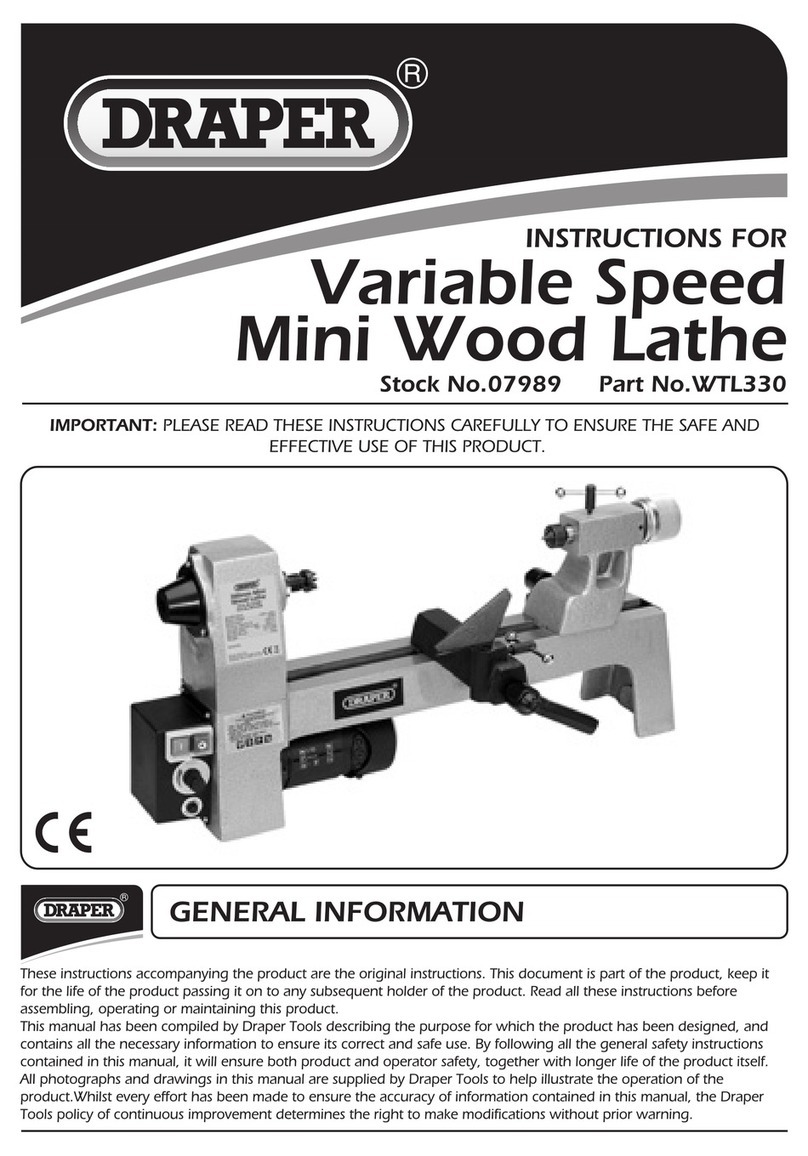

tornos MultiDeco 26/6 User manual

TORNOS SA

CH–2740 MOUTIER

http://www.tornos.ch

INSTALLATION

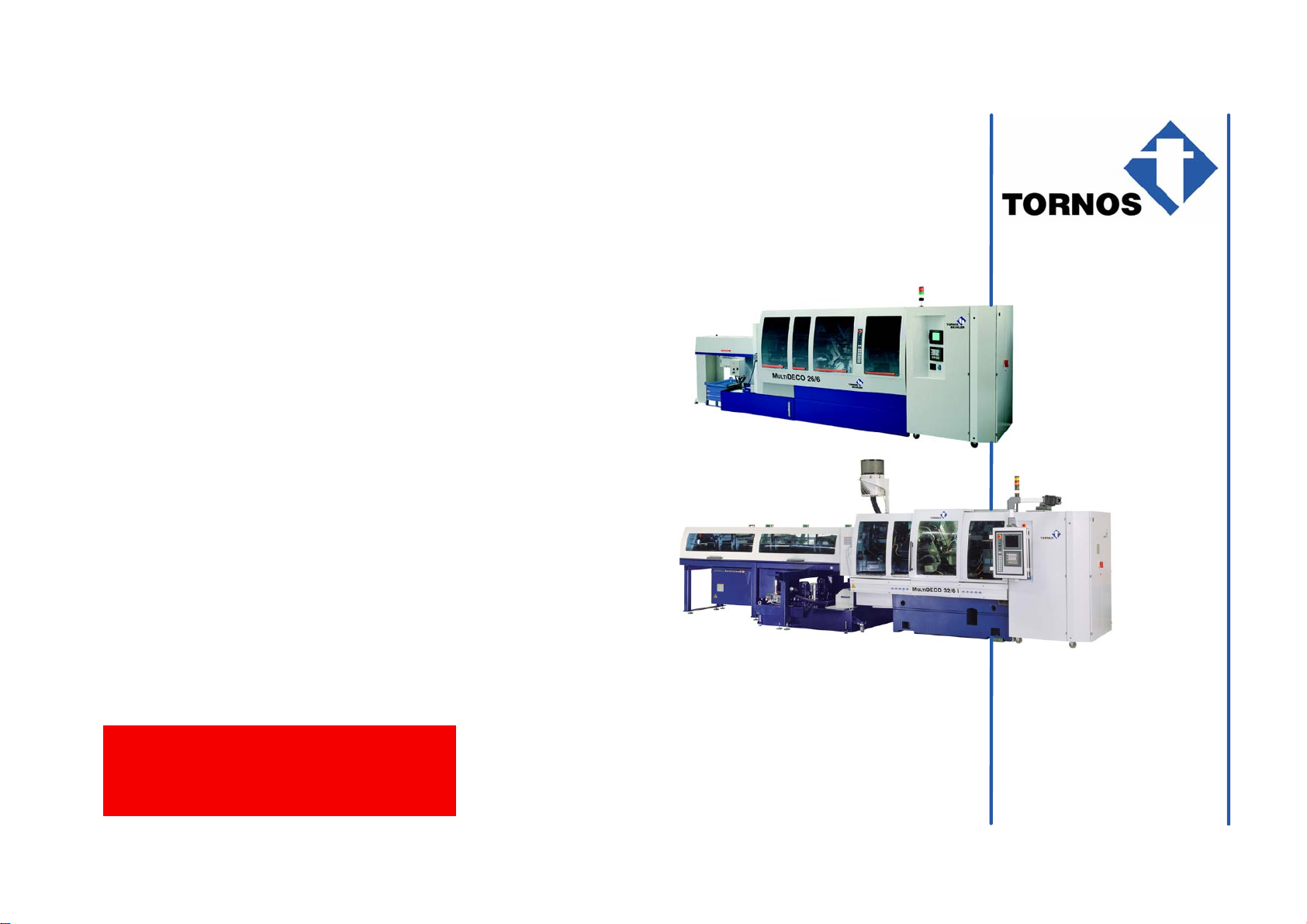

MULTIDECO 26/6

MULTIDECO 32/6i

300381 en

Printed in Switzerland

Copyright (c)1999–2002

∆ATTENTION !

Before handling / operating the machine,

read first the SAFETY REGULATIONS !

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. /2

These instructions are based on the information available at the moment of

their publication. Although the very best has been done to make them as com-

prehensive and precise as possible the instructions do not purport either to

cover all details of the hardware and software or to anticipate every con-

tingency.

TORNOS S.A. neither give any guarantee nor accept any liability for the

exactitude and the sufficiency of the information contained in this document.

The contents of the instructions remain the property of TORNOS S.A. who

reserve the right to modify, complete or correct them at any time.

Important Safety Indications

These instructions indicate a number of safety measure symbols which

appear also on the machine and are intended to protect the user, his/her

effects and the environment from injuries and damage as applicable.

Below, you will find the safety symbols, their headings and definitions. Please,

read these first before you continue.

∆Danger !

indicates a direct danger of death or serious injury.

∆Warning !

indicates an object or action which may cause death or serious

injury.

∆Attention !

indicates an object or action which may cause injury or serious

damage.

The original language of the instructions to be referred to is French. The haz-

ards of misinterpreting the instructions can be considerably reduced by

following the training courses organized and offered by TORNOS S.A.

The CE-marking indicates conformity with the European standards

of safety, health, environment and protection.

∆Caution !

indicates incorrect actions or such that may cause damage.

⊗Prohibition !

indicates an action or operation prohibited because of evident or

alleged hazards.

∆Info :

gives information or comment related to safety.

⇒Note :

gives information unrelated to safety.

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

3300381 en – 06/02

TABLE OF CONTENTS

1. GENERAL 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 IDENTIFICATION OF THE MACHINE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SAFETY MEASURES & DEVICES 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 GENERAL CHARACTERISTICS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 INSTALLATION OF AN IEMCA BARFEEDER FOR MULTIDECO 26/6 2. . . . . . . . . . . . . . . . . . . . .

1.5 PRESENTATION MULTIDECO 26/6 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 PRESENTATION MULTIDECO 32/6I 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. UNPACKING AND CLEANING 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Machine handling 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 UNPACKING 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 CLEANING 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Removal of rust–proofing 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. LOCATION/INSTALLATION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

