7

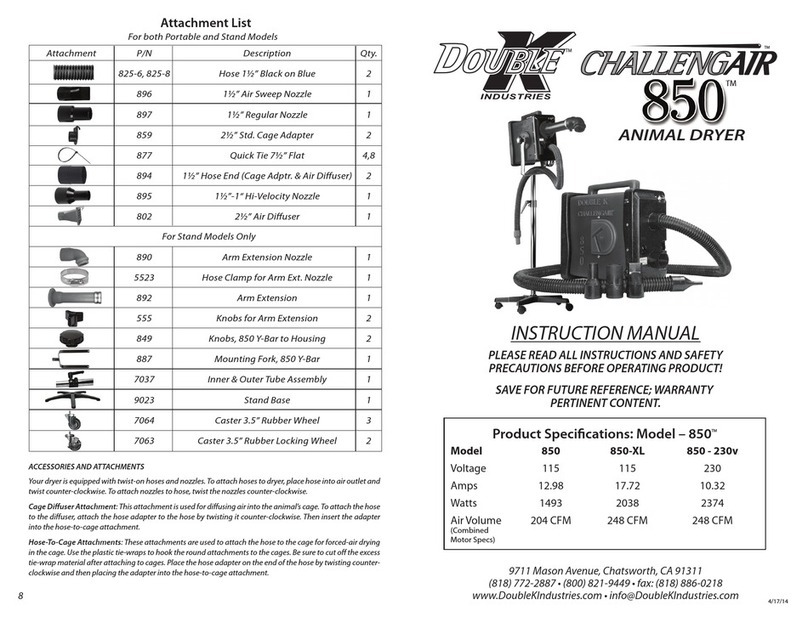

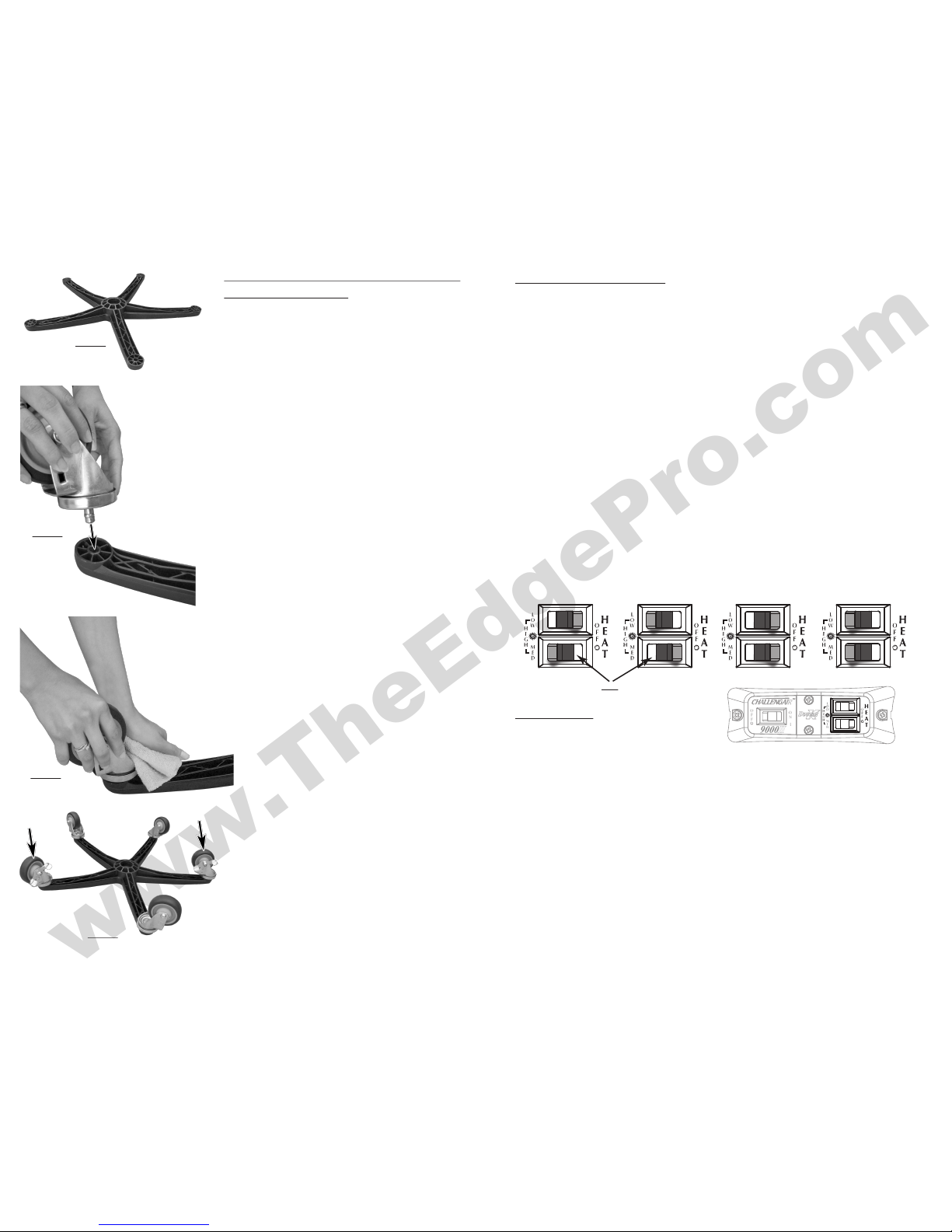

ASSEMBLY:

Dryer and Stand

The stand tube assembly is pre-assembled and wrapped in paper. The stand tube

assembly is compressed and held in position by the center clamp. Loosen the handle

on the clamp and allow the spring to extend the tube assembly. Place the end of the

larger outer tube down into the center of the stand base. Twist and push down rmly

(see ref #55, 57 on parts diagram). On the dryer head assembly, move the yoke to

a 90-degree angle to the dryer. Lift the dryer and position over the assembled

stand and slide the tube of the yoke into the upper stand tube (see ref #49, 53). With

clamping handle still loose, raise or lower dryer to desired height and tighten stand

adjustment handle as explained in the next paragraph (see ref #45).

Stand Height Adjustment and Dryer Angle Adjustment:

Your dryer has "ratchet" type adjustment handles on the stand and the dryer. To

tighten an adjustment handle, turn the handle clockwise as far as is comfortable. As

necessary, for additional tightening, pull the handle out to disengage the "ratchet"

and while keeping the handle pulled out, turn the handle counter-clockwise to a

suitable position for continued tightening. Release the handle to engage the

"ratchet" again and repeat these procedures until the adjustment handle is tight.

Reverse the turning direction of these actions to loosen an adjustment handle.

NOZZLE: The nozzle at the end of the extension arm may be rotated to change the

direction of the airow. Simply rotate nozzle to the desired direction (see ref #42).

Optional Attachment: A hose and nozzle kit is available for the Challengair 9000

II. To attach the hose to the dryer, insert hose end into the arm extension nozzle. To

attach nozzles to the hose, simply push nozzle securely onto the hose end.

