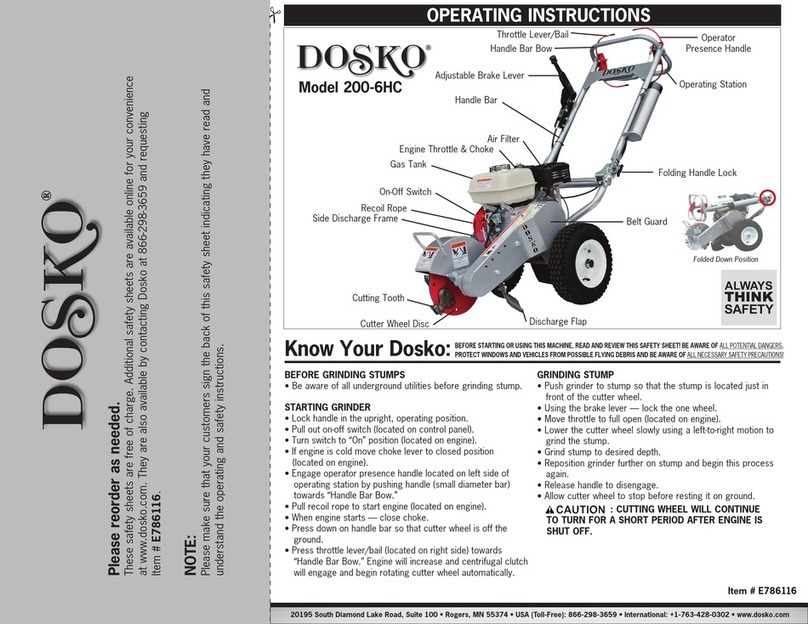

About Your Grinder

Thank you for purchasing or renting your Dosko grinder!

Owner/Operator/Renter Training

Read and follow all instructions and safety precautions presented throughout this manual. A summary of

important safety information can be found at the end of the manual. Keep this manual for reference and

review. If the owner of this unit is different than the operator, give a copy of this manual to any

operator to read.

Rental Companies

All persons to whom you rent/loan this grinder must have access to this manual and read it. Check the

tube on the side of the unit to make sure a manual is inside. Advise all persons who will operate the

machine to read it. You should also provide personal instruction on how to safely operate the grinder and

remain available to answer any questions a renter/borrower might have. If videos are available, have

renter watch training video.

Engine Instructions

For detailed Engine operation and maintenance information, always refer to the engine Owner’s Manual

furnished with the grinder.

Product Suitability

Before using, the user shall determine the suitability of this product for this intended use and assumes

liability therein.

Your Dosko grinder can be used to remove many tree stumps and exposed root systems close to ground

level. By moving the blade in sweeping movements laterally over the top and front of the stump, you can

gradually grind it away. Make sure you completely read and understand this manual before using the

grinder for the first time. If you have any questions, contact your retail or rental dealer or Dosko

Customer Service at 1-800-822-0295.

WARNING: Never attempt to cut on a slope exceeding 15.

Exercise caution when cutting stumps on an incline, as the machine may shift or slide unpredictably. Never

attempt to cut with the machine uphill or downhill from you as it may slide toward you or you may fall

toward the machine. Cut only on a slope from the side.

˙

Dosko is constantly improving its products. The specifications outlined herein are subject to change

without prior notice or obligation. The purchaser and/or user shall assume liability for any modification

and/or alterations of this equipment from original design and manufacture.

Contact Dosko Customer Service at 1-800-822-0295 for any questions about the appropriate use of

this grinder or about optional accessories.

Warranty Registration

Please fill out and submit the warranty registration card so that we have your contact information for any

future product literature or replacement parts you may need.