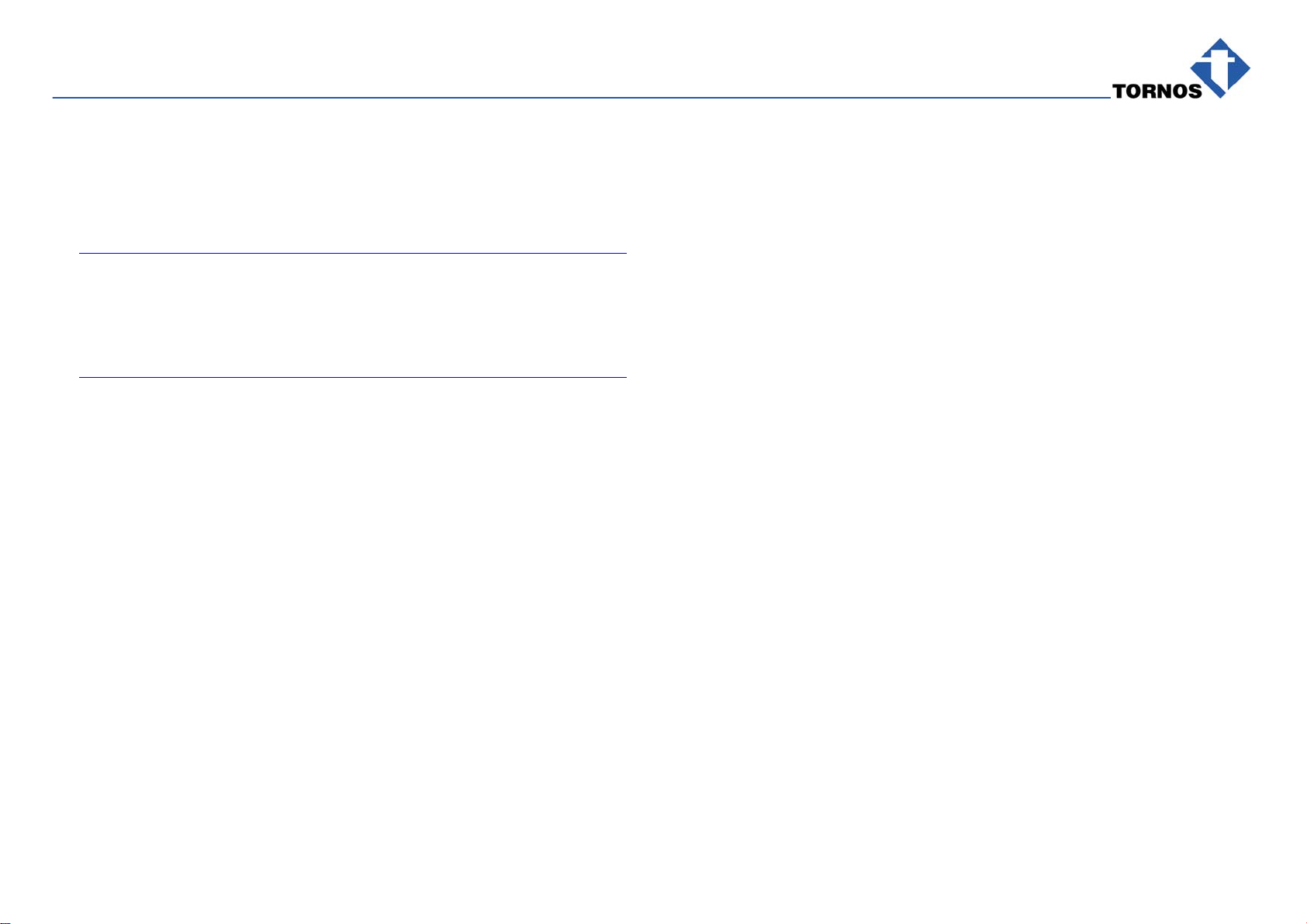

3.1 FLOOR PLAN 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Floor Plan MULTIDECO 26/6 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Floor Plan MSF–832 on MULTIDECO 26/6 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Floor Plan MULTIDECO 32/6i 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 INSTALLATION 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Surface load 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Levelling 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Removing transport locks 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

4300381 en – 06/02

3.3 MOVING THE MACHINE 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Mechanical locking of lathe mobile units 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 ELECTRIC INSTALLATION MULTIDECO 26/6 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Installation characteristics 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Electric Connection to 200V – 240VAC Mains 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Electric Connection to 380V – 480VAC Mains 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.4 Electric connection to 500VAC mains 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.5 Connection of various machine peripherals 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 ELECTRIC INSTALLATION MULTIDECO 32/6I 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Installation characteristics 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Connection of various machine peripherals 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Connection and inspection procedure 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.4 Electrical connection depending on mains type 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 PNEUMATICS INSTALLATION 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 Required air quality 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 1.3 /1

