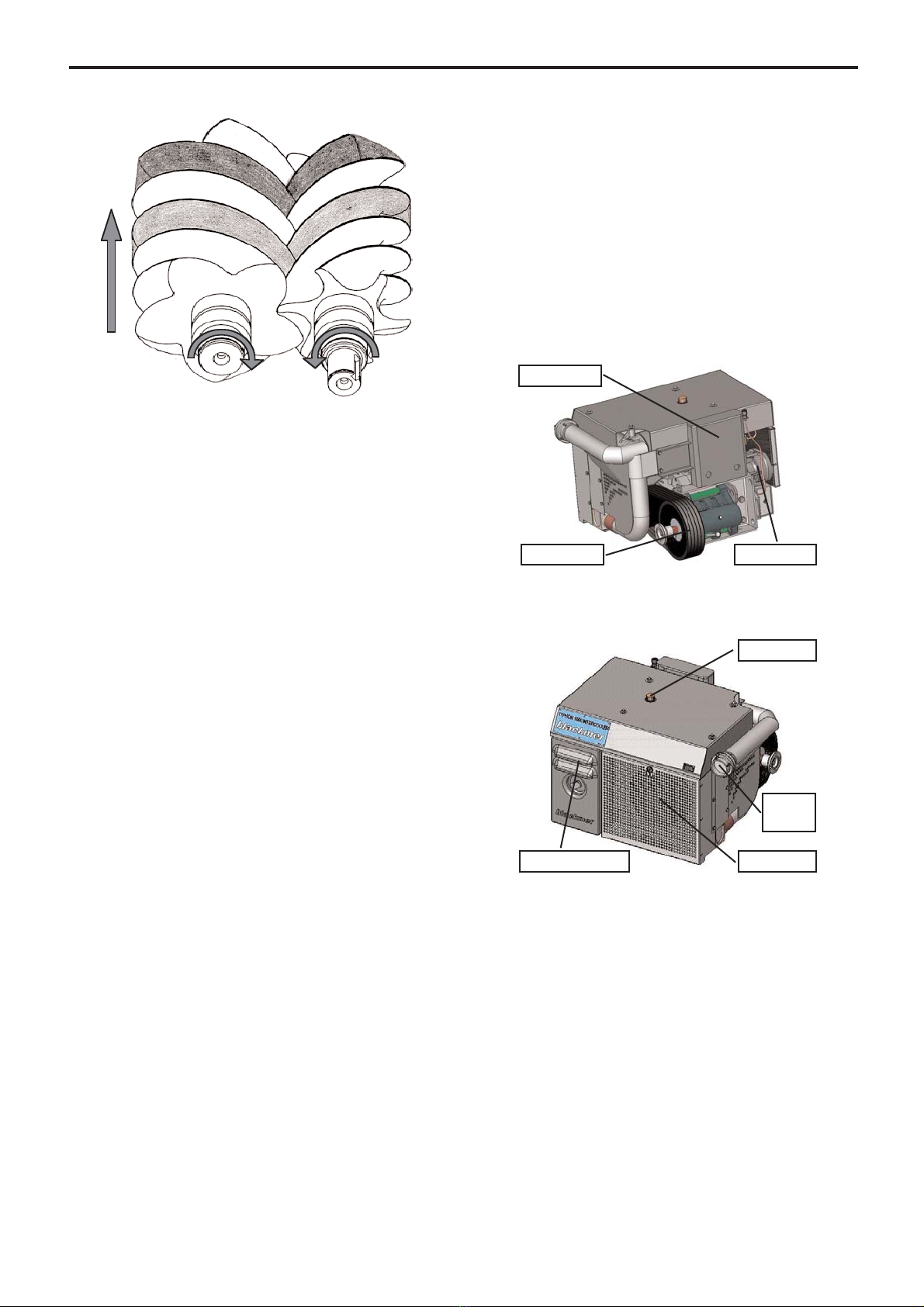

2.4.4. Location and Piping

An improperly designed piping system or unit installation

WILL significantly reduce package performance and life.

Blackmer recommends the following piping system

layout and unit installation.

1. Piping MUST be properly supported to prevent any

piping loads from being placed on the pump.

2. Intake piping and fittings MUST be at least as large in

diameter as the pump intake connection.

3. Minimize the number of intake line fittings (valves,

elbows, etc.) and piping turns or bends.

