2

Table of contents Page

Packing ................................................................................2

Delivery inventory ..............................................................3

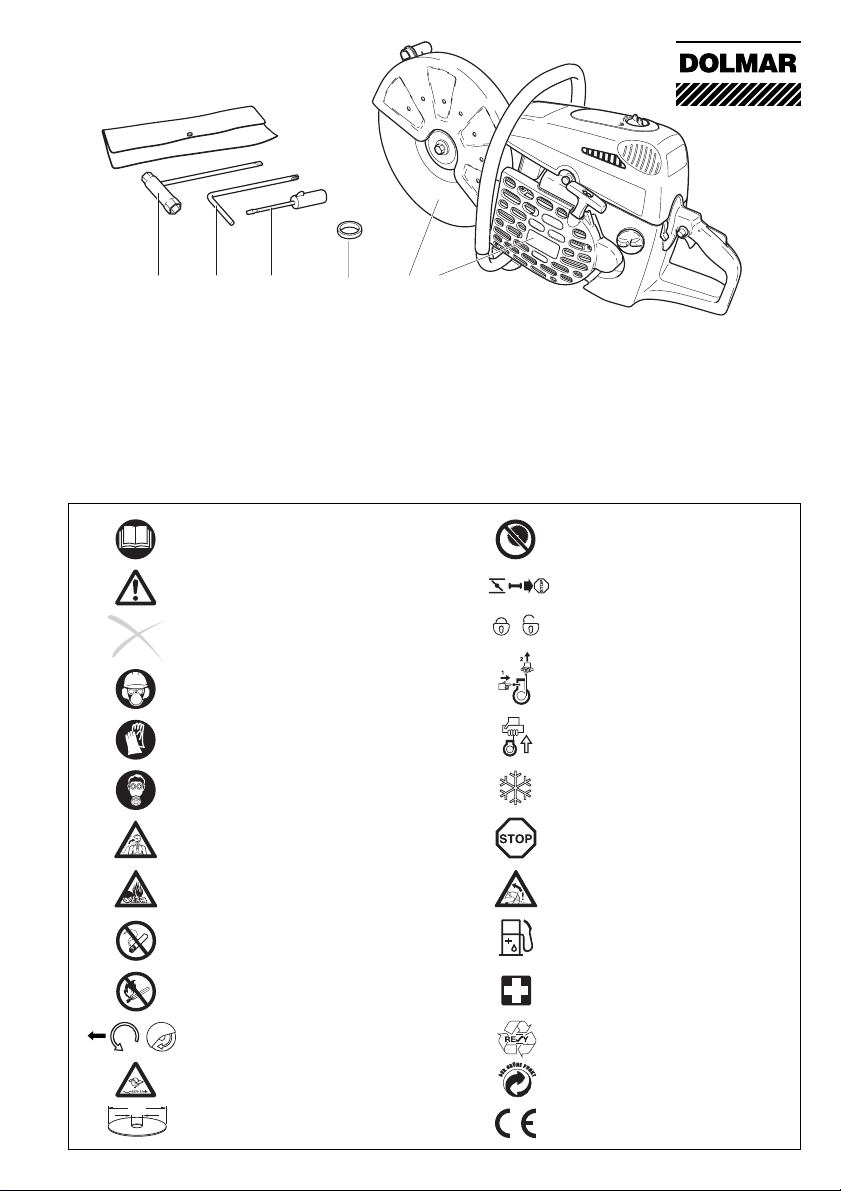

Symbols ...............................................................................3

SAFETY PRECAUTIONS

Intended use ...................................................................4

