6

WASTE LINE HOOKUP

The discharge waste water will

contain pool water treatment chemi-

cals that may harm certain plants

and vegetation. Therefore, position

the discharge end of the waste line in

a safe, out-of-sight area capable of

accepting 150 to 200 gallons of

waste water. Install a 1-1/2" inside

diameter waste discharge hose (not

supplied) on the waste port near

where the sight glass is located on

the valve. Slip a 1-1/2" hose clamp

(not supplied) over one end of the

hose. Then, push hose onto the port

fully and tighten clamp firmly.

plugging the underdrain slots.

Because pool water is lost during

this operation (150 to 200

gallons) keep a close check on

pool water level. Never let water

level get so low that no water

flows to pump. Refill pool as

required.

5. Push down on the valve handle

and rotate to the FILTER position

and start pump. Note the

pressure reading on your pres-

sure gauge for future reference

of when to backwash.

6. Check all fittings and hoses for

leaks and correct if

necessary.

FILTER OPERATION

A newly filled pool is normally filled

with unfiltered water and usually

requires continuous filtering for 24 to

48 hours along with chemical treat-

ment of the pool water. Because all

pool installations vary in environmen-

tal conditions (wind, rain, airborne

debris, heat and pool use, etc.),

it is impossible to provide an accu-

rate filtering time for normal usage.

Use a trial and error method to

determine how long your filter must

operate each day. Generally, 6 to 8

hours of filtering each day is suffi-

cient to maintain pool clarity if the

pool chemical treatment is correct.

When possible, avoid operating your

filter during peak electricity demands

in your community. Check with your

local electric utility company for the

best times they recommend for

operating your filter pump.

WHEN TO BACKWASH

As your filter removes debris from the

pool water during the filtering pro-

cess, the return flow will gradually

reduce. Backwash when the pres-

sure gauge increases 5 to 7 pounds

above the clean filter starting pres-

sure. Normal backwash duration is

1-1/2 to 2 minutes or until water runs

clear.

VACUUMING YOUR POOL

When vacuuming your pool, the filter

must work harder. Consequently, all

of that debris is caught in the filter at

a very rapid rate. This causes a rapid

increase in filter pressure as will be

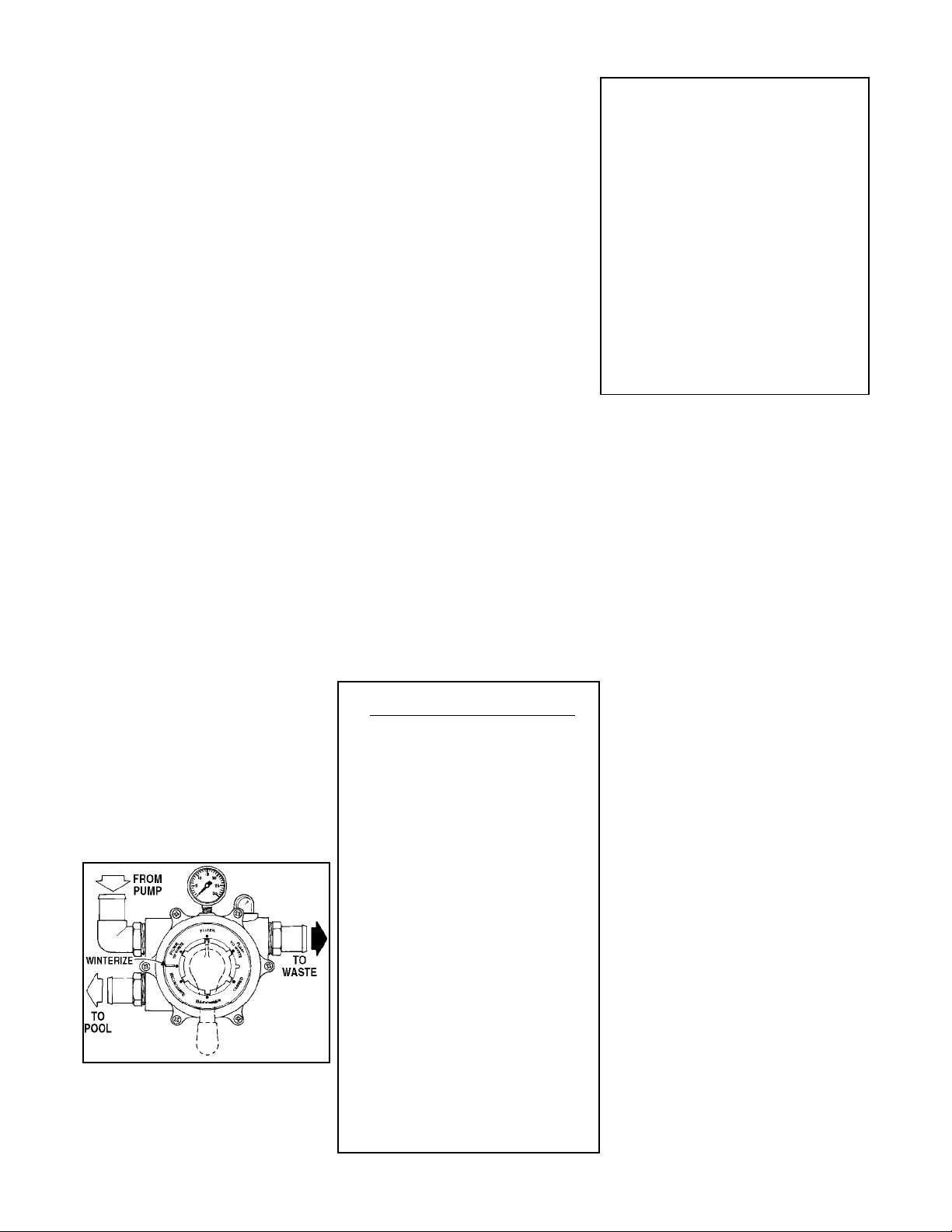

BACKWASH: Backwashing reverses

the flow of water through the filter to

flush out the dirt and debris, and

waste water is discharged to waste

from the valve body port with sight

glass.

FILTER TO WASTE: Place the valve

in the “Filter to waste” position after

backwashing your filter. (Normally,

for only 10 seconds.)

PUMP TO WASTE: This position

allows you to vacuum heavy debris

or larger amounts of settled contami-

nants from the pool floor directly to

waste.

RECIRCULATE POSITION: This

position allows you to increase the

water flow rate to circulate chemicals

throughout the pool more quickly.

Pool water passes through the valve

on top of the filter bypassing internal

filter components and travels back to

the pool at a rapid rate.

WINTERIZE POSITION: This posi-

tion allows you to drain trapped water

from the filter valve and relieve

compression on the rotor valve

gasket during winter storage.

CLOSED POSITION: When servicing

the filter, place the valve in the

“Closed” position to stop backflow of

water from pump. Stuff rag in return

fitting.

INITIAL START UP

Before you begin filtering your pool,

the filter sand must be backwashed

thoroughly to remove the extra fine

sand grains normally found in new

filter sand.

1. Loosen the pump strainer pot lid

to allow air to escape. Tighten lid

when water begins to flow

between strainer pot lid and

strainer body. Do not over

tighten.

2. Plug in your pump to the GFCI

protected receptacle. Refer to

WARNINGS.

3. Push down on the valve handle

and rotate to the BACKWASH

position. Make sure valve handle

indexes into the alignment slots

on valve.

4. Start pump. During this initial

start-up allow 4-5 minutes to

flush out the super-fine sand

grains to prevent them from

ELECTRICAL OUTLET

Refer to your pump owners guide for

detailed information pertaining to the

requirements and regulations for safe

electrical installation of the power

supply, receptacle outlet, switching

and ground fault interrupter.

FINISH FILLING POOL

Finish filling your pool, referring to

skimmer installation and pool assem-

bly instructions for proper water level.

