7

MOTOR BRUSHES

Your CHALLENGAIR 2000XL™ has a brush-type motor. The brushes should be

checked for wear after approximately 600 hours of use. If the carbon brushes are

worn shorter than 1/4 inch, the brushes should be replaced. Brushes may be ordered

from Double K Industries or an Authorized Service Center. Please be sure to specify

that your dryer is a 2000XL™, as the brushes are slightly dierent from one dryer

model to another.

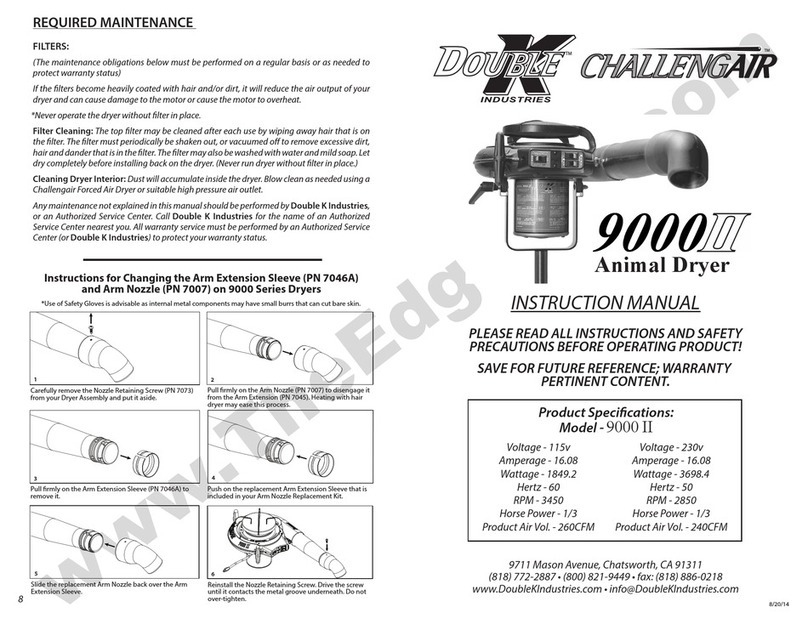

To check and/or replace brushes:

1. Unplug electrical cord from wall outlet.

Disassembly:

2. Slide o the end cap from the dryer by lifting tabs and pulling back o.

3. Remove all screws on the outside of the dryer that hold the two halves of dryer

housing in place. Lay the dryer on its side while removing these screws. Remove

the O-ring on the snout of the dryer and lift the top half.

4. The motor will be sitting in place inside the rubber silicone motor mount.

Removing the rubber silicone motor mount from the motor is not neces-

sary to replace brushes. The internal lter frame ts into slots on the inside

of the dryer housing. This piece can remain while changing brushes.

5. Disconnect motor power wires (see wiring diagram). Note where wires connect.

6. Motor: (a) Find the ag connector on the top of the brush assembly. There is a

wire leading to this connector. (b) Place a athead screwdriver with a ne tip

between the ag connector and the plastic brush housing. (c) Rock the screw-

driver back and forth and gently wedge the ag connector out of the brush

assembly. (d) Loosen the two brush assembly retainer bracket screws.

(e) Remove the brush assembly. (f) Replace the brush assembly with the new

one, making sure that the small tab on the bottom is tted onto the corre-

sponding slot on the motor frame. (g) Replace the brush assembly retainer

bracket and tighten the screws which hold it in place. (h) Attach the ag

connector to the new brush in the same position as was the old brush. (i)

Repeat these steps for the brush on the other side of the motor.

Reassembly:

7. Inspect the motor mount for cracks or damage -- replace with new motor

mount if damaged.

Set the motor back into its original position in the dryer housing. The

motor mount has slots that t over corresponding alignment tabs on the

inside of the dryer housing. These slots and tabs must match up for proper

t and function. (Note: In the event that the motor mount is removed from

the motor, simply replace it by being mindful to align the contours of the

motor mount with corresponding contours on the motor housing.) Make

sure that the internal lter housing is in its appropriate slot before putting

the halves together.

8. Reattach the screws around the outside of the dryer making sure the two

halves are matching up.

9. After the two halves of the dryer housing have been put together, replace

internal lter and push the end cap onto the rear of the dryer until tabs lock

in place. Always make sure all lters are in place before operating dryer.

Replace o-ring on snout.

2

WARNING: DISCONNECT POWER SUPPLY BEFORE SERVICING

AVERTISSMENT: COUPER L’ALIMENTATION AVANT L’ENTRETIEN ET LE DÉPANNAGE

IMPORTANT SAFEGUARDS

WARNING: IMPORTANT SAFETY PRECAUTIONS. PLEASE READ COMPLETELY

BEFORE USING PRODUCT.

When using electrical appliances, especially in the presence of children or animals, basic

safety precautions should always be followed to reduce the risk of re, electric shock, and

personal injury, including but not limited to the following:

DO NOT TURN ON DRYER WITHOUT FIRST HOLDING THE DRYER HOSE as the air volume

from the dryer can cause the hose to whip or move rapidly and may cause injury.

1. Do not leave dryer OR animal

unattended while in use.

2. Unplug unit when not in use.

3. Do not use extension cords with dryer.

4. Do not unplug unit by pulling on cord.

5. Do not expose dryer to rain or water.

6. Do not use or store dryer where it can fall

or be pulled into tub, sink or standing water.

If dryer falls into water . . . UNPLUG IT . . . Do

not reach into the water!

