dolycon CT112 Series User manual

Solar Pump Inverter Content

Content

Safety precautions……………………………………………………………………1

Chapter 1 System Introduction ……………………………………………………6

Chapter 2 Solar Pump Inverter ……………………………………………………7

Chapter 3 System Collection Diagram …………………………………………15

Chapter 4 Function Parameters …………………………………………………27

Chapter 5 Troubles Shooting ……………………………………………………40

Chapter 6 Warranty …………………………………………………………………44

Chapter 7 Communication protocol ……………………………………………45

User’s Information …………………………………………………………………53

Solar Pump Inverter Content

Solar Pump Inverter Safety precautions

1

Thank you for your using our solar pump inverter.

Please read this manual thoroughly to ensure proper usage, keep this manual at an

easily accessible place so that you can refer anytime as necessary.

Safety Precautions

Please read this operation manual carefully before installation, operation, maintenance or

inspection.

In this manual, the safety precautions were sorted to “WARNING” or “CAUTION”.

Indicates a potentially hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, will result in minor or moderate injury and physical

damage. This sign is also used for alert of any un-safety

operation.

In some cases, the contents of “CAUTION” could cause serious accident. Please follow

these important precautions in any situation.

★NOTE is the necessary step to ensure the proper operation.

Warning Marks were shown on the front keypad of inverters.

Please follow these indications when using the inverter.

1. WARNING

May cause injury or electric shock.

Please follow the instructions in the manual before installation or operation.

Disconnect all power line before opening front cover of unit. Wait at least 5

minute until DC Bus capacitors discharge.

Use proper grounding techniques.

Never connect AC power to output UVW terminals

Solar Pump Inverter Safety precautions

2

Before installation

Do not operate the inverter if there are any signs of water in the inverter when

unpacking.

Do not operate the inverter if there is any damage or components loss to the inverter

when unpacking. Otherwise, physical injury or damage to the devices may occur.

Do not touch the control terminals, PCB board or components inside the inverter

with hands or body.

Do not operate the inverter if the packing list is not consistent with the devices.

Do not operate the inverter if the information on the name plate is not consistent with

your order.

2. Installation

Only qualified electricians are allowed to perform the installation, otherwise electric

shock may occur.

Please install the inverter on fire-

retardant materials and keep the inverter away

from combustible materials, otherwise a fire may occur.

Please assemble and tighten the mounting screws of the inverter according to the

regulations, otherwise the inverter may fall off.

Do not install the inverter in explosive atmospheres, otherwise an expl

osion may

occur.

Solar Pump Inverter Safety precautions

3

Handle the inverter with care to prevent it falling off and thus leading to injury to your

feet or the device.

Keep the inverter away from the places with large vibrations, water drops and direct

sunlight.

When installing the inverter in the cabinet, especially two or more inverters are

installed in a cabinet, please pay attention to the installation space and ventilation.

Avoid screws, cables and other conductive matters falling into the inverter during

installation.

3. Wiring

Only qualified electricians are allowed to perform the wiring, otherwise electric shock

or device damage may occur.

Carry out wiring strictly in accordance with this manual, otherwise there is a risk of

electric shock or device damage.

Ensure any input power sup

ply is disconnected before wiring, otherwise electric

shock may occur.

Please select all cables, circuit breakers and contactors meeting the national

standards as required by the manual.

The inverter must be grounded reliably, otherwise electric shock may occur.

Carry out wiring strictly in accordance with the silk printing instructions and avoid

connecting the input and output wires reversely, otherwise the damage to the

devices may occur.

Keep the terminal signal cables of the inverter away from the power cables as far as

possible, or distribute the two categories of cables vertically-

crossed if the distance

is not far enough, otherwise it may cause signal interference.

Ensure that all the screws are tightened when wiring, otherwise damage to the

inverter may occur.

Solar Pump Inverter Safety precautions

4

» The encoders and sensors should be applied with the shielded cables and the shielded

layer should be grounded reliably.

4. Operation

Confirm that the wiring is completed and correct and then cover the plate before

power on.

Do not open the plate after power on, otherwise electric shock may occur.

Operate the inverter appropriately, otherwise damage to the inverter may occur.

Non-

professionals are not allowed to test the signals when the inverter is running.

Otherwise, physical injury or damage to the devices may occur.

Any arbitrary change in parameters of the inverter is prohibited, otherwise damage

to the inverter may occur.

Do not touch the fans and brake resistors, otherwise it may cause mechanical injury

or burn.

Do not start up or

stop the inverter by power on or off, otherwise damage to the

inverter may occur.

Ensure that the circuit breakers or contactors at the output sides of the inverter are

not in output state before switching, otherwise damage to the inverter may occur.

5. Others

Solar Pump Inverter Safety precautions

5

This inverter is not suitable for the occasions when the specifications exceed those

specified in this manual. If you have special requirements, please contact our

technical department.

The inverter is equipped with surge suppressors inside, which can protect it from the

lightning. It is necessary to mount external surge suppressors at the power input

side of the inverter in high lightning incidence areas.

