CLASS

CERTIFIEDTO

CAN/CSAC22.2NO.247

CONFORMSTO

ANSI/UL-325

VEHICULARGATEOPERATOR

HP

53382

MODEL

SERIAL

VOLTSPHASE

AMPS60Hz

MAXGATELOAD

DoorKing,Inc.,Inglewood,CA

MOVINGARM

can

causevehicledamage,

seriousinjuryordeath.

STAYCLEAR

ofarm

atalltimes.

NO:

Pedestrians

Bicycles

Motorcycles

WARNING

MovingGateCanCause

Serious Injury orDeath

KEEPCLEAR!Gate may move at any time

withoutpriorwarning.

Donot let children operate thegateor play

inthegate area.

Thisentranceis for vehicles only.

Pedestriansmust use separateentrance.

NOT A WALKWAY

A WALKWAY

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

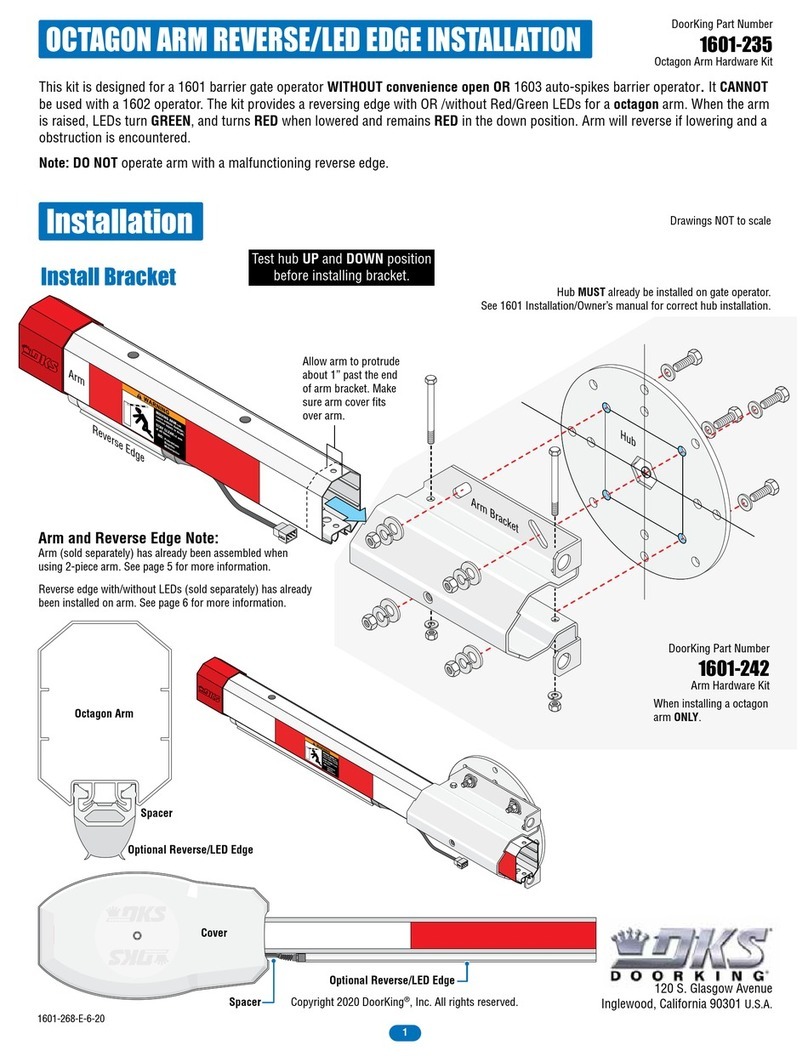

DoorKing Safety for Lane Barrier

IMPORTANT: A lane barrier gate

operator installed WITHOUT any

external safety sensors CANNOT

sense a person under the raised

arm and can strike them while

the arm is lowering.

This scenario is VERY

DANGEROUS and MUST

NEVER OCCUR!!

When the photo

beam gets interrupted by a

pedestrian, a lowering arm

will reverse and raise.

Photo Sensor

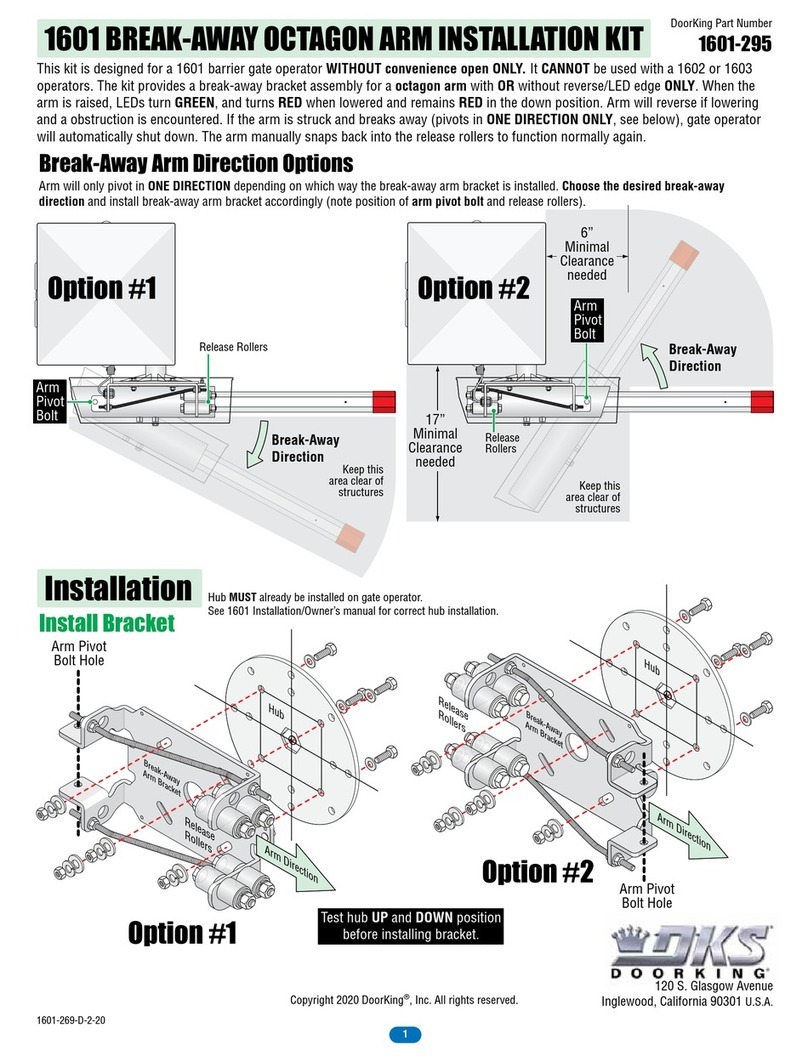

• DKS Lane Barrier System is NOT crash rated. It is intended to provide a formidable barrier to help prevent

passenger vehicles and light-duty trucks from driving through a controlled traffic lane.

• Lane barrier MUST have reverse/LED edge on arm, traffic light and photoelectric cell functioning or remove

lane barrier from service until repairs have been made.

• Make sure all warning signs are on operator and arm. They MUST be easily visible.

•Do not install the operator in such a way that the arms moves within 16 inches of a rigid object or 10 feet

from high voltage power wires with arm in the raised position.

• Speed limit through barrier area is 5 MPH. Install speed bumps, warning signs and hazard stripes where

visible in the area of the lane barrier gate, failure to do so may result in injury, damage to operator and vehicle.

• Users should be familiar with proper use of operator, these include; hardware operation, reversing functions and

testing, reversing loops, inherent reversing system, electric edges, photoelectric cells related external devices and

possible hazards.

• Keep adults, children and objects away from operator and HAZARD ZONES.

• Automotive ONE-WAY traffic only - No bicycles or motorcycles.

Pedestrians MUST be provided with separate access.

• All electrical connections should be made in accordance with local electrical codes.

• Security features should be installed to avoid unauthorized use.

• Controls intended for user activation must be located at least six feet (6') away from any moving part of the

barrier gate and where the user is prevented from reaching over, under or around the lane barrier gate to operate

the controls. Emergency access controls only accessible by authorized personnel (e.g., fire, police, EMS) may be

placed at any location in the line-of-sight of the lane barrier gate.

• When manually operating the gate operator arms, the user MUST make sure that the gate area is clear BEFORE operating the

controls. Any activity in the traffic lane should be monitored to ensure a safe operation when opening or closing the lane barrier

gate. The motion of the barrier arms must be directly observable by the person operating the lane barrier. While barrier arms are

in motion

NO pedestrian and NO vehicle shall be in the immediate vicinity of the lane barrier area.

• When removing the operator from service, move the arms to the full open position and shut off power at the

service panel.

• Operators and components should be properly installed and maintained following the

recommended service schedule, test the operator monthly. Keep all debris out of arm channel

and from operator housing vents and off of arms. Contact your service dealer for any

maintenance or repairs.

• Vehicular lane barrier gate operator can produce high levels of force, it is

important that you are aware and eliminate possible HAZARDS;

Pinch Points, Entrapment Areas, Overhead Power Wires,

Absence of Controlled Pedestrian Access, Traffic Backup.

2

1620-065-K-11-21