7. Unplug unit before attempting any

maintenance or service.

8. The 230 volt version of this appliance has

an earth connection for functional

purposes only.

9. Do not put any object into dryer

openings.

10. Keep loose clothing, jewelry and hair

away from dryer intake.

11. Do not direct dryer air towards eyes or

ears of people or pets.

12. Never use dryer if it has a damaged cord

or plug, has been dropped, damaged or

exposed to rain or water. Return to Double

K Industries or an Authorized Service

Center for service.

13. When using the cage attachment, do

not leave the animal unattended.

14. This product is for use on animals only.

15. Recommended operation by adults

only. Use caution when working around

children.

16. Do not use attachments not

recommended by Double K Industries.

17. Do not operate without lters in place.

Keep lters clean, as dirty lters limit air

intake and may damage the motor or

cause overheating.

18. Only plug into a properly grounded

receptacle. Always make sure the amperage

of the electrical outlet is sucient for the

amperage rating of the product. (See

Product Specications on front page for

amperage rating of this product).

19. Do not use product for anything other

than its intended purpose.

20. Do not attempt to perform any service

or maintenance not outlined in instruction

manual.

21. Do not attempt any product

modications or alterations. Do not use, if

any parts or switches are damaged. Send to

an Authorized Service Center or Double K

Industries for service.

22. When servicing, use only Double K

Industries parts.

INSTRUCTIONS

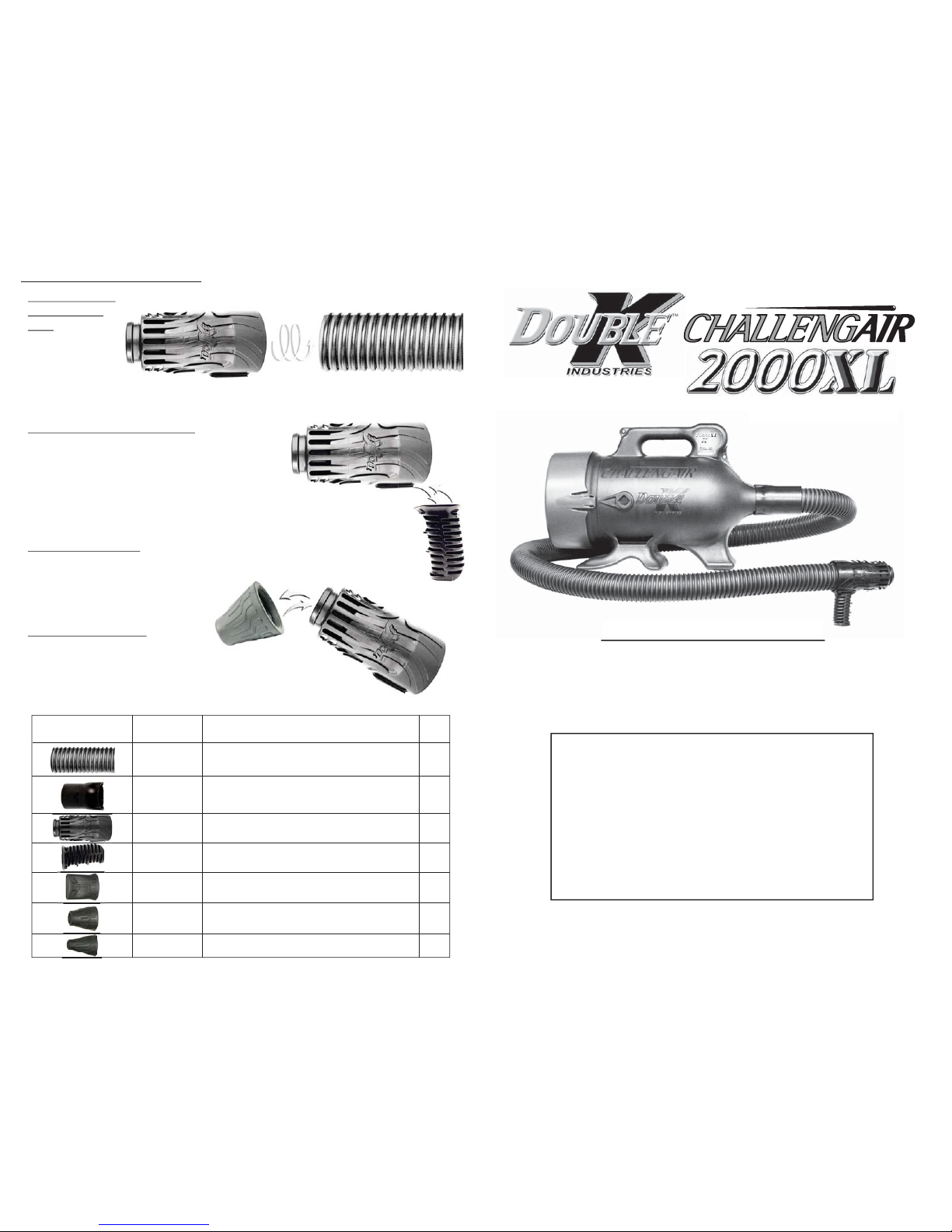

After assembly, hold nozzle and turn on dryer. Maximum operating temperature is

reached in about one minute but eective drying begins immediately. Generally dry

from the top of the animal, with a side-to-side sweeping motion, holding the nozzle

downwards to keep displaced water away from areas already dried. Hold the drying

nozzle at a downward angle and move either front-to-back or back-to-front,

making sure to progress toward parts of the animal that are still wet.