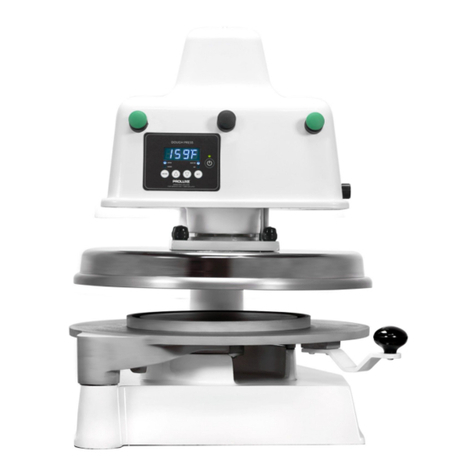

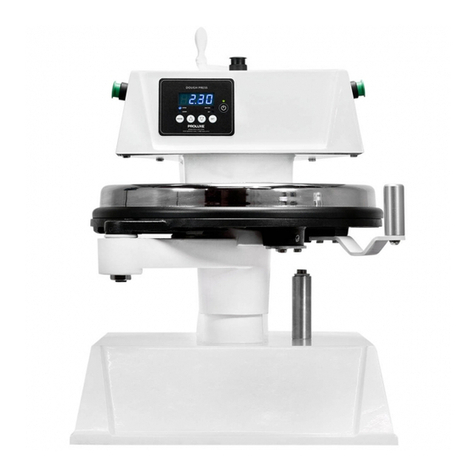

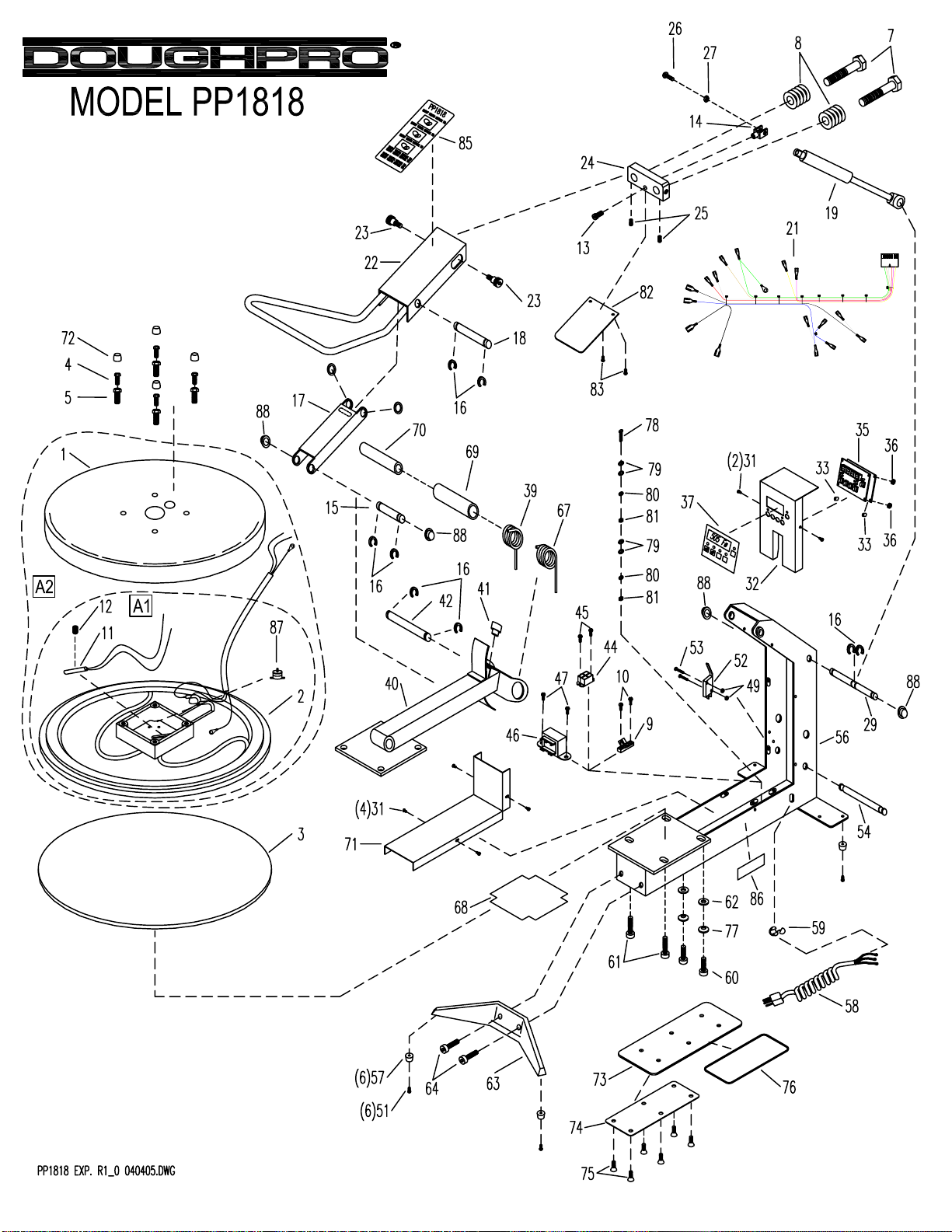

DOUGHPRO

PP1818

MODEL MODEL MODEL

1818A 1818B 1818C

NO PART NAME 120V AC 240V AC 240V AC

1 SHROUD, UPPER PLATEN 1109336 1109336 1109336

2 UPPER PLATEN 110074 110075 110075

3 LOWER PLATEN 110969076 110969076 110969076

4 LOCKING BOLT, ADJUSTMENT BH51618134G5 BH51618134G5 BH51618134G5

5 BOLT, LEVEL ADJUSTMENT 1109367 1109367 1109367

7 SCREW, PRESSURE ADJUST BLOCK BH58113 BH58113 BH58113

8 SPRING, PRESSURE ADJUST BLOCK 110969093 110969093 110969093

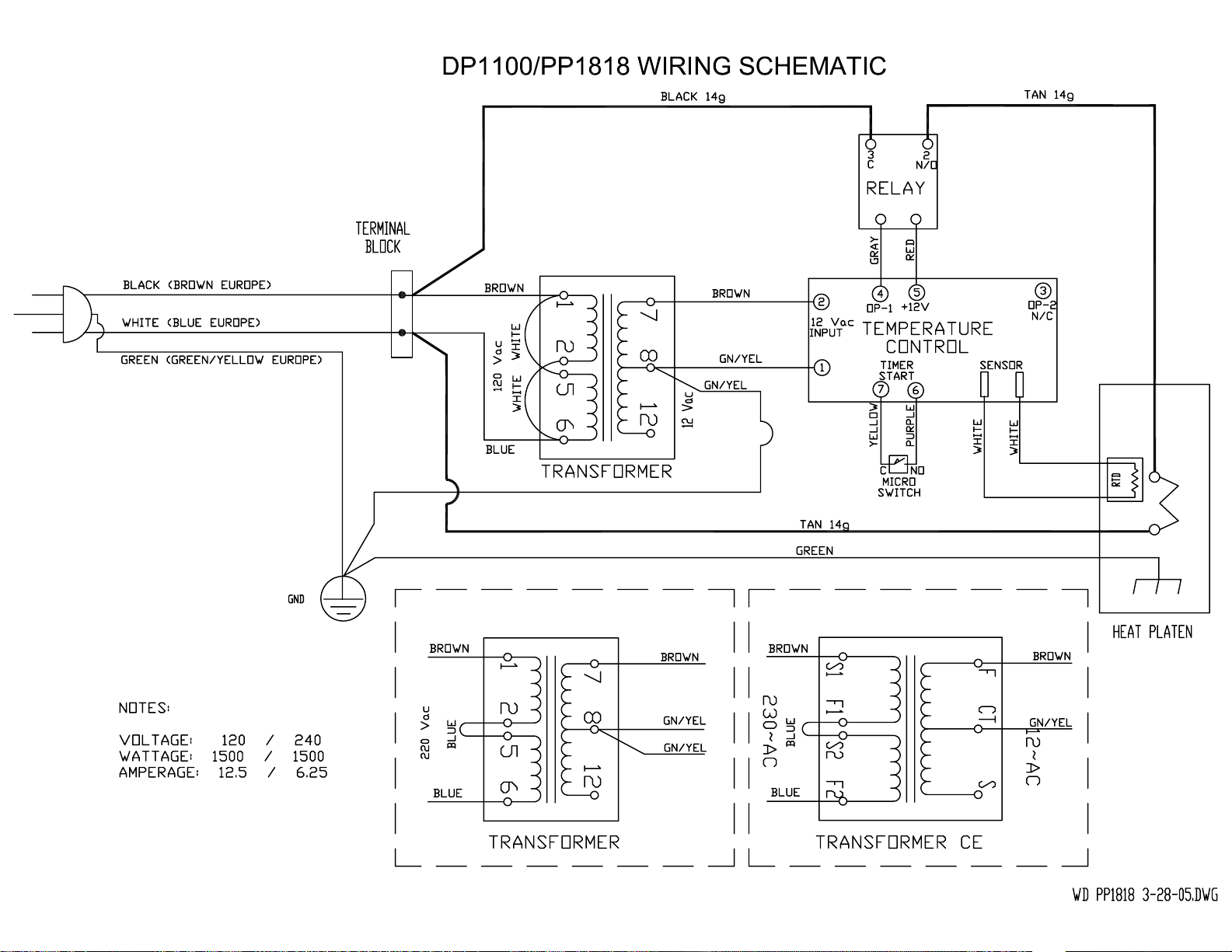

9 TERMINAL BLOCK 11096914 11096914 11096914

10 SCREW, TERMINAL BLOCK SP83258 SP83258 SP83258

11 SENSOR ASSEMBLY 110949110 110949110 110949110

12 SET SCREW, SENSOR SST381638 SST381638 SST381638

13 SCREW, SOCKET CAP ALLEN HEAD SCH1428114 SCH1428114 SCH1428114

14 PIVOT BLOCK CLEVIS 1101098919 1101098919 1101098919