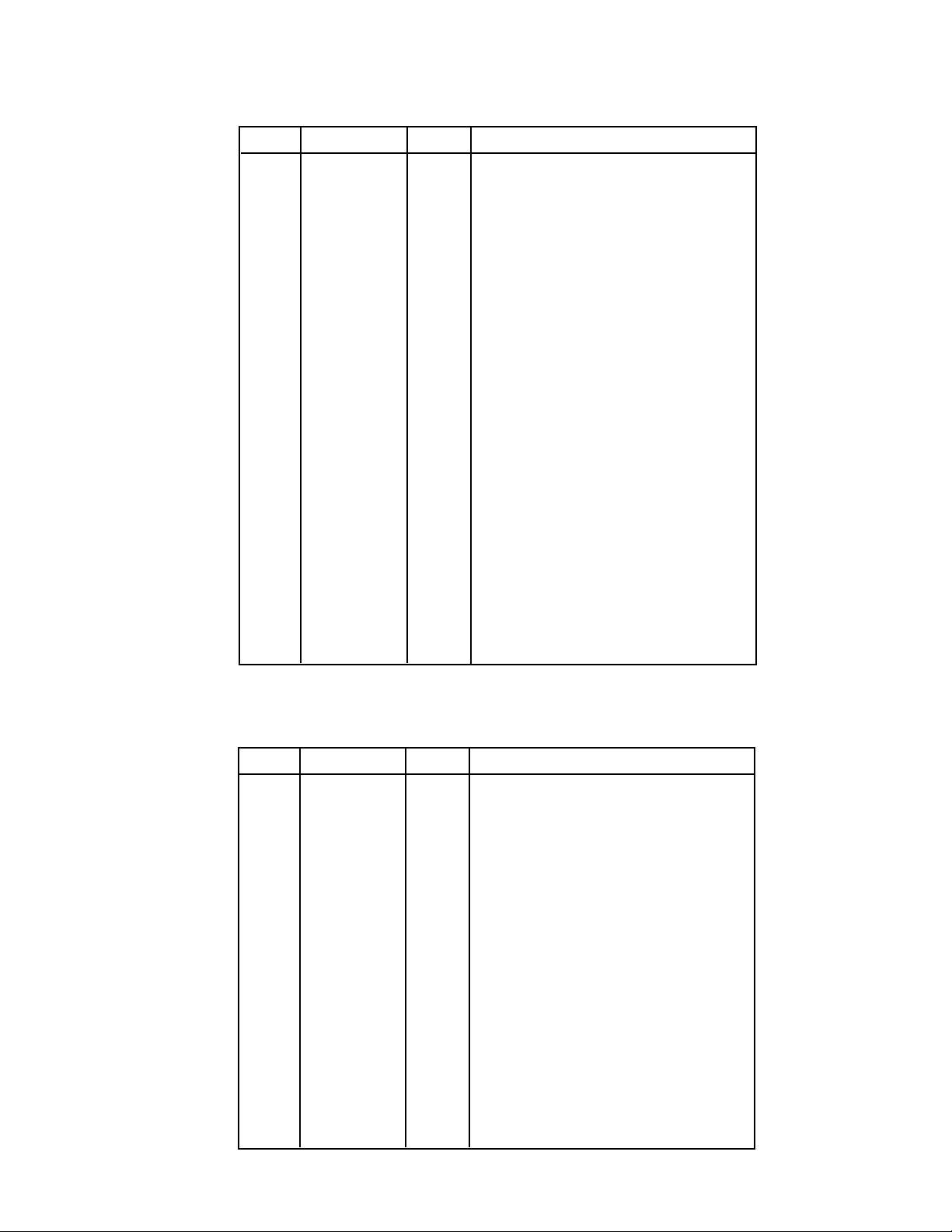

VALVE OPERATION

Your new filter has seven positions of

operation, which are explained below.

To change positions of the valve,

make sure the pump is OFF. Press

down on the valve handle enough to

free the locking tab. Rotate the

handle so the tab LOCKS in the

desired position.

FILTER: Normal pool filtering

position. May also be used when

vacuuming the pool.