakes can be installed vertically or horizontally to improve brake clearances.

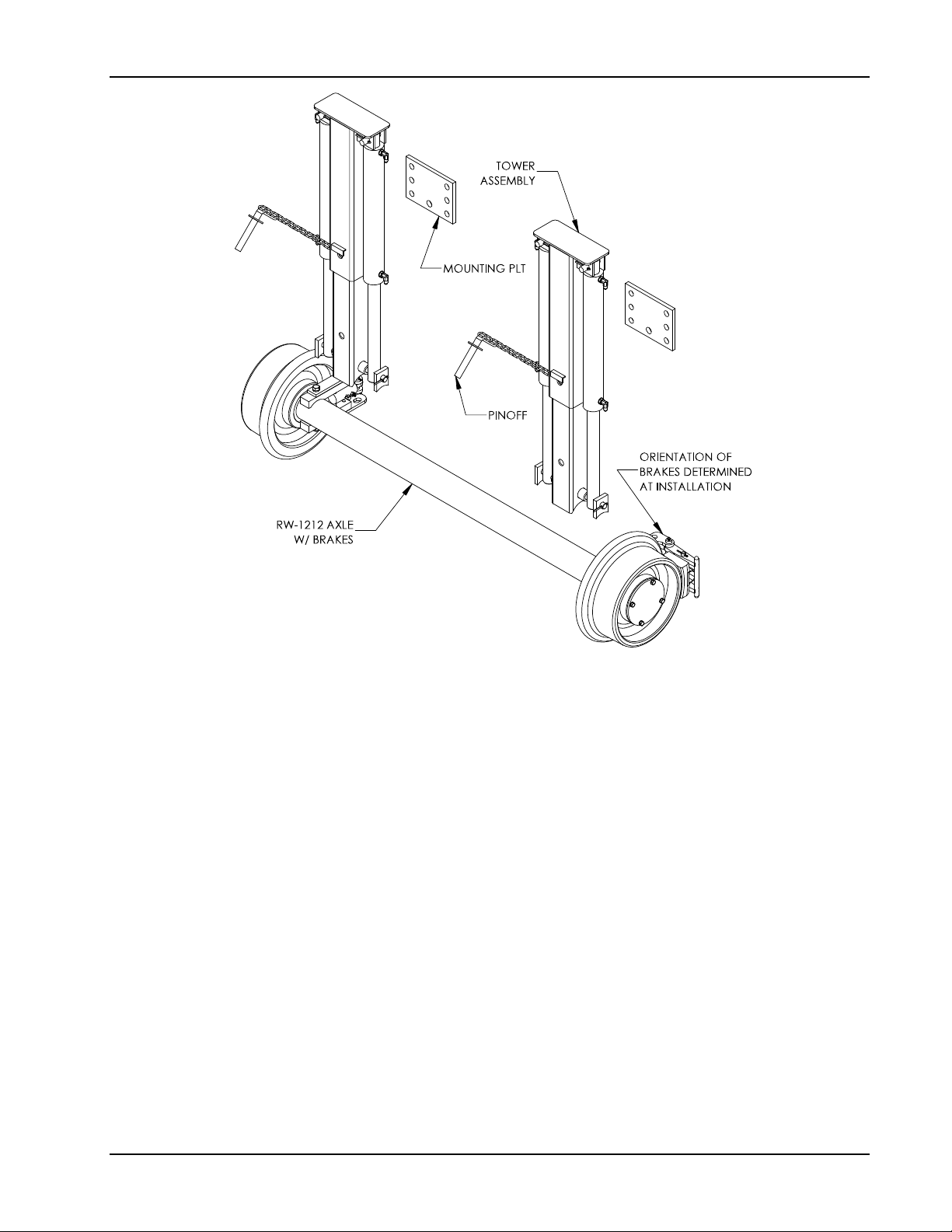

1.2.1 RW-1019 Chipper Railgear Components

Figure 1.2.1 identifies the key components of the RW-1019 Chipper Railgear. Appearances will

vary depending on the selected Railgear options. These item descriptions will be used

throughout this manual.

Figure 1.2.1 RW-1019 Chipper Railgear Components

1.2.2 RW-1212 Chipper Railgear Components

Figure 1.2.2 identifies the key components of the RW-1212 Chipper Railgear. Appearances will

vary depending on the selected Railgear options. These item descriptions will be used

throughout this manual.

DIVERSIFIED METAL FABRICATORS, INC. CHIPPER RAILGEAR

1-4 © 2020 DMF, Inc. All Rights Reserved.

Figure 1.2.2 RW-1212 Chipper Railgear Components

DIVERSIFIED METAL FABRICATORS, INC. CHIPPER RAILGEAR

© 2020 DMF, Inc. All Rights Reserved. 2-1

SECTION 2.0 OPERATIONS

2.1 BEFORE YOU OPERATE THE RAILGEAR ........................................................... 2-2

2.1.1 Familiarization of Railgear ................................................................................ 2-2

2.2 HIGHWAY OPERATION ................................................................................... 2-3

2.3 GETTING ON THE RAIL ................................................................................... 2-4

2.3.1 Getting Onto the Tracks ................................................................................... 2-4

2.3.2 Lowering Guide Wheels – Single Axle ................................................................ 2-4

2.3.3 Lowering Guide Wheels – Dual Axles ................................................................. 2-4

2.3.4 On the Tracks ................................................................................................. 2-5

2.4 GETTING OFF THE RAIL .................................................................................. 2-6

2.4.1 Single Axle ..................................................................................................... 2-6

2.4.2 Dual Axles ..................................................................................................... 2-6

DIVERSIFIED METAL FABRICATORS, INC. CHIPPER RAILGEAR

2-2 © 2020 DMF, Inc. All Rights Reserved

2.1 BEFORE YOU OPERATE THE RAILGEAR

2.1.1 Familiarization of Railgear

Clearances & Approach Angles

Installation of Railgear typically reduces ground clearance, with the rail wheels resting below

the frame of the chipper. This must be taken into consideration by the operator when

maneuvering on-road and positioning for Railgear deployment. To avoid equipment and

property damage, operators should be familiar with the modified clearances and working

envelope before towing.

Pin Off Systems and Locations

Walk around the chipper and identify the location and type of Railgear pin off system installed.

Locking valves are provided for each cylinder. Pin Offs are installed on both sides of the

Railgear assembly. It is required that the Pin Offs are used when the Railgear is in both the

highway and rail positions.

Operation Controls

Locate and be familiar with the location of the Railgear operating controls.

Locate the Hydraulic Power Unit, its power source and power switch on the trailer.

If the truck is equipped with Railgear brakes, locate the brake switch. This switch

should only be enabled on rail to avoid continuously running the hydraulic Power Unit.

This manual suits for next models

1

Table of contents

Other DMF Industrial Equipment manuals