15 BOTTOM PRESSURE PIN 11094961 11094961 11094961

16 E-CLIPS, BOTTOM PRESSURE PIN MPSC240 MPSC240 MPSC240

17 LOWER LINK 110949530 110949530 110949530

18 HANDLE PRESSURE PIN 11094962 11094962 11094962

19 GAS SPRING ASSEMBLY 1101098154 1101098154 1101098154

21 WIRE HARNESS 1101098050 1101098050 1101098050

22 HANDLE CHANNEL ASSEMBLY 110109889 110109889 110109889

23 SCREW, PRESSURE PIVOT BLOCK BSH1234 BSH1234 BSH1234

24 PRESSURE PIVOT BLOCK 1101098174 1101098174 1101098174

25 SET SCREW, PRESSURE PIVOT SST142014 SST142014 SST142014

26 SCREW, PIVOT BLOCK CLEVIS SP103258 SP103258 SP103258

27 NUT, PIVOT BLOCK CLEVIS NH1032 NH1032 NH1032

29 SPRING PIVOT PIN 110109862 110109862 110109862

31 SCREW SP83238S SP83238S SP83238S

32 CONTROLLER PANEL 110109822C1 110109822C1 110109822C1

33 SPACER, NYLON 11090109 11090109 11090109

35 DIGITAL CONTROL 11096905218 11096905218 11096905218

36 NUT, DIGITAL CONTROL NH632 NH632 NH632

