2/18

NT 1401-AL00 10 20 (2) MX12 e

MOUVEX TRUCK SCREW COMPRESSOR

SAFETY, OPERATION AND MAINTENANCE INSTRUCTIONS

MODEL : MX12

REMARKS :

MOUVEX truck screw-type compressors MUST be installed in sys-

tems designed by qualified personnel. The installation MUST be in

compliance with local standards, national regulations and rules of

safety.

This manual is designed to permit installation and commis-

sioning of MOUVEX truck screw-type compressors and MUST

accompany the compressor.

Maintenance of MOUVEX screw-type compressors must ONLY be

carried out by qualified technicians. This maintenance must meet

local and national standards as well as all safety regulations.

Read this manual, including all instructions and warnings, in

full BEFORE any use of MOUVEX compressors.

Do not remove the warning and use label stickers that are

found on the compressors.

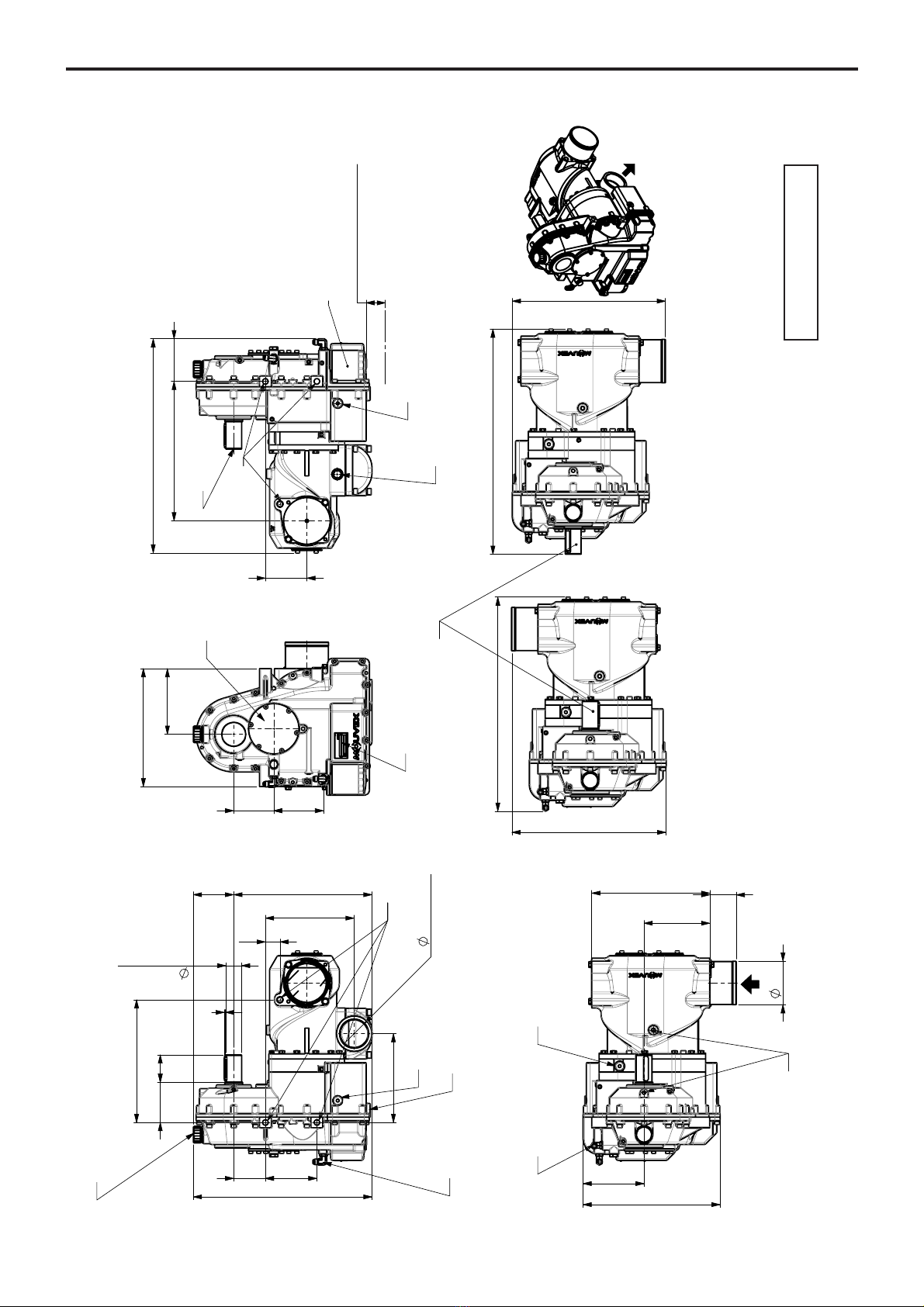

1. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .4

2. GENERAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

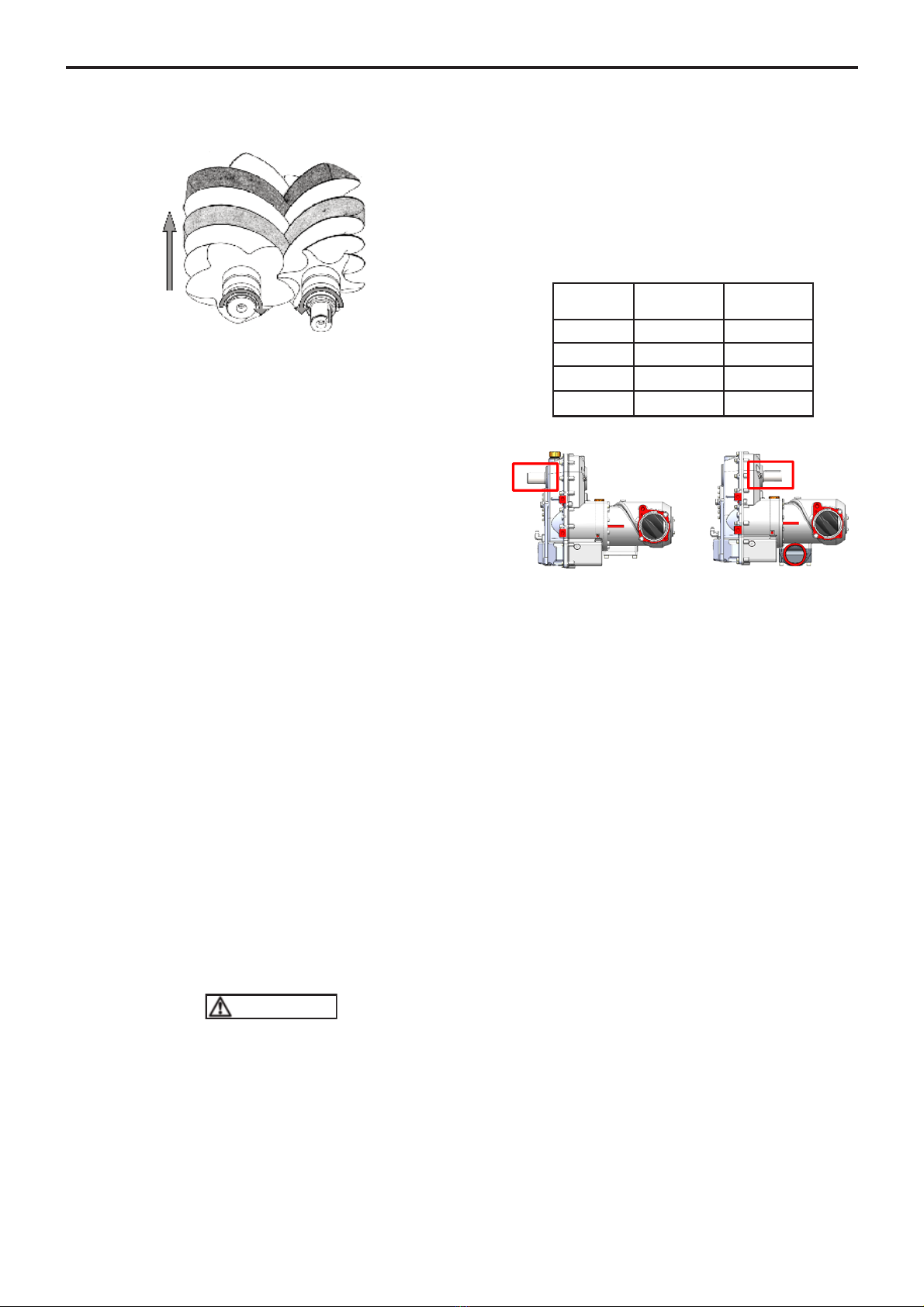

2.1 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . .7

2.3 Operating ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

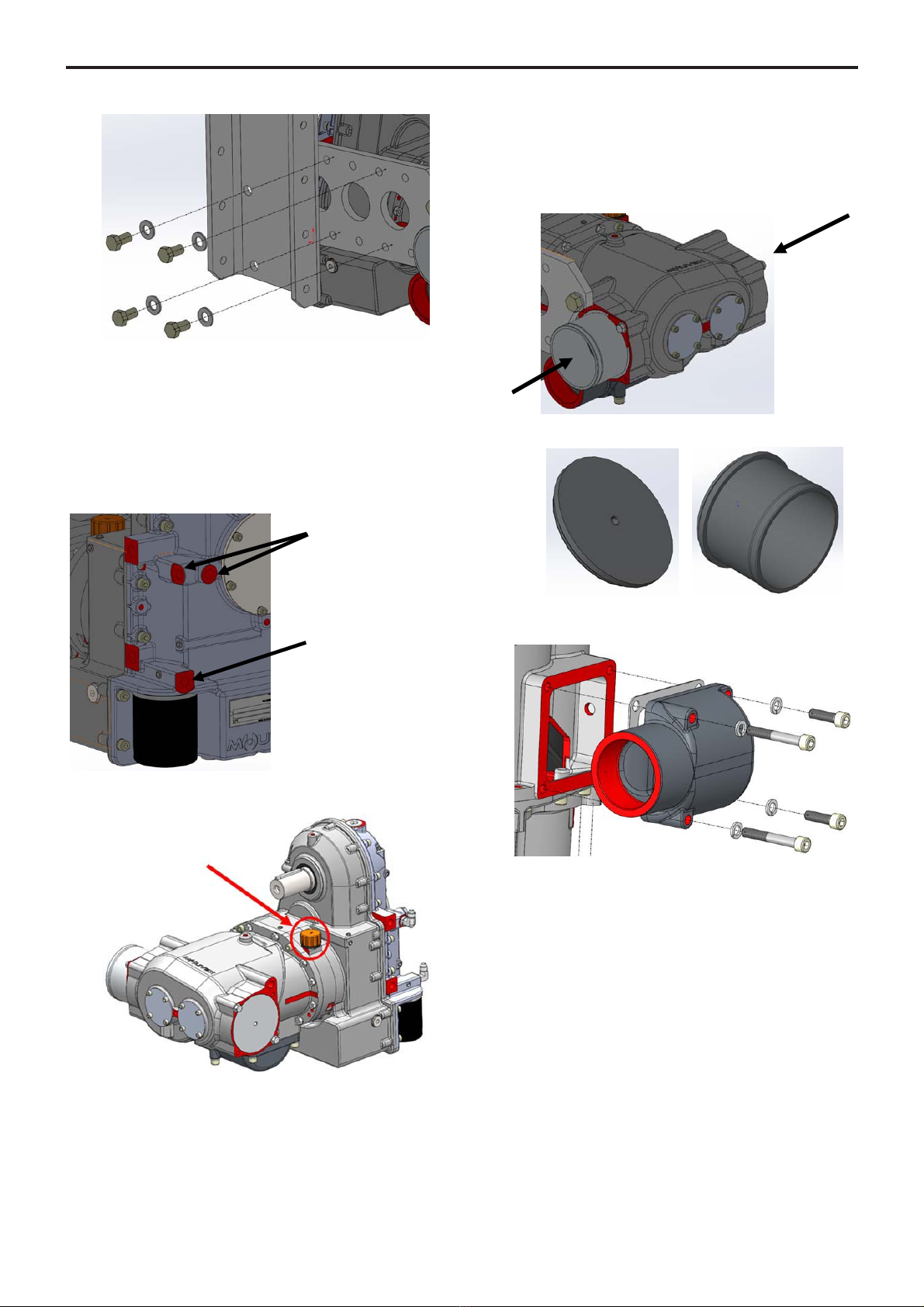

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.1 Mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2 Fixations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.3 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.4 At suction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.5 Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.6 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4. USE OF COMPRESSOR . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.1 Lubricant recommendations . . . . . . . . . . . . . . . . . . . .13

4.2 Filling of lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.4 Starting-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.1 Maintenance schedules . . . . . . . . . . . . . . . . . . . . . . .15

5.2 Compressor oil change procedure . . . . . . . . . . . . . . .15

5.3 Air filter replacement procedure . . . . . . . . . . . . . . . . .15

5.4 Drive train inspection . . . . . . . . . . . . . . . . . . . . . . . . .15

5.5 Check valve and relief valve inspection . . . . . . . . . . .15

6. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .16

7. WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.1 Warranty claims . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.2 24-months warranty extension with BSC3 oil . . . . . . .17