4. Discharge piping MUST be free of all leaks.

2.5 Electrical wiring

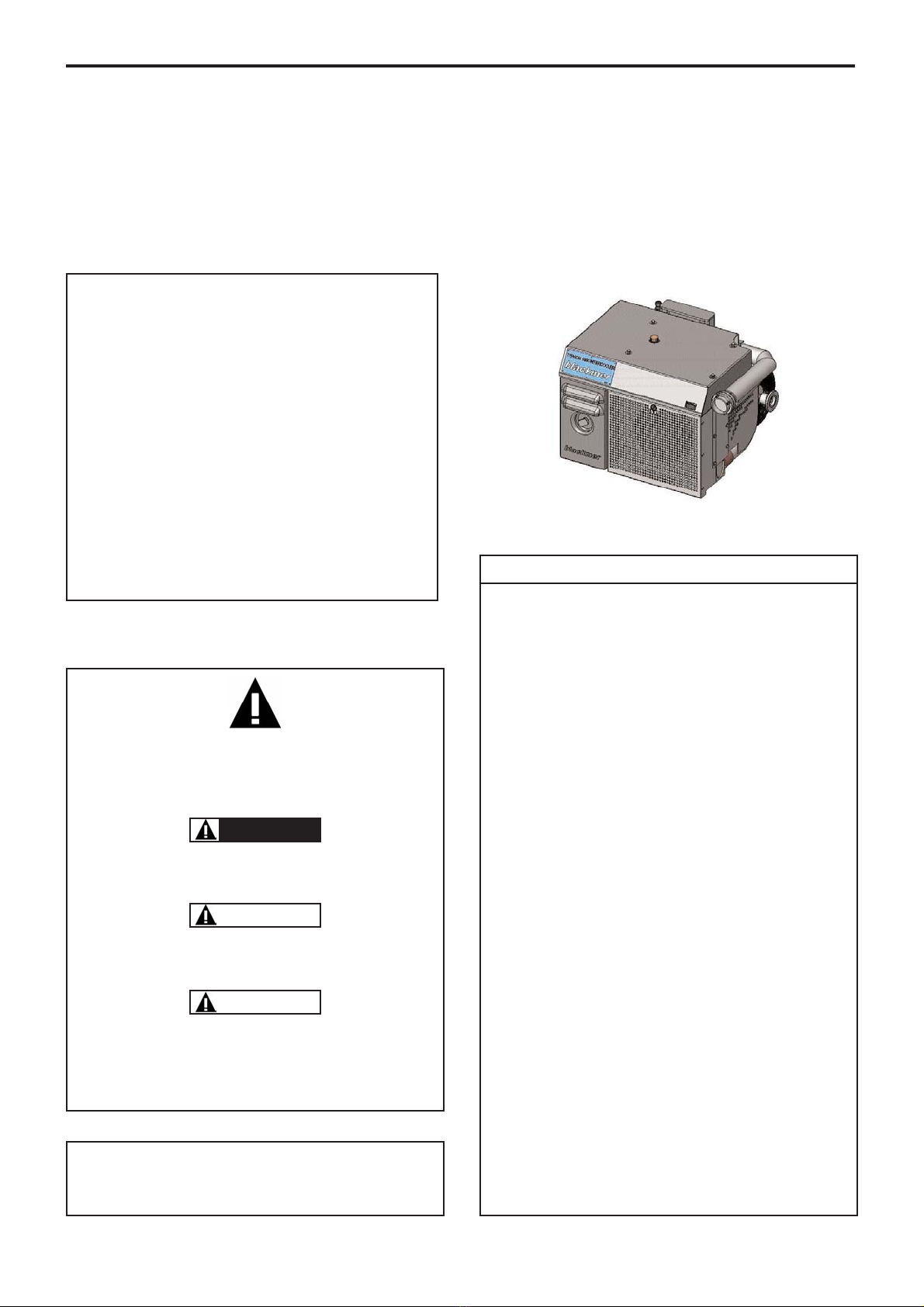

The TYPHON 1000 INTERCOOLER package needs

electrical power to propel the fan pulsing the cooling air

through the radiator.

To prevent unwanted operations of the fan, a temperatu-

re switch set to 78°C on the climb and 68°C on the fall

controls the supply of power to the fan. This system will

prevent power consumption on the package when the

system is not operating.

The systems are equipped with a button, which controls

the fan speed. When the button is on the cool position,

the fan works at max speed, and the discharge tempe-

rature of the compressor is at its minimum. When the

button is on the hot position, the fan is only supplied with

12 V, and the discharge temperature of the compressor

will remain above 150°C. You may want to use those

temperatures to dry the trailer after a cleaning cycle.

DO NOT FORGET TO CONNNECT THE 12 V

CONNEXION, as this will lead the package to work

without cooling and will create temperature inside the

package the fan is not abble to handle.

This thermal switch needs the package to stabilize in

temperature before operating. This may take several

minutes, depending on the ambiant temperature. Typical

start up time for ambiant temperature of 20°C is 150 s at

2 bar package discharge pressure.

