CT100G Series Inverter CHAPTER 1 PRODUCT INFORMATION

- 6 -

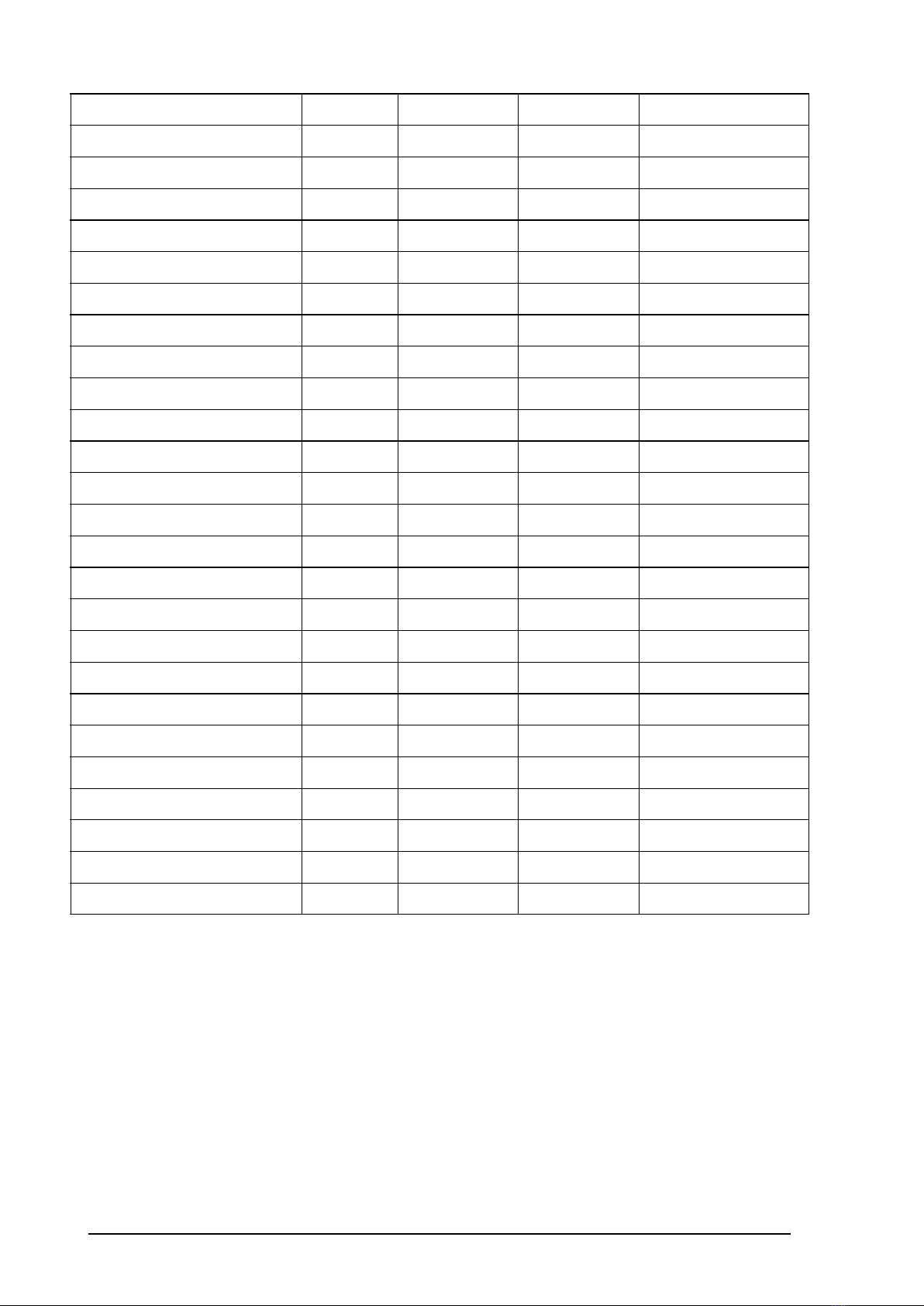

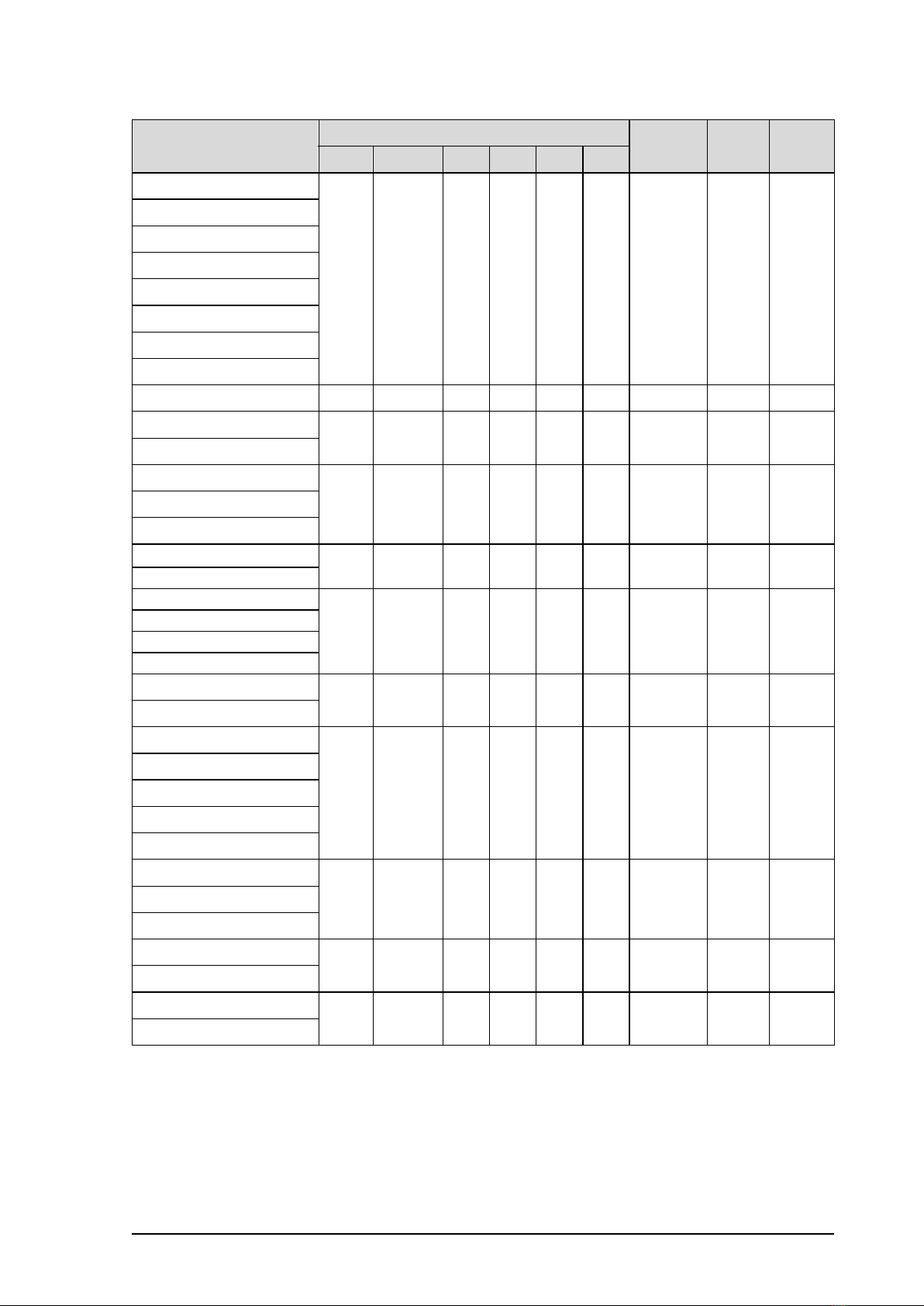

CT100G-4T-5.5G-B 5.5 18.5 14 5.5

CT100G-4T-7.5G-B 7.5 22.5 18.5 7.5

CT100G-4T-11G-B 11 30.0 25.0 11

CT100G-4T-15G-B 15 39.0 32.0 15

CT100G-4T-18.5G-B 18.5 45.0 38.0 18.5

CT100G-4T-22G-B 22 54.0 45.0 22

CT100G-4T-30G-B 30 68.0 60.0 30

CT100G-4T-37G 37 84.0 75.0 37

CT100G-4T-45G 45 98.0 92.0 45

CT100G-4T-55G 55 123.0 115.0 55

CT100G-4T-75G 75 157.0 150.0 75

CT100G-4T-90G 90 188.0 180.0 90

CT100G-4T-110G 110 221.0 215.0 110

CT100G-4T-132G 132 267.0 260.0 132

CT100G-4T-160G 160 309.0 305.0 160

CT100G-4T-185G 185 344.0 340.0 185

CT100G-4T-200G 200 384.0 380.0 200

CT100G-4T-220G 220 429.0 425.0 220

CT100G-4T-250G 250 484.0 480.0 250

CT100G-4T-280G 280 539.0 530.0 280

CT100G-4T-315G 315 612.0 600.0 315

CT100G-4T-355G 355 665.0 650.0 355

CT100G-4T-450G 450 805 795.0 450

CT100G-4T-500G 500 890 860.0 500

CT100G-4T-560G 560 1045 1015 560

CT100G-4T-630G 630 1224 1200 630

Note: 1. The inverters with power less than or equal to CT100G-4T-160G are

equipped with braking units, but 37-160kw models are optional with or without

braking units. And braking resistors inside whose power and resistance are as

required as the table 2-2, otherwise has risk of damage. CT100G-4T-185G and

bigger power models can be equipped with external braking units bought by

customers themselves.