1. GENERAL

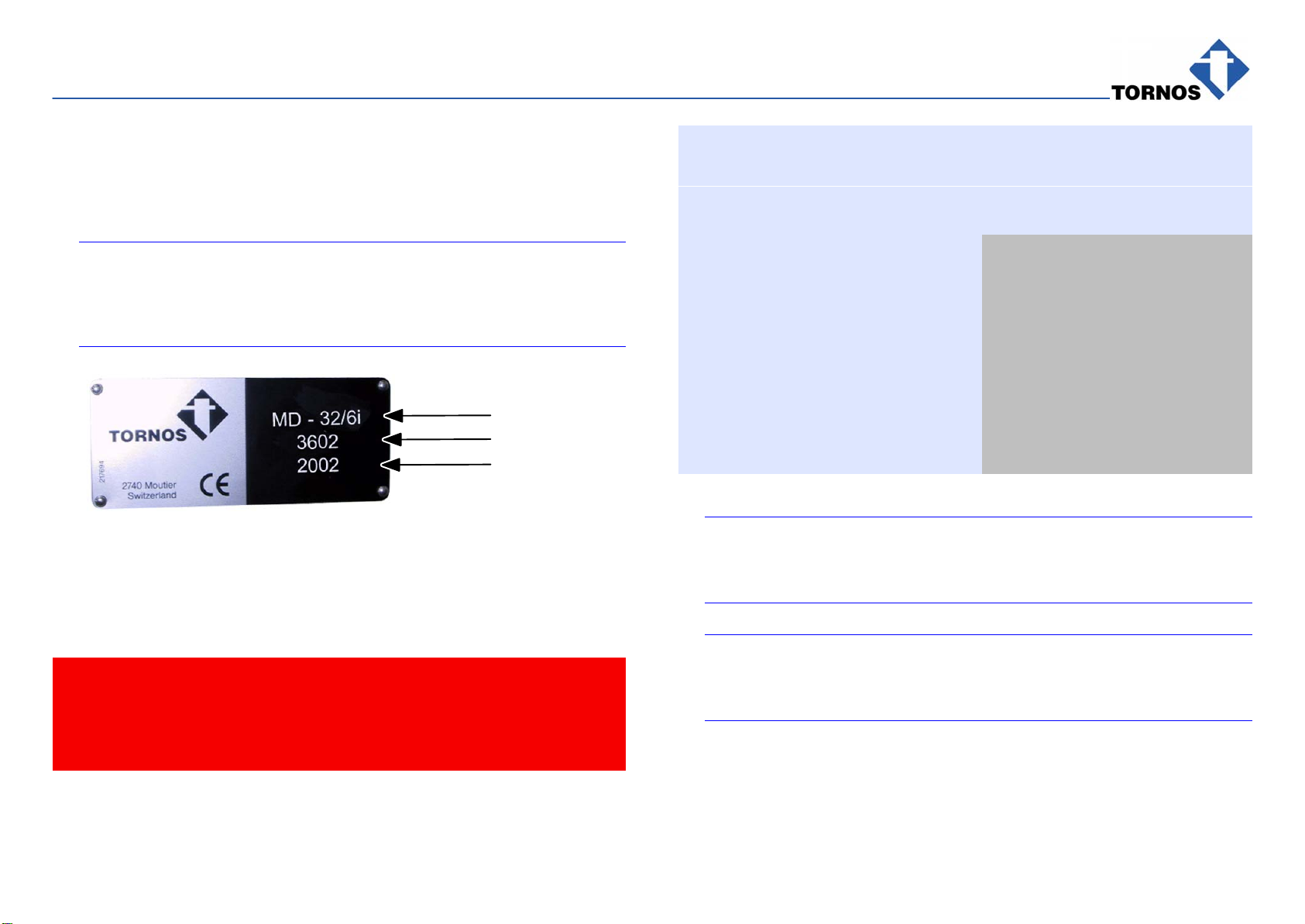

1.1 IDENTIFICATION OF THE MACHINE

⇒Note:

Placed on the right side of the machine, this plate indicates primarily the

machine version number, to be quoted when contacting TORNOS ser-

vices.

Type

Series

Year

1.2 SAFETY MEASURES & DEVICES

These are described in the Instructions 300460 “SAFETY REGULATIONS”.

∆ Caution!

Failure to comply with the safety regulations

may cause serious accidents.

1.3 GENERAL CHARACTERISTICS

Data Characteristics

MULTIDECO

26/6 MULTIDECO

32/6i

Length 6035 mm 8300 mm

Width 1600 mm 1720 mm

Height (without indicator lamp) 1950 mm 2158 mm

Weight of machine equipped with

switch cabinet 13 axes: 8000kg

17 axes: 8500kg

19 axes: 9000kg

8300kg

Load per surface unit of floor approximately

12

daN/cm2

approximately

12 daN/cm2

⇒Note :

For more details, consult your operating instructions entitled :

MACHINE EQUIPMENT.

⇒Note :

For more details, consult your operating instructions entitled :

OPERATION & MAINTENANCE.

DIMENSIONS

– See chapter entitled ”Location/Installation”

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 1.4 /2

1.4 INSTALLATION OF AN IEMCA barfeeder for MULTIDECO 26/6

∆Attention !

For impeccable operation of the BARFEEDER–LATHE assembly

TORNOS have issued instructions with the characteristics & functions

required for the feeder–lathe interface. The instructions are entitled :

INTERFACE SPECIFICATIONS FOR STOCK TUBE OR BARFEEDER

These specifications must be strictly complied with to avoid malfunction-

ing of the bar feeding system, which might be imputed to the lathe.

TORNOS declines any liability whatsoever, should a damage or acci-

dent be imputed to a tube / feeder which do not conform to the said

specifications &/or standards in force.

