ii

TABLE OF CONTENTS

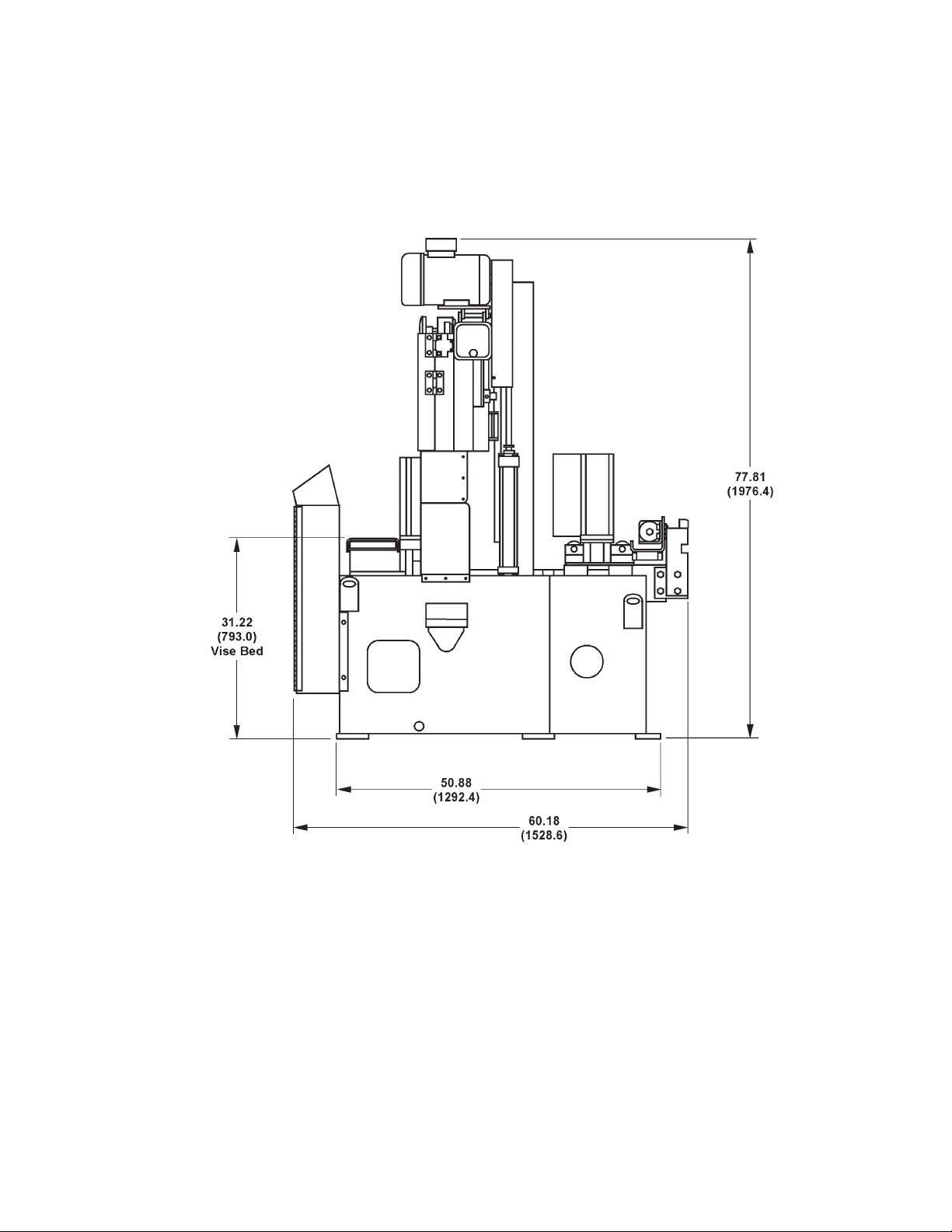

MACHINE DIMENSIONS

Floor Plan ............................................................... 1

Front View ............................................................. 2

Side View ................................................................ 3

MACHINE FEATURES

Front View .............................................................. 4

Rear View ............................................................... 5

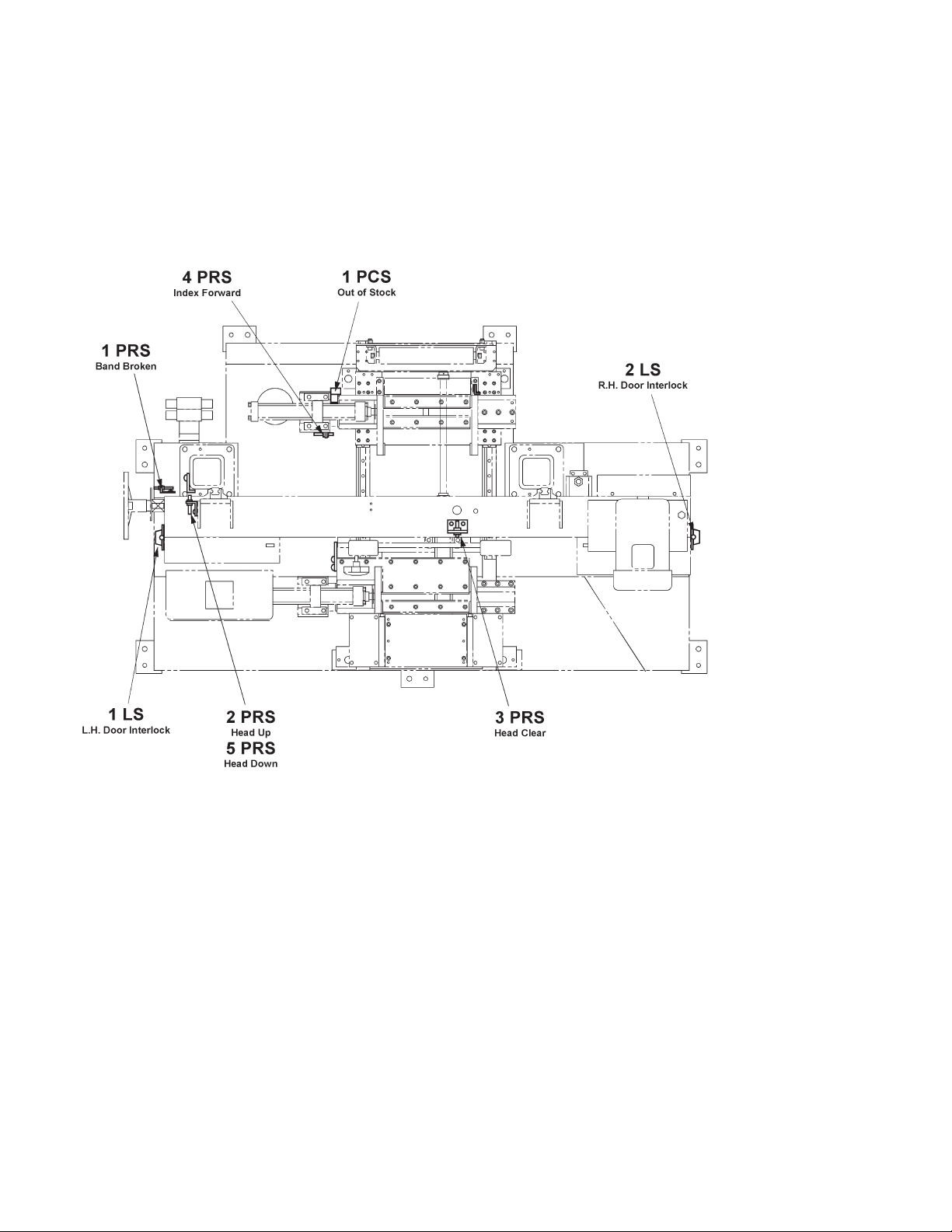

Proximity/Limit Switch Locations - Top View .......... 6

INSTALLATION

Location .................................................................. 7

OSHA Notice!! ........................................................ 7

Unpacking ............................................................... 7

Lifting ...................................................................... 7

Floor Installation ..................................................... 7-8

Electrical Installation ............................................... 8

Preparation for Use ................................................ 8-9

OPERATION

Safety Precautions ................................................. 10

Using the Job Selector ........................................... 10

Machine Capacities ................................................ 10

Machine Controls .................................................... 11-16

Saw Band Preparation ............................................ 16-18

Saw Guide Arm Adjustment .................................... 18

Feed Rate Adjustment ............................................ 18

Head Raise Limit Sensing Arm ............................... 19

Vise Jaw Adjustment .............................................. 19

Material Indexing .................................................... 19

Coolant Selection and Application .......................... 20

Dry Cutting .............................................................. 20

Band Brush and Chip Removal .............................. 20-21

Typical Operation Procedures ................................ 21-22

LUBRICATION

Lubrication Chart .................................................... 24

Lubrication Diagrams .............................................. 25

MAINTENANCE

Saw Guide and Back-Up Inserts ............................ 26

Band Drive Belt Replacement ................................ 26

Hydraulic System .................................................... 26-27

Coolant System ...................................................... 27

Machine Cleaning ................................................... 27

Machine Alignment ................................................. 27

Band Brush ............................................................. 27

Band Tension Measurement ................................... 28

Wear Plate Replacement ........................................ 28

Bandwheels ............................................................ 28

Cleaning Chip Trough/Chip Conveyor .................... 28

TROUBLE SHOOTING .................................. 29-32

ACCESSORIES

Roller Stock Conveyors .......................................... 33

Vertical Guide Rollers (Conveyors) ........................ 33

Variable Vise Pressure ........................................... 33

Nesting Fixture ....................................................... 34-35

Chip Conveyor ........................................................ 35

Mist Lubricator ........................................................ 35

Worklight ................................................................. 35

Material Handling .................................................... 35

How to read your serial number: