4

1. Preparation Before Machine Shipping

1. Preparation Before Machine Shipping

1.1 Selection of Machine Installation site

Temperature at the place of machine installation

Machine performance may be affected due to an irregularity of the lubrication system if

the temperature is lower than the temperature range allowed for machine operation, or

due to reduced cooling capacity of the oil cooler if the temperature at the place is higher.

Since the machine’s precision can be directly affected by displacements of the

respective parts of the machine resulting from a temperature change, the place of

installation needs to be carefully selected after examining it from various angles, in order

to ensure that the in-room temperature is maintained evenly.

①Avoid direct sunlight when selecting the place of machine installation.

▪If unavoidable, consider installing awning screens, etc. to help reduce the

machine’s exposure to direct sunlight.

②Avoid the following places: a place near a factory entrance; a place where a

temperature change is likely due to radiant heat from other machines or walls or due

to the flow of air from an air-conditioning unit.

▪If unavoidable, consider installing screens to help shut off areas subject to outside

air or heat from the surrounding area.

③

In the event of a low ceiling or when several units are installed in a confined space, a

temperature difference between the upper and lower parts of the space concerned

may occur.

▪If unavoidable, consider using a method of forcing

the movement of air between the

upper and lower parts.

※Allowable temperature range for machine operation:5∼40℃(humidity:30∼75%)

2) Vibration around the place of machine installation

The machine needs to be installed in a place as far away as possible fro

vibration such as a road or a press machine where there is a lot of vibration.

▪If unavoidable, consider installing a Damping Pit around the foundation surface of the

machine.

※Note) Vibration regulation value on general worksites : 0.8mm/sec

3) Machine installation floor

The floor on which the machine is installed should be firm, secure and flat.

▪Appropriate foundation work should be conducted if the place where the machine is

installed for the first time consists of soft ground or is prone to subsidence.

▪

If the ground is too weak and soft, drive concrete piles into the ground to reinforce it. In

this case, consult with a professional company before conducting the work.

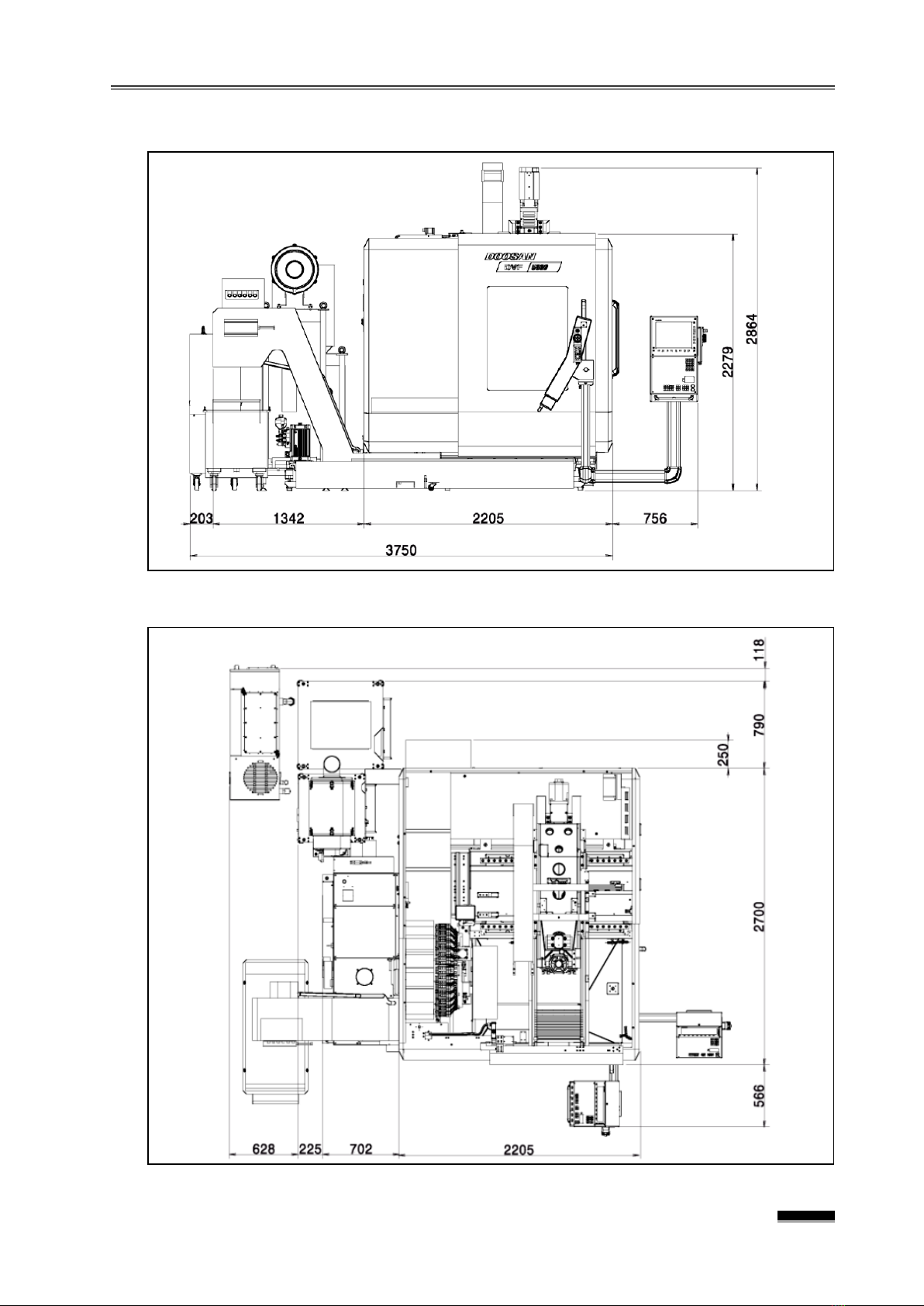

①In addition to the place of installation of the main machine body, secure sufficient

space for door opening, the chip conveyor’s length, and maintenance activities.

②Select a place that is not exposed to dust or strong corrosive gases.