2. The above models are the standard general purpose inverters, excluding the

industrial special inverters. You can customize non-standard inverters of other

specifications.

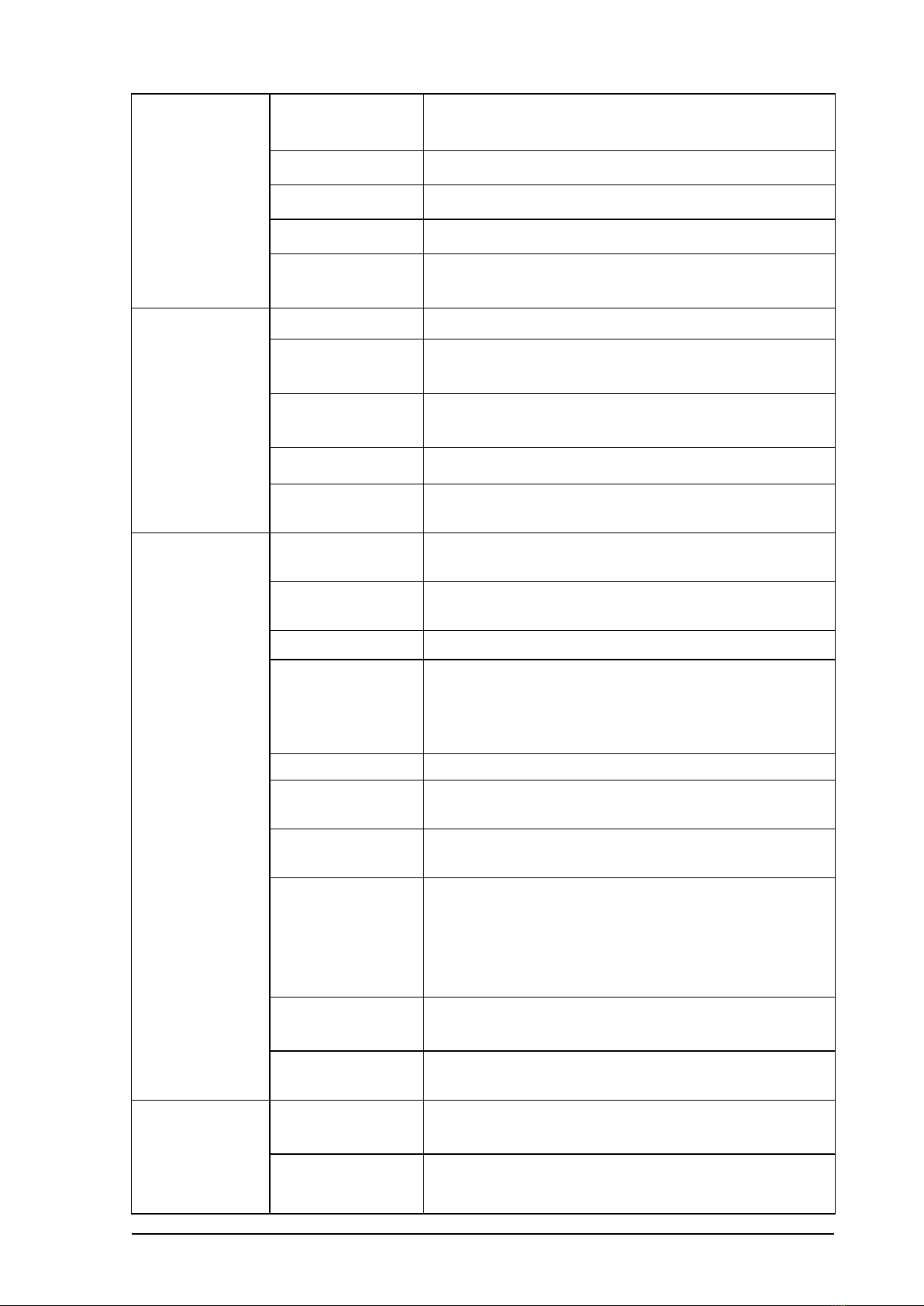

1.2.2 Technical parameters

Table 1-2 Technical parameters