6

Donaldson Company, Inc.

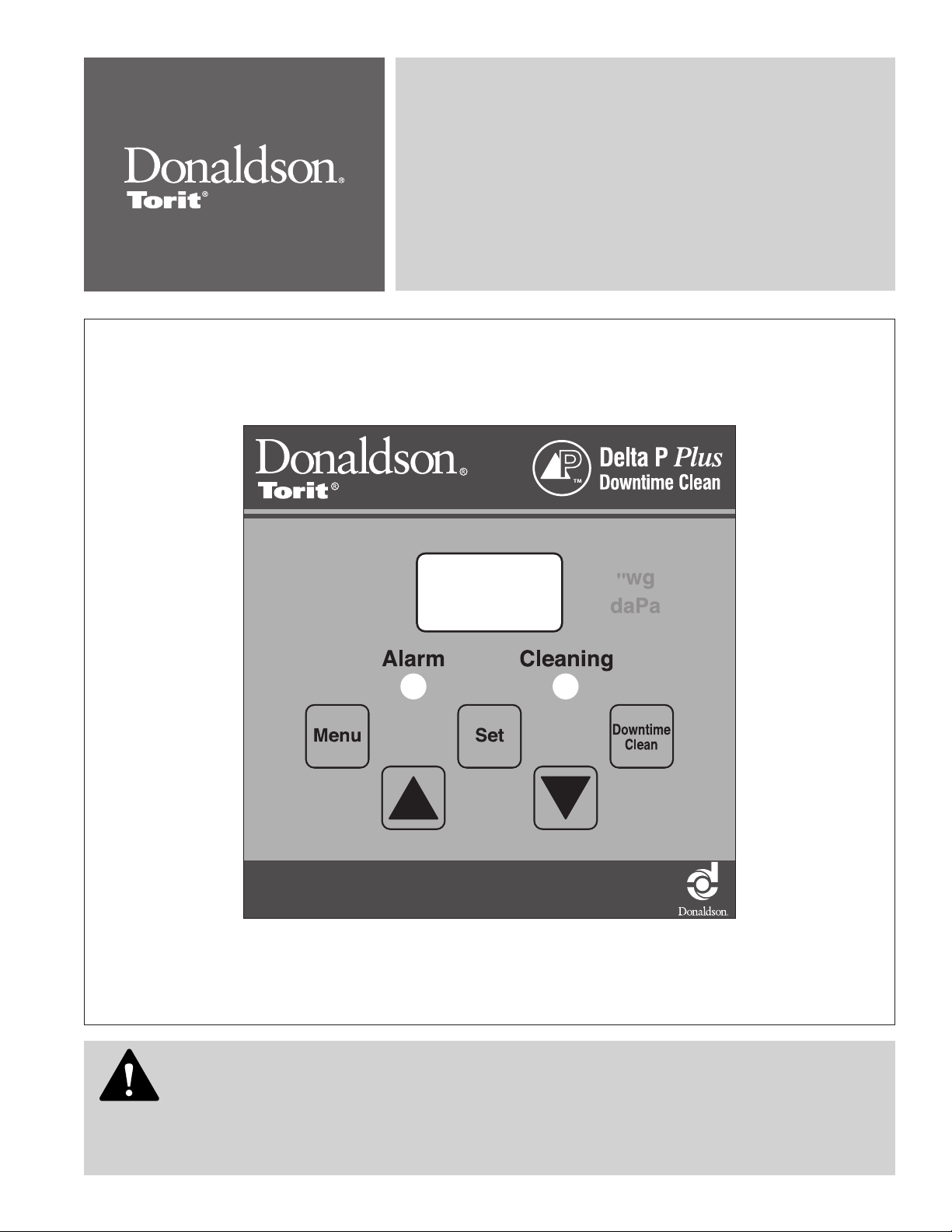

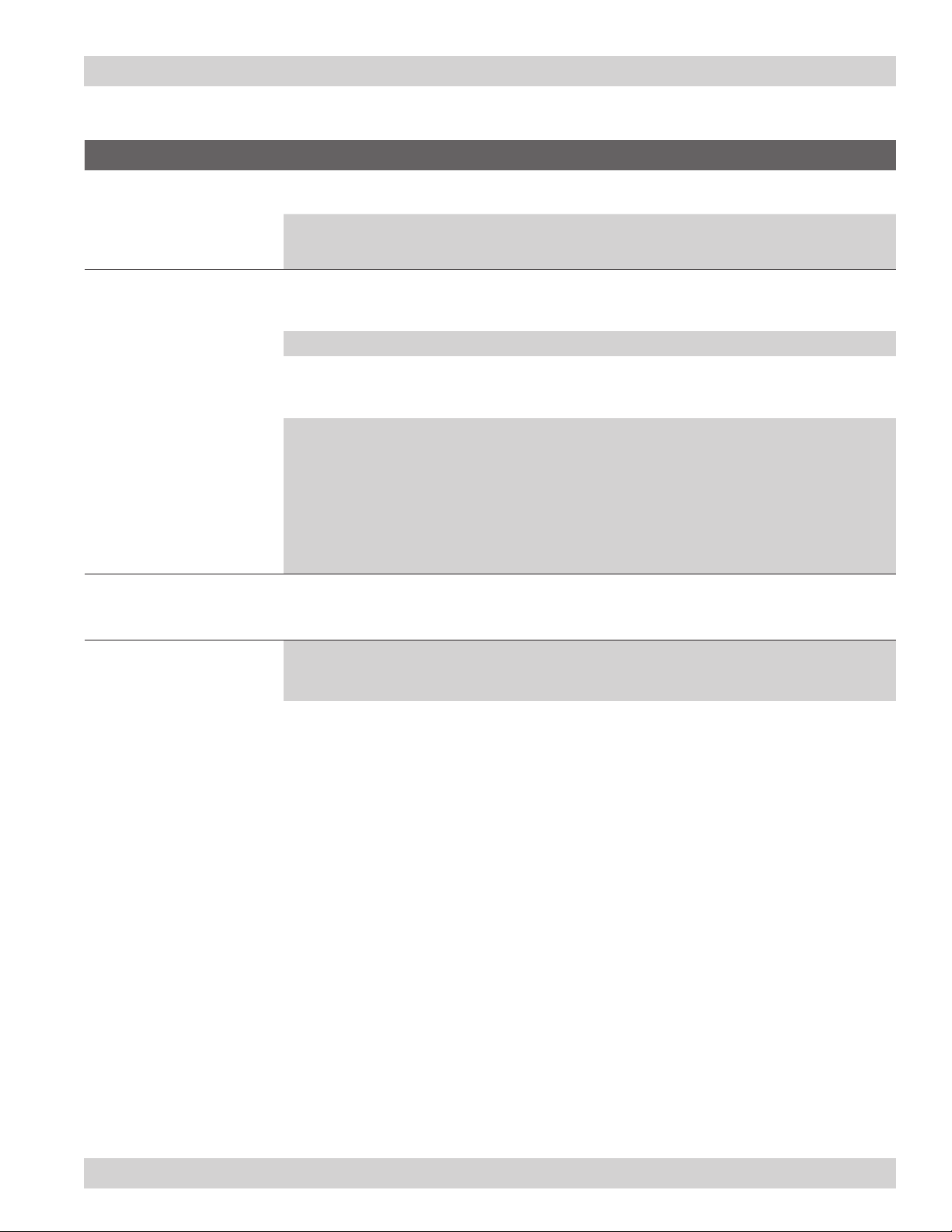

The Delta P Plus Controller monitors the differential pressure between the clean-air and dirty-air plenums, providing a visual

display of the lter condition. When combined with a pulse timer, it manages the pressure drop by turning the cleaning mechanism

On and Off at the chosen limits. There are three (3) set points: High Pressure On, Low Pressure Off, and Alarm. The rst two,

High Pressure On and Low Pressure Off, control the lter cleaning system. The third, Alarm, provides a relay output to activate an

external alarm supplied by others.

The user can program the Delta P Plus Controller to pulse while the collector is running, to maintain a relatively constant pressure

drop across the lters, pulse only after the collector is shut down (after-shift cleaning), or a combination of both, cleaning while

running as well as end of the shift.

