KeerPlus3 manual │ version 3 - 2022

Content

Introduction ..........................................................................................................................................................3

The workings of the

KeerPlus3

..............................................................................................................................4

The functionality of the KeerPlus3....................................................................................................................4

Turning loop requirements ...............................................................................................................................

5

Assembly...............................................................................................................................................................5

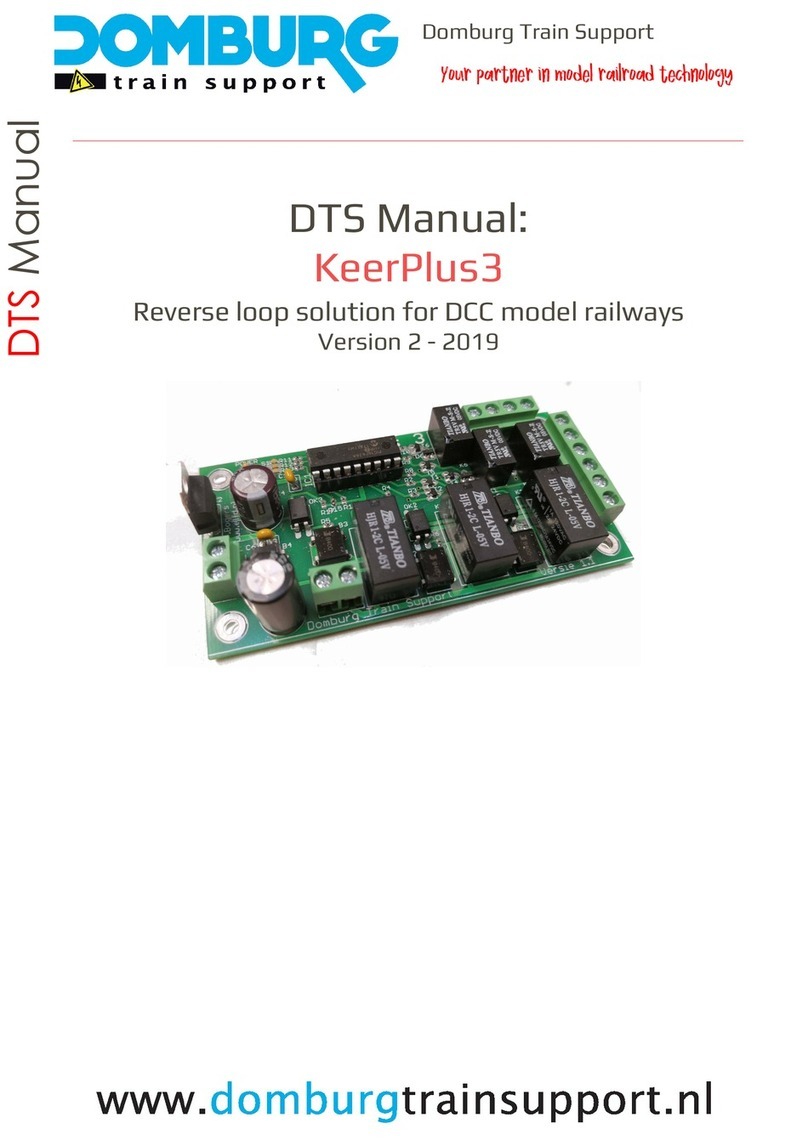

Overview KeerPlus3..............................................................................................................................................6

Connecting the KeerPlus3.....................................................................................................................................7

Supply voltage ...................................................................................................................................................7

DCC Signal .........................................................................................................................................................

7

The Loop............................................................................................................................................................8

Switching outputs..............................................................................................................................................9

Occupancy report............................................................................................................................................10

Frequently asked questions................................................................................................................................11

I connected everything, when the train enters the reversing loop I get instant closure ...............................11

The train gives a short circuit when it enters section 3 from section 2. (Or from S2 to S1)...........................11

I get no busy signal on the busy signal module...............................................................................................11

It gives a busy signal on S1 while the locomotive is running in S3..................................................................

11

Very occasionally I get a closure when it enters one of the sections .............................................................11

Afterword............................................................................................................................................................11