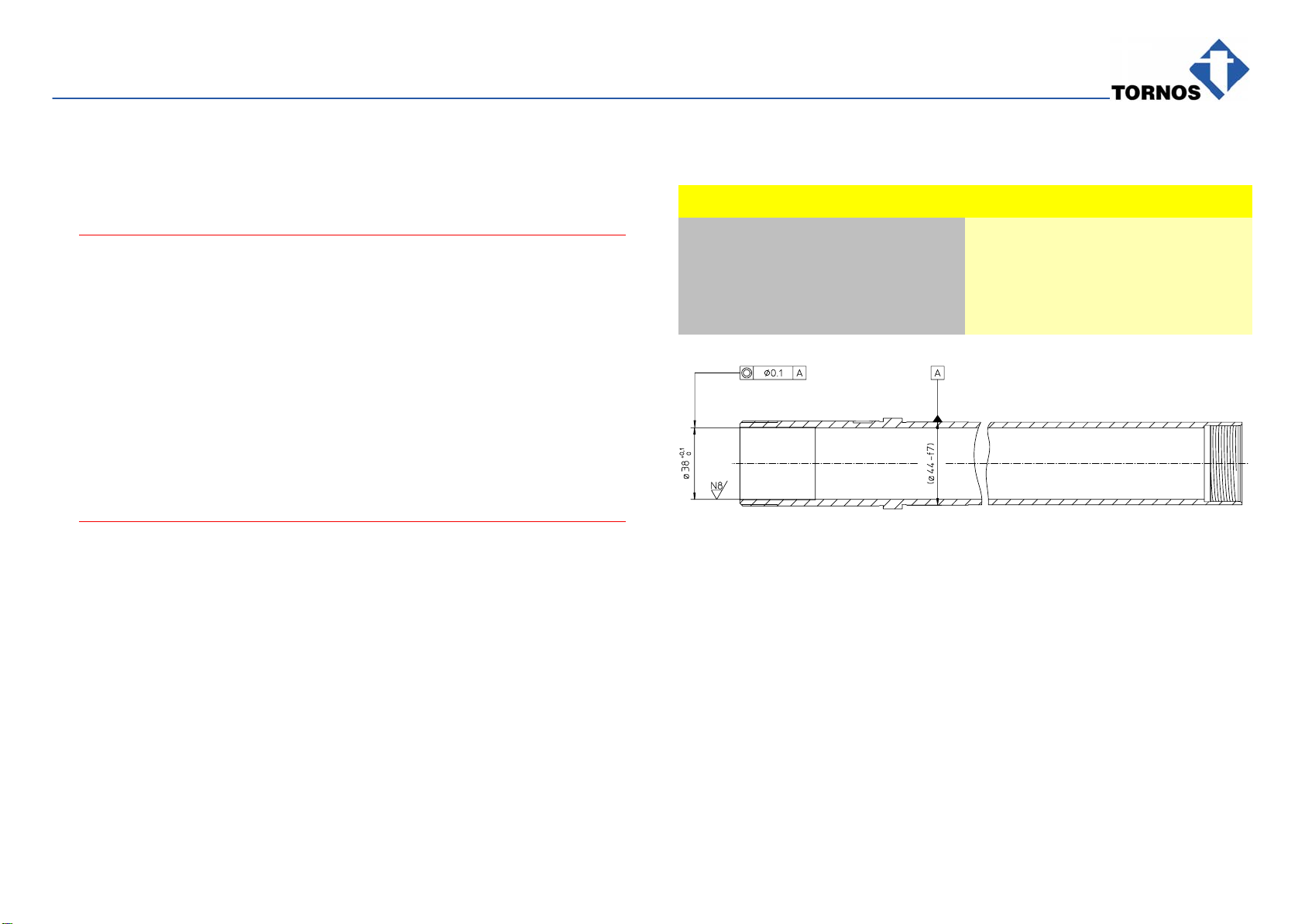

BARFEEDER INSTALLATION

Action Notes

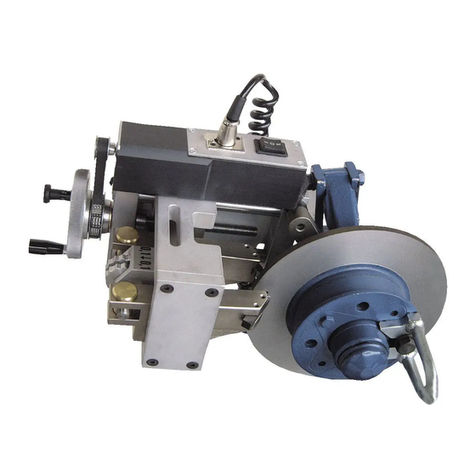

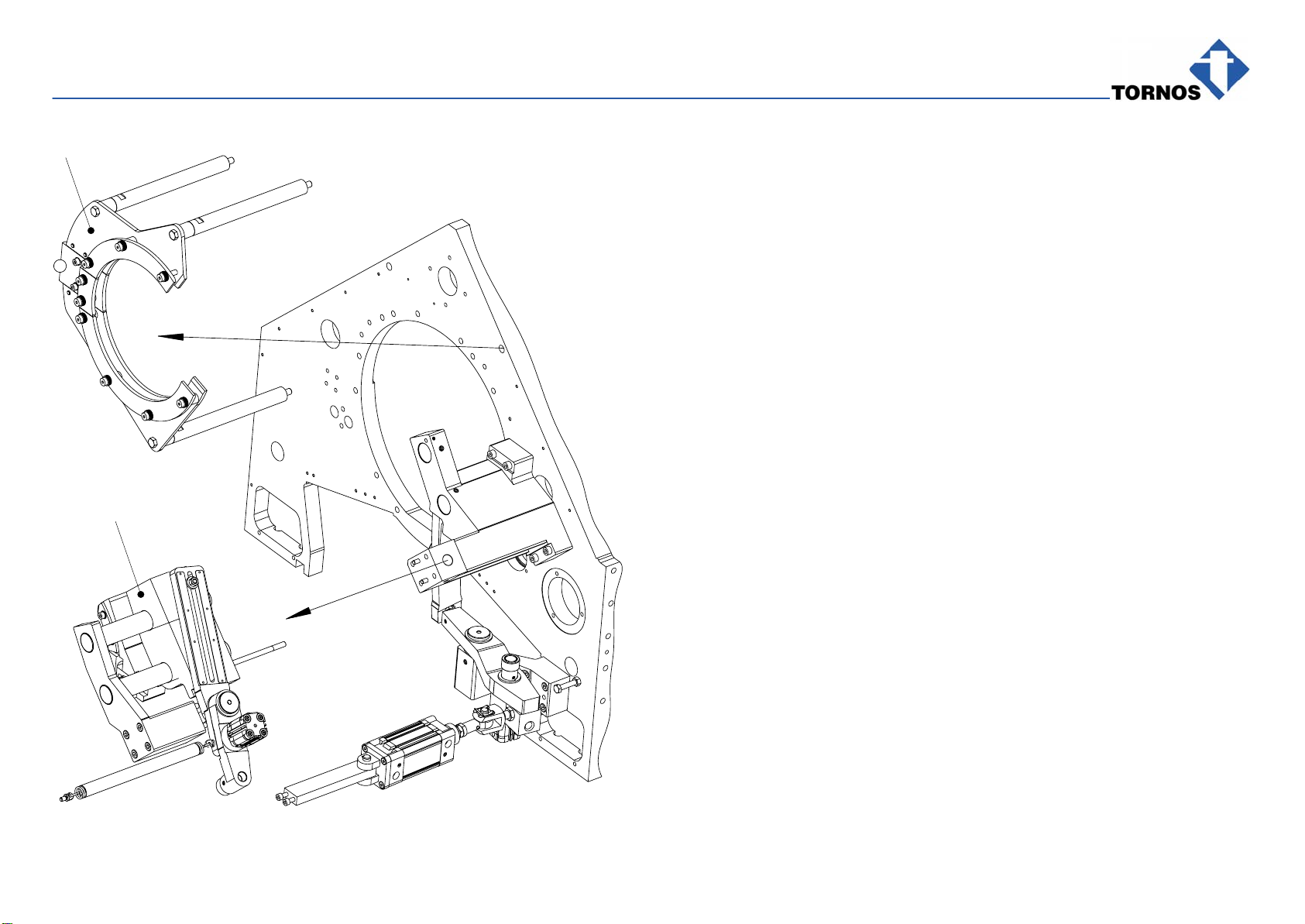

– Remove feed mechanism 1 and

stock feed tube 2. Fig. 112

– Turn dia. 38 in bronze rings. Fig. 111

111

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 1.4 /3

112

2

1

>>>

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 1.5 /4

1.5 PRESENTATION MULTIDECO 26/6

6

310

1

2

8

9

7

5

3

1

11

1. See–thru door for machining range

Ident. no. 217439

2. See–thru door for chuck and feed range

Ident. no. 217441

3. See–thru door for spindle housing

Ident. no. 217440

5. See–thru door for manual chucking range

Ident. no. 217441

6. NC Keyboard

7. Switch cabinet

8. Control panel

9. NC screen

10. See–thru door with opening on part output side

Ident. no. 217442

11. See–thru door for access to gear housing

Ident. no. 217441

Item nos. 1, 2, 3, 5, 10, 11: See–thru door alone with glued guiding “U” profile.

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 1.6 /5

1.6 PRESENTATION MULTIDECO 32/6i

8

7

6

5

4123 109

1. See–thru door for machining range

Ident. no. 217439

2. See–thru door for chuck and feed range

Ident. no. 217441

3. See–thru door for spindle housing

Ident. no. 217440

5. See–thru door for manual chucking range

Ident. no. 217441

6. NC Keyboard

7. Switch cabinet

8. Control panel

9. NC screen

10. See–thru door with opening on part output side

Ident. no. 217442

11. See–thru door for access to gear housing

Ident. no. 217441

Item nos. 1, 2, 3, 5, 10, 11: See–thru door alone with glued guiding “U” profile.

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 1.6 /6

>>>

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 2.1 /1

2. UNPACKING AND CLEANING

2.1 Machine handling

⇒Note

Lifting and moving of the machine must only be carried out using the

appropriate equipment supplied with the machine, which must be

located only in the places indicated in transport documents 300379 or

300369.

Lift the machine together with its switch cabinet by means of a pulley block

& beam or mechanical/hydraulic jacks.

With a lifting pulley block & beam:

Put four lifting bars 3, supplied with the machine, into the openings in the

base. Screw in 8 fixing screws 4 merely to keep the lifting bars from acciden-

tally slipping out of the base.

∆Attention!

Do not tighten the bolts. Leave 0.5–1.5 mm play between the screw

heads and the lifting bar flange.

Slip 2 ties 5 on 2 bars 3 and into axes 18 of the switch cabinet. Screw tie nuts

9 to bring the switch cabinet close to the machine and support it.