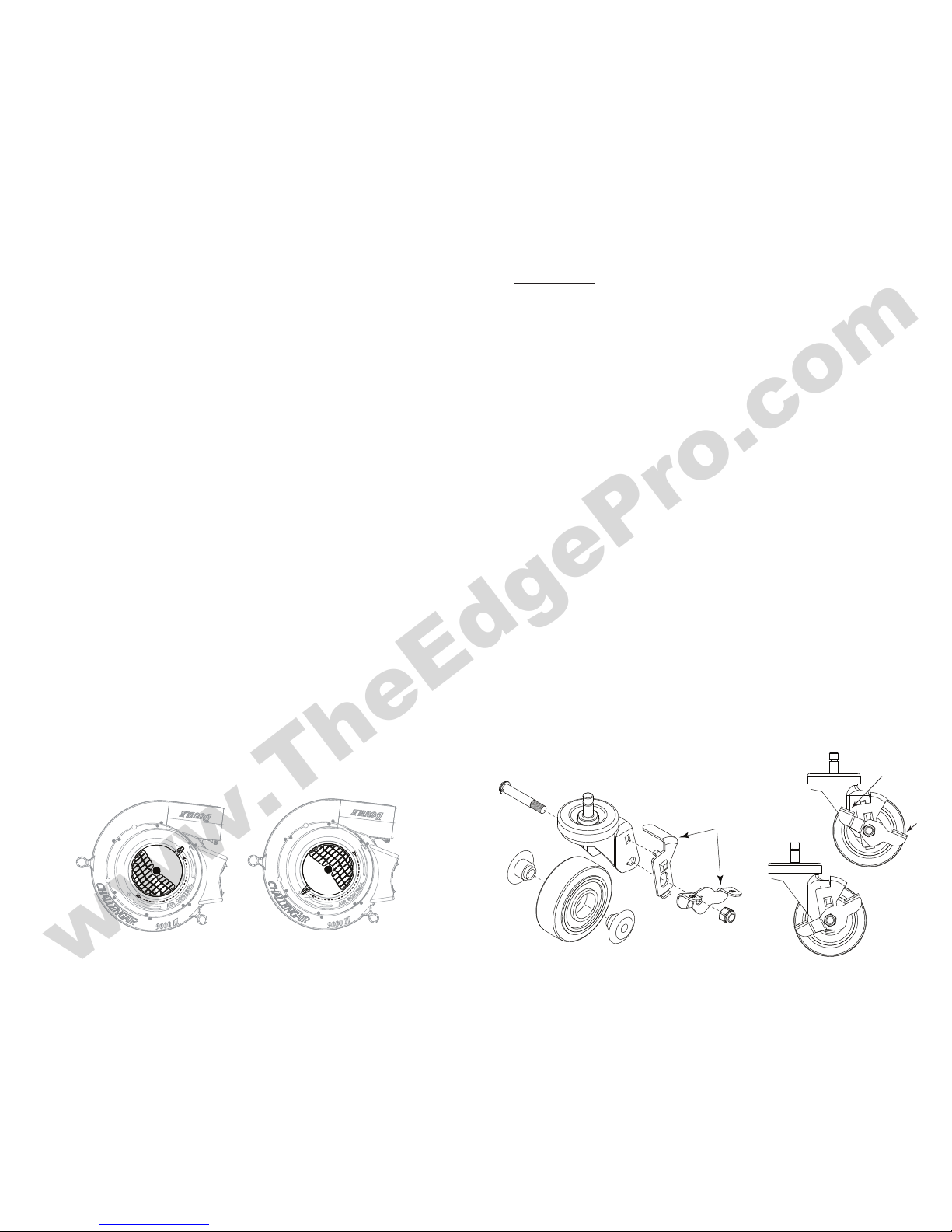

Dryer Stand: Your dryer stand has two locking casters to keep the dryer from rolling

inadvertently. To lock wheels, press down on the lock arm that has “ON” engraved on

it. To unlock, press down on the lock arm that has “OFF” engraved (see below). For

long life and smoother operation, avoid rolling casters through hair that has fallen

on the oor.

Locking

Wheels

Unlocked

Locked

ON

OFF

These parts only

on locking wheels

2

IMPORTANT SAFEGUARDS

WARNING: IMPORTANT SAFETY PRECAUTIONS! PLEASE READ

COMPLETELY BEFORE USING PRODUCT!

When using electrical appliances, especially in the presence of children and animals,

basic safety precautions should always be followed to reduce the risk of re, electric

shock, and personal injury, including, but not limited to the following:

1. Only use product for its intended purpose: animal drying.

2. Unplug unit when not in use.

3. Do not use extension cords with dryer.

4. Do not unplug unit by pulling on cord.

5. Do not expose dryer to rain or water.

6. Do not use or store dryer where it can fall or be pulled into tub or sink or stand-

ing water. If dryer falls into water . . . UNPLUG IT . . . Do not reach into the water!

7. Unplug unit before attempting any maintenance or service.

8. Do not put any object into dryer openings.

9. Keep loose clothing, jewelry and hair away from dryer openings.

10. Do not direct dryer air towards eyes or ears of people.

11. Never use dryer if it has a damaged cord or plug, has been dropped, damaged,

exposed to rain or water. Return to Double K Industries or an Authorized

Service Center for service.

12. Recommended operation by adults only. Use caution when working around

children.

13. Use only attachments recommended by Double K Industries.

14. Do not operate without lters in place. Keep lters clean, as dirty lters limit air

intake and may damage the motor or cause overheating.

15. Plug only into a properly grounded receptacle. Always make sure the amper-

age of the electrical outlet is sucient for the amperage rating of the product.

(See Product Specications for amperage rating of this product).

16. Do not attempt to perform any service or maintenance not outlined in instruc-

tion manual.

17. Do not attempt any product modications or alterations. Do not use, if any

parts or switches are damaged - send to an Authorized Service Center or

Double K Industries for service.

18. When servicing, use only Double K Industries parts.

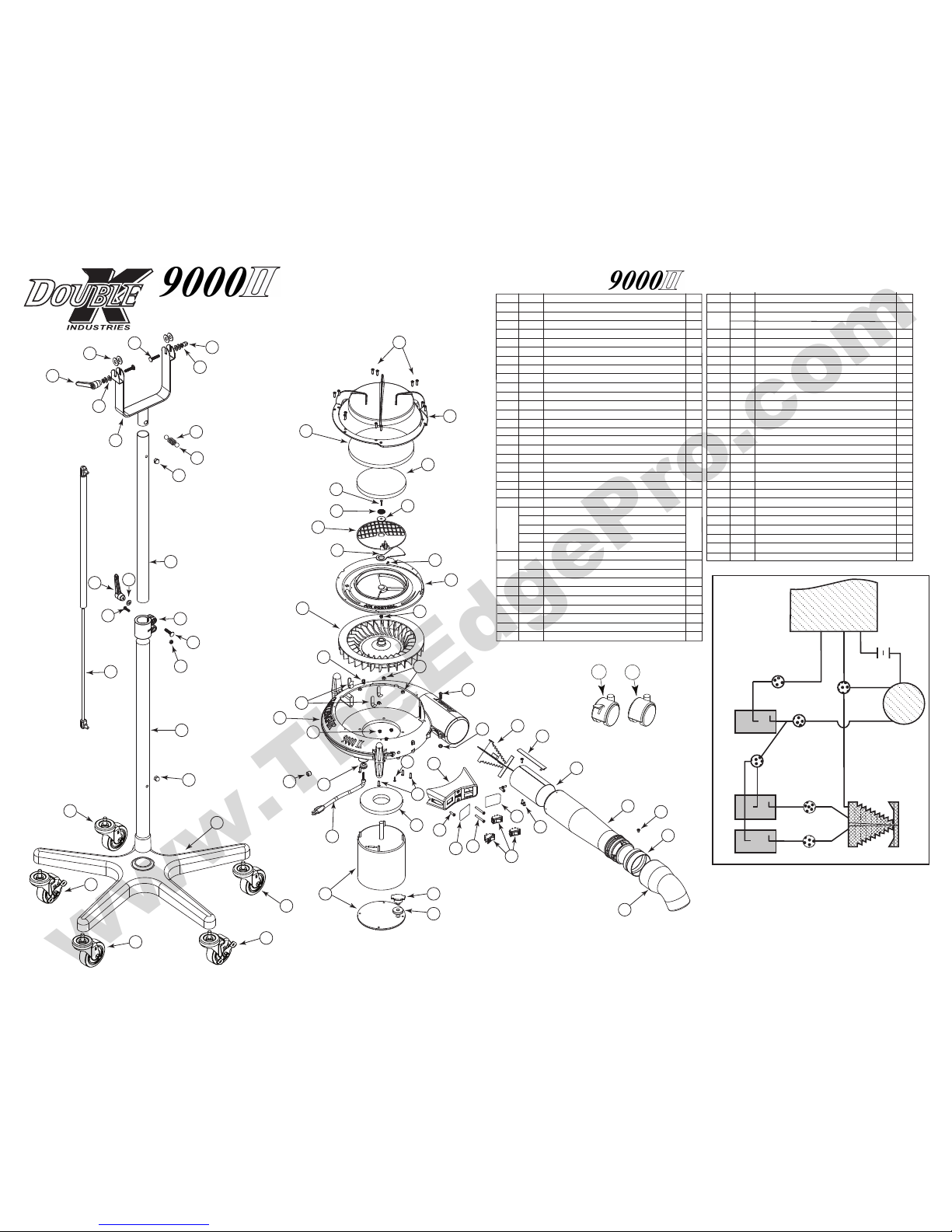

Minimum Airow Position Maximum Airow Position

(View with Sound Cap removed to show lever position)