General precautions ....................................................... 4

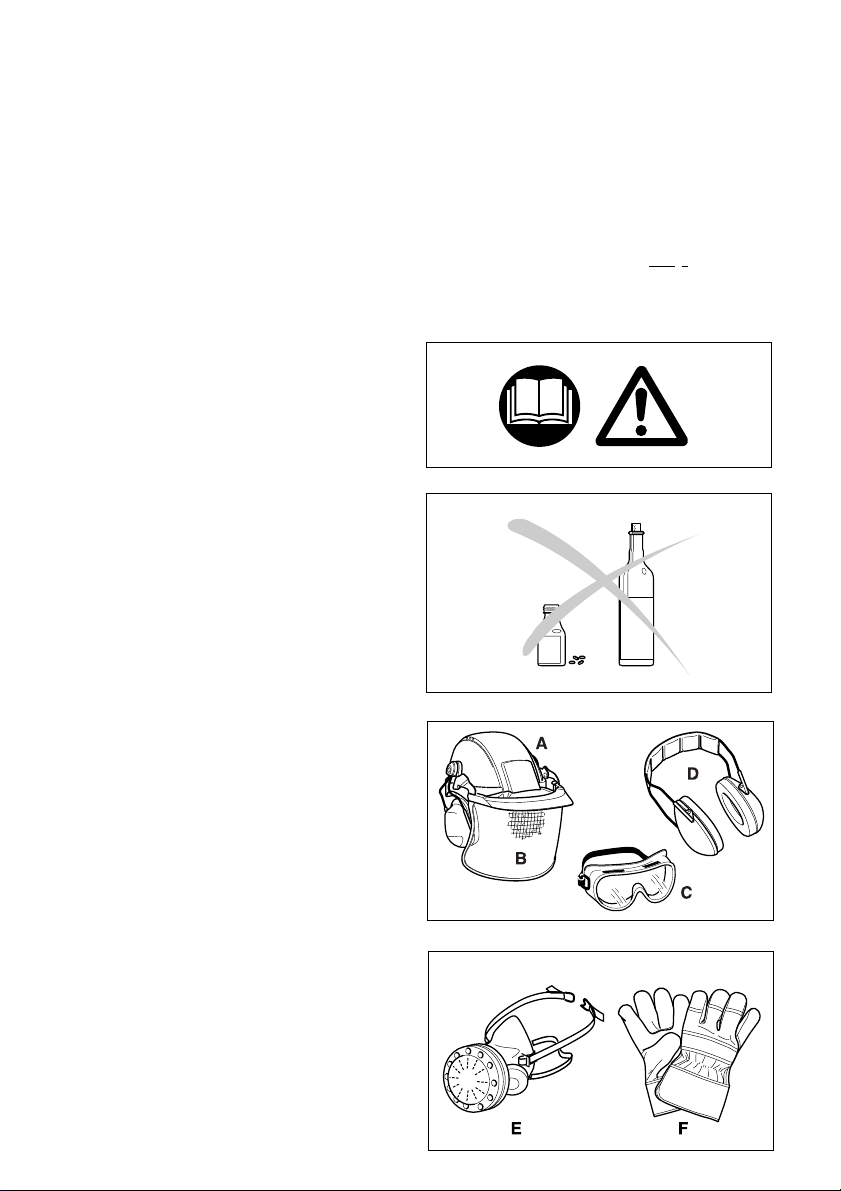

Protective equipment ...................................................4-5

Fuels / Refuelling ............................................................5

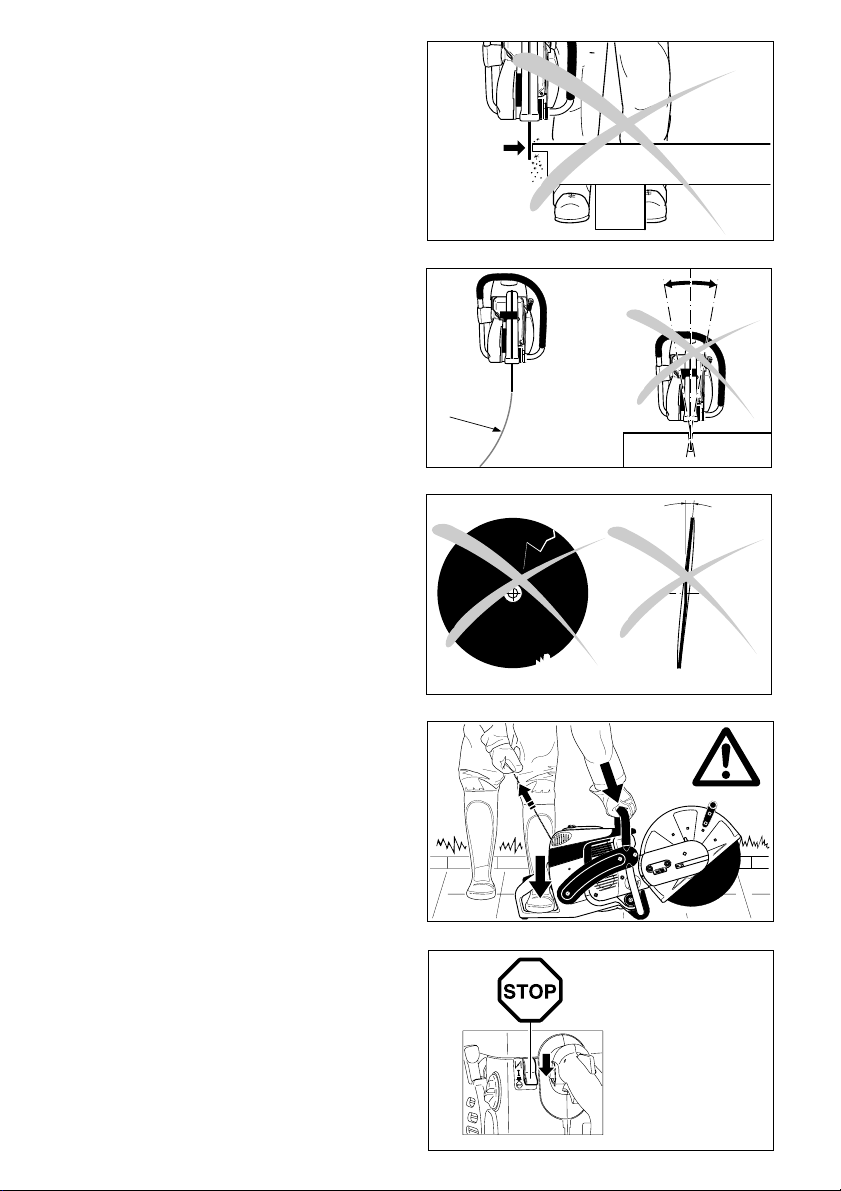

Putting into operation ......................................................5