Hitch lifting slings 6 round all bars 3 and at lifting beam 7. Put wooden wedges

between the slings and enclosure 8 to protect the latter. Fit the horizontal

door–handles in place. Lift the machine slowly; 2 beams inside the base also

support the switch cabinet.

With a mechanical / hydraulic jack:

Put 4 jacks under lifting bars 3. Lift the machine together with the switch cabi-

net. Slide 2 or 3 roller flats underneath to facilitate transport.

⇒Note.

The lifting and handling equipment (function 8910 of technical descrip-

tion 300429 for MULTIDECO 26/6 or 300519 for MULTIDECO 32/6) may

be returned to TORNOS S.A. after use.

Replace the coolant tank, the conveyor, the MAYFRAN tank, reconnect the

tubes.

Stabilise back plate 27 by fixing it with the 2 M24 screws of the coolant tank.

Fit the barguide and level it by means of the 3 levelling elements of its rear

support.

∆Attention!

The machine must not be operated with open doors and guards.

Before switching the machine on and starting up, make sure that all

doors, access doors and other guards are properly closed.

The switch cabinet is attached to the frame with 2 M16 bolts, situated down

in the cabinet and accessible through its door on the side of Main Switch QS0.

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 2.3.1 /2

2.2 UNPACKING

Pull out nails from the cover and then from the walls of the case. Remove the

vacuum–packing plastic.

Remove the wooden wedges and ropes that hold various items.

⇒Note:

Refer to the transport document

– 300379 for MULTIDECO 26/6 or

– 300369 for MULTIDECO 32/6i

supplied with all the machine documentation.

∆Caution!

Unlocking must not be performed until the machine has been set in

position.

2.3 CLEANING

2.3.1 Removal of rust–proofing

⇒Note:

The rust inhibitor applied depends on the particular destination.

∆Attention!

Cleaning must only be performed in well–ventilated areas

(inhalation of toxic vapours).

Action Notes

Clean carefully all the parts cov-

ered with anti–rust coating using

cloths soaked in benzine or paraf-

fin

∆Caution!

Cause no damage or misadjust-

ment.

∆Avoid using compressed air and

products which may damage

synthetic materials.

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 3.1 /1

3. LOCATION/INSTALLATION

3.1 FLOOR PLAN

⇒Note:

The dimensions relate to the standard configuration with optional (addi-

tional) tank and cooler. Be sure to take into account for your particular

floor plan the dimensions of other options added to the machine, such

as barfeeder, mist & smoke control unit, etc.