When the conductors between the inverter and the motor exceed 100m, it is

recommended to mount

the output reactors to avoid overcurrent caused by

excessive distributed capacitance.

Do not mount the compensation capacitors and the surge absorbers at the output

sides of the inverter. Otherwise, it may cause damage to the inverter due to

overheating.

Mounting the input or output reactors, special filters and magnetic rings at the input

or output sides of the inverter can effectively reduce the noise and thus avoid

interference to other devices.

Non-professionals are not allowed to perform withstand vol

tage tests on the

inverter, , otherwise damage to the inverter may occur.

Deal with the devices as industrial effluent after scrapping. Burning is strictly

prohibited, otherwise an explosion may occur.

The cooling effect of the inverter is reduced and the electrolytic capacitor electrolyte

is also volatile in high altitude areas, which will shorten the life of the inverter. Check

the altitude of the actual usage site is below 1000m. If exceeds, reduce rated output

current by 1% for every additional 100m.

Solar Pump Inverter Chapter 1 System Introduction

6

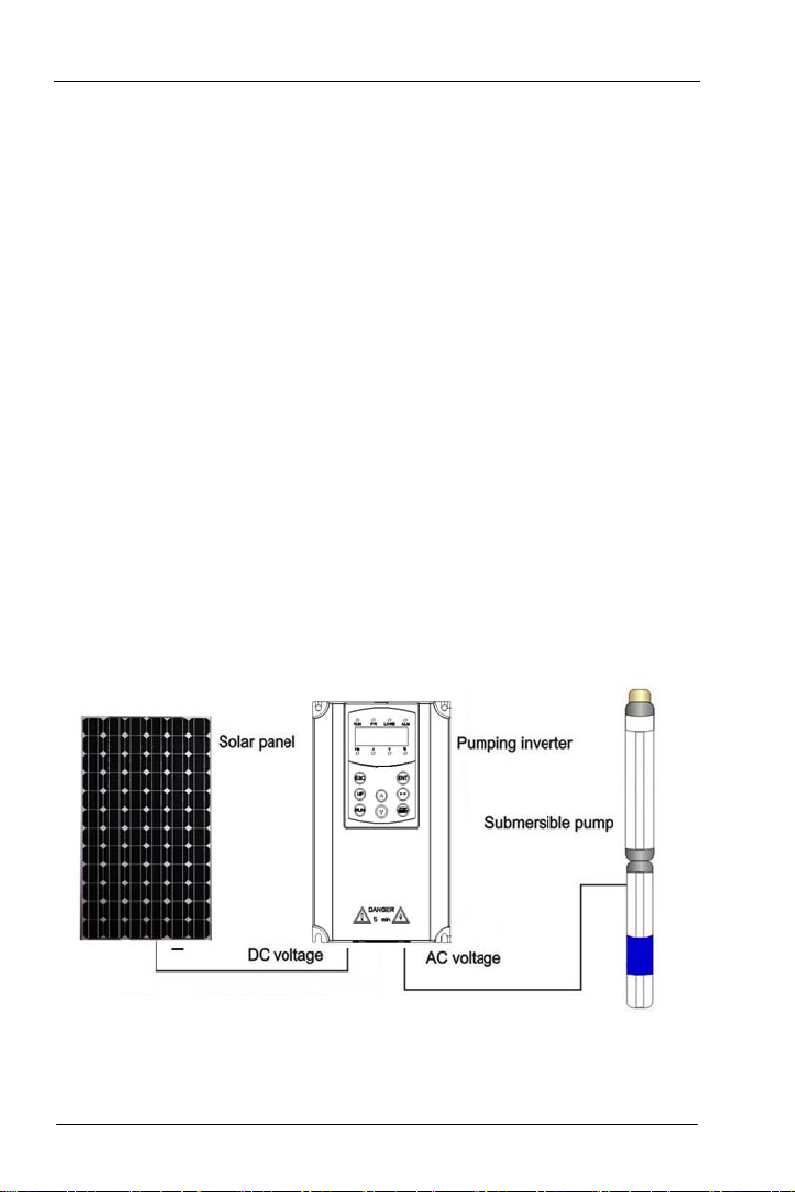

Chapter 1 System Introduction

1.1 Brief Introduction

A complete solar Pump system consist of solar array, pump and solar Pump inverter. The

inverter can convert DC power from solar PV array to AC power to run pump motors.

Solar array, an aggregation of many solar modules connected in series and parallel,

absorbs sunlight radiation and converts it into electrical energy, providing dynamical water

for the whole system.

Inverter controls the system operation and adjust the output frequency in real-time

according to the variation of sunlight intensity to realize the maximum power point tracking

(MPPT).

Pump, drive by 3-phase or single phase AC motor, can draw water from the deep wells or

rivers and lakes to pour into the storage tank or reservoir, or directly connect to the

irrigation system, fountain system, etc.

Figure 1 Structure of solar Pump system

This manual suits for next models

24

Table of contents

Other dolycon Inverter manuals

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual