Power Train Index3

Index

Specification

General Tightening Torque ...................................5

Drive Axle Specification........................................6

Torque Converter..................................................7

Transmission Pump..............................................7

Drive Axle Mounting..............................................8

Differential ............................................................8

Wheel Bearing and Drive Wheel ...........................8

Brake Assembly....................................................9

Brake Drum Diameter.........................................10

U - joint...............................................................10

System Operation

General Information............................................11

Power Shift Transmission....................................12

General Information.........................................12

Power Flow at Low Speed Forward..................13

Power Flow at High Speed Forward.................14

Power Flow at Low Speed Reverse..................15

Power Flow at High Speed Reverse.................16

Transmission Control Valve................................17

Cross-Section View..........................................17

Hydraulic Schematic........................................18

Differential and Drive Axles.................................20

Differential .......................................................20

Wheel Hub.......................................................20

Brake Components.............................................21

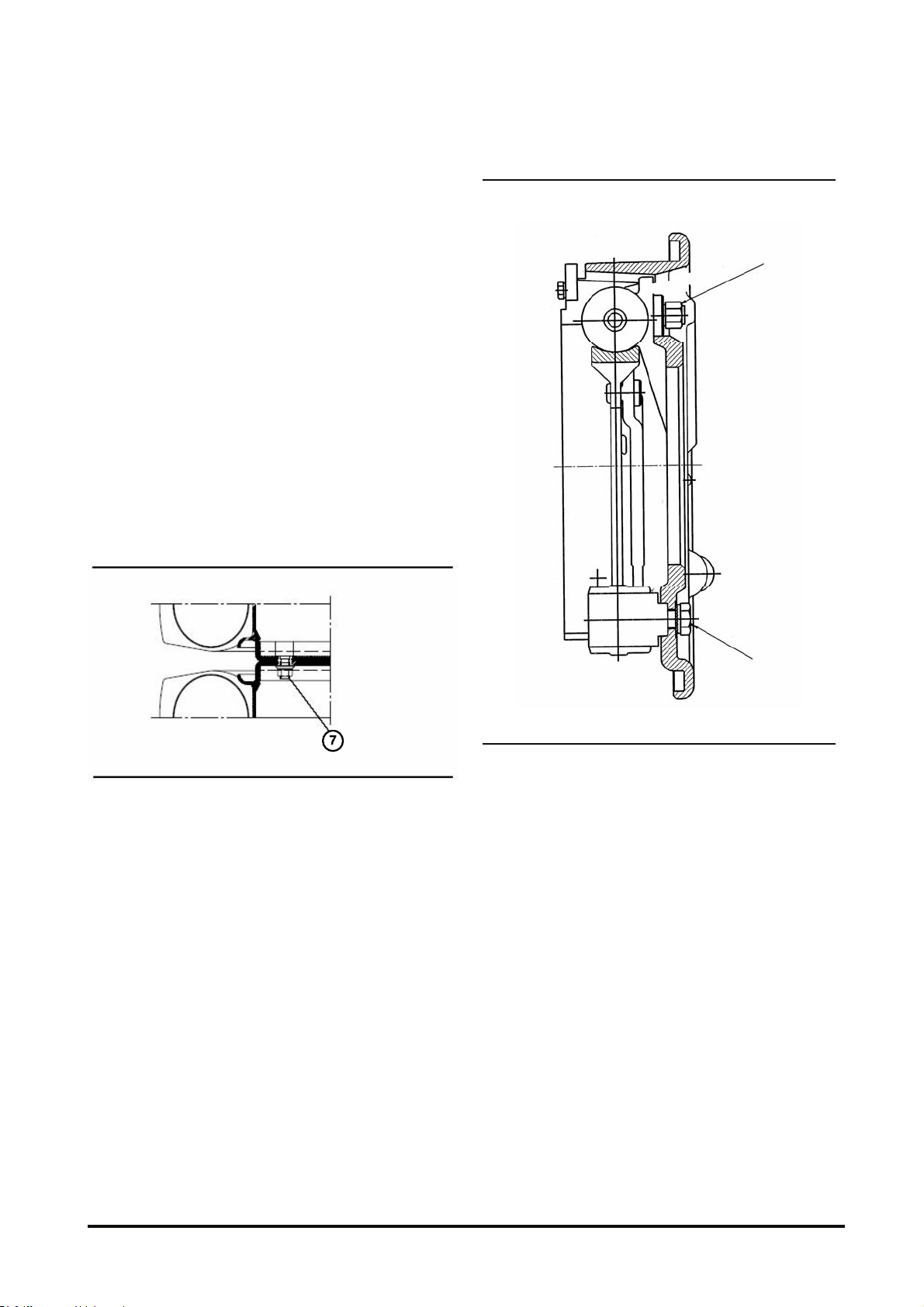

Shoe Brake......................................................21

Brake Adjuster.................................................21

OCDB..............................................................22

Testing and Adjusting

Troubleshooting..................................................23

Visual Checks..................................................23

Checks During Operation.................................23

Check List During Operation ............................23

Check List From Operation Noise.....................25

Check List From Pressure Test........................26

Differential .......................................................27

Transmission Pressure.......................................28

Converter Stall Test............................................29

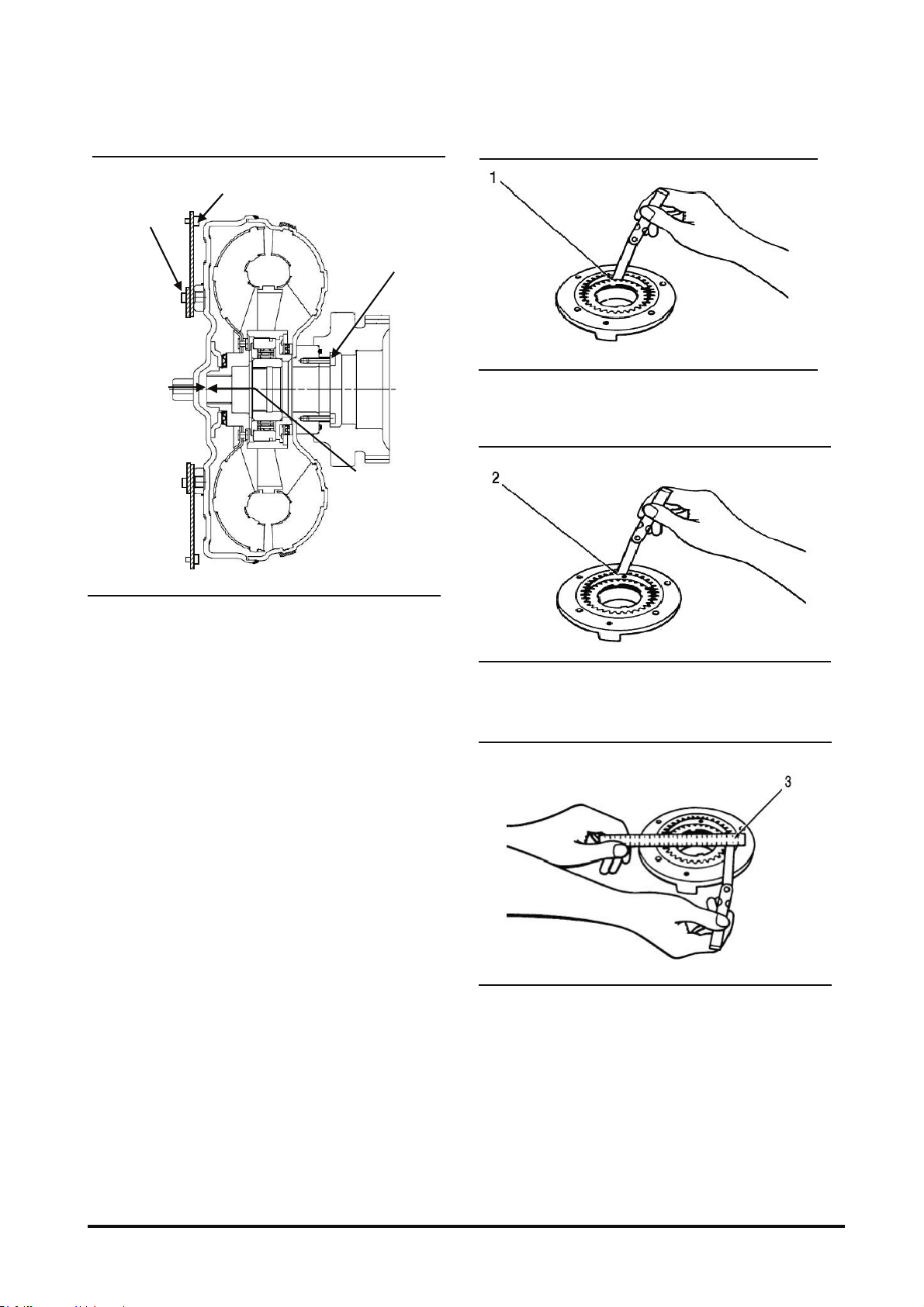

Shimming of Transmission Shaft.........................30

Wheel Brake Adjustment.....................................30

Inching Pedal Adjustment....................................32

Disassembly and Assembly

Drive Shaft and Universal Joint............................35

Engine, Torque Converter and Transmission.......36

Transmission Control Valve.................................40

Transmission.......................................................43

Drive Axle ...........................................................54