>>>

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 3.1.1 /2

3.1.1 Floor Plan MULTIDECO 26/6

199260f1

(dimensions with MSF–832 barfeeders for 4 metre bars)

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 3.1.2 /3

3.1.2 Floor Plan MSF–832 on MULTIDECO 26/6

(9300)

199413

(dimensions with MSF–832 for 4 metre bars)

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 3.1.3 /4

3.1.3 Floor Plan MULTIDECO 32/6i

199264f1

(dimensions with MSF–832 barfeeders for 4 metre bars)

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 3.2.2 /5

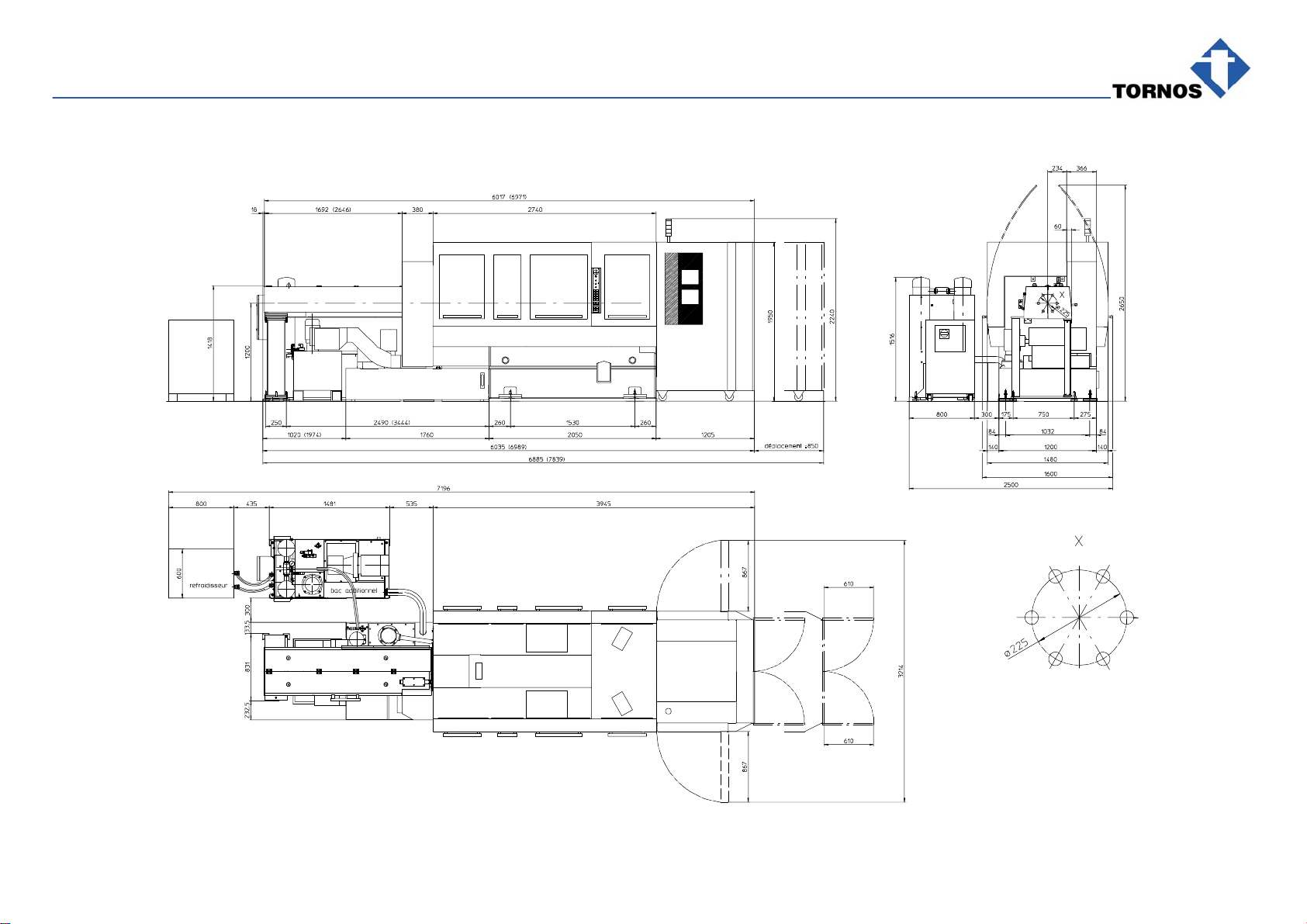

3.2 INSTALLATION

3.2.1 Surface load

∆Caution!

Take account of the admissible loading of the floor depending on the

machine equipment to be installed

– approximately 12 daN/cm2.

P = Floor loading per levelling pad.

