Doughty Low Profile Clamp User Manual Revision A Original User Manual Page 4of 18

Doughty has endeavoured to deliver the highest degree of accuracy possible. However,

continuous improvement of our products is a Doughty Policy. Therefore, product

specifications are subject to change without notice.

Readers and users are encouraged to notify Doughty of errors and send in suggestions for

improvement. All communications will be carefully considered for future printings of this

manual and changes to our products.

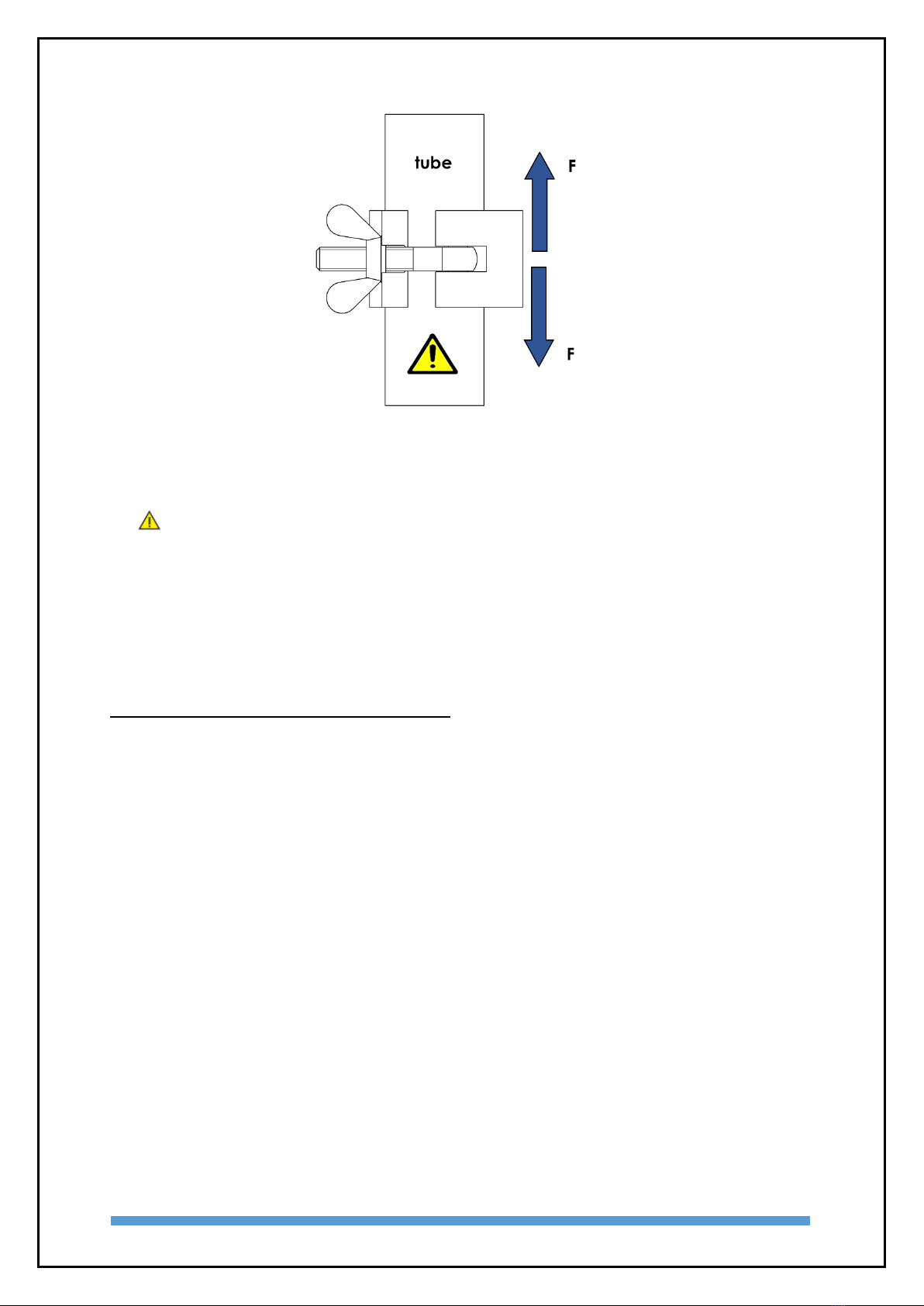

Some models of clamps are composed of different elements each with an individual Working

Load. The lowest of the working loads determines the overall strength and thus shall be

used as max working Load for the application.

When Doughty Low Profile Clamps form part of a lifting machine or lifting system, the lifting

machine or system shall be tested and marked with its SWL and appropriate certification

issued.

The resulting forces in the structure attached shall be verified before applying a load.

For the ease of reading this document the word “Clamps” or “Clamp” is used to cover all

Doughty Low Profile Clamp series and models.

2. SCOPE

The intended use of clamps is to be used as a lifting accessory to hang loads or create a

connection between structural elements. Loads can be, but not limited to, lighting fixtures,

video projectors, sound systems and stage sets.

Structural elements can be pipes, trusses, tubular frame works or lifting brackets.

Any use other than that mentioned is considered to be a case of misuse. The user/operator

and not the manufacturer shall be liable for any damage or injury resulting from such cases

of misuse.

The use of clamps for scaffolding purposes under EN74 is explicitly excluded from the

intended use.

Check local legislation for the application of use and adapt the use where ever necessary.

3. LIMITATIONS OF USE

•The Clamps can be operated in -20° Celsius up to +60° Celsius.

•Salt water environments require cleaning with fresh water at least once per week

•Doughty Low Profile Clamps shall only be used on steel or aluminium tubes or bars.

•When Doughty Low Profile Clamps are used as part of an outdoor lifting system,

special factors such as ground condition and profile, wind loading, water

accumulation on temporary structures and other criteria shall also be taken into

account.

•When clamps are used to secure equipment which is moved or suspended over

areas where persons are present an M12 self-locking nut shall replace the standard

nut and wingnut.