2 Product Description

3 Operation

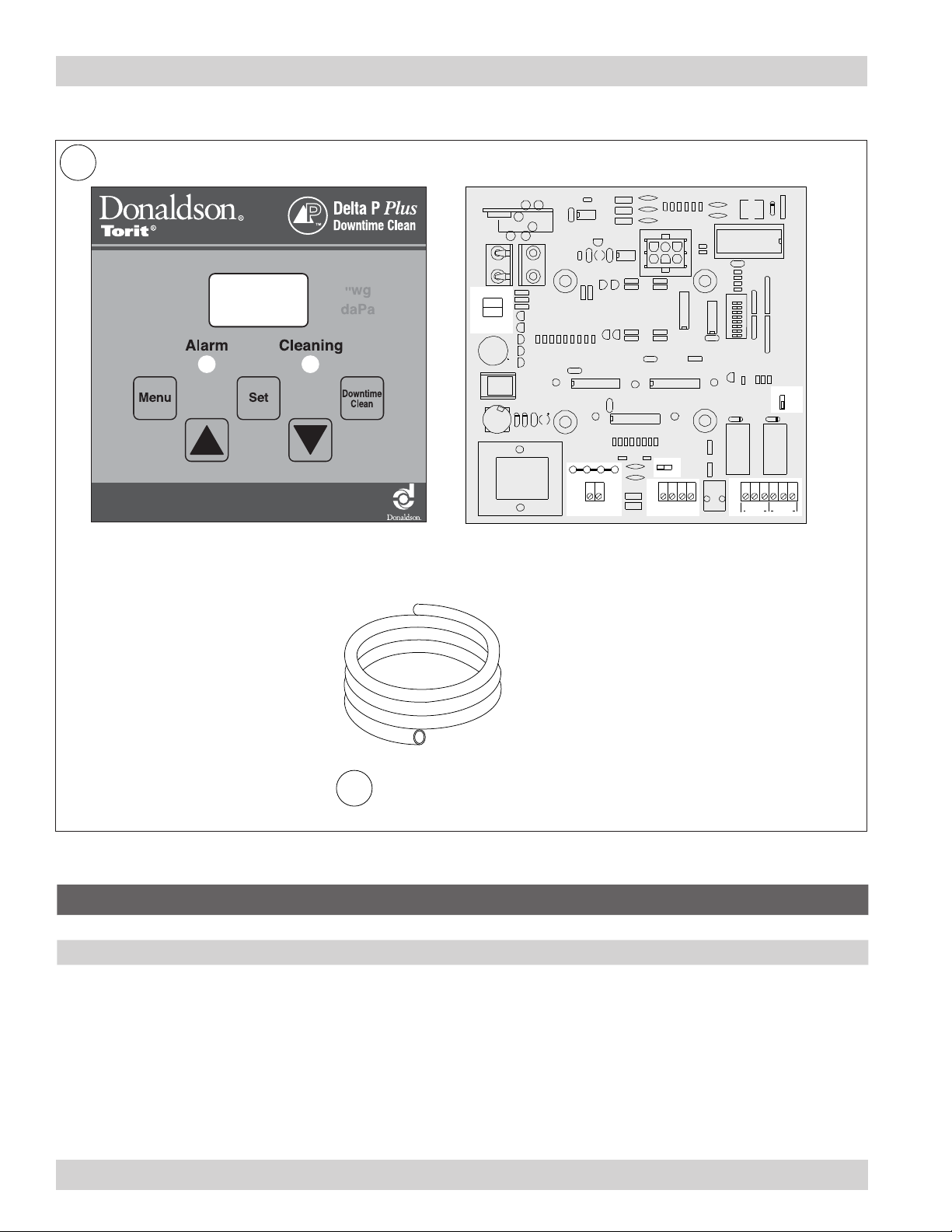

Three cleaning modes, Differential Pressure Cleaning (DFF), Downtime Cleaning (DTC), and Combined Differential and Downtime

Cleaning (ALL) are available with this controller and can be individually chosen by the user.

• Differential Pressure Cleaning (DFF) - When the differential pressure drop reaches the controller’s HIGH setpoint, the

controller closes an output relay initiating the cleaning cycle. When the differential pressure decreases to the LOW

setpoint, the relay opens and the cleaning cycle stops. This sequence continues as long as the collector is running,

maintaining the differential pressure drop within a specied range.

• Downtime Cleaning (DTC) – The Delta P Plus controller monitors for the differential pressure drop to exceed the LOW

setpoint. (Indicates the blower has been started). When the differential pressure drop later approaches zero (indicating

the blower has been shut down), the Delta P Plus engages the cleaning cycle for a pre-selected time. A delay timer

allows the blower to come to a stop before the cleaning cycle starts.

The delay timer and cleaning cycle durations are both user adjustable but password protected.

• Combined Differential and Downtime Cleaning (ALL) –The ALL mode combines the two functions described above,

maintaining the differential pressure drop in a specied range, then initiating a down-time cleaning cycle when the

differential pressure drop approaches zero. The downtime cleaning function can be toggled on or off from the keyboard.

Note: The DTC and ALL cleaning modes incorporate compressed air cleaning of the lters when the main collector fan is not

running. This may result in collected material “drifting” out the inlet duct of the collector. An isolation valve in the inlet duct of the

collector can reduce or eliminate that drifting.

Consideration should be made on the use of the DTC or ALL cleaning mode on small collectors where the relatively low volume

of the collector may produce pressure spikes with each pulse of the cleaning cycle. Such pressure spikes may accelerate the

fatigue, or damage of ancillary items such as pressure sensors or explosion relief panels.

Alarm

The Alarm setpoint is set to a higher setting than the High Pressure On used to start the lter cleaning cycle. It indicates situations

when the cleaning system cannot reduce the pressure drop due to cleaning system failure, lack of compressed air, or the end of

the lter’s useful life. There is a time delay prior to setting the Alarm to prevent nuisance trips. The Delta P Plus Controller also

provides an input connection for a remote Alarm reset.