P = 2500 kg

P = 5000 kg

250

=

250

=

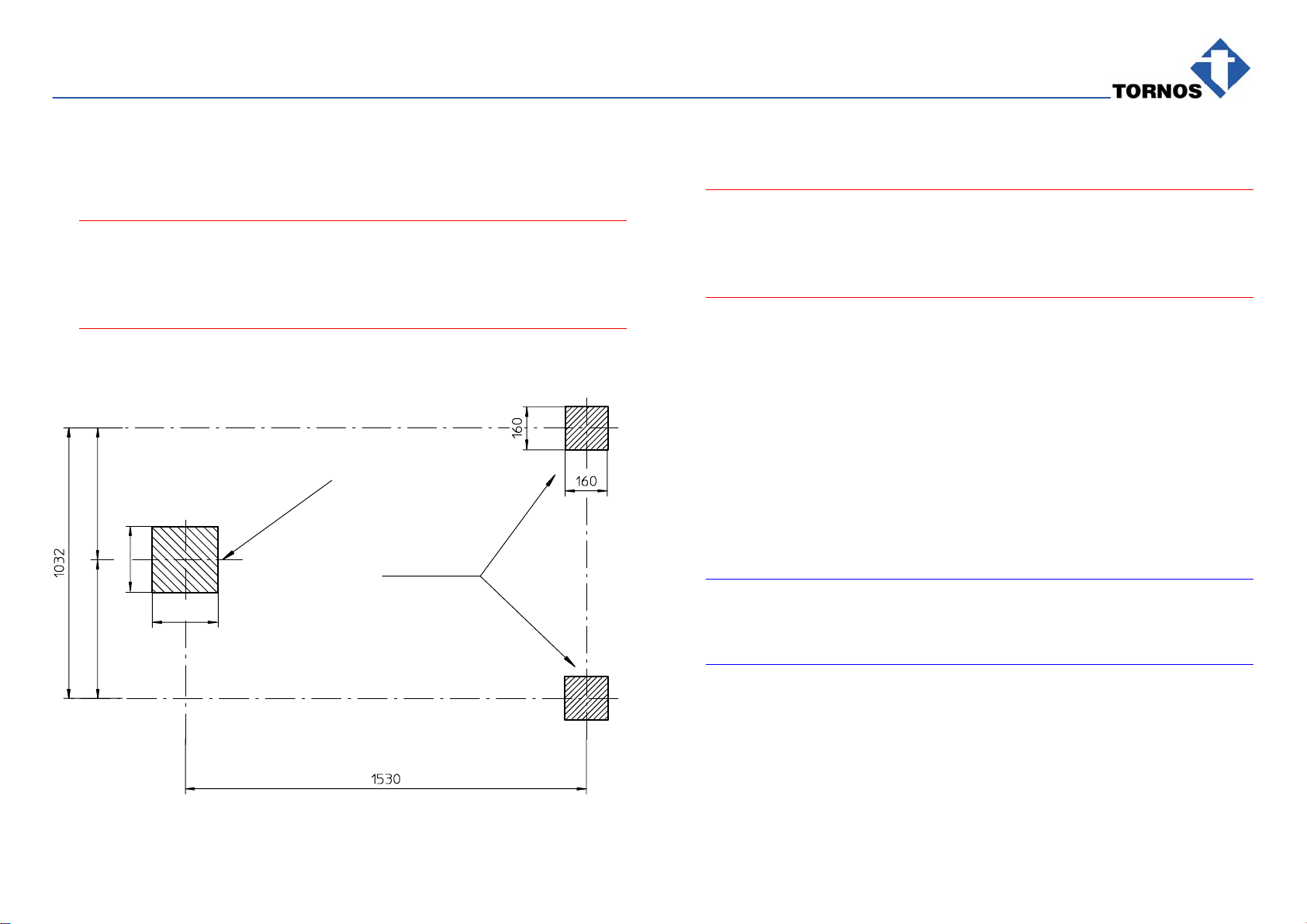

3.2.2 Levelling

∆Caution!

To ensure correct functioning of the machine under the best possible

conditions, the levelling procedure described hereafter must be strictly

complied with.

The machine must be installed on a hard, stable, vibration–free floor. If this

is not available, cast a concrete bedding.

While the machine is lifted, remove 4 (transport) plates 1, insert instead 2 bolts

10 of levelling elements 15 in the holes and keep screwing nuts 11 until level-

ling elements 15 rest against the bed plates, switch cabinet side.

Put the base definitively down on the floor directly or in a flat sump, ensuring

that the third support element is set in place (250 x 250 mm, see Fig. oppo-

site).

⇒Note:

The switch cabinet rollers must touch the floor. Ties 5 are then relieved

from carrying the weight of the cabinet.

Perform levelling carefully by turning the screws 17 of the levelling elements

15.

Use a precision spirit level: 0.020 mm/1000 mm, positioned on the base in

front of the control frame (Figs. 302 to 305).

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 3.2.2 /6

∆Caution!

Once the machine is in position, remove the foam rubber protection 6

from the machine base near the coolant tank. (Figs. 301 & 302)

53

2

301

6

5 (2x 240950) 3

4

(217147)

1

302

2

6Positioning of the level

1. The space nos. 2 and 3 (Figs. 301 & 302) must be relieved of any weight,

so that the machine base is borne only by element nos. 1, 4 and 5.

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 3.2.2 /7

303

2. With the level in diagonal position (Fig. 303), effect horizontal levelling by

means of levelling element nos. 1 and 4.

304

3. Place the level parallel to the longitudinal axis of the machine (Fig. 304)

and if necessary adjust the setting by means of levelling element no. 1.

INSTALLATION – MULTIDECO 26/6 – MULTIDECO 32/6i

300381 en – 06/02 Chap. 3.2.3 /8

305

4. Place the level perpendicularly to machine axis (Fig. 305) and check if

transverse axis of the base is horizontal. If necessary, adjust the setting

by means of levelling element nos. 1 and 4 by repeating the directional

checks under points 2 and 3.

3.2.3 Removing transport locks

Action Notes

Remove the wooden wedges and

ropes that hold various items in

place.

Oil tank, chip pan, manipulator,

hatches.

Remove mechanical locking

devices Locking device

Put away the locking pieces for

possible future use.

∆Caution!

Unlocking must not be performed until the machine has been set in

position.

This manual suits for next models

1

Table of contents

Other tornos Lathe manuals