Cutting discs ...................................................................6

Kickback and lock-in .......................................................7

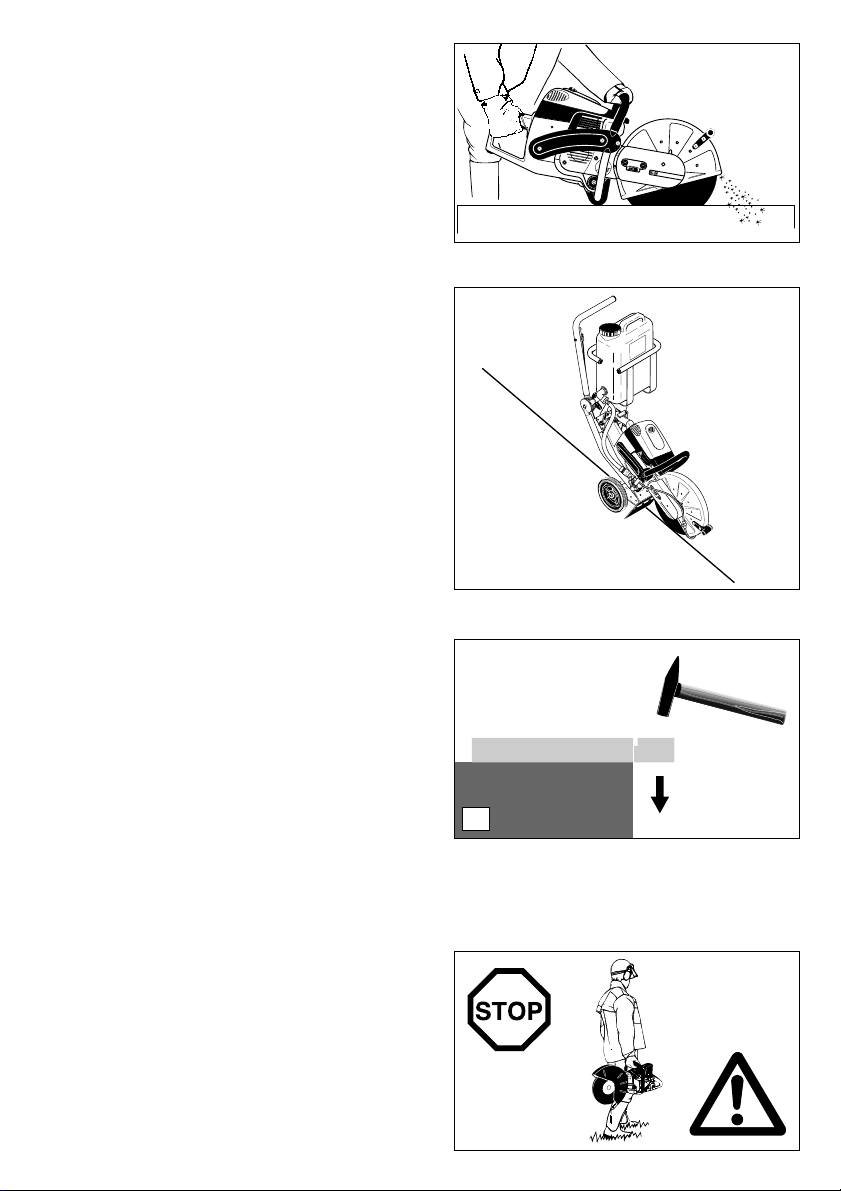

Working behavior / Method of working ............................7

Always observe the following when using

synthetic resin cutting discs ............................................. 8

Cutting metal ................................................................... 8

