7

NHM/NHP Series NHM/NHPAPCE2C

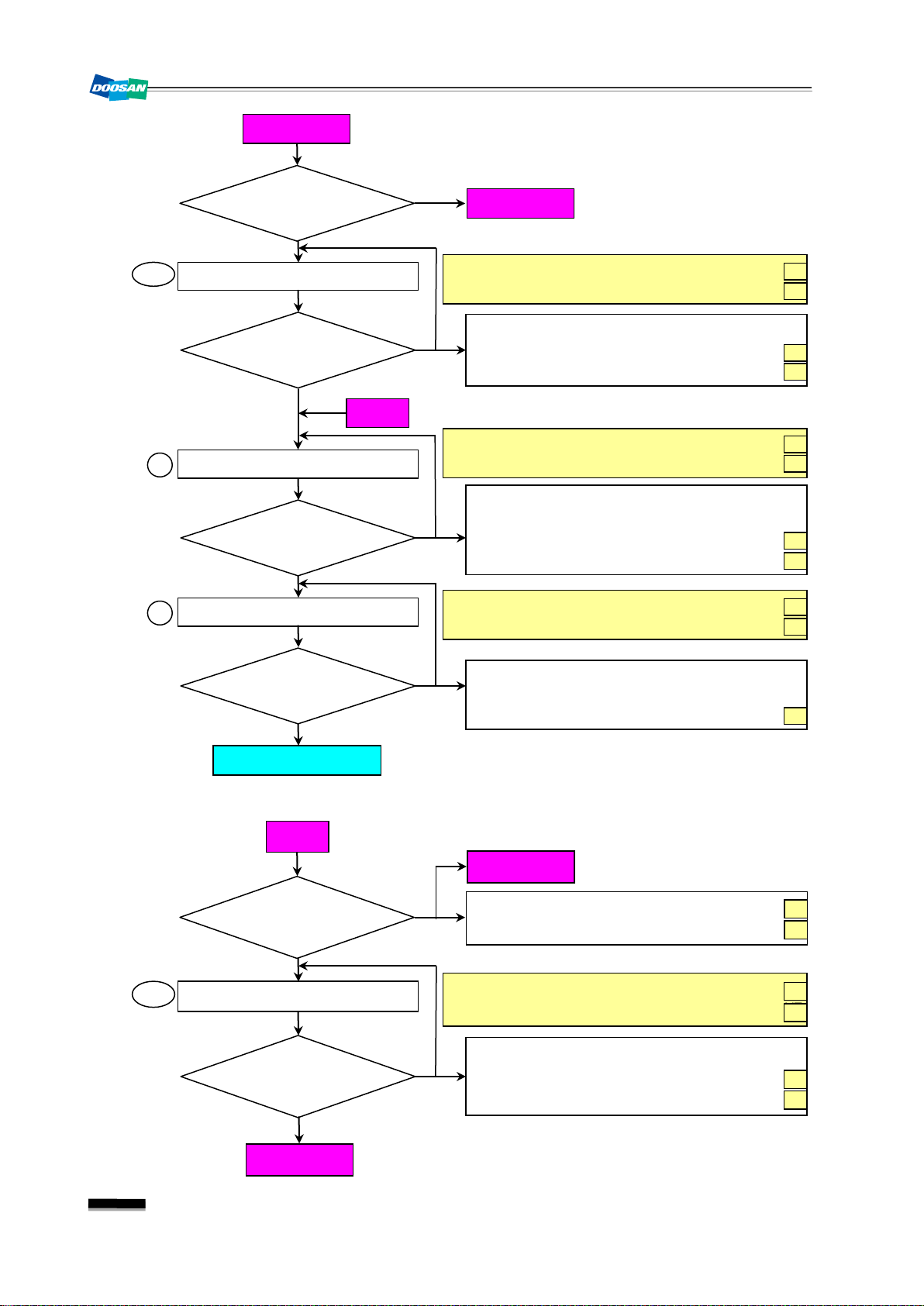

3. Conditions of each sequence during Manual Step Operation

(K33.2)

▪

OUTPUT SIGNAL : Y5.5(PAUC.R)

= 1

▪

COMPLETE SIGNAL : X11.4(RPTCL.M) = 0

1)

Select Manual Mode by the mode selector switch on Main O.P PANEL (

or

Mode)

2)

APC Manual Mode (X7.2 = 1)

3)

Select

in

state on

Screen.

4)

(X36.1 = 1)

(K32.6)

▪

OUTPUT SIGNAL : Y5.6(APUP.R) = 1

▪

COMPLETE SIGNAL : X12.0(APUP.M) = 1

1)

Set-Up Door Close (X13.1 = 0)

2)

Operator Door Close Confirm (X6.6, X6.7 = 1)

3)

Y,Z,B Axis APC Position (Y,Z Axis 2

nd

Ref, B axis Ref)

4)

APC Down Check (X12.1 = 1)

5)

Pallet Unclamp (X11.4 = 0, Y5.5 = 1)

6)

Select Manual Mode by the mode selector switch on Main O.P PANEL (

Mode)

7)

APC Manual Mode (X7.2 = 1)

8)

Select

in

state on

Screen

9)

(X36.1 = 1)

(K33.0)

▪

OUTPUT SIGNAL : Y10.1(POSI1.R) =1 COMPLETE SIGNAL : X16.0(PPSO1.M) = 1

and X16.7(PVPF.M) = 1

1)

Set-Up Door Close (X13.1 = 0)

2)

Operator Door Close Confirm (X6.6, X6.7 = 1)

3)

APC 180CCW Position(X16.0 = 1, X16.1 = 0 or K32.4 = 1)

4)

APC ARM Up (X12.0 = 1)

5)

Select Manual Mode by the mode selector switch on Main O.P PANEL (

Mode)

6)

APC Manual Mode (X7.2 = 1)

7)

Select

in

state on

Screen

8)

(X36.1 = 1)

(K33.1)

▪

OUTPUT SIGNAL : Y10.0(POSI0.R) =1

COMPLETE SIGNAL : X16.1(PPSO2.M) = 1

and X16.7(PVPF.M) = 1

1)

Set-Up Door Close (X13.1 = 0)

2)

Operator Door Close Confirm (X6.6, X6.7 = 1)