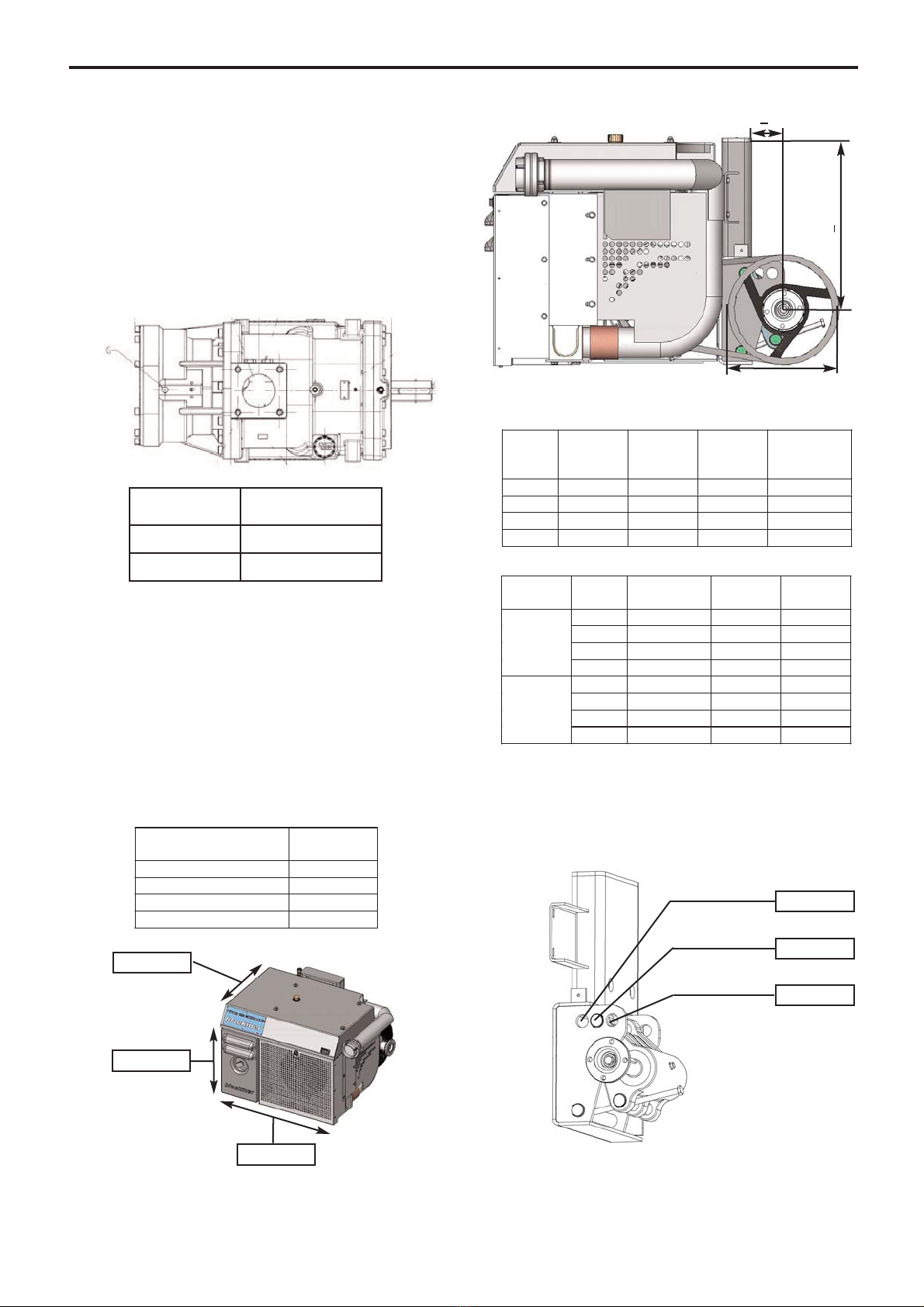

2.5.1 Electrical wiring diagram

2.5.2 Connection procedure

The supply line used to power the intercooler package

must be protected by a 16 Amps fuse on both the 12 V

and 24 V supply lines to prevent property damage and

body injuries.

The 3 wires to connect the main power supply to the bat-

tery are stripped 10 cm at the end of an 8 m long cable.

Color code for the wires :

• Blue . . . . . . . . . . . . . . . . .24 V connection

• Brown . . . . . . . . . . . . . . . .12 V connection

• Yellow / green . . . . . . . . . .Grounding connection

The electric cable connecting the Typhon intercooler to

the power supply should be properly supported to pre-

vent wear of the insulation coating.

The electrical wiring should be made in order to avoid

shorts to ground and microcuts.

DO NOT FORGET TO CONNNECT THE 12 V

CONNEXION, as this will lead the package to work

without cooling and will create temperature inside the

package the fan is not abble to handle.

2.6 Instrumentation connections

On gauges are available on the Intercooler and Cover

packages to check the clogging of the inlet filter,

This gauge has a resettable red clogging alarm. Any

operation with the clogging alarm on will lead to prema-

ture failure of the compressor and potential bodily injury

or property damage.