Cutting masonry and concrete .....................................8-9

Transport and storage .....................................................9

Maintenance .................................................................10

First aid .........................................................................10

Disposal and environmental protection ......................... 10

Technical data ................................................................... 11

Denomination of components .........................................12

PUTTING INTO OPERATION

Mounting the cutting disc...............................................13

Tightening the V-belt / Checking V-belt tension ............14

Fuels / Refuelling .....................................................14-15

Starting the engine ........................................................ 16

Cold-starting .................................................................16

Warm-starting ...............................................................17

Stop engine ................................................................... 17

Adjusting the carburetor ..................................................18

MAINTENANCE

Changing the V-belt ......................................................19

Cleaning the protection hood ........................................20

Cleaning / changing the air Þlter ..............................20-21

Replacing the spark plug ..............................................22

Replacing the suction head .......................................... 22

Replacing the starter cable ...........................................23

Replacing the return spring ........................................... 24

Instructions for periodic maintenance ...........................28

Cutting attachment in central / side position .................25

Repositioning the cutting attachment .......................25-26

SPECIAL ACCESSORIES

Diamond cutting discs, trolley, water tank

and pressure water system............................................ 27

Service, spare parts and guarantee ................................28

Troubleshooting ...............................................................29

Extract from spare parts list .......................................30-31

Accessories ..................................................................31

Packing

Your DOLMAR Power Cut is packed in a cardboard box to pre-

vent shipping damage.

Cardboardisabasicrawmaterialand is consequently reuseable

or suitable for recycling (waste paper recycling).

Thank you for purchasing a DOLMAR product!

Congratulations on choosing a DOLMAR Power Cut cutoff saw!

We are conÞdent that you will be satisÞed with this modern piece

of equipment. DOLMAR GmbH of Hamburg, Germany is the

world’soldestmanufacturerof gasoline-powered chainsaws -we

got our start in 1927 - giving us very extensive experience with

power hand tools. Like our chain saws, the DOLMAR Power

Cuts feature specially designed high-performance engines

with outstanding power-to-weight ratios, for heavy-duty yet

lightweight tools.

Other advantages of the DOLMAR Power Cuts:

• Sturdy construction and high reliability.

• Maintenance-free electronic ignition, hermetically sealed to

protect against dust and moisture.

• Vibration damping with the DOLMAR 2-mass system (D2M)

for tireless working even when guiding the Power Cut by

hand.

• Five-stage air-Þlter system for reliable working even under

very dusty conditions.

• Two options for mounting the cutter attachment: Either cen-

trally, for good balance when guiding the unit manually, or on

the side, for ßush cuts along walls or curbsides or horizontally

directly above the ground.

• Extensive range of resin-bonded and diamond grit cutting

discs, trolley with dust catcher, and systems for supplying

water to the disc.

The following industrial property rights apply: US 08510690,

SE 95027298, SE 95027306, IT 95000653, IT 95000654, GBM

9412558, GBM 9412559.

We want you to be satisÞed with your DOLMAR product.

In order to guarantee the optimal function and performance of

your Power Cut and to ensure your personal safety we would

request you to perform the following:

Read this instruction manual carefully before putting the

Power Cut into operation for the Þrst time, and strictly

observe the safety regulations! Failure to observe these

precautions can lead to severe injury or death!

EU Conformity Declaration

The undersigned, Shigeharu Kominami and Rainer Bergfeld,

as authorized by DOLMAR GmbH, declare that the DOLMAR

machines,

Type: (325) PC-6412 S, PC-6414 S; (394) PC-7312 S, PC-7314

S; (326) PC-8114, PC-8116

manufactured by DOLMAR GmbH, Jenfelder Str. 38, 22045

Hamburg, Germany, conforms to the basic safety and health

requirements of the applicable EU guidelines:

EU Machine guideline 98/37/ EG, EU EMC guideline 89/336/

EWG (modiÞed by 91/263/ EWG, 92/31/ EWG and 93/68/

EWG), Noise emission 2000/14/EG.

The most important standards applied to properly meet the re-

quirements of the above EU guidelines were: EN 1454, CISPR

12, EN ISO 14982, DIN EN 61000-4. The conformity assess-

ment procedure 2000/14/EG was performed per Annex V. The

measured noise level (Lwa) is 114 dB(A). The guaranteed noise

level (Ld) is 115 dB(A).

Hamburg, 4.4.2006

For DOLMAR GmbH

Shigeharu Kominami Rainer Bergfeld

Managing Director Managing Director