8. STORAGE CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . .17

8.1 Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

8.2 BSC oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

9. SCRAPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

10. CERTIFICATE OF CONFORMITY . . . . . . . . . . . . . . . . .18

TABLE OF CONTENTS Page

ADDITIONAL DOCUMENTATION

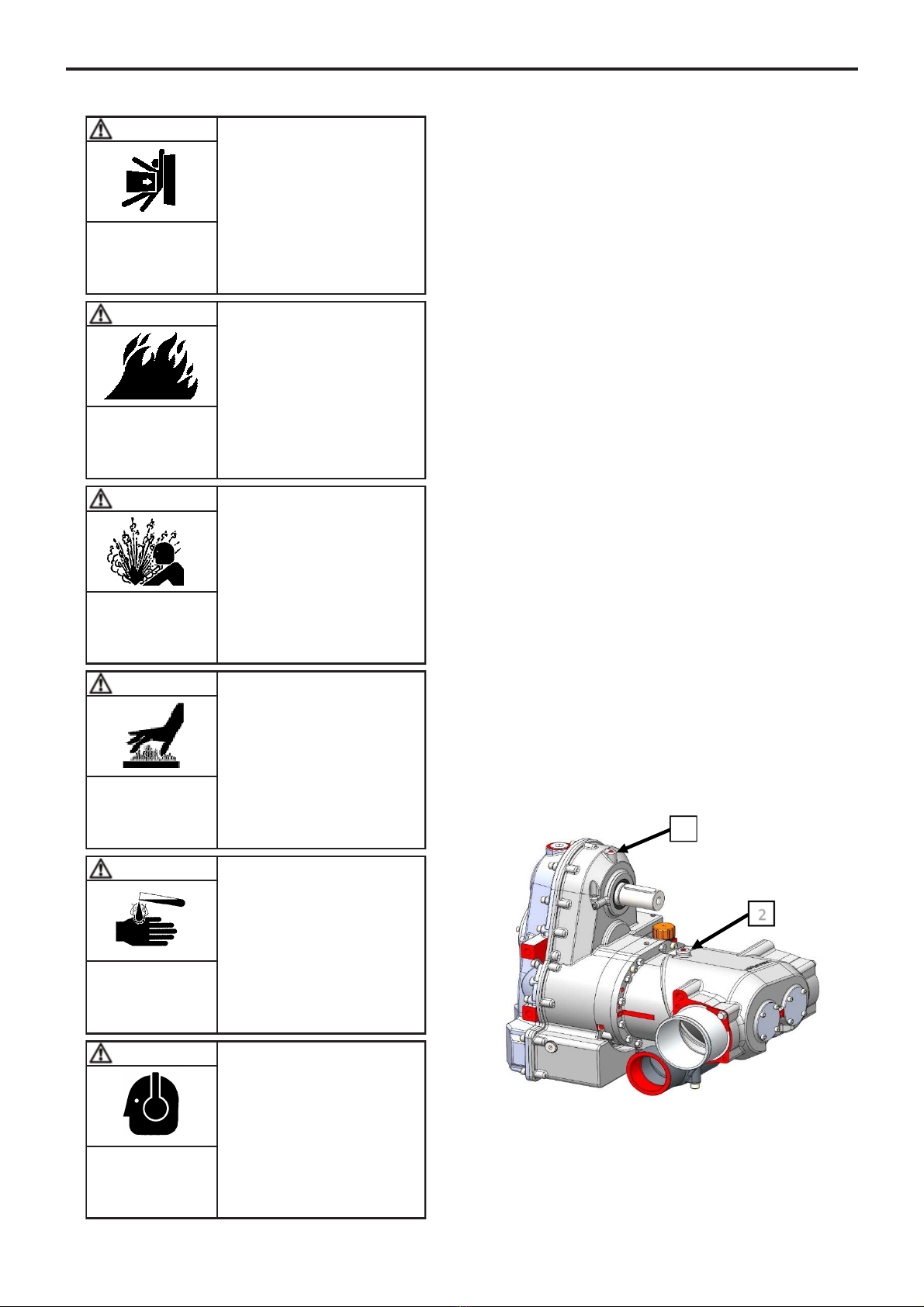

The table below gives the list of instructions in addition

to this central instruction :

MX12

application Instructions

Check and relief valve NT 1401-E00

Torque limiter NT 1401-B00

Air cooler NT 1401-AJ00

Definition of safety symbols

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the product, or in the manual,

look for one of the following signal words and be alert to the

potential for personal injury, death or major property damage.

Warns of hazards that WILL cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or property

damage.

NOTICE

Indicates special instructions which are very important and

must be followed.

DANGER

WARNING

CAUTION