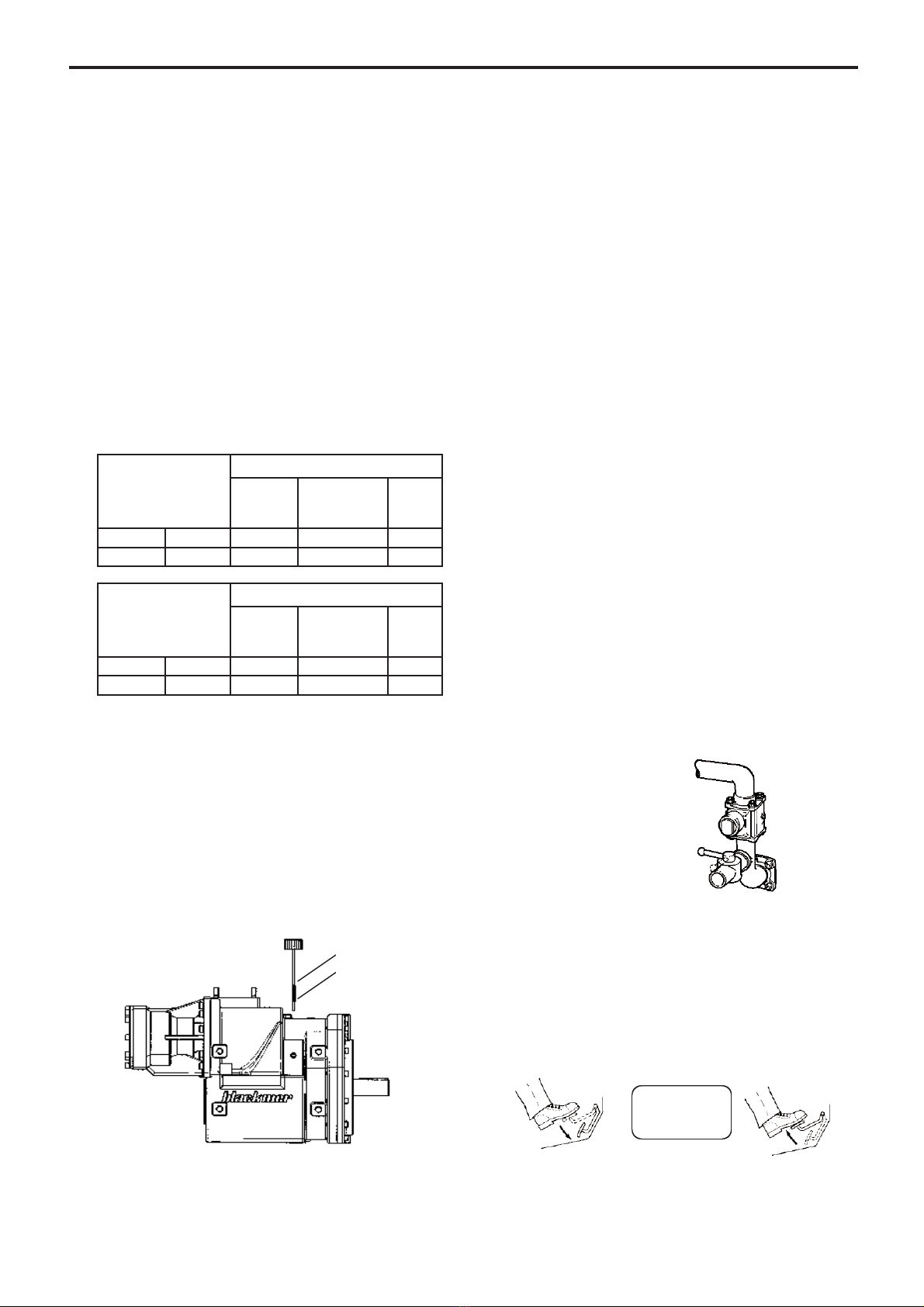

2.7 Chair modification

If the top of the chair is too high for a given application,

it is allowed to cut the extra high, provided that the chair

is closed on top by a steel plate equivalent to the one

delivered with the package, welded according to

ISO 5817 category C.

THE POWER SOURCE SHOULD BE SWIT-

CHED OFF PRIOR TO ANY ELECTRIC

WORK ON THE INSTALLATION TO PRE-

VENT ELECTROCUTIONS, PROPERTIES

DAMAGES AND INJURIES.

WARNING

Hazardous voltage.

Can shock, burn or

cause death.

9/21

NT 1401-F00 12.05 Cold front outlet Intercooler TYPHON e

22..

IINNSSTTAALLLLAATTIIOONN

((ccoonnttiinnuuoouuss))