37 CONTROL PANEL OVERLAY OPROPP1800 OPROPP1800 OPROPP1800

39 COUNTERBALANCE SPRING, LEFT 110949154L 110949154L 110949154L

40 PIVOT HANDLE ASSEMBLY 110109821 110109821 110109821

41 BUMPER, POLY 110969455 110969455 110969455

42 ARM PIVOT PIN 110109863 110109863 110109863

44 RELAY 110942520 110942520 110942520

45 SCREW, RELAY SP83238 SP83238 SP83238

46 TRANSFORMER 11096975 11096975 11096976

47 SCREW, TRANSFORMER SP83238 SP83238 SP83238

49 NUT, MICROSWITCH NH440 NH440 NH440

51 SCREW, RUBBER FEET SP83238 SP83238 SP83238

52 MICRO SWITCH MPS90130 MPS90130 MPS90130

53 SCREW, MICROSWITCH SR44034 SR44034 SR44034

54 SPRING RETAINER 11094926 11094926 11094926

56 BASE FRAME ASSEMBLY 110109811 110109811 110109811

57 FEET, RUBBER 2093W 2093W 2093W

58 POWER CORD 110969174 110969175 110969176

59 CABLE STRAIN RELIEF MPS90014 MPS90014 MPS90014

60 SCREW, LOWER PLATEN SB51618114 SB51618114 SB51618114

PP1818 PL. V1_0 1311_20019_40000